Join Us On Social Media!

3D Printed Models

70 Posts · 13 Followers · 65 Photos · 377 Likes

Began 7 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 5 months ago by

( Newest Posts Shown First )

📝 3D Printed Models

28 Views · 5 Likes

Country: 🇦🇺 Australia

Online: 3 months ago

Online: 3 months ago

Tim

I have ABS 3D printed parts as small as 72 scale that are over 10 years old and have not deteriorated at all. Others in our Association have parts that are much older and still no signs of and breakdown. Granted they are painted but I do have parts in my spares boxes, some 15 years old and no sign of deterioration and they have not been painted.

I very much enjoy 3D modelling it is one the most attractive aspects of the hobby. Although these days I use a combination of 3D Printing, CNC and Styrene stock to make most parts. Determining just how the part will be manufactured is very enjoyable. I will admit I do not always get this right first time around but you learn from every mistake.

I have ABS 3D printed parts as small as 72 scale that are over 10 years old and have not deteriorated at all. Others in our Association have parts that are much older and still no signs of and breakdown. Granted they are painted but I do have parts in my spares boxes, some 15 years old and no sign of deterioration and they have not been painted.

I very much enjoy 3D modelling it is one the most attractive aspects of the hobby. Although these days I use a combination of 3D Printing, CNC and Styrene stock to make most parts. Determining just how the part will be manufactured is very enjoyable. I will admit I do not always get this right first time around but you learn from every mistake.

▲

⟩⟩

EdW

Steves-s

jumpugly

RodC

AlessandroSPQR

📝 3D Printed Models

29 Views · 6 Likes

Country: 🇮🇹 Italy

Online: 7 hours ago

Online: 7 hours ago

Hi Tim, you've nailed one of the critical aspects of 3D printing: durability over time.

I honestly don't know how long they last.

Also, as you said, for those who can no longer model by hand, a 3D printer is an excellent fallback.

While I recognize the great utility of 3D printing, I don't rely on it to build particularly valuable pieces (for which I prefer other materials) or very small pieces subject to many types of stress (tensile and torsional stress, for example).

It's obvious that the hull of a barge can be made of plastic, and therefore also with a 3D printer, without losing much aesthetic quality, but a wooden hull absolutely cannot (especially if it's an ancient ship).

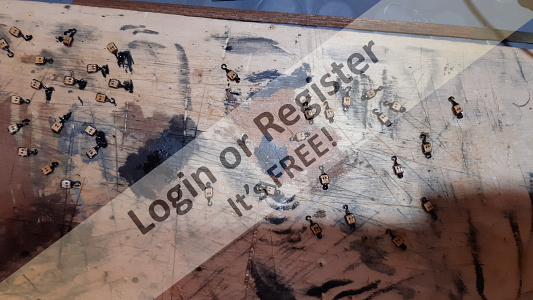

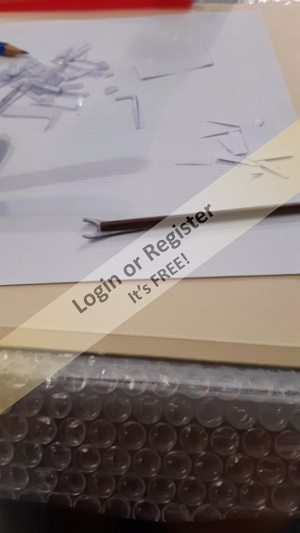

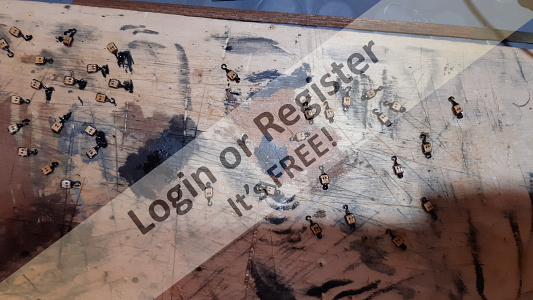

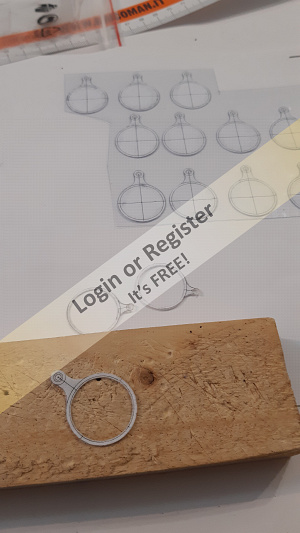

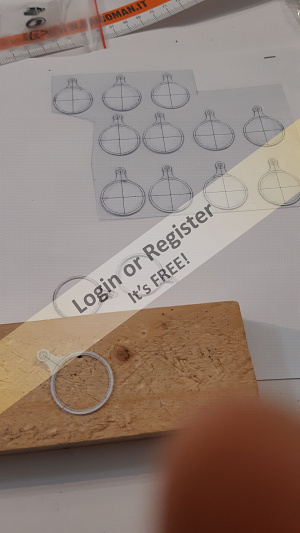

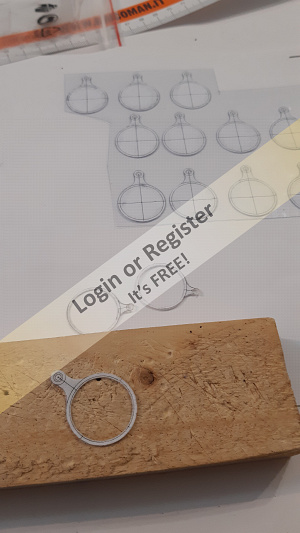

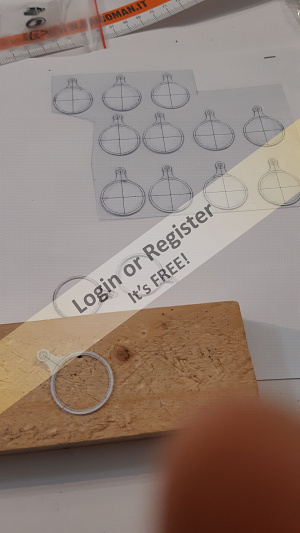

As I mentioned, I compared the resistance of very thin pieces, and in that case, the 3D printer didn't satisfy me. I preferred other materials to other construction techniques (see the images).

I mentioned cannons and cannon carriages. Well, I needed the cannon to be very light and not subject to any stress, so the 3D printer solution was optimal.

The carriage, on the other hand, was made of wood and brass.

Look at images. It's clear that I couldn't have made such small pieces with a 3D printer and expected them to resist traction and torsion. Moreover, these small objects are still subject to some stress.

I had to resort to tinning the copper to ensure it wouldn't bend every time the blocks were pulled.

Remaining in the realm of very fine objects, I've already mentioned the lateral cranes. Essentially, they are tapered tubes (ranging from a diameter of about 3 mm to about 1 mm) and curved.

I needed flexibility, lightness, and resistance to impacts and involuntary maneuvers, so I found an alternative solution that, in my opinion, is much better than 3D printing (if you're interested in the details, you can read message no. 514 in the link at the end).

In this regard, it's clear that for such small pieces, hollow parts don't exist. The ability to fill hollow parts with a more or less dense reinforcing mesh only exists for parts of a certain size, certainly not 1 or 2 mm.

Furthermore, creating hollow parts where you can specify the amount of infill is definitely not a "trick of the trade" but rather a fundamental skill in 3D printing—it's the ABCs. When I read that a basic function is called a trick of the trade, I understand a lot (or rather, I find confirmation).

I honestly don't know how long they last.

Also, as you said, for those who can no longer model by hand, a 3D printer is an excellent fallback.

While I recognize the great utility of 3D printing, I don't rely on it to build particularly valuable pieces (for which I prefer other materials) or very small pieces subject to many types of stress (tensile and torsional stress, for example).

It's obvious that the hull of a barge can be made of plastic, and therefore also with a 3D printer, without losing much aesthetic quality, but a wooden hull absolutely cannot (especially if it's an ancient ship).

As I mentioned, I compared the resistance of very thin pieces, and in that case, the 3D printer didn't satisfy me. I preferred other materials to other construction techniques (see the images).

I mentioned cannons and cannon carriages. Well, I needed the cannon to be very light and not subject to any stress, so the 3D printer solution was optimal.

The carriage, on the other hand, was made of wood and brass.

Look at images. It's clear that I couldn't have made such small pieces with a 3D printer and expected them to resist traction and torsion. Moreover, these small objects are still subject to some stress.

I had to resort to tinning the copper to ensure it wouldn't bend every time the blocks were pulled.

Remaining in the realm of very fine objects, I've already mentioned the lateral cranes. Essentially, they are tapered tubes (ranging from a diameter of about 3 mm to about 1 mm) and curved.

I needed flexibility, lightness, and resistance to impacts and involuntary maneuvers, so I found an alternative solution that, in my opinion, is much better than 3D printing (if you're interested in the details, you can read message no. 514 in the link at the end).

In this regard, it's clear that for such small pieces, hollow parts don't exist. The ability to fill hollow parts with a more or less dense reinforcing mesh only exists for parts of a certain size, certainly not 1 or 2 mm.

Furthermore, creating hollow parts where you can specify the amount of infill is definitely not a "trick of the trade" but rather a fundamental skill in 3D printing—it's the ABCs. When I read that a basic function is called a trick of the trade, I understand a lot (or rather, I find confirmation).

▲

⟩⟩

hermank

EdW

Steves-s

jumpugly

BobbyN

RodC

📝 3D Printed Models

38 Views · 4 Likes

Country: 🇺🇸 United States

Online: Today!

Online: Today!

ABS is a very common material and has been around for quite a long time. 3D printer filament in ABS is a quite common use in recent years.

You might have seen (and still see) ABS on cars, for instance door handles and other trim. Usually black in color. Some might have faded to some shade of gray. One might of heard of these breaking due to a combination of UV exposure and fatigue.

I'm sure that any breakdown of ABS can be controlled by a protective finish and for models I always paint my ABS prints. For real cars they have a spray coating that brings back the dark black finish that seems to absorb into the ABS. Makes it look new and feel again.

Bottom line is to protect the ABS with an opaque paint even if you are using black ABS and want a black finish. You will probably be happy with the results.

There are many "tricks of the trade" for 3D printing that many experienced users know about and doubters don't. This includes making hollow parts where you can specify the amount of infill. Take for instance a basic shape like a cube. You can make one with all six sides having a solid surface and the inside varying from empty up to completely full automatically. One can make virtually the vast majority of various shaped objects this way. (See photo with tops cut off.) This is only one example of the advantages of 3D printing.

Lew

You might have seen (and still see) ABS on cars, for instance door handles and other trim. Usually black in color. Some might have faded to some shade of gray. One might of heard of these breaking due to a combination of UV exposure and fatigue.

I'm sure that any breakdown of ABS can be controlled by a protective finish and for models I always paint my ABS prints. For real cars they have a spray coating that brings back the dark black finish that seems to absorb into the ABS. Makes it look new and feel again.

Bottom line is to protect the ABS with an opaque paint even if you are using black ABS and want a black finish. You will probably be happy with the results.

There are many "tricks of the trade" for 3D printing that many experienced users know about and doubters don't. This includes making hollow parts where you can specify the amount of infill. Take for instance a basic shape like a cube. You can make one with all six sides having a solid surface and the inside varying from empty up to completely full automatically. One can make virtually the vast majority of various shaped objects this way. (See photo with tops cut off.) This is only one example of the advantages of 3D printing.

Lew

▲

⟩⟩

jumpugly

RodC

hermank

EdW

Lew Zee (LewsModelBoats.org)

📝 3D Printed Models

36 Views · 7 Likes

Country: 🇬🇧 United Kingdom

Online: 1 day ago

Online: 1 day ago

Hello Alessandro and others who are interested,

Due to manual problems I have to use 3d printers to get the details that I want. I would much rather use more traditional and proven materials. I am incredibly pleased with the results that I can get using simple programs like online Tinkercad. However what worries me is how long do 3d printed parts last before they decompose? Will my models rot away before I do?

Currently I am trying to find a resin that is hard but not brittle also more environmentally friendly. Any suggestions let me know.

Best wishes to all Tim.

Due to manual problems I have to use 3d printers to get the details that I want. I would much rather use more traditional and proven materials. I am incredibly pleased with the results that I can get using simple programs like online Tinkercad. However what worries me is how long do 3d printed parts last before they decompose? Will my models rot away before I do?

Currently I am trying to find a resin that is hard but not brittle also more environmentally friendly. Any suggestions let me know.

Best wishes to all Tim.

▲

⟩⟩

jumpugly

BobbyN

RodC

hermank

AlessandroSPQR

LewZ

EdW

📝 3D Printed Models

38 Views · 4 Likes

Country: 🇬🇧 United Kingdom

Online: 2 days ago

Online: 2 days ago

I have made "kits" of parts in the past, like the LL sweep winch pictured down the thread somewhere, but I prefer to use a combination of all disciplines. Who remembers the "gummed paper tape" construction method?

▲

⟩⟩

hermank

AlessandroSPQR

EdW

tim morland

If it don't fit, use a hammer to make it fit....

📝 3D Printed Models

37 Views · 7 Likes

Country: 🇮🇹 Italy

Online: 7 hours ago

Online: 7 hours ago

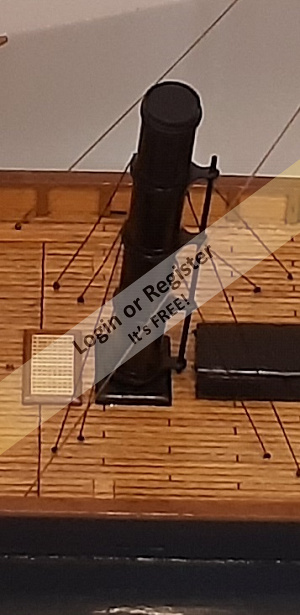

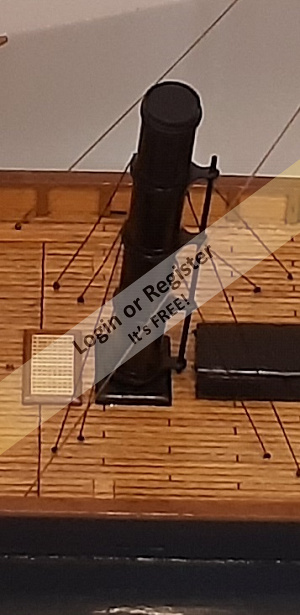

You're absolutely right, Nick.

Ultimately, it's the result that counts, and I'm very happy you like it.

Thanks for the compliments.

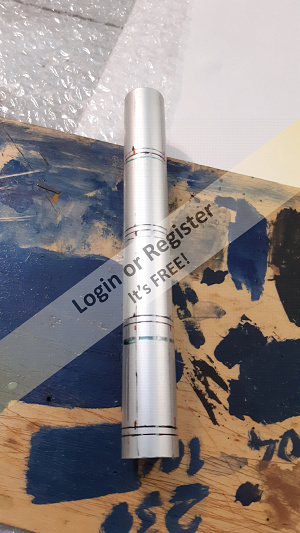

In this case, I preferred the piece made with this method rather than the 3D printer for several reasons, primarily aesthetics.

In fact, I liked this result much more than the one achieved with the 3D printer.

For the cannons, things were different. In that case, the 3D printer was the only solution, or at least the best.

I needed a customized design and lightweight products.

In that case, I was very pleased with the 3D printer result.

However, I'm only referring to the cannon, because the carriage is made of wood and brass (in addition to the rigging, of course).

Ultimately, it's the result that counts, and I'm very happy you like it.

Thanks for the compliments.

In this case, I preferred the piece made with this method rather than the 3D printer for several reasons, primarily aesthetics.

In fact, I liked this result much more than the one achieved with the 3D printer.

For the cannons, things were different. In that case, the 3D printer was the only solution, or at least the best.

I needed a customized design and lightweight products.

In that case, I was very pleased with the 3D printer result.

However, I'm only referring to the cannon, because the carriage is made of wood and brass (in addition to the rigging, of course).

▲

⟩⟩

BobbyN

jumpugly

hermank

EdW

tim morland

Nickthesteam

RodC

📝 3D Printed Models

39 Views · 6 Likes

Country: 🇬🇧 United Kingdom

Online: 2 days ago

Online: 2 days ago

Nice funnel! Good to use different techniques and materials. At the end of the day, it matters not how a quality piece like that is produced, it is the end result that counts.

▲

⟩⟩

BobbyN

RodC

hermank

EdW

jumpugly

AlessandroSPQR

If it don't fit, use a hammer to make it fit....

📝 3D Printed Models

38 Views · 8 Likes

Country: 🇮🇹 Italy

Online: 7 hours ago

Online: 7 hours ago

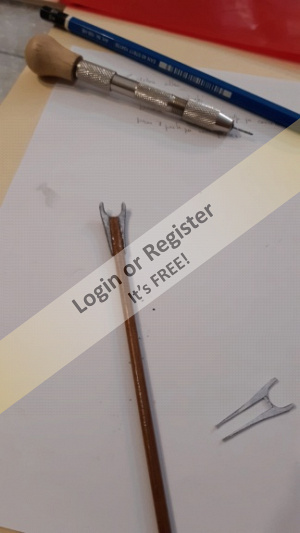

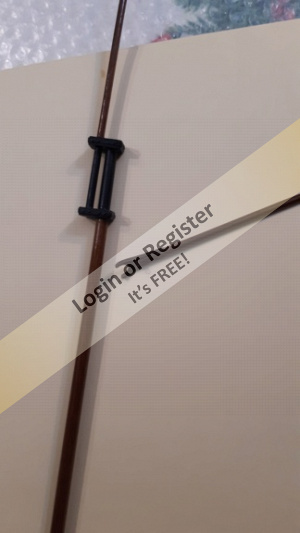

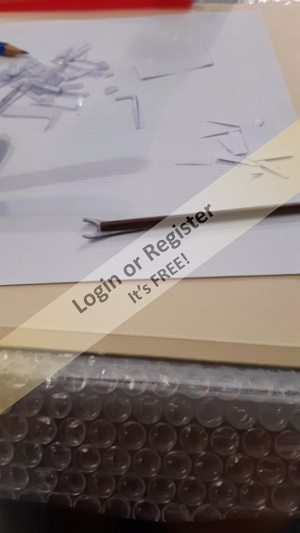

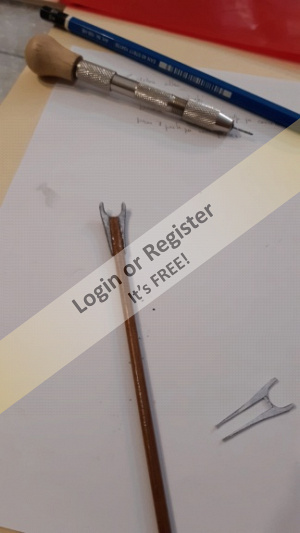

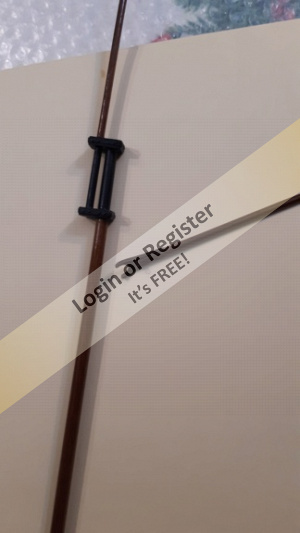

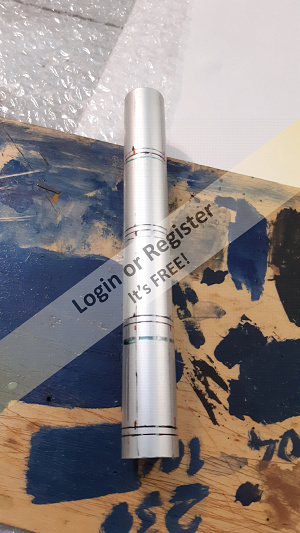

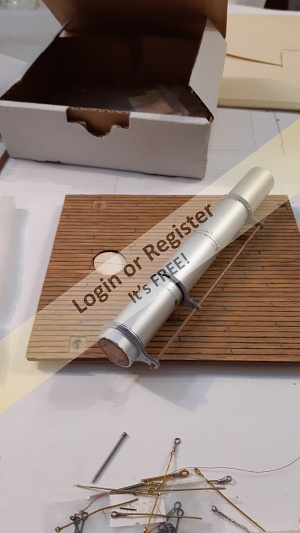

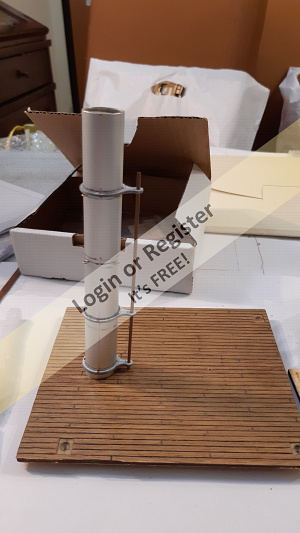

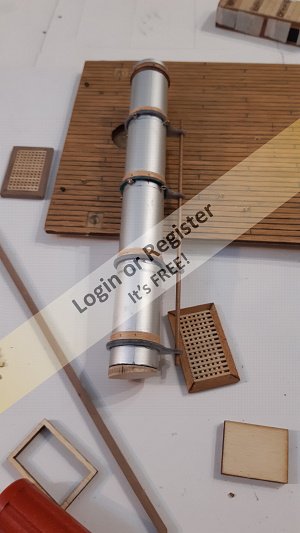

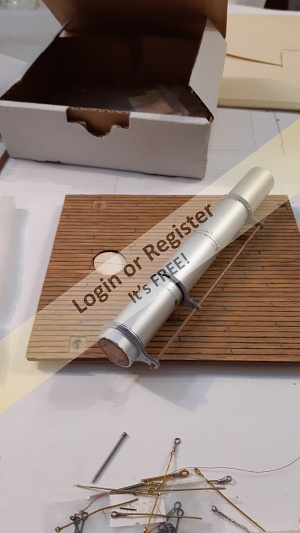

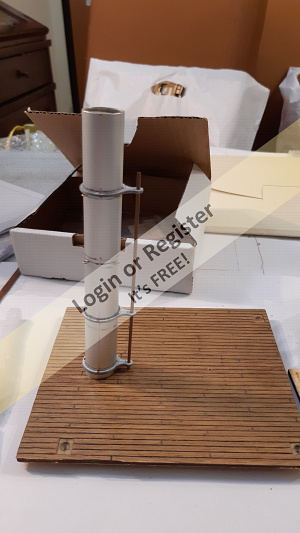

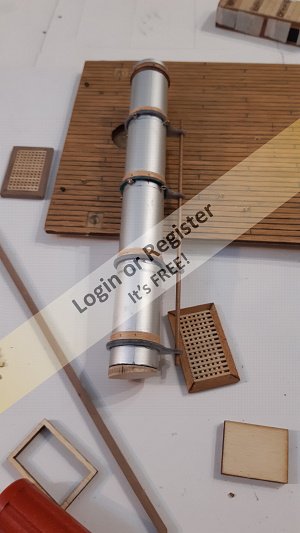

Hi Tim, in message no. 52 of this topic, I also wrote this:

"I had a bad experience with the funmel. I had designed it and had it printed. I left it in a wooden tool shed for a few months before assembling it. When I was ready to attach it, I noticed it had warped. Unfortunately, I don't remember if it was made of ABS or PLA.

I discarded it and made the new funmel out of three materials (aluminum, plastic, and wood). I don't have a PC with me, but as soon as I can, I'll attach photos so you can see the notable difference."

Sorry but I forgot to attach the photos.

As they say: better late than never.

As you can see I used the different materials I mentioned.

From the sequence of images, the method I used should be pretty clear, but if you have any questions, please ask.

"I had a bad experience with the funmel. I had designed it and had it printed. I left it in a wooden tool shed for a few months before assembling it. When I was ready to attach it, I noticed it had warped. Unfortunately, I don't remember if it was made of ABS or PLA.

I discarded it and made the new funmel out of three materials (aluminum, plastic, and wood). I don't have a PC with me, but as soon as I can, I'll attach photos so you can see the notable difference."

Sorry but I forgot to attach the photos.

As they say: better late than never.

As you can see I used the different materials I mentioned.

From the sequence of images, the method I used should be pretty clear, but if you have any questions, please ask.

▲

⟩⟩

BobbyN

RodC

xtramaths

hermank

EdW

tim morland

jumpugly

Nickthesteam

📝 3D Printed Models

44 Views · 5 Likes

Country: 🇦🇺 Australia

Online: 3 months ago

Online: 3 months ago

Thanks Lew that is clearer now. I use a combination of 3D printing, CNC for parts that are flat and styrene rods and bars both rectangular and round. Also I have used brass and regularly use cerated nuts which can be mounted into the 3D print using heat or softening with glue. This allows parts to be unscrewed. Whilst I still use 3D printing exclusively for my parts and swear by it I augment the manufacturing process as described above.

Bob

Bob

▲

⟩⟩

RodC

jumpugly

hermank

tim morland

LewZ

📝 3D Printed Models

50 Views · 3 Likes

Country: 🇺🇸 United States

Online: Today!

Online: Today!

What I was getting at is if someone makes a claim that rather than use a 3D print there is a stock material that is better and more resilient.

Lew

Lew

▲

⟩⟩

jumpugly

xtramaths

hermank

Lew Zee (LewsModelBoats.org)

Commodore

Commodore United Kingdom

United Kingdom Chief Petty Officer 1st Class

Chief Petty Officer 1st Class Australia

Australia Fleet Admiral

Fleet Admiral Vice Admiral

Vice Admiral Rear Admiral

Rear Admiral