Join Us On Social Media!

1/24 RAF 68Ft Vosper RTTL

24 Posts · 13 Followers · 65 Photos · 162 Likes

Began 1 year ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 2 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Finishing the Deck

2 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 27 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

After a 6 month layoff I finally got back in the mood to do something on the boat.

I trimmed the edges of the deck and added the rubbing strips and stern re-enforcement using basswood that I'll paint black shortly.

I also added framing to 2 of the 3 openings to keep the removable covers from moving around too much.

Finally I added the spurn water strips using some leftover deck planking ripped down the centre and cut to size. It took some inventive use of the vices that I bought to build the keel on to get the curved section towards the bow glued up.

This all felt like a lot of work for not very much visual difference, but it was good to get back building again after so long away from it.

I trimmed the edges of the deck and added the rubbing strips and stern re-enforcement using basswood that I'll paint black shortly.

I also added framing to 2 of the 3 openings to keep the removable covers from moving around too much.

Finally I added the spurn water strips using some leftover deck planking ripped down the centre and cut to size. It took some inventive use of the vices that I bought to build the keel on to get the curved section towards the bow glued up.

This all felt like a lot of work for not very much visual difference, but it was good to get back building again after so long away from it.

▲

⟩⟩

hermank

chugalone100

PhilH

ChrisF

|

💬 Re: Finishing the Deck

2 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 26 Views · 2 Likes

Flag

Yes, that's the way with model boat building, sometimes you can spend a lot of time and not look as though you have made much progress and other times, as with building the superstructure it can come on in leaps and bounds.

▲

⟩⟩

hermank

peterbro

|

Login To

Remove Ads

Remove Ads

📝 Deck Planking

2 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 29 Views · 4 Likes

Flag

💬 Add Comment

I did this way back in July, but work and life got in the way and I stopped the build before posting an update.

I decided to plank the hull with 1.5mm x 6mm mahogany strips. Cornwall Model Boats didn't stock teak strips, which the deck would have been made of on the real thing, so the deck will end up a bit redder that it should be, but I thought it would still be better than using a lighter wood and a stain.

I used full length strips, rather than scale length planks so that I wouldn't have to add any extra supports, and used scoring to give some indication of planks joining every 16', which seemed like a reasonably good standard length of timber.

I offset the scoring for every other plank, but in the end that didn't look all that great. If there's a next time, I'll use 3 offsets with I think would look better. I don't think it's the end of the world, I just won't shade any of the score marks to make them stand out.

I laid the first planks along the outside edges of the raised engine room walls, which I hoped (and as it turned out did) give me a straight and symmetrically aligned deck. The centre plank only needed light sanding to get it to fit in at the end, so that also worked out nicely.

The finished deck isn't completely smooth, and as you can probably see from the pictures I haven't sanded, or trimmed all the ends at this point, but I'm pleased with it overall so far.

I decided to plank the hull with 1.5mm x 6mm mahogany strips. Cornwall Model Boats didn't stock teak strips, which the deck would have been made of on the real thing, so the deck will end up a bit redder that it should be, but I thought it would still be better than using a lighter wood and a stain.

I used full length strips, rather than scale length planks so that I wouldn't have to add any extra supports, and used scoring to give some indication of planks joining every 16', which seemed like a reasonably good standard length of timber.

I offset the scoring for every other plank, but in the end that didn't look all that great. If there's a next time, I'll use 3 offsets with I think would look better. I don't think it's the end of the world, I just won't shade any of the score marks to make them stand out.

I laid the first planks along the outside edges of the raised engine room walls, which I hoped (and as it turned out did) give me a straight and symmetrically aligned deck. The centre plank only needed light sanding to get it to fit in at the end, so that also worked out nicely.

The finished deck isn't completely smooth, and as you can probably see from the pictures I haven't sanded, or trimmed all the ends at this point, but I'm pleased with it overall so far.

▲

⟩⟩

GARTH

hermank

chugalone100

ChrisF

📝 Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 59 Views · 8 Likes · 5 Comments

Flag

💬 Add Comment

Another long post I'm afraid...

I got a pair of 1.4" scale propellers from Prop-Shop a few weeks ago - one right hand and one left hand, so I could have them turning in opposite directions.

Around the same time I got a couple of 8" 4mm shaft/6mm tube propeller shafts from Cornwall Model Boats. At the time I was guesstimating the length I needed, but I turned out to be OK in the end. I also bought a couple of propshaft fitting sets because it didn't look like the shafts came with enough bolts (which turned out to be correct) and some shaft oiler kits, which I didn't end up using.

Just so Amazon didn't feel left out, I got some solid couplings and universal couplings from there once I knew the shaft size on the motors I was going to use.

Given the shallow angle that the shafts are going through the hull I knew I'd have to drill several holes and join them up, but the holes were alarmingly large (for a first timer anyway) by the time I got anywhere near being able to align the shaft with the motor. The holes ended up wider and longer than they really needed to be while I was messing about trying to get the shafts to align with the rudders and motors and still have propeller clearance. Maybe I'll be better at that next time round, but somehow I doubt it.

I used lots of two part epoxy glue to fix the prop shafts in place, starting with the inside of the hull. This didn't have to be too neat, but it did try to drip straight through past the pro-shafts at first, which could have been messy if I wasn't expecting it to happen.

Once the epoxy was dry on the inside, I repeated the process on the outside. As you can see from the photos, one side looks relatively ok, but the other looks like it was done by a 3 year old. I think this was because I was mixing too much of the epoxy at one time and it was starting to go off by the time I got to the messy side. Not my finest hour, but I'll know better next time and nobody will see it much so it's not the end of the world.

Once the shafts were glued in place I removed the inner shafts from the tubes and greased them before replacing them in the tubes. I used gun grease for this because I think it's a bit lighter than the bike grease I also have, but also because it was in the house and didn't involve walking out to the shed.

To attach the propellers to the shaft I added some locktite to the threads and also used the nut that came with the shaft as a lock nut. Before doing this I checked several times that the right hand shaft would push water backwards when rotated clockwise when viewed from the rear, and anti clockwise for the left hand shaft.

At the other end of the shaft I again added som locktite, then tightened up the nut that came with the propeller shaft until there was a tiny bit of play and the shaft still turned freely. I then used one of the nuts from the shaft fixing kits as a lock nut.

One thing I hadn't considered, but was pretty obvious, was that once the propeller shafts were fixed in place it would be very difficult to get the motor mount back out. I did manage it in the end, but the forward bracket to hold the propeller shafts had to be glued in place on refitting because the screws were impossible to refit. If I do this again I'll make sure the mount is ready to be glued in place before, or at the same time as the shafts.

In the end I couldn't get the shafts and the motors to line up exactly, so I used the universal couplings rather than the solid ones. The universal couplings were a little longer, which turned out to be useful. The universal couplings used a grub screw to fix the shafts, so I had to file the propeller shafts a bit to get a flatter section for the grub screw to tighten onto.

With all the drive train fitted I put the ESCs and batteries back in (I glued some velcro straps to the hull to keep the batteries in place), programmed the ESCs and limited the motor outputs to 60% in the transmitter. I then gave the boat another float test in the bath to make sure there were no leaks and that I'd got the propellers on the right way round - thankfully I had!

On the RC side, I've gone for a channel per throttle, which will allow me to control each motor independently. The only issue with that is that the transmitter I have only has one stick that is non-centering. Flysky RC sell replacement throttle modules and I've ordered one, but it is still enroute from China, so that's a job for another day.

I got a pair of 1.4" scale propellers from Prop-Shop a few weeks ago - one right hand and one left hand, so I could have them turning in opposite directions.

Around the same time I got a couple of 8" 4mm shaft/6mm tube propeller shafts from Cornwall Model Boats. At the time I was guesstimating the length I needed, but I turned out to be OK in the end. I also bought a couple of propshaft fitting sets because it didn't look like the shafts came with enough bolts (which turned out to be correct) and some shaft oiler kits, which I didn't end up using.

Just so Amazon didn't feel left out, I got some solid couplings and universal couplings from there once I knew the shaft size on the motors I was going to use.

Given the shallow angle that the shafts are going through the hull I knew I'd have to drill several holes and join them up, but the holes were alarmingly large (for a first timer anyway) by the time I got anywhere near being able to align the shaft with the motor. The holes ended up wider and longer than they really needed to be while I was messing about trying to get the shafts to align with the rudders and motors and still have propeller clearance. Maybe I'll be better at that next time round, but somehow I doubt it.

I used lots of two part epoxy glue to fix the prop shafts in place, starting with the inside of the hull. This didn't have to be too neat, but it did try to drip straight through past the pro-shafts at first, which could have been messy if I wasn't expecting it to happen.

Once the epoxy was dry on the inside, I repeated the process on the outside. As you can see from the photos, one side looks relatively ok, but the other looks like it was done by a 3 year old. I think this was because I was mixing too much of the epoxy at one time and it was starting to go off by the time I got to the messy side. Not my finest hour, but I'll know better next time and nobody will see it much so it's not the end of the world.

Once the shafts were glued in place I removed the inner shafts from the tubes and greased them before replacing them in the tubes. I used gun grease for this because I think it's a bit lighter than the bike grease I also have, but also because it was in the house and didn't involve walking out to the shed.

To attach the propellers to the shaft I added some locktite to the threads and also used the nut that came with the shaft as a lock nut. Before doing this I checked several times that the right hand shaft would push water backwards when rotated clockwise when viewed from the rear, and anti clockwise for the left hand shaft.

At the other end of the shaft I again added som locktite, then tightened up the nut that came with the propeller shaft until there was a tiny bit of play and the shaft still turned freely. I then used one of the nuts from the shaft fixing kits as a lock nut.

One thing I hadn't considered, but was pretty obvious, was that once the propeller shafts were fixed in place it would be very difficult to get the motor mount back out. I did manage it in the end, but the forward bracket to hold the propeller shafts had to be glued in place on refitting because the screws were impossible to refit. If I do this again I'll make sure the mount is ready to be glued in place before, or at the same time as the shafts.

In the end I couldn't get the shafts and the motors to line up exactly, so I used the universal couplings rather than the solid ones. The universal couplings were a little longer, which turned out to be useful. The universal couplings used a grub screw to fix the shafts, so I had to file the propeller shafts a bit to get a flatter section for the grub screw to tighten onto.

With all the drive train fitted I put the ESCs and batteries back in (I glued some velcro straps to the hull to keep the batteries in place), programmed the ESCs and limited the motor outputs to 60% in the transmitter. I then gave the boat another float test in the bath to make sure there were no leaks and that I'd got the propellers on the right way round - thankfully I had!

On the RC side, I've gone for a channel per throttle, which will allow me to control each motor independently. The only issue with that is that the transmitter I have only has one stick that is non-centering. Flysky RC sell replacement throttle modules and I've ordered one, but it is still enroute from China, so that's a job for another day.

▲

⟩⟩

chugalone100

premecekcz

hermank

SimpleSailor

ChrisF

EdW

ToraDog

thadlietz

|

💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 peterbro (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 48 Views · 4 Likes

Flag

Hi John, Chris, thanks for the suggestions.

Adding a jig on the outside of the hull is something I think I'd do next time - the metal motor mount I used basically provided the interior jig, but I eyeballed the outside, which was OK, but fiddly, and prone to error. I also like the idea of the putty/filler on the underside for sand ability. I did try to sand the epoxy on the bad side, but it is pretty impervious, which is good from a fixing perspective, but less so from a fixing mistakes perspective. For glue application I've reverted back to my primary school days with the wee plastic spreaders!

▲

⟩⟩

chugalone100

ChrisF

hermank

thadlietz

|

|

Login To

Remove Ads 💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 55 Views · 3 Likes

Flag

It is quite nerve-wracking gluing in prop shafts for the first time, so well done.

As well as the tape method recommended by ToraDog the way I do it is to fill the underside first with epoxy putty or P38 filler which as well as blocking the hole can be filed and sanded to shape. I then fill from inside the hull using the 2 part epoxy which I drip into place using small timber offcuts and cocktail sticks. As you have found out the glue still needs to be runny to do this so best to make up several small amounts. I know you have painted now but did you try filing the epoxy on the underside? But as you say it won't really be seen. Looking forward to seeing it on the water. Chris ▲

⟩⟩

hermank

peterbro

SimpleSailor

|

|

💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 JOHN (

Midshipman) Midshipman)✧ 54 Views · 8 Likes

Flag

hi there,

As has already been mentioned, adding electrician tape to the outside of the hull, whilst epoxying your propeller shafts in place, is one of the best methods. Also, one of the tips which I learned was to make 2 plywood templates up with the correct distance between your prop shafts and the hull & this is placed over the end of the prop shafts to keep them in line. One plywood jig on the outside and one identical plywood jig on the inside over the prop shafts. This helps keep the shafts parallel whilst the epoxy sets. John

▲

⟩⟩

chugalone100

premecekcz

AlessandroSPQR

hermank

thadlietz

peterbro

SimpleSailor

ChrisF

|

|

💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 peterbro (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 53 Views · 1 Like

Flag

Thanks, that's a handy tip for next time. I don't think it would have completely saved me from the epoxy going off, but if I combine those two lessons I'll likely get a better result next time.

I've got a variety of options with the throttles including various mixing options in the transmitter, fully independent control and using a splitter to run both motors from a single channel. I'm starting with fully independent control, but I'll definitely have a play around with the configuration of it to try and find what works best for me and my hand eye coordination limitations. ▲

⟩⟩

hermank

|

|

💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇺🇸 ToraDog (

Commodore) Commodore)✧ 61 Views · 3 Likes

Flag

You have done a wonderful job.

I wish I had been able to advise you to apply tape to the outside of the hull around the shaft tubes. It makes for a neater look. I would expect that you could mix your throttle with your "other" throttle and use just your throttle stick most of the time while running you boat. The only time you need independent is playing and perhaps docking. You should be able to do this.😊 ▲

⟩⟩

hermank

ChrisF

peterbro

|

📝 Motors, ESCs and All The Rest

8 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 70 Views · 10 Likes · 3 Comments

Flag

💬 Add Comment

I've never done any RC models before, so I've been putting off buying motors and all the RC components to make everything go while I try to read up on it all.

After fitting the rudder the other week I realised that to test it I'd need to buy all the things I'd been putting off - The rudder servo needs to be connected to the receiver, which gets power from an ESC, which gets power from the main LIPO battery, which in turn needs to be charged.

Hence no blog post last weekend because I was still waiting for some things to arrive.

My final major component shopping list from Amazon was as follows:

Hawk's Work FS-i6X 10 Ch Transmitter, with FS-iA6B Receiver

Two Ezrun Max10 G2 80A ESCs with 3652SD 3300kv G3 brushless motors.

Injora Low Profile Digital Servo

Two Hilldow 2S Lipo 5100mAh Batteries with an XT60 Connector

ISDT PD60 60W 6A Lipo Balance Charger

Hobbywing 30501003 Programming Box for the ESCs

Given what I've read, the motors may be too powerful. Time will tell, but the transmitter has the capability to dial back the output of channels if necessary, so my only real worry is excess weight being a problem.

I also got a metal double servo arm and rudder arms to replace the plastic ones and some threaded rods and ball head link joints to join them together.

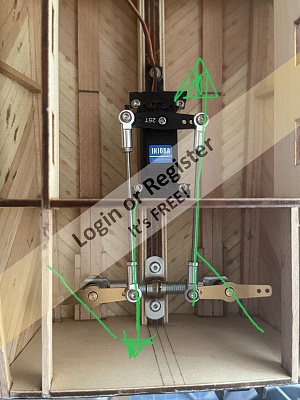

As you can see from the photo, I decided to link the servo to the inner rudder arms.

I've tested this setup and I can get what looks like a decent amount of rudder deflection without pulling anything out of shape, or binding.

One thing I've been quite concerned about was mounting the motors in the hull. I found some nice looking mounts on Amazon and a site called 'Noah's RC Ark' that have three cast aluminium pieces clamped between two side plates - two to clamp the motor and one to clamp the propeller shaft at a fixed angle. Unfortunately they were a bit pricey, especially on Amazon. In the end, since the mounts were Chinese imports anyway, I decided to cut out the middle man and look on Ali Express where I found the same thing for a third of the price.

The motor mounts took some modification to fit the motors that I had bought, and to fit into the hull.

I had to add some metal standoff bolts because the motor was too short to bolt it directly to the middle aluminium plate.

I only used the outer two of the four side plates and added threaded rods to bolt the aluminium parts together to turn two single motor mounts into one twin motor mount with the required 75mm/3" spacing.

I also had to cut the front part off of the side plates in order to get the assembly to fit between the bulkheads.

After the modifications, there were enough side plate parts left over to make mounts for the rudder servo, the ESCs and the receiver, so they turned out to be a really good buy.

All the mounts (excluding motor and battery) have been fixed in place, and the components clamped to them to make sure I'll be able to get at everything once the deck goes on.

I managed to put everything in where it will eventually go tonight and gave give it a float test in the bath.

It sits very slightly bow down with two batteries on board, but No leaks visible!

After fitting the rudder the other week I realised that to test it I'd need to buy all the things I'd been putting off - The rudder servo needs to be connected to the receiver, which gets power from an ESC, which gets power from the main LIPO battery, which in turn needs to be charged.

Hence no blog post last weekend because I was still waiting for some things to arrive.

My final major component shopping list from Amazon was as follows:

Hawk's Work FS-i6X 10 Ch Transmitter, with FS-iA6B Receiver

Two Ezrun Max10 G2 80A ESCs with 3652SD 3300kv G3 brushless motors.

Injora Low Profile Digital Servo

Two Hilldow 2S Lipo 5100mAh Batteries with an XT60 Connector

ISDT PD60 60W 6A Lipo Balance Charger

Hobbywing 30501003 Programming Box for the ESCs

Given what I've read, the motors may be too powerful. Time will tell, but the transmitter has the capability to dial back the output of channels if necessary, so my only real worry is excess weight being a problem.

I also got a metal double servo arm and rudder arms to replace the plastic ones and some threaded rods and ball head link joints to join them together.

As you can see from the photo, I decided to link the servo to the inner rudder arms.

I've tested this setup and I can get what looks like a decent amount of rudder deflection without pulling anything out of shape, or binding.

One thing I've been quite concerned about was mounting the motors in the hull. I found some nice looking mounts on Amazon and a site called 'Noah's RC Ark' that have three cast aluminium pieces clamped between two side plates - two to clamp the motor and one to clamp the propeller shaft at a fixed angle. Unfortunately they were a bit pricey, especially on Amazon. In the end, since the mounts were Chinese imports anyway, I decided to cut out the middle man and look on Ali Express where I found the same thing for a third of the price.

The motor mounts took some modification to fit the motors that I had bought, and to fit into the hull.

I had to add some metal standoff bolts because the motor was too short to bolt it directly to the middle aluminium plate.

I only used the outer two of the four side plates and added threaded rods to bolt the aluminium parts together to turn two single motor mounts into one twin motor mount with the required 75mm/3" spacing.

I also had to cut the front part off of the side plates in order to get the assembly to fit between the bulkheads.

After the modifications, there were enough side plate parts left over to make mounts for the rudder servo, the ESCs and the receiver, so they turned out to be a really good buy.

All the mounts (excluding motor and battery) have been fixed in place, and the components clamped to them to make sure I'll be able to get at everything once the deck goes on.

I managed to put everything in where it will eventually go tonight and gave give it a float test in the bath.

It sits very slightly bow down with two batteries on board, but No leaks visible!

▲

⟩⟩

chugalone100

premecekcz

Steves-s

SimpleSailor

Len1

hermank

EdW

peterd

thadlietz

ChrisF

|

💬 Re: Motors, ESCs and All The Rest

8 months ago by 🇬🇧 peterbro (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 68 Views · 4 Likes

Flag

The centre of gravity seems pretty central when I balance it in my hand and it looks pretty level by eye, it just doesn't match the water line on the model.

If it runs OK, I guess that just means I got the waterline wrong! I haven't thought about an absolute number for the propeller shaft angle before tbh, but looking at the plans with that in mind, 10 - 12 degrees is roughly what it has them set at. Something around 12 degrees should be achievable - there might be some tweaking to do with the motor mount and I'll have to get the holes in the hull in the right place. I have some thinking time left as the hull is too tight for a drill, so I'm waiting for a pin vice that will take a drill bit big enough for the propeller shaft holes. ▲

⟩⟩

SimpleSailor

Len1

ChrisF

hermank

|

|

Login To

Remove Ads 💬 Re: Motors, ESCs and All The Rest

8 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 75 Views · 3 Likes

Flag

Those motors are a bit big and a high kV and probably quite heavy but as you have them positioned quite far back they shouldn't be contributing to the slight nose down attitude too much. The weight of the prop shafts and tubes should help with this though. Have you been able to achieve a fairly low angle circa 12 degrees for the prop shaft given the position of the motors?

You certainly had some work with the motor mounts! But all nicely done as is the rudder connection. Will be interesting to see how it goes. ▲

⟩⟩

Len1

peterbro

hermank

|

|

💬 Re: Motors, ESCs and All The Rest

8 months ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 72 Views · 3 Likes

Flag

|

📝 Rudders Fitted

8 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 91 Views · 10 Likes · 3 Comments

Flag

💬 Add Comment

I got a pair of 40mm x 26mm brass rudders from Cornwall Model Boats a couple of weeks ago, but after spending so long planking the hull I didn't want to rush into drilling holes in it.

The threaded tubes for the rudders were 8mm diameter, which was a bit close to the width of the hull bracing planks for my liking. To make sure I didn't destroy the planks when drilling I added some extra bracing along the sides, along with another plank to give enough depth for the threads to tighten.

I also added a couple of spring strut end joints connected by a length of M8 Rod mounted to the keel. The idea is that this will keep the rudders aligned and reduce the stress on the hull when they are pushed and pulled by the servo - probably total overkill, but I'm happy with it.

The threaded tubes for the rudders were 8mm diameter, which was a bit close to the width of the hull bracing planks for my liking. To make sure I didn't destroy the planks when drilling I added some extra bracing along the sides, along with another plank to give enough depth for the threads to tighten.

I also added a couple of spring strut end joints connected by a length of M8 Rod mounted to the keel. The idea is that this will keep the rudders aligned and reduce the stress on the hull when they are pushed and pulled by the servo - probably total overkill, but I'm happy with it.

▲

⟩⟩

Len1

EdW

thadlietz

Wolle

SimpleSailor

JOHN

hermank

peterd

premecekcz

Ronald

|

Login To

Remove Ads 💬 Re: Rudders Fitted

8 months ago by 🇬🇧 peterbro (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 90 Views · 2 Likes

Flag

I've got a couple of ideas for how to set things up.

There's plenty room at the sides for the arms that came with the tillers, but not quite enough at the stern. I can trim them a bit if necessary, but I don't think they'll need a full 180 degrees of movement to provide decent steering so it might well be OK as is. As for the servos, I've got a couple of ideas to try. My initial plan is to use the arms aligned as they are in the picture and connect each outer tiller arm to the corresponding outer arm on a single servo sitting on the keel. If that doesn't work, I'll try something that is probably more standard - using an 'L' shaped arm on one of the tillers, connecting the tiller arms aligned with the keel together and connecting the other leg of the 'L' arm to a single servo. ▲

⟩⟩

Len1

hermank

|

|

💬 Re: Rudders Fitted

8 months ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 95 Views · 2 Likes

Flag

How much clearance do you have between the control horns and the sides? Are you using two control rods linked to separate servos for each rudder?

I always thought the rudder control horns were linked together with a rod fixture and then the control rod/s to the control arm of the single servo. Maybe it’s too early to ask about this and you have it all figured out.🤔 ▲

⟩⟩

Len1

hermank

|

📝 Hull Stand

9 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 92 Views · 6 Likes

Flag

💬 Add Comment

No actual progress on the boat itself this week, but I made a stand for the hull to enable me to take it off the build jig for the first time.

It turns out that Hobby Craft sell a plywood box which is just the right size to sit between bulkheads 2 and 4 on the plan. All I had to do was remove the lid and trace and cut out the bulkhead shapes from the ends of the box.

I used deep mahogany wood stain to make it look a bit nicer and some red self adhesive felt (also from Hobby Craft) to protect the hull from scratches.

It turns out that Hobby Craft sell a plywood box which is just the right size to sit between bulkheads 2 and 4 on the plan. All I had to do was remove the lid and trace and cut out the bulkhead shapes from the ends of the box.

I used deep mahogany wood stain to make it look a bit nicer and some red self adhesive felt (also from Hobby Craft) to protect the hull from scratches.

▲

⟩⟩

hermank

peterd

premecekcz

EdW

SimpleSailor

jostro65

📝 Hull Finishing Touches

9 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 95 Views · 6 Likes

Flag

💬 Add Comment

Some small bits and bobs of progress this week.

I added stern numbers and porthole frames, then some gloss varnish over the entire hull.

Next, I completed the first bit of superstructure - the hatch cover between the main cabin and the raised engine room deckhead. The hatch will be removable on the model to maximise access to the hull space.

The hatch is made from 1.5mm ply with 1/8" x 1/16" edging and 1/2" square balsa underneath to keep the ply flat. The scuttle and inspection hatches are from Mac's mouldings.

I used Humbrol acrylic no 127 as the main grey colour with a Windsor & Newton burnt umber wash to pick out the details and add some dirt.

I added stern numbers and porthole frames, then some gloss varnish over the entire hull.

Next, I completed the first bit of superstructure - the hatch cover between the main cabin and the raised engine room deckhead. The hatch will be removable on the model to maximise access to the hull space.

The hatch is made from 1.5mm ply with 1/8" x 1/16" edging and 1/2" square balsa underneath to keep the ply flat. The scuttle and inspection hatches are from Mac's mouldings.

I used Humbrol acrylic no 127 as the main grey colour with a Windsor & Newton burnt umber wash to pick out the details and add some dirt.

▲

⟩⟩

EdW

SimpleSailor

jostro65

hermank

JOHN

premecekcz

📝 Adding some Colour and Details

9 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 96 Views · 7 Likes

Flag

💬 Add Comment

Painting the hull before fitting the running gear probably isn't the usual order, but I'm still researching brushless motors, propellers and all that side of things so I decided to just keep going. I'll have to fix up some of the hull paint once I add those things, but I think (hope) that it will work out ok.

I started off using crimson acrylic paint from Windsor and Newton because I had some. I found that it was slightly transparent, so switched to deep cadmium red instead, which worked much better. The upper hull was painted using mars black, also from Windsor and Newton.

Next up I used some 3mm water line vinyl tape (car trim) from Amazon.

The roundel and the number markings took some time. Initially I was looking for things that matched the plan, but noticed that the photos I have for 2757 have a later type roundel and numbering font.

I found a selection different sizes of the later type roundel without the yellow outline on the Castle Signs website.

I got the numbering from Vinyl Lettering Online, who supply custom lettering to your specific size, spacing and font on backing film - this makes it really easy to apply. I found that Open Sans Bold was a pretty good match for the numbering font shown in photos of 2757.

For the stern details I added a couple of 6mm eyelets as exhausts, then used 4mmx11mm staples and m1.2 washers to make the rungs of the ladder (all from Amazon). Gluing the staples and washers in place was really fiddly.

I made the ladder protectors from one of the 1.5mmx6mm mahogany strips that I got to do the deck planking.

Slightly late in the day I found a picture of the stern of 2757 on the RAF Museum website.

This showed that the number and position of the exhausts on the plan was wrong, but I decided to ignore that since they were already glued on.

It also showed details of vertical rollers on the towing hawse fairlead (if that's what it's called) in the hull, which I made up using some old sprue and plasticard that I had lying around. This detail isn't on the plan at all, or at least I can't see it.

I still have some portholes to add and the stern number (another detail shown in my late photo find and not on the plan), but the paint and markings have made a huge difference to how the hull looks.

I started off using crimson acrylic paint from Windsor and Newton because I had some. I found that it was slightly transparent, so switched to deep cadmium red instead, which worked much better. The upper hull was painted using mars black, also from Windsor and Newton.

Next up I used some 3mm water line vinyl tape (car trim) from Amazon.

The roundel and the number markings took some time. Initially I was looking for things that matched the plan, but noticed that the photos I have for 2757 have a later type roundel and numbering font.

I found a selection different sizes of the later type roundel without the yellow outline on the Castle Signs website.

I got the numbering from Vinyl Lettering Online, who supply custom lettering to your specific size, spacing and font on backing film - this makes it really easy to apply. I found that Open Sans Bold was a pretty good match for the numbering font shown in photos of 2757.

For the stern details I added a couple of 6mm eyelets as exhausts, then used 4mmx11mm staples and m1.2 washers to make the rungs of the ladder (all from Amazon). Gluing the staples and washers in place was really fiddly.

I made the ladder protectors from one of the 1.5mmx6mm mahogany strips that I got to do the deck planking.

Slightly late in the day I found a picture of the stern of 2757 on the RAF Museum website.

This showed that the number and position of the exhausts on the plan was wrong, but I decided to ignore that since they were already glued on.

It also showed details of vertical rollers on the towing hawse fairlead (if that's what it's called) in the hull, which I made up using some old sprue and plasticard that I had lying around. This detail isn't on the plan at all, or at least I can't see it.

I still have some portholes to add and the stern number (another detail shown in my late photo find and not on the plan), but the paint and markings have made a huge difference to how the hull looks.

▲

⟩⟩

EdW

SimpleSailor

jostro65

hermank

premecekcz

Wolle

SouthportPat

📝 Second Layer of Hull Planking Complete

9 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 101 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

I've been working steadily on the second layer of planking for a while, but since none of it made much of a visual difference I didn't post an update until it was finished.

Before starting the second layer I added a layer of 20gsm lining silk that I found on amazon and two more coats of sanding sealer. I decided on silk rather than tissue as I thought it would give me a stronger hull in the end.

The second layer of planking went on a lot faster than the first as I could clamp more planks in one go, and was much easier to bend and trim given the 0.5mm thickness.

The chine rubbing strip went on this morning with the help of some sniper tape I found in a drawer, which did a nice job of holding things in place while the glue set.

A load of sanding, and the first coat of sanding sealer is also done.

There are still some lumps and bumps as you can see from the photographs, but the hull looks straight and pretty symmetrical (the photo makes things look warped, but that's my photography skills).

Overall I'm pretty pleased with it for a first attempt at planking.

Before starting the second layer I added a layer of 20gsm lining silk that I found on amazon and two more coats of sanding sealer. I decided on silk rather than tissue as I thought it would give me a stronger hull in the end.

The second layer of planking went on a lot faster than the first as I could clamp more planks in one go, and was much easier to bend and trim given the 0.5mm thickness.

The chine rubbing strip went on this morning with the help of some sniper tape I found in a drawer, which did a nice job of holding things in place while the glue set.

A load of sanding, and the first coat of sanding sealer is also done.

There are still some lumps and bumps as you can see from the photographs, but the hull looks straight and pretty symmetrical (the photo makes things look warped, but that's my photography skills).

Overall I'm pretty pleased with it for a first attempt at planking.

▲

⟩⟩

ChrisF

EdW

Wolle

Ronald

hermank

premecekcz

SimpleSailor

RossM

|

💬 Re: Second Layer of Hull Planking Complete

9 months ago by 🇨🇿 premecekcz (

Master Seaman) Master Seaman)✧ 104 Views · 2 Likes

Flag

nice, precise work

👍 ▲

⟩⟩

AlessandroSPQR

hermank

|

📝 Solid Bow Section Installation

10 months ago by 🇬🇧 peterbro ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 110 Views · 8 Likes

Flag

💬 Add Comment

The plans call for the lower section of the bow to be carved out of balsa.

I decided to use 1/2" balsa sheet cut roughly to size and laminated on installation.

I also made a conscious decision to add these after the first layer of planking to allow me to cover them over with the second layer so that the whole hull looks planked.

It looks pretty awful to start with when roughly shaped, but planes and sands down quite easily to something that looks much better.

Compared to planking the hull it didn't take very long, so I also added some wood filler to smooth out the lower hull and bits of bow that were looking a bit rough.

A final bit of sanding and the first coat of sanding sealer is also now on.

I decided to use 1/2" balsa sheet cut roughly to size and laminated on installation.

I also made a conscious decision to add these after the first layer of planking to allow me to cover them over with the second layer so that the whole hull looks planked.

It looks pretty awful to start with when roughly shaped, but planes and sands down quite easily to something that looks much better.

Compared to planking the hull it didn't take very long, so I also added some wood filler to smooth out the lower hull and bits of bow that were looking a bit rough.

A final bit of sanding and the first coat of sanding sealer is also now on.

▲

⟩⟩

peterd

EdW

Wolle

hermank

jbkiwi

robbob

BOATSHED

Len1

United Kingdom

United Kingdom