Join Us On Social Media!

You have have been viewing a lot of topics!

Please consider becoming a member to help keep this website afloat.

Mantua Bruma - with possible conversion to sail

24 Posts · 14 Followers · 52 Photos · 198 Likes

Began 3 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 7 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Final launch day

7 months ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 38 Views · 5 Likes · 5 Comments

Flag

💬 Add Comment

After 2 years of on and off work Bruma is ready for the maiden voyage! In my excitement I unfortunately I forgot to attach the mainsheet to the boom!

Having it as a sailing vessel is in phase 2 - I have bought some ripstop white sail cloth to make some test sails. The detachable keel has been made and for a this trial test I'm attaching a 900gram fish shaped fishing weight.

We christened the boat with a small bottle of fizz. When I have some time I will edit the video taken and post it on here. For now here are some stills - one looks like she is just leaving a harbour wall! Pity that the duck brings us back to reality!!

Having it as a sailing vessel is in phase 2 - I have bought some ripstop white sail cloth to make some test sails. The detachable keel has been made and for a this trial test I'm attaching a 900gram fish shaped fishing weight.

We christened the boat with a small bottle of fizz. When I have some time I will edit the video taken and post it on here. For now here are some stills - one looks like she is just leaving a harbour wall! Pity that the duck brings us back to reality!!

▲

⟩⟩

ToraDog

Len1

RNinMunich

hermank

AlessandroSPQR

|

💬 Re: Final launch day

7 months ago by 🇺🇸 ToraDog (

Commodore) Commodore)✧ 20 Views · 3 Likes

Flag

Very Nice! Great photos as well!😀

▲

⟩⟩

Len1

hermank

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Final launch day

7 months ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 25 Views · 2 Likes

Flag

Hi Duncan I must be slow! Just cottoned on to the bottle and the launching ceremony!

Roy ▲

⟩⟩

Len1

hermank

|

|

💬 Re: Final launch day

7 months ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 25 Views · 3 Likes

Flag

Hi Duncan she looks great, you must be very pleased with yoursef and deservedly so too. And the photos are excellent as well.

As far as test sails go if you use Rip Stop nylon you can cut them out with scissors and the edges will not fray. I keep looking at the kit but I have to finish 2 other boats first. Decision based on my age, I was 87 last week and any unfinished models have little value until completed. Energy is good once enthused but the next day somewhat dulled. Did the electric motors do the job? If so what are they? A few months ago I bought some smaller sub C cells to make up into 7.2 volt batteries. I have a mini welder and have made up a couple of configurations to suit small models. They are 4/5ths. sub C and 2800mAh and are 2 off 3 cell units so they sit across the keel. They now drive my 16 inch long Huntsman at planing speed and last a good half hour. I am working on another boat a small fishing boat ex decorative model which should be on the water in a week or so. I have been a bit busy. Best regards and well done, Roy

▲

⟩⟩

Len1

hermank

DuncanP

|

|

💬 Re: Final launch day

7 months ago by 🇬🇧 Steve P (

Master Seaman) Master Seaman)✧ 27 Views · 2 Likes

Flag

Lovely build

▲

⟩⟩

hermank

Len1

|

|

💬 Re: Final launch day

7 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 29 Views · 2 Likes

Flag

Wonderful!

▲

⟩⟩

Len1

hermank

|

Login To

Remove Ads

Remove Ads

📝 Getting near to completion

8 months ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 42 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

Just a bit of an update. Basically I think that all that is left now is the standing and running rigging to complete. Because I plan to eventually in stage 2 have it with sails, I have had to consider strengthening everything. I have purchased 2 purpose made goosenecks which I have slightly modified so that the swivel doesn't easily pop out of its socket. In order to lock it in I have attached a cut down winch which was in the kit. The smallest gooseneck was for a 10mm mast and these masts are 8mm. Therefore I used the brass in the kit which was for you to make a gooseneck as a filler to bring the mast diameter up to 10mm. I have also bought replacement 15.3mm dummy bottlescrews from Mantuamodels.co.uk. Unfortunately they come in packs of 10 and I needed 12 - so hence 2 packs! The eyes on these are much bigger, so threading the rigging through will be much easier! All the eyelets I've soldered the ends so they won't uncurl under strain and glued them in with the original slow setting Araldite. I've been informed by another model boat builder that the fast setting 5min Araldite goes soft in water so I thought I wouldn't take any chances! I will have to think carefully about the rigging and extra fittings as I don't want jib sheet and mainsheet getting caught on something like the horn and search light etc. Hopefully in the next few weeks I will be able to show some photos and video of it run under motors. Roy can you please give me some ideas on how to make some test sails for the model please? Also Roy, I hope seeing these last stages will inspire you to start this model which I believe you have on your shelf!

Hopefully all rigging will be done by the end of this week as I'm helping my grandson in building his first model boat which is a HA Kits Flying Christine II. It is a model of the St. John's Ambulance boat that was used to ferry patients from the island of Guernsey for medical treatment to the mainland. He is coming to stay with us next weekend for 10days and we are hoping to have it completed in that time! I will do a build blog with him - so I hope you will all follow this build as well!😊

Hopefully all rigging will be done by the end of this week as I'm helping my grandson in building his first model boat which is a HA Kits Flying Christine II. It is a model of the St. John's Ambulance boat that was used to ferry patients from the island of Guernsey for medical treatment to the mainland. He is coming to stay with us next weekend for 10days and we are hoping to have it completed in that time! I will do a build blog with him - so I hope you will all follow this build as well!😊

▲

⟩⟩

Len1

GaryLC

peterd

roycv

RNinMunich

hermank

Ronald

Wolle

AlessandroSPQR

|

💬 Re: Getting near to completion

8 months ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 33 Views · 1 Like

Flag

Hi Duncan she looks really nice, well done. Your photos are definitely inspiring.

Have you got any rip stop nylon? It cuts out easily and if you strengthen the corners with adhesive sail material then it will tie on. How do you propose to connect the sails to the mast? There are several options. A jack line about 1mm away from the back of the mast with dress hooks sewn onto the sails at intervals. A similar system with a jack line but using good sellotape holding white 1mm plastic diameter tubing. This is cut into 1cm lengths and hardly shows but here the jack line needs to thread through the tubes first and then tightly secured. Instead of a wire jack line then try tiny eye hooks, or very small split pins are even better, push in holes drilled up the back of the mast and glued in every 15 cms or so. The loop hole in the split pin (they are small about 8mm long) should take a piece of piano wire through the sail dress hooks or tubes. I have also used carbon fibre stiff ▲

⟩⟩

hermank

|

|

💬 Re: Getting near to completion

8 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 38 Views · 1 Like

Flag

Hi Duncan, sorry to repeat myself, but this ship is beautiful.

You've chosen a fantastic model and you're doing it in the best way. So far this is the most beautiful Bruma I've seen. I hope you can sail it even with just the wind. It's fortunate you found the right parts, like the gooseneck. I couldn't find one at the time and had to make it myself. It's great news that your nephew is starting his first boat. I hope he likes it and continues. ▲

⟩⟩

hermank

|

📝 Tank test

8 months ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 49 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

After our Guide Dog puppy had finished having fun cooling off in a pet pool, I took the opportunity to have the first floating test of the motor sailor Bruma

All the radio gear, battery, motors, servo and winch were in place and I was very pleased with how she floated level. Pool is not deep enough to test with the detachable keel attached. That will be for another time. Initially I will just sail as a motor sailor and then try with sails on. Still lots to do before ready for maiden voyage! 😊

All the radio gear, battery, motors, servo and winch were in place and I was very pleased with how she floated level. Pool is not deep enough to test with the detachable keel attached. That will be for another time. Initially I will just sail as a motor sailor and then try with sails on. Still lots to do before ready for maiden voyage! 😊

▲

⟩⟩

RNinMunich

Wolle

tomarack

jbkiwi

peterd

Len1

roycv

AlessandroSPQR

hermank

|

💬 Re: Tank test

8 months ago by 🇬🇧 DuncanP (

Commander) Commander)✧ 49 Views · 4 Likes

Flag

Thank you Alessandro! I really appreciate your comments especially coming from such an accomplished model boat builder as yourself. It's taking a long time but it's getting there slowly. Thanks again😊

▲

⟩⟩

hermank

tomarack

Len1

AlessandroSPQR

|

|

💬 Re: Tank test

8 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 43 Views · 4 Likes

Flag

Hi Duncan, besides being beautiful, it looks great in the water.

You have chosen to build a magnificent model and you are doing it very very well. ▲

⟩⟩

hermank

tomarack

Len1

DuncanP

|

📝 Made some progress!

9 months ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 57 Views · 12 Likes · 7 Comments

Flag

💬 Add Comment

After a lot of careful thought, planning and ingenuity I managed to get all the electrics installed fairly neatly - well at least I hope you think so!! After a lot of searching on the internet I found the perfect set of clear plastic boxes. These boxes contain 2 x ESC's, W-Tail Mixer and connections for 2x motors and 1 x rudder and the receiver plus connections to the NICAM battery. The battery and plastic boxes are fastened in place with velcro.

Now that I have completed the electrics installation, I can now carry on with the installation of the remaining stantions. I didn't want to do that earlier as it could have interfered with access to the hold. Doing the wooden stantions was a bit tricky - having to drill 0.7mm holes to accept brass nails. The commodore from the boat club drilled the holes top and bottom on each stantion with a table mounted mini drill, but I did the deck rail and the handrail with a USB drill which new only cost £8.50 off eBay. Great little drill! I first fastened the toe-rail and handrail together on the deck with yellow masking tape to make sure all the holes lined up. Then used superglue to fix them in place - which I had to do quickly by lining up the whole handrail, before the glue 'went off'.

Hopefully I'm now well on the way to completion !😊😊

Now that I have completed the electrics installation, I can now carry on with the installation of the remaining stantions. I didn't want to do that earlier as it could have interfered with access to the hold. Doing the wooden stantions was a bit tricky - having to drill 0.7mm holes to accept brass nails. The commodore from the boat club drilled the holes top and bottom on each stantion with a table mounted mini drill, but I did the deck rail and the handrail with a USB drill which new only cost £8.50 off eBay. Great little drill! I first fastened the toe-rail and handrail together on the deck with yellow masking tape to make sure all the holes lined up. Then used superglue to fix them in place - which I had to do quickly by lining up the whole handrail, before the glue 'went off'.

Hopefully I'm now well on the way to completion !😊😊

▲

⟩⟩

Wolle

jbkiwi

Ronald

Fred

Len1

EdW

ChrisF

jostro65

AlessandroSPQR

hermank

RNinMunich

roycv

|

💬 Re: Made some progress!

9 months ago by 🇬🇧 DuncanP (

Commander) Commander)✧ 54 Views · 4 Likes

Flag

Hi Ronald. No I'm planning to have it either running on the motors or sailing under full sail. I spent a lot of time working out how to arrange a removable keel and also planning how to get two motors, battery and a winch into the small space! Then recently I had to think how to get the electrics safely stored away. Roy recommended using two motors rather than a single one mentioned in the kit which has a gear box because apparently this version is very noisy. We also discussed keel arrangements. It is going to be a lot of trial and error! Initially I will only sail it on the motors and then do the sails later but at least everything will be in place for conversion to sail! Hope this answers your query. Cheers Duncan 😊

▲

⟩⟩

AlessandroSPQR

roycv

hermank

Ronald

|

|

Login To

Remove Ads 💬 Re: Made some progress!

9 months ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 51 Views · 1 Like

Flag

Duncan,

Are you planning on modelling the Mantua Bruma, with sail furled? Thus using the electric motors to glide her gently through the harbour and around obstacles, and casually maneuvering in amongst other vessels. ▲

⟩⟩

hermank

|

|

💬 Re: Made some progress!

9 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 48 Views · 2 Likes

Flag

Great, Roy has cleared your doubts.

I have to admit that I am a bit over the top with security and testing. Based on Roy's experience you can skip testing. ▲

⟩⟩

hermank

DuncanP

|

|

💬 Re: Made some progress!

9 months ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 52 Views · 2 Likes

Flag

Hi Duncan I have used these esc's for some time now (5+ years). I have run them with 2-3 amps and they do not even get warm. I doubt the motors you are using take as much as 1.5 amps.

So they should be fine the way you have them in a box. However, Alessandro is right for the older generation of esc's where FET's and even older power transistors were used to provide o/p power. So why do the older ones need heat sinks? On power transistors there is a 0.7 volt drop across the emmitter base junction. If the current is 4 amps then the power lost is volts X amps. 0.7 x 4 = 2.8 Watts and this is dissipated as heat into a fin or heat sink. It will need air cooling and gets hot! The next generation saw the o/p power supplied by Mos Fets (Field Effect Transistors). They have just 0.1 volts drop (although different in design) so the power loss is 0.1 X 4 = 0.4 watts and they just get warm, so no large heat sink or power loss. The small esc's as far as I know are a mark / space ratio system and there is almost no loss at all and as the esc's come with all the circuit board almost encapsulated there is no attempt to dissipate any heat from the circuit. They are sold as able to control 10 amps +. Roy ▲

⟩⟩

DuncanP

hermank

|

|

💬 Re: Made some progress!

9 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 48 Views · 2 Likes

Flag

Hi Duncan, let me explain.

Putting electronic components in a closed box is a great idea to preserve them in case water gets into the hold. However, electronic components need air exchange to dissipate heat. For this reason, I recommend you do a test in the bathtub. Leave the motor running continuously (from half an hour to an hour) until the battery is almost flat. Every now and then, test the temperature (with a thermometer it is better but with your hand it is also fine). If the temperature is not excessive then the insulation system you made with the plastic boxes is also fine from that point of view. It's simply a precaution. ▲

⟩⟩

hermank

DuncanP

|

|

💬 Re: Made some progress!

9 months ago by 🇬🇧 DuncanP (

Commander) Commander)✧ 54 Views · 2 Likes

Flag

Roy - Alessandro mentioned about heat dissipation. I've used those cheap ESC's you recommended. From your experience have you found whether they generate much heat? There are two of them in one plastic container and the other plastic box contains the W-tail mixer and receiver - plus lots of spare wiring!

Any thoughts please? Cheers ▲

⟩⟩

hermank

AlessandroSPQR

|

|

💬 Re: Made some progress!

9 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 52 Views · 3 Likes

Flag

Very important progress Duncan.

Great work, take into account the proper heat dissipation of the electrical components. ▲

⟩⟩

hermank

Len1

DuncanP

|

📝 Reply to Roy

1 year ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 76 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

Hi Roy, You actually sent me a link to the detailed instructions and yes it says do the deck planking at this early stage. I've given the inside of the hull a coat of epoxy resin and where the planks would not be assessible I coated them with waterproof glue (Aliphatic) before attaching them to the hull. So hopefully it will be Ok!

I'm also waiting for a cataract operation but it is more complicated because I had a corneal graft when I was about 40. It now has no cells remaining so I will have to have another corneal graft and cataract operation at the same time. Ugh!

Enjoy the rest of your holiday in Australia and have a good trip back. I hope you decide to start the Bruma soon ! 😊Cheers

I'm also waiting for a cataract operation but it is more complicated because I had a corneal graft when I was about 40. It now has no cells remaining so I will have to have another corneal graft and cataract operation at the same time. Ugh!

Enjoy the rest of your holiday in Australia and have a good trip back. I hope you decide to start the Bruma soon ! 😊Cheers

▲

⟩⟩

hermank

AlessandroSPQR

|

💬 Re: Reply to Roy

1 year ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 67 Views · 2 Likes

Flag

I claim senility and memory complications!!!

I do hope the operation goes well as eyes are so precious. Glad I sent the link though, I live in the present and look forward to the future. The past can often have holes in it. Best Roy ▲

⟩⟩

hermank

DuncanP

|

📝 Painting the hull and advise on NOT following the instructions!

1 year ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 75 Views · 6 Likes · 4 Comments

Flag

💬 Add Comment

Finally we had some warmer weather today so hopefully it didn't cost too much to heat up the back of the garage! I've painted the hull with epoxy resin, then applied an under coat and several coats of paint. I found that the matt paint showed up some blemishes so I have filled them again. Unfortunately the colour of the filler is showing through very slightly, so I will have to apply yet another coat of Humbrol Matt white!

I followed the build instructions to the letter but I personally don't think it is a good idea to plank the deck at such an early stage. This is because of the difficulty in applying the masking tape on the planked deck especially through the 2mm slots at the top of the hull planking (gunnel). Given my time again, I would leave the deck planking until after the hull has been painted. My only thought is the sheet of decking is very thin and whether the kit creators thought that the planking was required at the beginning of the build to give the structure more rigidity - who knows!

Hopefully we will get another mild day so that I can apply another coat of matt white.

I followed the build instructions to the letter but I personally don't think it is a good idea to plank the deck at such an early stage. This is because of the difficulty in applying the masking tape on the planked deck especially through the 2mm slots at the top of the hull planking (gunnel). Given my time again, I would leave the deck planking until after the hull has been painted. My only thought is the sheet of decking is very thin and whether the kit creators thought that the planking was required at the beginning of the build to give the structure more rigidity - who knows!

Hopefully we will get another mild day so that I can apply another coat of matt white.

▲

⟩⟩

hermank

Colin H

Mike Stoney

AlessandroSPQR

roycv

Len1

|

💬 Re: Painting the hull and advise on NOT following the instructions!

1 year ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 68 Views · 3 Likes

Flag

Hi, re-reading this thread I note a remark about not having double planking on real ships. Well ships implies large vessels. But the wooden hulls of motor gun/ torpedo boats were first planked and then canvas was applied and then a second planking. Usually double diagonal planking.

It made a sturdy covering and survived the heavy vibrations of multiple high powered engines. Roy ▲

⟩⟩

EdW

hermank

DuncanP

|

|

Login To

Remove Ads 💬 Re: Painting the hull and advise on NOT following the instructions!

1 year ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 68 Views · 2 Likes

Flag

Hi Duncan re your Bruma build, I too queried planking the deck first, and I am not sure what to do. I did find more complete set of building instructions on-line about 14 pages if I remember correctly.

I think they also suggest the deck be planked first. I would tend to agree with your thoughts and get the access spaces sorted out first and then plank. By the way if you have to have a flush hatch with the deck try and make the hatch edges line up with the plank edges as this takes your eye off them. I have had a stop in my boat building for 5 months as I had 2 cataract operations which made previous glasses redundant. So when both eyes were done I had an eye test and now I only need single lens reading glasses. As I had varifocal glasses before there is no distortion of vision now so I can rely on what I see. Distant vision is excellent and OK for driving. Then my trip to Australia came up which is where I am now. I am raring to go when I get back in early March but need to finish my Wild Duck yacht first. Then either Bruma or Trotamares or my Aeronaut Victoria. Best Roy ▲

⟩⟩

hermank

DuncanP

|

|

💬 Re: Painting the hull and advise on NOT following the instructions!

1 year ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 68 Views · 3 Likes

Flag

Hi Duncan, You cannot judge where the imperfections lie after planking until the hull is one uniform colour.

I first get a thinned keying of paint or varnish on the hull and then go to any colour for the first coat. I use up the small amounts of paint left over for this. Wet and dry rubbing down and with different left over colours as the rubbing down progresses. This gives you an idea of how far you have rubbed down the paint as various different colours emerge. I have yet to use epoxy or glass cloth on the hulls as for me it is overkill as far as strength goes. I have several hulls that are 30 odd years old and with the 10 or so layers of paint before puttting on the final ones have stood the test of time. But you must waterproof the inside so that the wood does not absorb moistureon the inside. regards Roy ▲

⟩⟩

hermank

AlessandroSPQR

DuncanP

|

|

💬 Re: Painting the hull and advise on NOT following the instructions!

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 71 Views · 2 Likes

Flag

I'm glad you're back to working on your model, Duncan.

▲

⟩⟩

hermank

roycv

|

📝 1st coat of primer applied

1 year ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 96 Views · 7 Likes · 2 Comments

Flag

💬 Add Comment

Finally managed to complete the double layer of planking in limewood on the Mantua Bruma which is a plank on frame hull. I then did some filling and sanding before applying two coats of sanding sealer. Having 'chewed over' all of discussions about fibre glassing the hull I 'chickened out' and instead just applied a coat of Z-epoxy 2 part finishing resin. Another sand down with 120 grade paper (as advised on the bottles) before applying a Rustins primer & undercoat. This has now shown up some imperfections so I plan to remove these with Holts Knifing putty which is designed to fill small scratches and paint chips. I need to fit the bulwarks but I'm not sure about how to cut a 2mm 'slot' along the limewood planks. The slot is from around 6" from the bow to about 6" from the stern. I've tried a steal ruler and modelling knife but it still seems to follow along the grain of the wood on these 6mm wide limewood strips. Any suggestions gratefully received.

▲

⟩⟩

Mike Stoney

GARTH

Len1

RodC

AlessandroSPQR

roycv

hermank

|

💬 Re: 1st coat of primer applied

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 82 Views · 4 Likes

Flag

Hi Duncan, I cut the hull with a simple cutter.

They recommended electric cutters to do it but I didn't trust them, the work was too delicate. To follow the line you want and not the grain you can use a steel ruler, or a mark (pencil, marker, tape, etc. etc.) the important thing is that the first grooves are light, then gradually you can sink and push more because the blade will not take other paths. "Having 'chewed over' all of discussions about fiber glassing the hull I 'chickened out' and instead just applied a coat of Z-epoxy 2 part finishing resin." Excellent decision. ▲

⟩⟩

hermank

Len1

Peejay

DuncanP

|

|

💬 Re: 1st coat of primer applied

1 year ago by 🇨🇦 RossM (

Captain) Captain)✧ 88 Views · 5 Likes

Flag

CUTTING THROUGH LIMEWOOD

When I was cutting through 3mm pine stock, I found a box cutter had a better grip for control. I would score it 3 to 5 times cutting in about .75mm per stroke ▲

⟩⟩

hermank

Len1

AlessandroSPQR

Peejay

DuncanP

|

📝 1st layer completed at last

2 years ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 114 Views · 9 Likes

Flag

💬 Add Comment

Finally got some time to work on my model after working on other jobs that needed doing around the home and also a holiday down the Rhine river on a cruise. Weather was good today which enabled me to do the sanding outside and save the mess of dust everywhere in doors! Hopefully the hull is now smooth enough for the second layer of planking. Fingers crossed not too many more interruptions to the build program ! I used for the first time sanding sponges which seemed to work very well. I also did the sanding in a large box lid which kept most of the sanding residue in one place. Unfortunately when I first started sanding I forgot to put the yellow foam supports under the hull and as a consequence it has snapped the plastic tube which will carry the mainsheet off at deck level. It was originally designed to go through the cabin deck which also had the secondary purpose of holding the removable cabin in place. Hey Ho - one step forward and two back!!😐

▲

⟩⟩

Peejay

SimpleSailor

Len1

EdW

ChrisG

RNinMunich

AlessandroSPQR

roycv

hermank

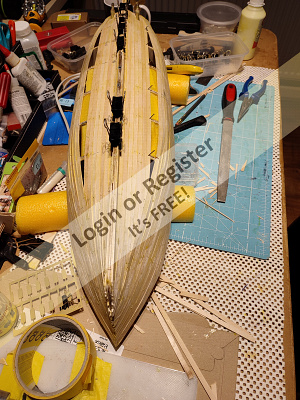

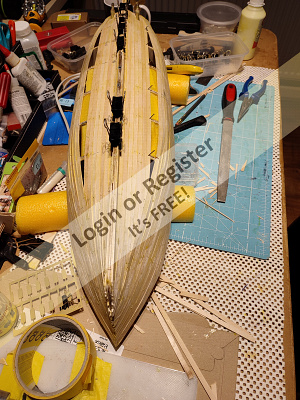

📝 1st layer nearing completion

2 years ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 132 Views · 10 Likes · 5 Comments

Flag

💬 Add Comment

Nearly there with the 1st layer of planking. Been a bit of a challenge especially around the stern. Once the remaining planks have been added I will shape bow and stern, fill between planks and then sand back before starting the second layer. Having planked from the deck towards the waterline I decided to because of the hull curvature the best way to complete the the planking was to then start from the keel and work towards the completed side planking. It seems to have worked out as a good method. Hope this might help future builders of this model. 😊

▲

⟩⟩

Peejay

ChrisG

AlessandroSPQR

flaxbybuck

mturpin013

Trident73

Len1

hermank

Wolle

roycv

|

💬 Re: 1st layer nearing completion

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 113 Views · 4 Likes

Flag

Hi Duncan I understand you. It's annoying to interrupt work.

I don't have grandchildren, but many other reasons prevent me from continuing the model quickly. Tonight, if I can, I'll paint the cannons. There is another peculiarity in your work. You've built the planking around the propeller shafts. I, however, prefer to complete the planking and then drill it. The differences in model building techniques are always fascinating and I really enjoy looking at other methods. ▲

⟩⟩

Peejay

hermank

Len1

DuncanP

|

|

Login To

Remove Ads 💬 Re: 1st layer nearing completion

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 113 Views · 4 Likes

Flag

Hi Len, very interesting observation.

I would very much like to discuss this topic with you and the other modelers but if the discussion gets too long, as it is likely to happen, we could disturb Duncan's work. For this reason I prefer to open a separate topic and in this topic continue to comment on the work of Duncan's Bruma. ▲

⟩⟩

Peejay

hermank

Len1

DuncanP

|

|

💬 Re: 1st layer nearing completion

2 years ago by 🇺🇸 Len1 (

Lieutenant Commander) Lieutenant Commander)✧ 114 Views · 3 Likes

Flag

Just a thought on double planking on real ships is that it adds so much weight to the vessel and that could reduce its load carrying capability and therefore revenue. Maybe double planking on warships would make sense.

This just conjecture on my part and not based on any facts. Len ▲

⟩⟩

Peejay

hermank

AlessandroSPQR

|

|

💬 Re: 1st layer nearing completion

2 years ago by 🇬🇧 DuncanP (

Commander) Commander)✧ 126 Views · 6 Likes

Flag

Hi Alessandro, Building has come to a halt whilst the grand children are staying with us. Two reasons. 1) I have had to remove everything from their bedroom/modelling room and 2) they keep me that busy I have no time!!

The only progress is the 1st layer of planking is complete. Next stage is filling and sanding. I want to do the sanding outside to avoid dust in the house so that will also be weather dependant! Will update the build blog before the second layer starts.😊 ▲

⟩⟩

Peejay

ChrisG

hermank

AlessandroSPQR

Len1

Wolle

|

|

💬 Re: 1st layer nearing completion

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 119 Views · 3 Likes

Flag

Hi Duncan, I haven't seen any posts on this forum for a while.

I'm glad you've almost finished the first planking and your method is very interesting. Even though I have always started from the top down to the keel, I think yours could be excellent, I will take it into consideration for next time. P.S. No, I've never heard of "double planking" for real ships. Maybe it will even have been done on some real boats. Why not. I ignore it. I am sure that for all (and I mean all) the scale models I have seen to date, in person or on the internet, made with double planking, no real ship (and I mean none) had double planking. In other words: modeling = double planking is always or almost always used even when real models do not require it. real ships = always or almost always single planking. This is why I can say that double planking is above all a modeling technique. ▲

⟩⟩

Peejay

hermank

Len1

|

📝 Pond Noodle buoyancy

2 years ago by 🇬🇧 DuncanP ( Commander)

Commander)

Commander)

Commander)✧ 139 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

Planking slowly coming along. Attaching each 7mm strip of limewood with Aliphatic glue. Before fitting I'm spreading the glue the entire length of the strip to waterproof it. I've decided to put strips of Pond Noodle under the flooring to stop any build up of water and also to provide buoyancy if required - hopefully not!! It also provides a suitable scratch free support for the hull when turned upside down as the deck is already complete. It is getting more tricky as I'm now encountering curves in two directions. I'm using a Model craft electric plank bending tool which certainly helps. Unfortunately it is rather time consuming and then I keep having recurring thoughts that I need to do it all again for the second layer! Hopefully with a flat surface to glue to it will be easier - wishful thinking! 😊 Happy Easter to everyone. Cheers D

▲

⟩⟩

Peejay

Wolle

EdW

RNinMunich

Colin H

Len1

boatmam

ChrisG

hermank

AlessandroSPQR

|

💬 Re: Pond Noodle buoyancy

2 years ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 129 Views · 4 Likes

Flag

SPQR - Contrary to your statement, I supposed you never heard of "Double Planking" on real boats?

Lew Florida, USA ▲

⟩⟩

Peejay

hermank

Len1

River Rat

|

|

💬 Re: Pond Noodle buoyancy

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 135 Views · 3 Likes

Flag

Certainly Duncan, it's as you say: the second planking (which only exists in the modeling sector) is usually always easier, because there is already a surface on which to attach the wooden strips.

▲

⟩⟩

Peejay

Len1

hermank

|

United Kingdom

United Kingdom