Join Us On Social Media!

Victory Industries Vosper Fire Boat RC conversion

8 Posts · 2 Followers · 15 Photos · 1 Like

Began 12 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 12 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Victory Industries Vosper Fire Boat RC conversion

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes · 16 Comments

Flag

💬 Add Comment

Post Script.

My boat's davit went missing many moons ago so encouraged by Dave M I have bitten another bullet and made one. But this one Is more than just cosmetic. I've never been happy with the security of the small deck between the two cabins so I have fixed this. I put a lip along one end that hooks under the deck flange. The locating peg on the davit Is long enough to take a hole and a short length of wire (paper clip obviously) that hooks under the deck flange at the other end. When the davit Is turned to be over the side of the boat It's unlocked and when It Is turned to point forward It's locked, securing the deck. (Photo 11)

My boat's davit went missing many moons ago so encouraged by Dave M I have bitten another bullet and made one. But this one Is more than just cosmetic. I've never been happy with the security of the small deck between the two cabins so I have fixed this. I put a lip along one end that hooks under the deck flange. The locating peg on the davit Is long enough to take a hole and a short length of wire (paper clip obviously) that hooks under the deck flange at the other end. When the davit Is turned to be over the side of the boat It's unlocked and when It Is turned to point forward It's locked, securing the deck. (Photo 11)

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇺🇸 subdave (

Able Seaman) Able Seaman)✧ 24 Views · 0 Likes

Flag

Here is a short video I did to test the belt drive.

I am using 7.4V and a rubber band for the belt. I will test in in water when I get a proper sized O ring for the drive.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 jarvo (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

Hi Dave, your worries are well founded, they are very susceptible to going astern and following waves, my original one as a kid sank on several occasions. Don't worry about removing the deck, the glue is brittle, go slowly from the middle of the hull and gently work your way round, there will be a little breakaway from the hull edge but this gives you the key to re-sighting the deck, you then get proper access to the inner hull to mount the motors properly

Mark ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇺🇸 subdave (

Able Seaman) Able Seaman)✧ 24 Views · 0 Likes

Flag

I was thinking of adding access hatches in the rear deck well.

I did not want to risk removing the deck and breaking something. Plus having done this in builds before if you don't get it sealed good you will end up underwater very fast. 😯 Dave ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 smiggy (

Master Seaman) Master Seaman)✧ 27 Views · 0 Likes

Flag

This is the props bit from the instructions, "I bought a pair of contra-rotating brass props from the Prop Shop taking their advice on the best size for the boat (their ref 0871/3 M2). The prop shafts are Graupner jobs with 96mm tubes, 114mm shafts with M2 threads. At around the same time I bought half a dozen cheap 6V motors, the intention being to use one per shaft."

Forget the cheap motors, I'm running 2 x 280's at the moment and a 9V pack of AAA batteries spread out around the area where the original battery tray was. Not ideal. it's either more power, brushless, and lighter batteries or major weight loss, re-building the deck and above in lighter material. I still intend to rebuild the old one I dissected to see exactly was inside. I haven't the 'oomph' to this at the moment but it will happen, honest. in fact this discussion has got the juices stirred..... 👍 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 jarvo (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

Sound like new shafts and props, lower the shaft angle and 2 x 280 or 380 motors

Mark ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 smiggy (

Master Seaman) Master Seaman)✧ 27 Views · 0 Likes

Flag

I'm with Dave about the old Midget motor and running it on a higher voltage. it sound like you're keeping the lovely original large brass props but they will take a lot of turning at higher speeds and I do fear for the 1950's motor.

Also when I was 'researching' the project I met a guy who had done the conversion and whilst he was reluctant to tell me anything about the steering, other than a hole in the well deck was the only way, he did say that if you stick with the original props they generate a lot of torque at higher speeds as they not handed and both spin the same way. The result makes the boat unstable and rolly, if you see what I mean. Whatever you do don't take the deck off. There has to be a perfect watertight seal or the boat will take on water as it sits low in the water. I can't think of any way of achieving this and maintaining easy access to the mechanical gubbins inside. A hole in the well deck lets you get at the steering hear and is fairly easy to seal. As Dave says please do let us know how you get on. Graham ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 jarvo (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

Hi dave, mine takes 4 x c cells, not flat 4.5v going up to 7.2 pack should not be to bad also some weight saving with NiMh

Mark ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 Dave M (

Vice Admiral) Vice Admiral)✧ 24 Views · 0 Likes

Flag

When I had one of these many moons ago I well remember the hot smell coming from the veritable Mighty Midget motor. I believe it ran on a 4.5 v dry flat pack so you may have a problem with 7.5 volts. The rubber band drive was quite reliable. Sadly lost at sea on a rather windy rough water day in a large deep and dirty pool.

Please share how you fit the servo for the rudders. Good luck Dave 😀 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇺🇸 subdave (

Able Seaman) Able Seaman)✧ 24 Views · 0 Likes

Flag

I think I may adapt the if it ain't broke don't fix it saying with this conversion.

😊 So many times I have ripped out the stock motor and added a more powerful unit. This time I think I will try the Mighty Midget and belt drive. I powered it up with a rubber band for now and a two cell 7.4V battery and I was impressed with the speed the props were turning. I have found that powering a motor made for dry cell batteries with a more modern battery capable of supplying more current the motor will deliver more power. I have vet to try an in water test as I know the poor rubber band would not survive. I plan to get a suitable size O ring to use for the drive. It should be just a matter of adding a small ESC and servo for the rudders. I don't want to cut the deck off so this may prove challenging. Still in the thinking stage. Can you smell the smoke. 💭 Dave ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 smiggy (

Master Seaman) Master Seaman)✧ 27 Views · 0 Likes

Flag

Hi All

I rather think that the angle of the props is to allow the original design to use the Mighty Midget motor and drive both props with a rubber drive band (laggy band to you and me). As the resultant power was enough to potter around the boating pond it was considered 'job done' at the time. I think Dave M is bang on in altering the angle, if you look at the fuzzy outline on the Plans and Docs page you can see that the prototype prop shafts were at a much more shallow angle and had less showing through the hull. Anything to save weight is a must and LiPo batteries and brushless motors are a great idea. I say this but because of stories of doom and fire about the LiPos and my view that brushless motors are the work of Beelzebub (because they have 3 wires) I haven't gone so far. Brushless motors indeed, you'll be telling me next that they're going to put a man on the moon! Smiggy ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 Dave M (

Vice Admiral) Vice Admiral)✧ 24 Views · 0 Likes

Flag

Hi Mark

I have not converted my pair yet but you will note from the above comments that the props are at far too an acute angle. if you fit two small brushed motors you should be able to lower the shafts. The rudders need to be resited and extended above the aft deck and a control rod run down one side. They are v small boats so lots of power is not needed but a LiPo will keep the weight down Good luck and please post your efforts Dave ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇬🇧 jarvo (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

Smiggy and Dave, I am also converting both the Fire boat and the Triple screw yacht, looks like a new set of models will set sail, I was looking to use the old rudders with brass tube soldered over the rudder posts with brass tube for the posts. With a micro servo between the tiller arms, lets see if it will fit!!!!!

Possibly with a lipo battery to save weight, maybe brushless motors as well???? Mark ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

10 years ago by 🇺🇸 subdave (

Able Seaman) Able Seaman)✧ 24 Views · 0 Likes

Flag

Nice build.

I just aquired this model and am thinking of adding RC. Dave ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

12 years ago by 🇬🇧 smiggy (

Master Seaman) Master Seaman)✧ 27 Views · 0 Likes

Flag

Hammer, I find it very hard to throw anything away in case it comes in useful. Mind you, finding it again is another matter. 😯

Alan, feel free to pinch away. As for the circle - no idea. The decking is thicker there but the circle doesn't appear to do anything as all the deck/cover did was give access to the motor and drive belt, or laggy band as we called it. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

12 years ago by 🇬🇧 AlanP (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

That's a good idea smiggy, might pinch it 😁 can I ask what the circle is on the underneath.

Alan ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion part 8

12 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 24 Views · 0 Likes

Flag

Ingenuity is what I like, especially using what is to hand. (not spending money). Me being a poor old pensioner. 😁

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

Login To

Remove Ads

Remove Ads

📝 Victory Industries Vosper Fire Boat RC conversion part 7

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 28 Views · 1 Like

Flag

💬 Add Comment

The maiden voyage.

Well, mixed fortunes. The Cunning Plan Mk1c - steering system, small fire boats for the use of worked a treat 👍 Unfortunately the overall weight proved more of a problem than I expected. There was power a plenty and she went like the clappers but getting there was a bit nerve wracking. The angle of the props forced the bow down and I had to be careful until the hull generated enough lift to get the bow up and a give nice bow wave. Not planing like her larger sisters but she did look something like the picture on the box. You can see the problem in the water shot, the green stuff on the foredeck is some pond weed we're plagued with at the moment. (Photos 10 and 10A)

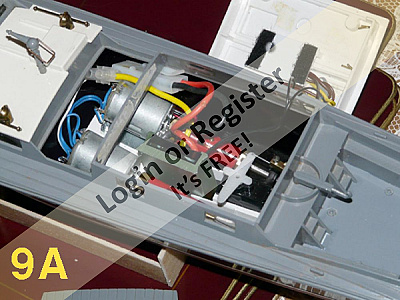

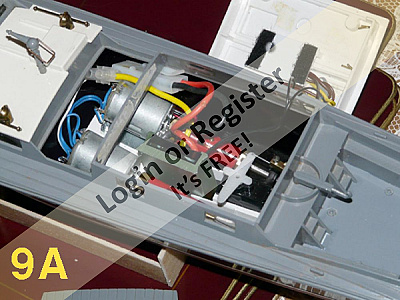

The battery position is tricky as this will be single heaviest part of the kit. As you see in Photo 9 I tried Velcro-ing it to the roof of the aft cabin but this put the CoG of the boat too far back and left the transom gunwale just above the water meaning that the well deck would fill with the slightest wave or when reversing. The maiden trip was with a 'hump' 6v pack just ahead of the motors but this meant that although the boat was level the bows were a bit too low. The current set-up is 4 AA batteries, 2 either side of the motors and 2 in the roof as before. it looks OK in the bath........

I hope this will inspire some of you to take the plunge. I'm no engineer and have completed this with a standard household drill, a Dremel type drill for cutting the cockpit hole and the usual small pliers, wire cutters, small files and tweezers any modeller will have to hand and a small desk mounted vice. The only slightly specialist tools were a pack of fine drill bits and a couple of pin drills obtained on Ebay. A small pillar drill would have made drilling the rudder shafts a lot easier but I passed the initiative test (and only broke one drill bit). I only have a very basic understanding of electricity and have only just figured out soldering.

This isn't intended to be a definitive solution and if you can see alternatives to the above, especially the power plant let us know. Using lighter motors will help and using just one will too, but driving contra-rotating props from one motor is beyond me - at the moment. Oh, and I really wouldn't advise taking the whole deck off. You'll never get it back on properly unless you're very good or very lucky. I am contemplating rebuilding the test boat but with a completely new deck structure probably made of balsa wood to save weight - and because I bought a load cheap a while ago...........

Well, mixed fortunes. The Cunning Plan Mk1c - steering system, small fire boats for the use of worked a treat 👍 Unfortunately the overall weight proved more of a problem than I expected. There was power a plenty and she went like the clappers but getting there was a bit nerve wracking. The angle of the props forced the bow down and I had to be careful until the hull generated enough lift to get the bow up and a give nice bow wave. Not planing like her larger sisters but she did look something like the picture on the box. You can see the problem in the water shot, the green stuff on the foredeck is some pond weed we're plagued with at the moment. (Photos 10 and 10A)

The battery position is tricky as this will be single heaviest part of the kit. As you see in Photo 9 I tried Velcro-ing it to the roof of the aft cabin but this put the CoG of the boat too far back and left the transom gunwale just above the water meaning that the well deck would fill with the slightest wave or when reversing. The maiden trip was with a 'hump' 6v pack just ahead of the motors but this meant that although the boat was level the bows were a bit too low. The current set-up is 4 AA batteries, 2 either side of the motors and 2 in the roof as before. it looks OK in the bath........

I hope this will inspire some of you to take the plunge. I'm no engineer and have completed this with a standard household drill, a Dremel type drill for cutting the cockpit hole and the usual small pliers, wire cutters, small files and tweezers any modeller will have to hand and a small desk mounted vice. The only slightly specialist tools were a pack of fine drill bits and a couple of pin drills obtained on Ebay. A small pillar drill would have made drilling the rudder shafts a lot easier but I passed the initiative test (and only broke one drill bit). I only have a very basic understanding of electricity and have only just figured out soldering.

This isn't intended to be a definitive solution and if you can see alternatives to the above, especially the power plant let us know. Using lighter motors will help and using just one will too, but driving contra-rotating props from one motor is beyond me - at the moment. Oh, and I really wouldn't advise taking the whole deck off. You'll never get it back on properly unless you're very good or very lucky. I am contemplating rebuilding the test boat but with a completely new deck structure probably made of balsa wood to save weight - and because I bought a load cheap a while ago...........

▲

⟩⟩

jugge

📝 Victory Industries Vosper Fire Boat RC conversion part 6

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes

Flag

💬 Add Comment

Final assembly, read this all through before starting.

All the modules were designed to fit into the hull through the existing removable hatches and the hole cut in the cockpit deck. This is how I did it to achieve a reasonable balance fore and aft using my existing motors and battery packs.

The esc fits neatly between the servo and motor mounting plate and the wiring was connected up before fitting the motors into the boat. The receiver fits in the front half of the boat but the position of the battery pack is a problem, see the end of the assembly. This was the best position to balance the boat but on final assembly I got obsessed with sticking a stick battery under the old battery hatch roof. Big mistake as this moved the CoG back and the transom waterline was just under the deck.

I found it easier to plug the esc and servo wires into the receiver before fitting the motors into the boat. So, fit the battery and then feed the receiver and motor/esc assembly through the old battery hatch and fiddle it forward into position and feed the receiver around or next to the battery. Fit the motors mounting plate over the mounting lugs and make sure it is firmly mounted. The rudder servo can now be placed in position over its mounting lug and between the two prop shaft humps. Fit the prop shafts and connect the UJs to them.

Now comes the fiddly part. Hone the bearing surface of each rudder shaft with some fine wet and dry and fit a rudder into the boat and make sure you can see the tiller hole. Now, remember those molding lugs under the cockpit? On the test boat they came off with the access hole but on my boat they were slightly different and had to be cut off. A fiddle but it has to be done. Using a small amount of superglue on the end of the tiller fit it into the hole making sure that no glue gets onto the rudder tube and glues everything together. if you do need to get everything apart later it's quite easy to break the glue join by twisting the tiller. Repeat for the other rudder. Then, using a piece of wire, put a drop or two of light oil down the rudder tube from the bottom. This will seep into the gap between the tube and shaft and the honing will retain the oil like the honing of the bore in an engine and form a flexible seal.

If you didn't get reduced to swearing at that you probably will at this. Fit the push rod onto the RAL so that you can feed it forward towards the servo as you fit the control assembly onto the two tillers and the RAL pivot. Now fit the other part of the pushrod onto the servo arm and connect the two parts of the connector. Sounds easy but make sure you have some valium handy. Dentists and gynecologists should find this easy. Tweezers and fine pliers are essential.

All you need to do now is fire it all up for a final check that everything works, and why shouldn't it, you've been so careful. Now is also the time to adjust the rudder linkage to make sure the rudders are straight when the radio stick is in the middle, but you knew that anyway. And whilst you're asking, the RAL should stay on the pivot, but to make sure it does I put some packing under the cockpit floor so that this rests on top of the pivot when its all put together. (Photo 8)

When you have finished it should all look something like Photos 9 & 9A.

Now seal the gubbins under the cockpit away under a watertight lid. The cockpit will get water in it and it will find a way into the boat and it won't take much to consign all your hard work to Davey Jones. it took me two goes, eventually using silicone and the best named product around - Captain Tolley's Creeping Crack Cure, available on the interweb.

All the modules were designed to fit into the hull through the existing removable hatches and the hole cut in the cockpit deck. This is how I did it to achieve a reasonable balance fore and aft using my existing motors and battery packs.

The esc fits neatly between the servo and motor mounting plate and the wiring was connected up before fitting the motors into the boat. The receiver fits in the front half of the boat but the position of the battery pack is a problem, see the end of the assembly. This was the best position to balance the boat but on final assembly I got obsessed with sticking a stick battery under the old battery hatch roof. Big mistake as this moved the CoG back and the transom waterline was just under the deck.

I found it easier to plug the esc and servo wires into the receiver before fitting the motors into the boat. So, fit the battery and then feed the receiver and motor/esc assembly through the old battery hatch and fiddle it forward into position and feed the receiver around or next to the battery. Fit the motors mounting plate over the mounting lugs and make sure it is firmly mounted. The rudder servo can now be placed in position over its mounting lug and between the two prop shaft humps. Fit the prop shafts and connect the UJs to them.

Now comes the fiddly part. Hone the bearing surface of each rudder shaft with some fine wet and dry and fit a rudder into the boat and make sure you can see the tiller hole. Now, remember those molding lugs under the cockpit? On the test boat they came off with the access hole but on my boat they were slightly different and had to be cut off. A fiddle but it has to be done. Using a small amount of superglue on the end of the tiller fit it into the hole making sure that no glue gets onto the rudder tube and glues everything together. if you do need to get everything apart later it's quite easy to break the glue join by twisting the tiller. Repeat for the other rudder. Then, using a piece of wire, put a drop or two of light oil down the rudder tube from the bottom. This will seep into the gap between the tube and shaft and the honing will retain the oil like the honing of the bore in an engine and form a flexible seal.

If you didn't get reduced to swearing at that you probably will at this. Fit the push rod onto the RAL so that you can feed it forward towards the servo as you fit the control assembly onto the two tillers and the RAL pivot. Now fit the other part of the pushrod onto the servo arm and connect the two parts of the connector. Sounds easy but make sure you have some valium handy. Dentists and gynecologists should find this easy. Tweezers and fine pliers are essential.

All you need to do now is fire it all up for a final check that everything works, and why shouldn't it, you've been so careful. Now is also the time to adjust the rudder linkage to make sure the rudders are straight when the radio stick is in the middle, but you knew that anyway. And whilst you're asking, the RAL should stay on the pivot, but to make sure it does I put some packing under the cockpit floor so that this rests on top of the pivot when its all put together. (Photo 8)

When you have finished it should all look something like Photos 9 & 9A.

Now seal the gubbins under the cockpit away under a watertight lid. The cockpit will get water in it and it will find a way into the boat and it won't take much to consign all your hard work to Davey Jones. it took me two goes, eventually using silicone and the best named product around - Captain Tolley's Creeping Crack Cure, available on the interweb.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Victory Industries Vosper Fire Boat RC conversion part 5

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes

Flag

💬 Add Comment

The base plate that supports the pivot for the right angled lever that converts the side to side movement to fore and aft is located over the inner P bracket lugs and extends to the lug at the rear of the servo mounting using the same bolt to retain it. All very neat. The actual pivot is the same 2mm brass rod used for the rudder shafts. The mounting block is two pieces of scrap glued together and drilled to take the rod. The only odd 'found' component is the white plastic tube that supports the lever. Any diabetic that injects will be sick of the sight of these as they cover the needle points. At last, a use for them - well one at least.

If you do decide to use this system don't stick the pivot down Immediately as its position relies on the lengths of the various levers. I made the levers and when satisfied put everything together in situ and fiddled with the pivot position (double sided tape helped to tack the pivot down whilst doing this). When happy with the position I marked it and then stuck it down.

The plate that connects the rudder tillers and the right angled lever (there must be a shorter term for this) has a slot in it to take the RAL (there, that'll do). What you see in the photos is the Mk3. The trick is to stop the lever fouling the slot whilst supporting the plate. The part of the lever that slots through is 'U' shaped and there's a small thin plastic plate glued to the U either side of the connecting plate. By forming the pivot loop around the 2mm brass rod meant that the RAL stayed horizontal keeping everything in line. (Photo 7)

NB On final assembly the crank on the arm from the servo is fitted upside down to this photo to make it easier to fit the whole thing into the boat.

The last piece of the jigsaw is the link between the servo and the RAL. Without using a clevis this can't be fitted with everything in situ so is split to make this possible. The join also allows for some final adjustment. The joining piece is the brass insert and screws from a small electrical connector block. The split has to be one long and one short as the only access to the join is either through the cockpit hole or the old battery hatch but the choice is made because the brass connector can foul the floor under the cockpit.

If you do decide to use this system don't stick the pivot down Immediately as its position relies on the lengths of the various levers. I made the levers and when satisfied put everything together in situ and fiddled with the pivot position (double sided tape helped to tack the pivot down whilst doing this). When happy with the position I marked it and then stuck it down.

The plate that connects the rudder tillers and the right angled lever (there must be a shorter term for this) has a slot in it to take the RAL (there, that'll do). What you see in the photos is the Mk3. The trick is to stop the lever fouling the slot whilst supporting the plate. The part of the lever that slots through is 'U' shaped and there's a small thin plastic plate glued to the U either side of the connecting plate. By forming the pivot loop around the 2mm brass rod meant that the RAL stayed horizontal keeping everything in line. (Photo 7)

NB On final assembly the crank on the arm from the servo is fitted upside down to this photo to make it easier to fit the whole thing into the boat.

The last piece of the jigsaw is the link between the servo and the RAL. Without using a clevis this can't be fitted with everything in situ so is split to make this possible. The join also allows for some final adjustment. The joining piece is the brass insert and screws from a small electrical connector block. The split has to be one long and one short as the only access to the join is either through the cockpit hole or the old battery hatch but the choice is made because the brass connector can foul the floor under the cockpit.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Victory Industries Vosper Fire Boat RC conversion part 4

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes

Flag

💬 Add Comment

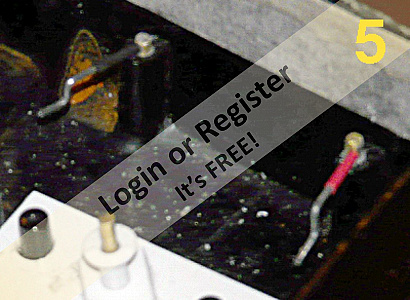

It was obvious from the start that the original rudders had to go but how do you control them? I had toyed with the idea of starting from scratch and moving the shafts away from the transom giving a bit more room to attach a lever to the top but surveying the deckless hull it was obvious that this would involve a lot of work including making new P brackets to get the props further forward. The idea of drilling a small hole in the shafts to take a wire tiller facing forward was hatched as this would give a large range of movement but not take any room to the rear of the shaft.

First the hole that takes the original rudders is opened out to take a 2mm ID tube and carefully drilled through to the inside of the hull. Whilst it's fairly clear above the mounting bosses stop as soon as the drill breaks through. You will need a 19mm length of tube to sleeve the hole, this will just fit leaving enough room above it for the tillers to fit in the hole you will need to drill in the top of the shafts. The shafts should be 2mm dia to match the tube and 46-47mm long and the centre for the hole for the tillers should be 1.5-2mm from the top. The diameter depends on the wire (paper clip) you use for the tillers. The tillers are bent from wire with a crank in the end. I put a piece of heatshrink onto the tillers to act as a stop when you insert them on final assembly but a piece of tape would be just as good. (Photo 5)

The rudder blades can be salvaged from the original and soldered onto the shafts or new ones made from plastic and glued on. I know the purist would baulk at this but if I soldered them on they would fall off just after the boat got out of reach of the shore. I've put my faith in modern adhesives. I do have another cunning plan involving yoghurt pots if this plan fails. Photo 6 shows the assembled mechanism that was designed to be easily fitted through a hole cut in the well deck floor. in practice the word 'easily' is open to interpretation.

First the hole that takes the original rudders is opened out to take a 2mm ID tube and carefully drilled through to the inside of the hull. Whilst it's fairly clear above the mounting bosses stop as soon as the drill breaks through. You will need a 19mm length of tube to sleeve the hole, this will just fit leaving enough room above it for the tillers to fit in the hole you will need to drill in the top of the shafts. The shafts should be 2mm dia to match the tube and 46-47mm long and the centre for the hole for the tillers should be 1.5-2mm from the top. The diameter depends on the wire (paper clip) you use for the tillers. The tillers are bent from wire with a crank in the end. I put a piece of heatshrink onto the tillers to act as a stop when you insert them on final assembly but a piece of tape would be just as good. (Photo 5)

The rudder blades can be salvaged from the original and soldered onto the shafts or new ones made from plastic and glued on. I know the purist would baulk at this but if I soldered them on they would fall off just after the boat got out of reach of the shore. I've put my faith in modern adhesives. I do have another cunning plan involving yoghurt pots if this plan fails. Photo 6 shows the assembled mechanism that was designed to be easily fitted through a hole cut in the well deck floor. in practice the word 'easily' is open to interpretation.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Victory Industries Vosper Fire Boat RC conversion part 3

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes

Flag

💬 Add Comment

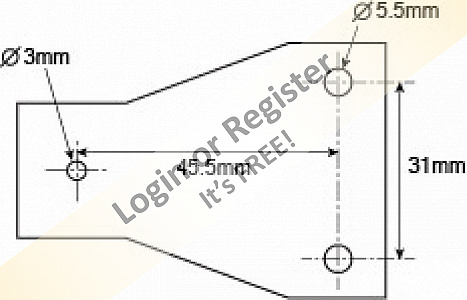

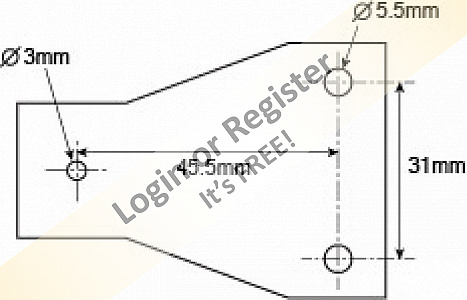

So to the steering. Before we start, all the wire used in this was kindly donated by various paperclips of different sizes. First cut a hole in the cockpit floor around the embossed hatch markings and adding the 2 semI circular extensions to give access to the tops of the rudder shafts. Make sure to leave an adequate lip to mount a false floor over the hole and make a watertight join. Attached is a jpeg file of the shape of the floor to act as a template but the resultant floor will need fettling to get a good fit. This is supposed to be a pdf file but I can't upload that so I can't guarantee the size. I recommend cutting a thick paper or thin card one first to check for problems before cutting a plastic one. I made mine out of 1mm plastic and to avoid an ugly gap around the steps I shortened slots for the sides of the steps by about 1mm and the chamfered the ends of the slots so they rest against the steps. The original hatch is marked on the pdf so when transferring the shape down you can pin prick through to mark the corners and then draw the hatch, I used the point of a pair of dividers.

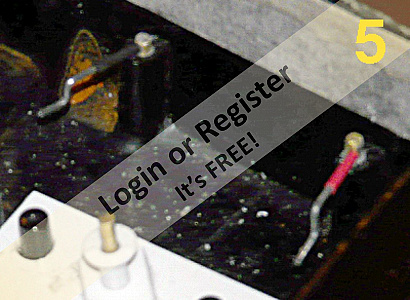

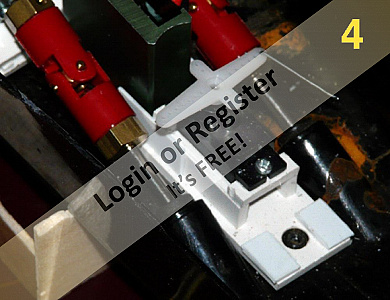

Fitting a small servo between the humps where the prop shafts exit the hull seemed a good idea. There is a central lug to the rear of these that is used to mount the battery box on some boats that offered a handy mounting point for a base plate to mount the mechanism on. The base plate was made to fit comfortably between the humps to locate it sideways and long enough to fit over the lug and be screwed down. The mounting for the servo was glued to this plate. (Photo 4)

Fitting a small servo between the humps where the prop shafts exit the hull seemed a good idea. There is a central lug to the rear of these that is used to mount the battery box on some boats that offered a handy mounting point for a base plate to mount the mechanism on. The base plate was made to fit comfortably between the humps to locate it sideways and long enough to fit over the lug and be screwed down. The mounting for the servo was glued to this plate. (Photo 4)

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Victory Industries Vosper Fire Boat RC conversion part 2

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes

Flag

💬 Add Comment

I had already been advised not to use the nice original brass props as they are too large and exert too much torque on the boat at speed. To this end I bought a pair of contra-rotating brass props from the Prop Shop taking their advice on the best size for the boat (their ref 0871/3 M2). The prop shafts are Graupner jobs with 96mm tubes, 114mm shafts with M2 threads. At around the same time I bought half a dozen cheap 6V motors, the intention being to use one per shaft.

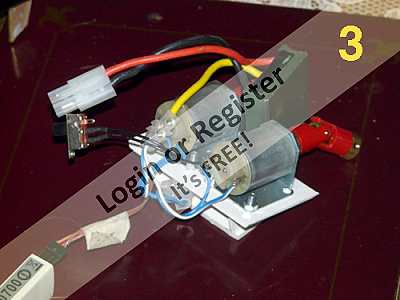

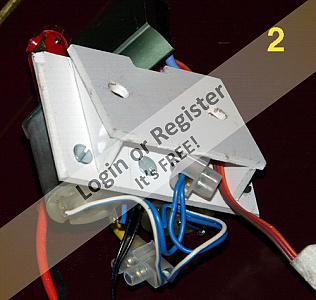

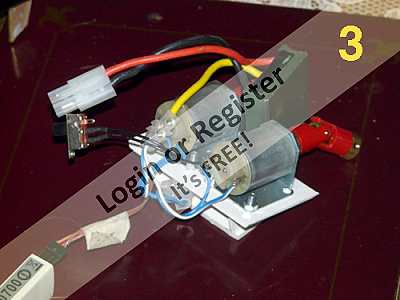

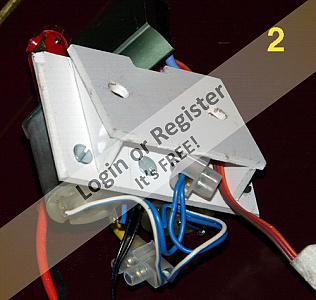

The prop shafts are a straight swap for the originals being the same outer diameter, always assuming the O rings that seal the hull-shaft join are OK. The motor mounting push fits over the original lugs. Once the motors are attached to the prop shafts everything is secure without having to screw the base down. This alleviates the problem of access to the screws and the motor and bracket assembly is easily fitted and removed. Once the base plate is made and fitted and the motors are mounted onto their base and connected to the shafts and UJs it's a simple job of measuring the wedges that join the two and present the motors at the correct angle. I guess you could just mount the motors horizontally onto the base plate but I don't know what the tolerance of the UJs is. (Photos 2 & 3)

The options for different motors and drives, including sticking with the original are many, this is just my take on the issue. The motors I used are quite heavy at 40g each and I have thought of fitting smaller lighter ones. I have a couple but they are 9V and the extra weight of the batteries, let alone the space taken, put me off. Has anyone experience of or ideas about brushless motors and lipo batteries? I was put off lipo when I saw a fire proof bag to put the batteries in when charging them and then the problems Boeing had. They sound like the work of the devil to me! Plus I'd have to cough up some beer tokens for a brushless/lipo set up.

The prop shafts are a straight swap for the originals being the same outer diameter, always assuming the O rings that seal the hull-shaft join are OK. The motor mounting push fits over the original lugs. Once the motors are attached to the prop shafts everything is secure without having to screw the base down. This alleviates the problem of access to the screws and the motor and bracket assembly is easily fitted and removed. Once the base plate is made and fitted and the motors are mounted onto their base and connected to the shafts and UJs it's a simple job of measuring the wedges that join the two and present the motors at the correct angle. I guess you could just mount the motors horizontally onto the base plate but I don't know what the tolerance of the UJs is. (Photos 2 & 3)

The options for different motors and drives, including sticking with the original are many, this is just my take on the issue. The motors I used are quite heavy at 40g each and I have thought of fitting smaller lighter ones. I have a couple but they are 9V and the extra weight of the batteries, let alone the space taken, put me off. Has anyone experience of or ideas about brushless motors and lipo batteries? I was put off lipo when I saw a fire proof bag to put the batteries in when charging them and then the problems Boeing had. They sound like the work of the devil to me! Plus I'd have to cough up some beer tokens for a brushless/lipo set up.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Victory Industries Vosper Fire Boat RC conversion

12 years ago by 🇬🇧 smiggy ( Master Seaman)

Master Seaman)

Master Seaman)

Master Seaman)✧ 27 Views · 0 Likes · 2 Comments

Flag

💬 Add Comment

(When you read this section try to Imagine the opening sequence to the first Star Wars film with the text disappearing into the distance.) 😯

It was a great birthday when I was given a Victory industries RAF Crash Tender. The picture on the box showed a boat planning at speed, but despite the best efforts of the Might Midget electric motor the model never actually reached such velocities. it was a free sailor following the course set by its two brass rudders at a disappointingly pedestrian speed. Nevertheless I loved that boat. There was something about its looks. Obviously I wasn't the only one judging by the number of models of the two prototype craft that have been produced over the years despite such a short active service.

It was always my dream to see my boat speeding across the water and under full control. A dream I had when I polished its shiny, sleek black hull. I knew nothing about radio control other than it was for adults and cost money way beyond my pocket money. Now I am an adult and have a bit more pocket money and by a happy accident I now play with radio controlled model boats. An expedition into the loft uncovered my beloved boat and I started to think about how to go about achieving the two goals of making it go faster and under radio control. Parts were bought with this intention but work never commenced as I didn't have the confidence or experience to start cutting into the boat I'd kept for so long. Converting a RNLI Severn to 'proper' RC was the inspiration I needed.

The main breakthrough came when I bought an old boat that was way past its best and had lost all the deck fittings off Ebay. I cut the deck off to see what problems lay hidden and started to work out the best way of fitting a rudder system into a confined space. What follows is the result........

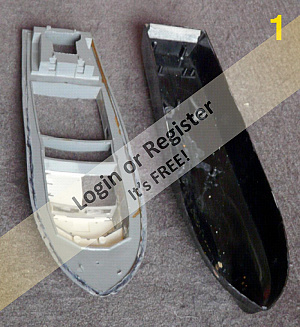

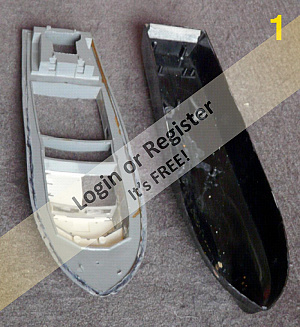

Through the removable hatches on a complete boat you can see the obvious mounting lugs for the motor and the four lugs that take the screws that hold the prop shaft P brackets. The big mystery was what else is there under the rear cockpit deck. The answer is not a lot. The main problem is 4 molding lugs under the well deck floor that look like a by product of the molding process. At this point I will say never assume, assumption is the mother of all cock-ups. As it turned out the shape of these lugs differs between my two boats so don't assume that you can work around them, more later. (Photo 1)

It was a great birthday when I was given a Victory industries RAF Crash Tender. The picture on the box showed a boat planning at speed, but despite the best efforts of the Might Midget electric motor the model never actually reached such velocities. it was a free sailor following the course set by its two brass rudders at a disappointingly pedestrian speed. Nevertheless I loved that boat. There was something about its looks. Obviously I wasn't the only one judging by the number of models of the two prototype craft that have been produced over the years despite such a short active service.

It was always my dream to see my boat speeding across the water and under full control. A dream I had when I polished its shiny, sleek black hull. I knew nothing about radio control other than it was for adults and cost money way beyond my pocket money. Now I am an adult and have a bit more pocket money and by a happy accident I now play with radio controlled model boats. An expedition into the loft uncovered my beloved boat and I started to think about how to go about achieving the two goals of making it go faster and under radio control. Parts were bought with this intention but work never commenced as I didn't have the confidence or experience to start cutting into the boat I'd kept for so long. Converting a RNLI Severn to 'proper' RC was the inspiration I needed.

The main breakthrough came when I bought an old boat that was way past its best and had lost all the deck fittings off Ebay. I cut the deck off to see what problems lay hidden and started to work out the best way of fitting a rudder system into a confined space. What follows is the result........

Through the removable hatches on a complete boat you can see the obvious mounting lugs for the motor and the four lugs that take the screws that hold the prop shaft P brackets. The big mystery was what else is there under the rear cockpit deck. The answer is not a lot. The main problem is 4 molding lugs under the well deck floor that look like a by product of the molding process. At this point I will say never assume, assumption is the mother of all cock-ups. As it turned out the shape of these lugs differs between my two boats so don't assume that you can work around them, more later. (Photo 1)

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

|

💬 Victory Industries Vosper Fire Boat RC conversion

12 years ago by 🇬🇧 smiggy (

Master Seaman) Master Seaman)✧ 27 Views · 0 Likes

Flag

HI Emma, I'm a little confused as the story of the project should be visible with the post with this photo attached. if you found this in a random search the rest of the project write up its in the Build Blog section of the site. if you are around I'll be at the King Lear event with the finished boat from around lunch time on. Who knows, if the water is calm enough I might even risk a turn on the water!

Graham (smiggy) ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Victory Industries Vosper Fire Boat RC conversion

12 years ago by 🇬🇧 twinkle (

Master Seaman) Master Seaman)✧ 24 Views · 0 Likes

Flag

Interesting Project

any update yet ? regards emma ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

United Kingdom

United Kingdom