Join Us On Social Media!

You have have been viewing a lot of topics!

Please consider becoming a member to help keep this website afloat.

Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

10 Posts · 5 Followers · 104 Photos · 29 Likes

Began 5 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 5 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 10

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 23 Views · 3 Likes

Flag

💬 Add Comment

A few more pics of the tissue being applied, plenty of overlapping at the tissue joints, let it all dry and will be easily cut away with a craft knife after. Did fit a couple of side rubbing strips besides the spray rails and deck level strips, basically to support the sides against collision, always carry a tube of balsa cement, if the unfortunate occurance of such things and splits or cracks appear, just rub some balsa cement into the crack and it will reseal the hull for you, its waterproof, so no thinning of the glue, and is easily repaired apon return to boat yard .. Happy sailing and enjoy the unorthodox quick build. Regards Muddy ..

▲

⟩⟩

Steve P

EdW

peterd

Login To

Remove Ads

Remove Ads

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 9

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 22 Views · 1 Like

Flag

💬 Add Comment

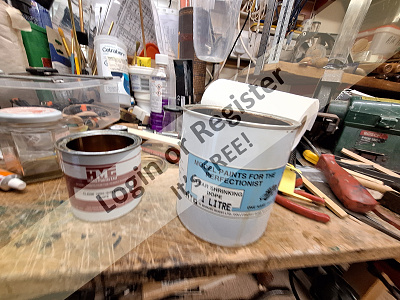

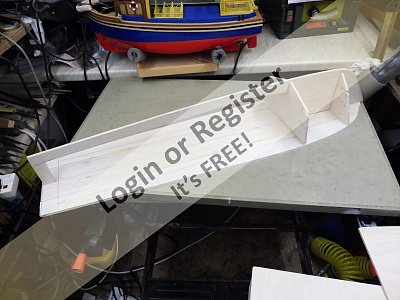

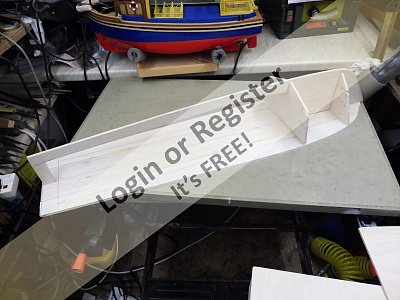

Now the furniture is all lined up and fixed plus the steering servo, one can start on the side skins again verticaly sheeting, this will give the hull a lot of strength, again best left overnight to thoroughly dry and glue set. only the Bow to infill with block balsa or any left over bits of sheet, i think the more glue joints the stronger the bow will be ? maybe. Again this part of the build is best left overnight for the glue to set. Next step is to Dope and tissue the hull all over, best give the hull about 3 coats minimum well thinned about 25% is good, a quick rub with the sandpaper between coats. Then apply the tissue, i have found that using small patches of tissue, say about 4-6 inch squares according to the depth of the sides and bottom skins, but Ripped or Torn NOT cut with scissors of a craft knife, when the tissue is ripped it just blends in when the overlaps are brushed on, i did tend to use long pieces of tissue on this hull and it didnt really work, so another lesson learnt, practice what you preach, was probably in a hurry, but it took more time to sand out the creases after. Another min: of 3 coats of tinned dope to be applied, by this time all the lines in the bals should have disappeared and there will be a nice smooth skin ready to accept the paint, again as many coats of primer as you feel is best, but a min: of 3 again, ready for a top coat of 1..

▲

⟩⟩

EdW

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 8

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 2 Likes

Flag

💬 Add Comment

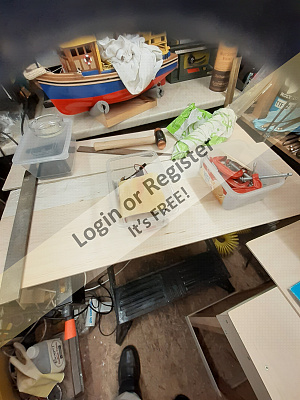

One thing to note if you build as you go the cabin/upperworks on the deck, it will be a very good fit !

Now we are getting somewhere near , its time to fit the motors. with the side skins off makes life easy for alignment's.

Now we are getting somewhere near , its time to fit the motors. with the side skins off makes life easy for alignment's.

▲

⟩⟩

EdW

thadlietz

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 7

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 2 Likes

Flag

💬 Add Comment

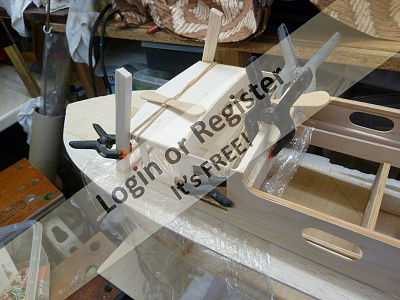

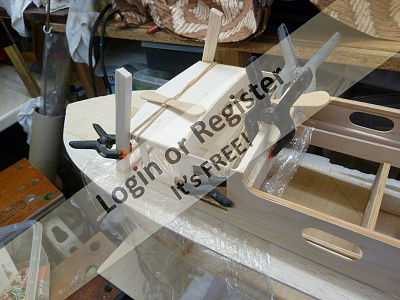

Continuing with the bottom skins, always glue and pin both sides of the hull equally, Port and Starboard. This is best left overnight to let the glue set right off and then one can start the sanding and cutting to profile the next day. Its a good time to start thinking about the upperworks/cabin etc: .... I like the open access type, or one big hole in the deck with a removable top, something to get your hands into, especially if you are going to experiment with motors and radio gear are to be contemplated. You really need as much room for access as possible. And as this is an experimental boat i did exactly thay. The cabin is not to drawing as the hull is also, not to drawing or its construction. Just an outline to shape that worked, note the "that" .. in previous model a 30" Telectra. Lierally it was place everything but stretch lengthwise and widthwise, decided on a deck combing, about 1/2" high and lined the top rim with 3/16" square to act as a water diverter, we hope. Although a wet deck is not a good sign on a calm pond. First thing was to lay Cling Film all over the deck covering the motor and drive shaft access/aperture. Space the sides off the deck combing and measure the cabin formers, balsa is my preferred wood for this, its a lot easier and quicker than ply. Basically its a build as go, but keeping the windows and windscreen in prospective to suit. ... .8mm ply was used for the cabin roof, if one watches the grain it forms very nicely thank you, and use some odd lengths of timber laid over the length of the roof's to stop them "Barreling" .. Elastic bands are great for this job, and if yours aint long enough just join a couple together like a daisy chain.

▲

⟩⟩

EdW

thadlietz

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 6

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 29 Views · 2 Likes

Flag

💬 Add Comment

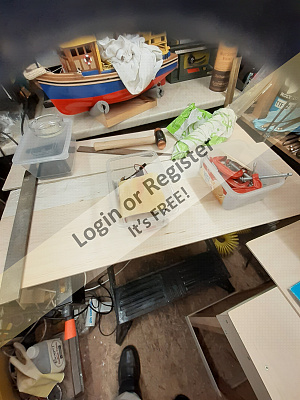

Propulsion, once glue is dry on all the fittings and supports for motors shafts and rudder, time to start on skins, normally i will go for the bottom ones first, they consist of 1/8" sheet balsa laid and glued across the underside, keel to chine, this will give the model a lot of strength. But first, get the Dumbells out and a bit of a workout, cos the edges of the deck , keil and chine have to match in angles for the sheet balsa to be applied , and fit well.. Have used for years a piece of 3/8" ply about 8" x 3", this is my sanding block, apply a piece of sandpaper to it just by hold, it's folded around on one face of the 3/8 ply, the idea is to span the chine and keel so there is only one edge for the balsa skin to sit on. This is also used to sand to shape the edges of the deck and chine. Again i use the Aliphatic glue for this. ( think its Titbond ). Have always cut the skin span to long, when the glue is applied and pinned, one can trim the overlength after the glue drying process. The bottom skins are fitted all the way up to the bow first bulkhead, as the bow will be balsa blocked, its a lot quicker and easier, moreso easily repaired..

▲

⟩⟩

thadlietz

EdW

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 5

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

▲

⟩⟩

thadlietz

EdW

Steve P

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 4

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

Once the main frame/Hull frame glue is dry, one has to start thinking about the Furniture, ie: Propulsion and steering. Tend to use Twin Screw arrangement with a single Rudder, just my choice, but i did find that a single Rudder with Twin Screws made the steering "Softer" , stopped the bow digging in on tight turns, the rudder acts more like a trim tab, that is as long as there is not to much throw, I always use about 20-25 Degrees either way works great for me, and the boat. As the construction is balsa use plenty of wood around the prop shaft exit from the hull and the rudder shaft, there is a lot of stress at this point, or maybe more if one fits Brushless motors.. The other major point is where the motors are to be mounted, try to align motors to shafts as accurately as possible, if one makes up a motor platform and then shims motor mountings with wedges, at this point I have always used an Epoxy glue for the mounting plate and in 6mm ply full hull width if possible. it is well advisable to fit "Furniture" before the skins are applied, but fitting the bottom skins can be advantageous, it will strengthen the hull, before one sets about the Furniture install with a 4 lb hammer and cold chiesel.. ( just a funny ).. Included is a pic of prop to be used , from Prop shop, i like these props and they have served me well in all of my models.

▲

⟩⟩

thadlietz

EdW

Steve P

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 3

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 2 Likes

Flag

💬 Add Comment

When all the bulkheads are cut out and the chines. Construction can actually start by laying the Deck onto a flat surface and dry fitting the keel and bulkheads in place, it feels a bit funny at first as one is constructing upside down, but dont worry it grows on you. If the dry fit is ok, then pull it all apart and apply glue where appropriate, have always used an Aliphatic, these glues i think are PVA family but they do dry hard and not rubbery, presumably resin based. Also use a Cyno type of glue for tacking parts into place then line the joint with the Alphatic. One the keel, bulkheads and chines are glue in place weigh it all down on the flat surface, use anthing heavy , old batterys , files engineering blocks, my transom split, another one, so quickly found a piece of 1/2" balsa and cut to shape, inserted and glued. Now is the time for a cuppa, and scrounging, your looking for a piece of polystyrene, the sort that is premoulded from a TV, CD player or tape recorder packaging, use this as a building stand in place of the usual ply frame, the reason for the polystyrene is, its soft and wont damage the delicate balsa even if you drop the frame onto the poly: if neccesary cut a couple of V shapes in the poly: to match the hull shape, that helps a lot.

▲

⟩⟩

thadlietz

EdW

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 2

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 45 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

A bad explanation on my part concerning Grease proof paper and cling film. Just like to put the record straight, Before Cling Film, being used as protection for a Drawing or worktop/bench, we used grease proof paper or rubbed soap over the drawing which hopefully left a wax'y film on the drawing or bench worksurface preventing glues stickng to the drawing /worktop, but since clingfilm which is a lot better to use and out performs soap and greaseproof paper by keeping glues off the valuable drawings/worktop's. Continuing on, when one traces the outlines of the deck at close to 36" long, the A3 size of draft film aint big enough to cover this length, join a couple of A3 film together using a Selotape type of bond, i tend to use 3M Scotch Magic Tape, it has an opaque look and matt finish, this is great for drawing on either in pencil or Ballpoint pen.

Whereas standard Sellotape type of tape has a gloss finish and pencil lines do not adhere or ball point pen ink. Once you have traced the Deck outline, place it over the Balsa deck and copy it onto the balsa, some folks like Carbon copy paper and copy that way, i prefer to use a pin and prick through the tracing paper into the wood, then remove the film and join up the pricked marks, ( I love this bit ), now do the same for the Keel, being careful not to break off the upright at the Transom end, if this happens do not worry, a small amount of super glue/cyno will do an instant repair then fit a couple of 1/8" Balsa doublers. Next is to the same with the Bulkheads , trace onto the wood mark out and cut out, i did have trouble with one of these bulkheads, spliting with the grain, i scrapped it, and recut the bulkhead in 1/8" times 2, laminating these two together.

Whereas standard Sellotape type of tape has a gloss finish and pencil lines do not adhere or ball point pen ink. Once you have traced the Deck outline, place it over the Balsa deck and copy it onto the balsa, some folks like Carbon copy paper and copy that way, i prefer to use a pin and prick through the tracing paper into the wood, then remove the film and join up the pricked marks, ( I love this bit ), now do the same for the Keel, being careful not to break off the upright at the Transom end, if this happens do not worry, a small amount of super glue/cyno will do an instant repair then fit a couple of 1/8" Balsa doublers. Next is to the same with the Bulkheads , trace onto the wood mark out and cut out, i did have trouble with one of these bulkheads, spliting with the grain, i scrapped it, and recut the bulkhead in 1/8" times 2, laminating these two together.

▲

⟩⟩

thadlietz

EdW

|

💬 Re: Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 2

5 months ago by 🇳🇿 Nick Ward (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 47 Views · 1 Like

Flag

Hi Muddy,

I bought this plan many years ago (about 30+ I think) along with various Vic Smeed plans including the Vivacity which I've just started to build. I re-discovered it in a file in the loft and have since unfolded it with a view to building one in the future (along with lots of others!) I too am a big fan of balsa, and agree that when covered with tissue it can be surprisingly resilient to knocks. I'll be following your build with interest.👍👍👍😊 Best of luck with it - keep the pics coming. Best regards, Nick ▲

⟩⟩

Steve P

|

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 67 Views · 9 Likes · 4 Comments

Flag

💬 Add Comment

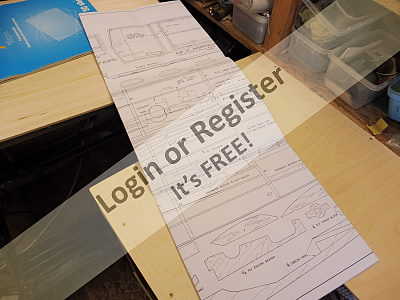

Part 1 - 7 Pictures ...

Made up a Spec for something light twin screw and not to big in length. Having built and sailed this model earlier about 2014 ish... with twin 777 Brushed drive motors, it's performance was in my opinion good.

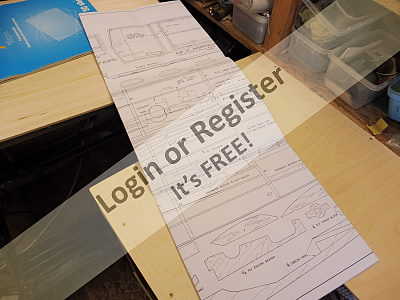

But decided to lengthen the hull from abt 30 inches to 36 inch, why, I dont know, just for a bit of fun and thought the earlier version looked a bit short and sweet, and the build would be in Balsa.. Some folks frown upon this timber but i love it, easy to work, cut and sand and if tissue covered will be quite strong. First set of pics show the drawing, Drafting Film/Tracing Paper and joining of three sheets of balsa to form the deck which are laid on Cling Film, good stuff this, a lot better than the old grease proof paper. 3 x 3" sheets of balsa were glued up together edgewise on.. To be continued -

Made up a Spec for something light twin screw and not to big in length. Having built and sailed this model earlier about 2014 ish... with twin 777 Brushed drive motors, it's performance was in my opinion good.

But decided to lengthen the hull from abt 30 inches to 36 inch, why, I dont know, just for a bit of fun and thought the earlier version looked a bit short and sweet, and the build would be in Balsa.. Some folks frown upon this timber but i love it, easy to work, cut and sand and if tissue covered will be quite strong. First set of pics show the drawing, Drafting Film/Tracing Paper and joining of three sheets of balsa to form the deck which are laid on Cling Film, good stuff this, a lot better than the old grease proof paper. 3 x 3" sheets of balsa were glued up together edgewise on.. To be continued -

▲

⟩⟩

IanL1

Nick Ward

Steves-s

Steve P

Doogle

hermank

EdW

jumpugly

thadlietz

|

💬 Re: Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 Doogle (

Vice Admiral) Vice Admiral)✧ 51 Views · 3 Likes

Flag

Looking forward to seeing how your build goes. All the best 👍

▲

⟩⟩

AlessandroSPQR

Nick Ward

muddy

|

|

Login To

Remove Ads 💬 Re: Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 66 Views · 2 Likes

Flag

I've still got a roll of 791mm x 10m of tracing paper from the days when I used to work on the drawing board doing drawings for house extensions etc.! Heavy grade and as you say a lot better than grease proof paper.

▲

⟩⟩

Doogle

hermank

|

|

💬 Re: Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 Steve P (

Master Seaman) Master Seaman)✧ 65 Views · 4 Likes

Flag

By the way I should add it is now 50 years later!

▲

⟩⟩

Nick Ward

muddy

Doogle

hermank

|

|

💬 Re: Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 Steve P (

Master Seaman) Master Seaman)✧ 65 Views · 4 Likes

Flag

I bought this plan as a spotty 15 year old many years ago as an aspirational build. Like many, lack of money and knowledge and the impact of hormones kicked in and it was never started.

I came across the plan on a well known auction site a couple of weeks ago and it is now on my next to build list. Really interested how you get on and look forward to your build updates ▲

⟩⟩

Nick Ward

muddy

Doogle

hermank

|

United Kingdom

United Kingdom