Join Us On Social Media!

Midwest/Model Expo Fireboat

16 Posts · 9 Followers · 61 Photos · 98 Likes

Began 3 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 12 days ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Lobster Smack

12 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 16 Views · 1 Like

Flag

💬 Add Comment

Jumpugly:

Your father’s model is truly outstanding…more than craftsmanship, it feels like a piece of his spirit lives in it.

I think many of us are quietly looking forward to the day your own skill and care bring it back to full glory, as a beautiful tribute to his memory.

Model Expo also offers a Lobster Smack kit, though it isn’t quite as large as your father’s. I thought you might enjoy seeing it:

Your father’s model is truly outstanding…more than craftsmanship, it feels like a piece of his spirit lives in it.

I think many of us are quietly looking forward to the day your own skill and care bring it back to full glory, as a beautiful tribute to his memory.

Model Expo also offers a Lobster Smack kit, though it isn’t quite as large as your father’s. I thought you might enjoy seeing it:

▲

⟩⟩

jumpugly

Login To

Remove Ads

Remove Ads

📝 Midwest/ Model Expo The Fireboat

13 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 22 Views · 2 Likes

Flag

💬 Add Comment

Hi Chris:

That was actually one of the questions I asked the Production Manager. According to him, they have already started setting up parts of the model. Now that all of the upgrades are finalized, his estimate is that it may take about two months for the kit to appear in their catalog as soon as possible.

Both of the videos you’ve seen here were shown to Mark, the owner, and he approved moving forward with production of the kit.

The next time I stop by, I’ll be more specific in asking about the release date. I’ll keep everyone posted as soon as possible.

😎

That was actually one of the questions I asked the Production Manager. According to him, they have already started setting up parts of the model. Now that all of the upgrades are finalized, his estimate is that it may take about two months for the kit to appear in their catalog as soon as possible.

Both of the videos you’ve seen here were shown to Mark, the owner, and he approved moving forward with production of the kit.

The next time I stop by, I’ll be more specific in asking about the release date. I’ll keep everyone posted as soon as possible.

😎

▲

⟩⟩

jumpugly

cjanik001

📝 Midwest/ Model Expo The Fireboat

14 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 29 Views · 8 Likes · 5 Comments

Flag

💬 Add Comment

I just returned from Model Expo today, where I had an extended discussion with both the production manager and the designer. At the conclusion of that meeting, I left the model in their care.

After many months of designing, assembling, painting, and refining every detail, the final result was extremely satisfying.

Letting go of a freshly completed model does bring an unexpected sense of detachment.

However, knowing that this improved version will benefit both new and experienced model builders makes the experience a positive one. It’s gratifying to know that my contribution will ultimately serve the greater modeling community.

😎

After many months of designing, assembling, painting, and refining every detail, the final result was extremely satisfying.

Letting go of a freshly completed model does bring an unexpected sense of detachment.

However, knowing that this improved version will benefit both new and experienced model builders makes the experience a positive one. It’s gratifying to know that my contribution will ultimately serve the greater modeling community.

😎

▲

⟩⟩

ChrisF

LeeA

cjanik001

hermank

DWBrinkman

RodC

Ronald

jumpugly

|

💬 Re: Midwest/ Model Expo The Fireboat

12 days ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 21 Views · 3 Likes

Flag

|

|

Login To

Remove Ads 💬 Re: Midwest/ Model Expo The Fireboat

13 days ago by 🇺🇸 cjanik001 (

Warrant Officer) Warrant Officer)✧ 16 Views · 2 Likes

Flag

Is there a timeline as to when this redesigned version will be released?

Chris ▲

⟩⟩

jumpugly

chugalone100

|

|

💬 Re: Midwest/ Model Expo The Fireboat

13 days ago by 🇺🇸 chugalone100 (

Captain) Captain)✧ 27 Views · 4 Likes

Flag

I’ll tell them cash. As a matter of fact, I need to stop by anyway to give them the decal file I created with the help of a coworker.

😎 ▲

⟩⟩

jumpugly

Cashrc

hermank

DWBrinkman

|

|

💬 Re: Midwest/ Model Expo The Fireboat

14 days ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 23 Views · 5 Likes

Flag

I’m so glad to see Model Expo picking up the old Midwest line of boats. Chug, next time you go to see them tell them a lot of modelers say thanks.

Cash ▲

⟩⟩

jumpugly

hermank

DWBrinkman

chugalone100

Ronald

|

|

💬 Re: Midwest/ Model Expo The Fireboat

14 days ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 31 Views · 5 Likes

Flag

Good for you Chug! Well done!!!

👍 ▲

⟩⟩

AlessandroSPQR

hermank

DWBrinkman

chugalone100

Cashrc

|

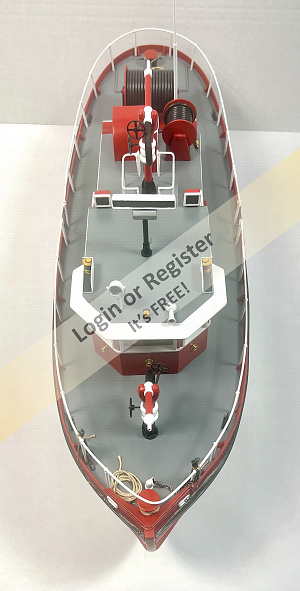

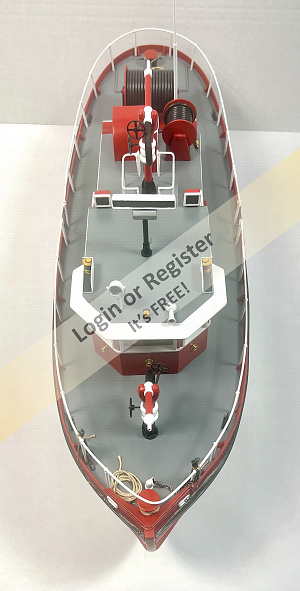

📝 Midwest/ Model Expo Fireboat

14 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 29 Views · 5 Likes · 3 Comments

Flag

💬 Add Comment

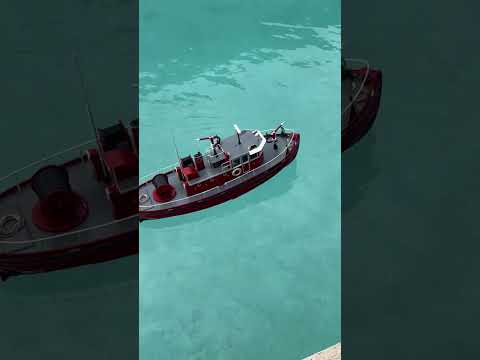

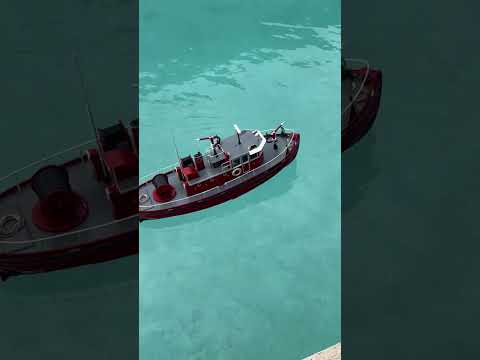

Finally the youtube videos are ready.

THE PHOTO SHOOT.

THE PHOTO SHOOT.

▲

⟩⟩

GARTH

Ronald

hermank

jumpugly

DWBrinkman

|

💬 Re: Midwest/ Model Expo Fireboat

14 days ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 30 Views · 3 Likes

Flag

Aren’t you gonna be popular at the summer tea garden watering the flowers 🌺 🥀🌸🌼🪻💐💐🌷

▲

⟩⟩

hermank

Cashrc

chugalone100

|

|

Login To

Remove Ads 💬 Re: Midwest/ Model Expo Fireboat

14 days ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 33 Views · 4 Likes

Flag

This is so COOL!!!!!! Chug I want one!!!!!

👍😊😉 ▲

⟩⟩

AlessandroSPQR

Cashrc

hermank

chugalone100

|

|

💬 Re: Midwest/ Model Expo Fireboat

14 days ago by 🇺🇸 DWBrinkman (

Commodore) Commodore)✧ 26 Views · 3 Likes

Flag

Looks great!

Nicely done. Now, I'm shamed! Gonna havta clean up the insides of mine Dave B ▲

⟩⟩

Cashrc

hermank

chugalone100

|

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 12 Likes · 2 Comments

Flag

💬 Add Comment

Final Chapter: Midwest Fireboat Build Completed

After many months of planning, building, and fine-tuning, I’m happy to share the final photos of the completed model, along with a video of the water trials. The boat performed flawlessly, spending a total of 45 minutes in the water with zero leaks; a very satisfying result!

I truly hope this series of photos and detailed build descriptions will inspire and help many newcomers as they discover our enjoyable and rewarding model shipbuilding hobby. Thank you to everyone who followed along and offered advice and encouragement throughout the build.

😎

After many months of planning, building, and fine-tuning, I’m happy to share the final photos of the completed model, along with a video of the water trials. The boat performed flawlessly, spending a total of 45 minutes in the water with zero leaks; a very satisfying result!

I truly hope this series of photos and detailed build descriptions will inspire and help many newcomers as they discover our enjoyable and rewarding model shipbuilding hobby. Thank you to everyone who followed along and offered advice and encouragement throughout the build.

😎

▲

⟩⟩

Wolle

cjanik001

GARTH

LewZ

luckyduck

oefranz

ChrisF

hermank

EdW

AlessandroSPQR

DWBrinkman

jumpugly

|

💬 Re: Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 DWBrinkman (

Commodore) Commodore)✧ 40 Views · 4 Likes

Flag

Nicely Done!

Dave B ▲

⟩⟩

Cashrc

hermank

chugalone100

AlessandroSPQR

|

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

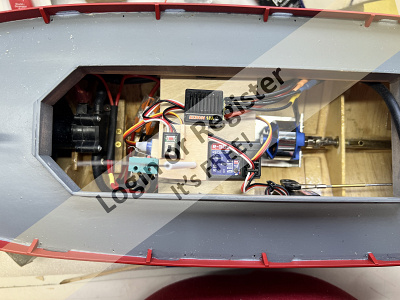

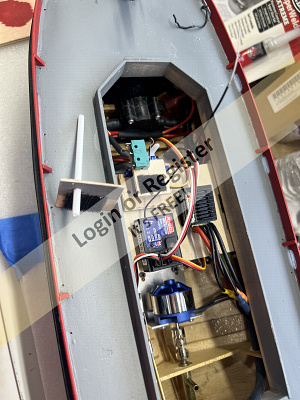

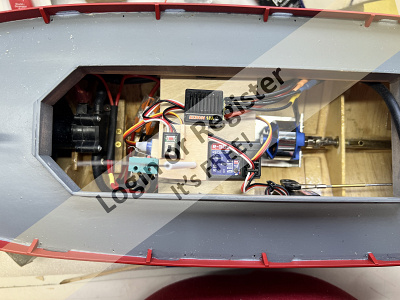

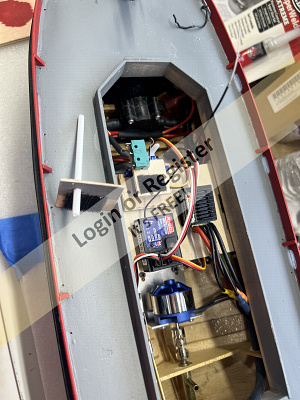

This is a compact assembly I fabricated using a mini switch and a mini servo to conserve space within the hull and to activate the water pump for the fire monitors.

The assembly was constructed by cutting two thin pieces of plywood to size and gluing them to the top and bottom of the mini servo.

The switch itself is Velcro-mounted for easy removal and servicing.

It may look crude, but it works well for my application.

😎

The assembly was constructed by cutting two thin pieces of plywood to size and gluing them to the top and bottom of the mini servo.

The switch itself is Velcro-mounted for easy removal and servicing.

It may look crude, but it works well for my application.

😎

▲

⟩⟩

hermank

oefranz

AlessandroSPQR

jumpugly

|

💬 Re: Midwest/Model Expo Fireboat

14 days ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 23 Views · 1 Like

Flag

Chug, I’ve been using little 10 amp aircraft brushed speed controls to power my pumps in boats that have a fire monitor. On some you have to arm them, off-on-off and then they’re good. I use a y harness in parallel between the battery and both the main esc and the pump to power both units from one battery. However, your micro switch is done right and obviously works well too.

Cash ▲

⟩⟩

hermank

|

|

💬 Re: Midwest/Model Expo Fireboat

18 days ago by 🇺🇸 oefranz (

Master Seaman) Master Seaman)✧ 36 Views · 1 Like

Flag

This is very clever!👍

▲

⟩⟩

hermank

|

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 7 Likes

Flag

💬 Add Comment

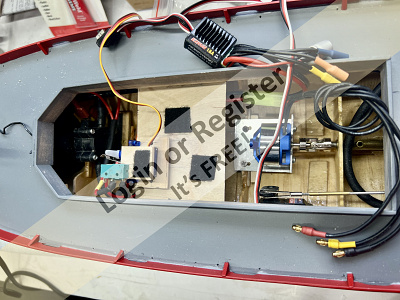

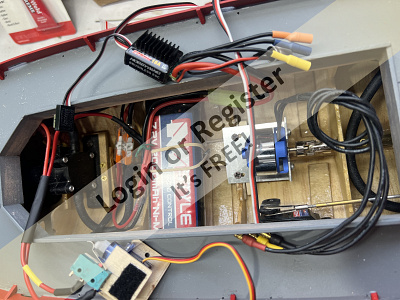

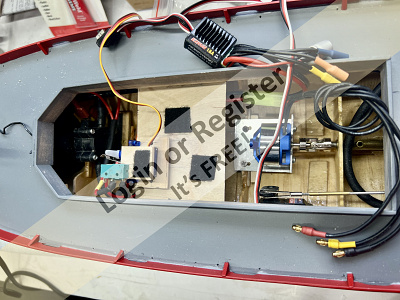

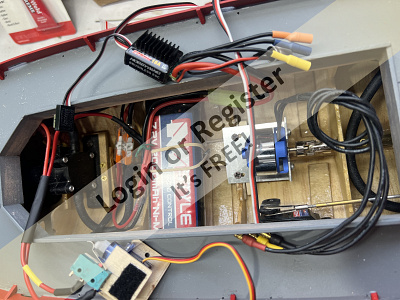

Due to the very limited space, the heaviest component (the battery) was installed low in the hull to keep the center of gravity down. An upper wooden mounting platform was then added and secured with Velcro. This platform will hold the speed controller, water-pump switch, main on/off switch, and the antenna, all mounted using Velcro for easy access and servicing.

😎

😎

▲

⟩⟩

Wolle

hermank

EdW

AlessandroSPQR

DWBrinkman

jumpugly

cumbrae

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

The Electronics

I’ll be the first to admit that I’m no R/C electronics expert. This is only my third boat that actually floats and operates properly. There’s still a lot for me to learn about batteries, wiring, fuses, switches, transmitters, and receivers.

Most of what I do know comes from the many blogs and posts you guys have shared here.

Some of you seasoned builders might get a chuckle out of my setup, but it works—and that’s a win in my book. Most importantly, the smoke stayed inside the wires, so I’ll call that a success. Everything here represents the best I could do with the knowledge I’ve picked up so far, mainly from reading and learning from other modelers.

This first image shows an automotive windshield-wiper washer pump repurposed for the build, the side-mounted rudder servo installation, and a brushless tug motor from Zippkits.

😎

I’ll be the first to admit that I’m no R/C electronics expert. This is only my third boat that actually floats and operates properly. There’s still a lot for me to learn about batteries, wiring, fuses, switches, transmitters, and receivers.

Most of what I do know comes from the many blogs and posts you guys have shared here.

Some of you seasoned builders might get a chuckle out of my setup, but it works—and that’s a win in my book. Most importantly, the smoke stayed inside the wires, so I’ll call that a success. Everything here represents the best I could do with the knowledge I’ve picked up so far, mainly from reading and learning from other modelers.

This first image shows an automotive windshield-wiper washer pump repurposed for the build, the side-mounted rudder servo installation, and a brushless tug motor from Zippkits.

😎

▲

⟩⟩

Cashrc

hermank

EdW

AlessandroSPQR

DWBrinkman

jumpugly

|

💬 Re: Midwest/Model Expo Fireboat

14 days ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 23 Views · 0 Likes

Flag

Zippkits 650 for the win!! Good Choice!!

Cash ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 6 Likes

Flag

💬 Add Comment

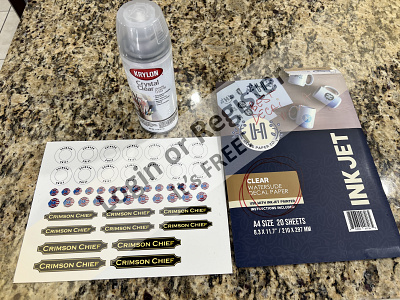

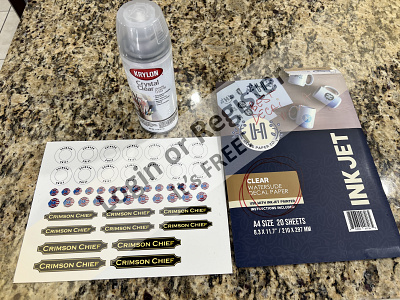

After the rings were primed and painted flat white, I created a digital file to add the name plate and the vessel name around the life rings. Below is the material I used for this process.

One funny thing happened while I was analyzing the size of the blueprint rings, I noticed that the name read “City of Bath.” That got me curious, so I went looking to see if the City of Bath actually had a fireboat. To my surprise, they don’t.

So, with that discovery, I decided to create one and named it “Crimson Chief.”

😎

One funny thing happened while I was analyzing the size of the blueprint rings, I noticed that the name read “City of Bath.” That got me curious, so I went looking to see if the City of Bath actually had a fireboat. To my surprise, they don’t.

So, with that discovery, I decided to create one and named it “Crimson Chief.”

😎

▲

⟩⟩

hermank

GaryLC

EdW

DWBrinkman

AlessandroSPQR

jumpugly

📝 Midwest/Model Expo Fireboat

19 days ago by 🇺🇸 chugalone100 ( Captain)

Captain)

Captain)

Captain)✧ 41 Views · 5 Likes

Flag

💬 Add Comment

Life Rings

The next small detail was the life rings. I ran into an issue here because the original model—purchased from M.E. (Model Expo) and later given to me, was missing these parts. I didn’t want to use aftermarket replacements, as they would not be to the correct scale for this model.

To resolve this, I fabricated a master plug, encased it, and produced a mold. The life rings were then cast using white casting resin, resulting in parts that matched the required dimensions and appearance.

For future modelers purchasing this kit, there’s no need for concern—these parts will be included in the new production kits.

Below is a series of photos showing the process used to accomplish this task.

😎

The next small detail was the life rings. I ran into an issue here because the original model—purchased from M.E. (Model Expo) and later given to me, was missing these parts. I didn’t want to use aftermarket replacements, as they would not be to the correct scale for this model.

To resolve this, I fabricated a master plug, encased it, and produced a mold. The life rings were then cast using white casting resin, resulting in parts that matched the required dimensions and appearance.

For future modelers purchasing this kit, there’s no need for concern—these parts will be included in the new production kits.

Below is a series of photos showing the process used to accomplish this task.

😎

▲

⟩⟩

hermank

Ronald

EdW

AlessandroSPQR

jumpugly

United States

United States