Join Us On Social Media!

Non true brass prop shaft in a kit.

9 Posts · 7 Followers · 2 Photos · 33 Likes

Began 6 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 months ago by

( Newest Posts Shown First )

📝 Non true brass prop shaft in a kit.

36 Views · 3 Likes

Country: 🇺🇸 United States

Online: 13 hours ago

Online: 13 hours ago

Just a thought on checking to see if a shaft is straight is to roll it on a flat surface and see if it hops up and down. If it rolls smoothly it is straight.

The addition of bearings or bushings is certainly recommended to prevent ware to the shaft and tube. I try to have the ID of the tube match the OD of the bearing and this results in a gap between the shaft and tube and I fill this gap with water-resistant grease such as Sta-Lube marine grease. The grease adds lubrication and also stops water entering the tube. I install a grease fitting onto the tube as it allows me to use a grease gun to inject grease on a regular basis.

Definitely use a Stainless Steel shaft and not a brass shaft.

Len

The addition of bearings or bushings is certainly recommended to prevent ware to the shaft and tube. I try to have the ID of the tube match the OD of the bearing and this results in a gap between the shaft and tube and I fill this gap with water-resistant grease such as Sta-Lube marine grease. The grease adds lubrication and also stops water entering the tube. I install a grease fitting onto the tube as it allows me to use a grease gun to inject grease on a regular basis.

Definitely use a Stainless Steel shaft and not a brass shaft.

Len

▲

⟩⟩

cenbeth

Doogle

DuncanP

LEN1

📝 Non true brass prop shaft in a kit.

60 Views · 4 Likes

Country: 🇺🇸 United States

Online: 29 seconds ago

Online: 29 seconds ago

If I am scratch building or have a kit with no shafts I make my own. I typically use brass/copper tubing for the stuffing box and solid round for the prop shaft. Always check to see that the shaft freely turns in the stuffing box before installing. I add struts inside and outside of the boat to keep the assembly in line. No leak/wear issues after a good number of years of operation with all of my boats.

Lew

Florida ⛱️, USA

Lew

Florida ⛱️, USA

▲

⟩⟩

DuncanP

Len1

RobW1

Colin H

Lew Zee (LewsModelBoats.org)

📝 Non true brass prop shaft in a kit.

62 Views · 3 Likes

Country: 🇬🇧 United Kingdom

Online: 2 days ago

Online: 2 days ago

Hi I have had a vibration problem caused by the bearings at either end of the shaft. One end was removed to fill the tube with grease. When I re fitted the bearing it did not line up and also made the shaft tight.

If I have to remove the now I mark the bearing with a line on the tube to ensure they line up as sold

If I have to remove the now I mark the bearing with a line on the tube to ensure they line up as sold

▲

⟩⟩

DuncanP

Len1

Colin H

📝 Non true brass prop shaft in a kit.

70 Views · 6 Likes

Country: 🇺🇸 United States

Online: 11 hours ago

Online: 11 hours ago

Duncan,

First, I would advise against a brass shaft. It should be stainless steel. They are readily available. Second, your stuffing box/tube should have brass or oilite bushings in the ends. They will hold, but not wear the shaft, if it is stainless. It the shaft is brass, it will wear, causing vibration and leaks. It sounds like now is the time to spend a little more and get much better results and life of your model.😉

First, I would advise against a brass shaft. It should be stainless steel. They are readily available. Second, your stuffing box/tube should have brass or oilite bushings in the ends. They will hold, but not wear the shaft, if it is stainless. It the shaft is brass, it will wear, causing vibration and leaks. It sounds like now is the time to spend a little more and get much better results and life of your model.😉

▲

⟩⟩

cenbeth

Doogle

Len1

RobW1

Colin H

DuncanP

📝 Non true brass prop shaft in a kit.

72 Views · 3 Likes

Country: 🇬🇧 United Kingdom

Online: 1 hour ago

Online: 1 hour ago

Hi Duncan you can also check the shafts against a metal ruler straight edge. Rotate the shaft and see if there is a bend in it.

Roy

Roy

▲

⟩⟩

Len1

Colin H

DuncanP

📝 Non true brass prop shaft in a kit.

73 Views · 4 Likes

Country: 🇬🇧 United Kingdom

Online: 1 hour ago

Online: 1 hour ago

Hi are you sure the shafts are not straight? It looks like you have screwed the couplings on and it may be the couplins have a little play in the internal diameter and the grub screws have forced the coupling across.

I have had this happen to me. Not sure how much difference there is in the diameters but is it possible to run some solder over the shaft end to make it slightly wider?

If you do this shake off all the surplus solder and see if you can force the coupling back on, if not take some fine sandpaper and twist it round to remove some of it and try again. Then screw down the grub screw carefully.

regards

Roy

I have had this happen to me. Not sure how much difference there is in the diameters but is it possible to run some solder over the shaft end to make it slightly wider?

If you do this shake off all the surplus solder and see if you can force the coupling back on, if not take some fine sandpaper and twist it round to remove some of it and try again. Then screw down the grub screw carefully.

regards

Roy

▲

⟩⟩

Doogle

Len1

Colin H

DuncanP

📝 Non true brass prop shaft in a kit.

78 Views · 2 Likes

Country: 🇬🇧 United Kingdom

Online: 16 hours ago

Online: 16 hours ago

Unfortunately I don't have a lathe or space to accommodate one! I'll have to see if I can find someone who has one that can help me. Thank you for your suggested solution. Cheers Duncan 😊

▲

⟩⟩

Len1

Colin H

📝 Non true brass prop shaft in a kit.

92 Views · 5 Likes

Country: 🇬🇧 United Kingdom

Online: 10 hours ago

Online: 10 hours ago

The only way is to hold the shaft in a lathe chuck and using a dial indicator tap it until it reads true

I have found many commercial shafts out of true and so I always make my own they are so easy to make not requiring any specialist machines just hand tools. I use K&N brass tube and standard silver steel with Olite or phosphor bronze bushes in each end. The most difficult part is threading the shaft but with care can be done successfully (agreed best done in the lathe), and its cheaper.

I have found many commercial shafts out of true and so I always make my own they are so easy to make not requiring any specialist machines just hand tools. I use K&N brass tube and standard silver steel with Olite or phosphor bronze bushes in each end. The most difficult part is threading the shaft but with care can be done successfully (agreed best done in the lathe), and its cheaper.

▲

⟩⟩

johnf

Len1

Colin H

DuncanP

stevedownunder

📝 Non true brass prop shaft in a kit.

80 Views · 3 Likes

Country: 🇬🇧 United Kingdom

Online: 16 hours ago

Online: 16 hours ago

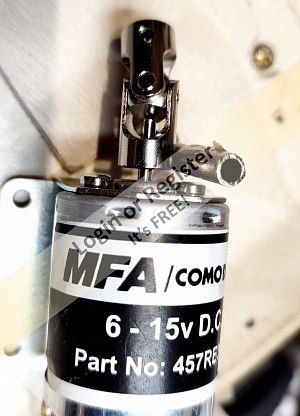

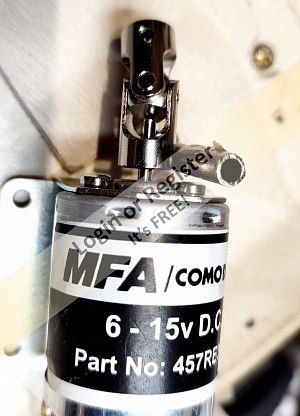

Hi, Just wondered if anyone else has ever suffered the problem with an out of true brass prop shaft supplied within a kit? I seem to have two - one worse than the other - see video. I have a solid coupling which is easier to see the problem plus in the photo is a universal joint as well. When testing the motor alignment I noticed that the motor was violently moving up and down with the universal coupling. So I used the solid brass coupling and could see the movement more easily. The couplings have the correct size of holes so no play. Any suggestions to making them true again? Cheers Duncan

▲

⟩⟩

Len1

Colin H

stevedownunder

Lieutenant

Lieutenant United Kingdom

United Kingdom United States

United States Commodore

Commodore Chief Petty Officer 1st Class

Chief Petty Officer 1st Class Captain

Captain Rear Admiral

Rear Admiral Admiral

Admiral