Join Us On Social Media!

Sea Plane tenders

11 Posts · 13 Followers · 91 Photos · 125 Likes

Began 1 year ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 7 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Sea Plane Tenders 11 - Final touches

7 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 54 Views · 12 Likes · 1 Comment

Flag

💬 Add Comment

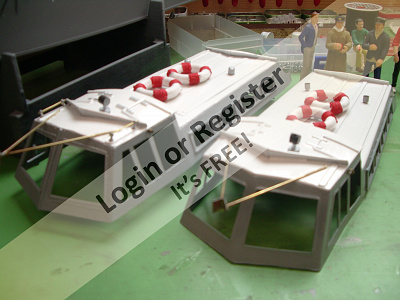

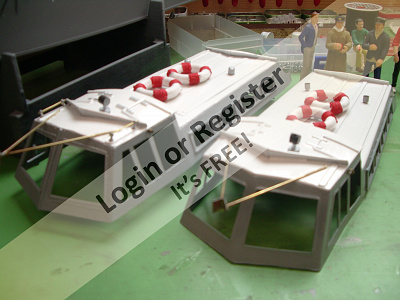

In these photos I have been giving the boats their final coats of paint, decals and fittings.

The object had been to scratch build a facsimile of the Deans model, and to see how possible it is to achieve the same features and appearance without compromising on weight or performance. Well, SPT409 (the scratch built model) came in at some 100grams less in weight than SPT 441 when ready for the water.

The differences are:

1. SPT441 uses a Speed 400 motor

SPT409 uses an A2212, 1000KV brushless motor

2. SPT441 uses a 6V 1.6Ah NiMH battery

SPT409 uses a 2S 1500mAh lipo battery

3. SPT441 has forward and reverse

SPT409 has forward only.

4. Performance

SPT441 is fast but at speed quickly drains the

battery

SPT409 is super fast and flighty. Battery life is

much longer than SPT441, in excess of 40

minutes (but not trialed)

Both take on water when run at speed, from the prop tube or rudder tube, but only a manageable quantity.

Conclusions

1 Scratch building takes much longer but can result in a model every bit as good, or better than the commercially made kit.

2 The Speed 400 motor /NiMH battery weigh more than the brushless motor /Lipo battery and perform less well.

3 Building boats of this size presents challenges to fingers and patience to a person of my age ! However, when completed they are much easier to store, lift, transport, handle, launch and recover than larger boats ! 😉

The object had been to scratch build a facsimile of the Deans model, and to see how possible it is to achieve the same features and appearance without compromising on weight or performance. Well, SPT409 (the scratch built model) came in at some 100grams less in weight than SPT 441 when ready for the water.

The differences are:

1. SPT441 uses a Speed 400 motor

SPT409 uses an A2212, 1000KV brushless motor

2. SPT441 uses a 6V 1.6Ah NiMH battery

SPT409 uses a 2S 1500mAh lipo battery

3. SPT441 has forward and reverse

SPT409 has forward only.

4. Performance

SPT441 is fast but at speed quickly drains the

battery

SPT409 is super fast and flighty. Battery life is

much longer than SPT441, in excess of 40

minutes (but not trialed)

Both take on water when run at speed, from the prop tube or rudder tube, but only a manageable quantity.

Conclusions

1 Scratch building takes much longer but can result in a model every bit as good, or better than the commercially made kit.

2 The Speed 400 motor /NiMH battery weigh more than the brushless motor /Lipo battery and perform less well.

3 Building boats of this size presents challenges to fingers and patience to a person of my age ! However, when completed they are much easier to store, lift, transport, handle, launch and recover than larger boats ! 😉

▲

⟩⟩

PeteJev

Rookysailor

boatmam

RodC

roycv

hermank

Ronald

Scratchbuilder

luckyduck

RNinMunich

AlessandroSPQR

Colin H

|

💬 Re: Sea Plane Tenders 11 - Final touches

7 months ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 62 Views · 1 Like

Flag

Nice gift! Appear to be well built and finished.

▲

⟩⟩

AlessandroSPQR

|

Login To

Remove Ads

Remove Ads

📝 Sea Plane Tenders 10

9 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 69 Views · 10 Likes

Flag

💬 Add Comment

Here I am preparing and painting the top-sides and superstructures of both boats. I cannot over emphasise the need for good masking when preparing to paint. Overspray can get to places you wouldn't imagine, and paint can track under the edge of ordinary masking tape. So use good quality masking tape that you know will not bleed, and thoroughly mask off everywhere you are not painting.

The motor covers are easily made and painted, the rubbing strips being done last.

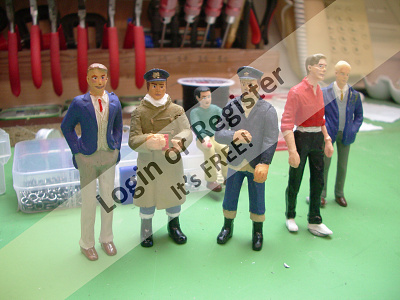

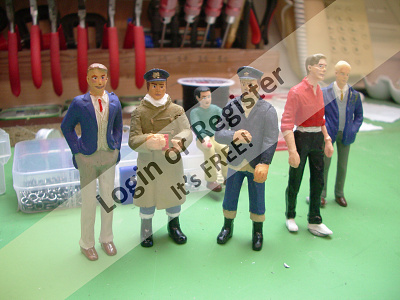

With the superstructures made and painted I then turned my attention to manning the boats, using a mix of cheap Chinese figures and a more expensive British make. You can tell the difference. Painting the figures needed a large magnifying glass, good work light and tiny paint brushes. The smallest has just one bristle ! This comes in handy when painting the eyes. You can see from the pictures that I have not yet mastered the art of painting faces, but I will keep practicing .

Adding detail to the superstructure is shown next with items like lifebelts, lights, horns etc going on. The lifebelts were made from large rubber O rings which just happen to be the right size. Rigging to the masts was deliberately kept quite simple with just rear stays to the back of the cabin and a single forestay. These are all made of black elastic cord (another delivery from China) and tiny brass hooks made using cane-crimping pliers. The masts both have a brass ferrule glued on, with corresponding brass tube mountings. This enables the masts and rigging to be easily removed to permit removal of the superstructure.

Next time, finishing touches.

The motor covers are easily made and painted, the rubbing strips being done last.

With the superstructures made and painted I then turned my attention to manning the boats, using a mix of cheap Chinese figures and a more expensive British make. You can tell the difference. Painting the figures needed a large magnifying glass, good work light and tiny paint brushes. The smallest has just one bristle ! This comes in handy when painting the eyes. You can see from the pictures that I have not yet mastered the art of painting faces, but I will keep practicing .

Adding detail to the superstructure is shown next with items like lifebelts, lights, horns etc going on. The lifebelts were made from large rubber O rings which just happen to be the right size. Rigging to the masts was deliberately kept quite simple with just rear stays to the back of the cabin and a single forestay. These are all made of black elastic cord (another delivery from China) and tiny brass hooks made using cane-crimping pliers. The masts both have a brass ferrule glued on, with corresponding brass tube mountings. This enables the masts and rigging to be easily removed to permit removal of the superstructure.

Next time, finishing touches.

▲

⟩⟩

Rookysailor

RodC

hermank

Colin H

SimpleSailor

AlessandroSPQR

Doogle

Fred

Rogal118

RNinMunich

📝 Sea Plane Tenders 9

9 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 84 Views · 11 Likes · 2 Comments

Flag

💬 Add Comment

At this point I was able to progress the two boats side by side.

These pictures show the hulls being prepared for primer by masking off other areas, and in the last picture, after further masking off, application of red paint to the hull bottoms.

Paint used was Halfords grey and red primer spray paints (rattle cans).

After a little practice I learnt how to avoid unwanted blobs of paint. The trick seemed to be to (a) warm the paint by immersing in hot water for a few minutes and (b) rattling it well and (c) starting and ending each pass beyond the boat. Any blobs tend to come at the beginning or end of a pass so start and finish beyond the subject. Then (d) apply a number of light passes (say 3 or 4), pausing a few moments between each pass. Then wait for the paint to dry before applying further passes. Repeat this until happy with the result.

With these small items (including the hulls which are quite small) I put them on a sheet of newspaper. They could then easily be turned by spinning the paper around.

😉

These pictures show the hulls being prepared for primer by masking off other areas, and in the last picture, after further masking off, application of red paint to the hull bottoms.

Paint used was Halfords grey and red primer spray paints (rattle cans).

After a little practice I learnt how to avoid unwanted blobs of paint. The trick seemed to be to (a) warm the paint by immersing in hot water for a few minutes and (b) rattling it well and (c) starting and ending each pass beyond the boat. Any blobs tend to come at the beginning or end of a pass so start and finish beyond the subject. Then (d) apply a number of light passes (say 3 or 4), pausing a few moments between each pass. Then wait for the paint to dry before applying further passes. Repeat this until happy with the result.

With these small items (including the hulls which are quite small) I put them on a sheet of newspaper. They could then easily be turned by spinning the paper around.

😉

▲

⟩⟩

AlessandroSPQR

PeteJev

Trident73

RNinMunich

chugalone100

Doogle

Colin H

RodC

Scratchbuilder

Fred

hermank

|

💬 Re: Sea Plane Tenders 9

9 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 84 Views · 2 Likes

Flag

I have two projects on the go at present, one being the Ark and the other being my recycling steam punk project. As both are scatch built and no plans involved, I tend to put one to the side if something not quite clear and move to the other or "tinker"with something else until I get a solution 😀.

I also have an old kitchen stool left behind by the previous owner, found a square tray and bolted 🔩 this through the top of the stool with a couple of washers top and bottom. Makes an effective turntable for spraying on as well as for working on if you don't want to physically move a vessel round on the workbench. ▲

⟩⟩

AlessandroSPQR

Scratchbuilder

|

|

💬 Re: Sea Plane Tenders 9

9 months ago by 🇨🇦 RodC (

Lieutenant) Lieutenant)✧ 83 Views · 3 Likes

Flag

I favour building 2 vessels at the same time, especially if they are similar. This can lead to economy of time. No sitting around waiting for glue to dry, there is always something to be done on the other hull. Other members in my local club advise against this...along the lines of "finish one thing before you move on to your next project"

▲

⟩⟩

AlessandroSPQR

RNinMunich

Doogle

|

📝 Sea Plane Tenders 8

10 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 94 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

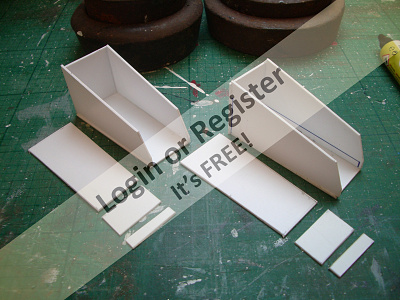

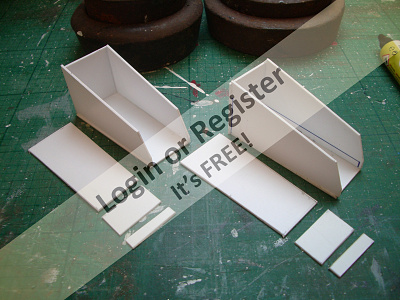

In these pictures you can see how I progressed the two boats side by side.

The Deans kit included a moulding for the superstructure which speeded things along, but in the case of my boat I had to construct this from scratch. I chose to do this with sheet plastic which, with patience, turned out OK.

Making the engine covers was a little more complicated than making a simple box, but not much more. Patience both with the assembly and painting was key to getting a reasonable result. 😉

The Deans kit included a moulding for the superstructure which speeded things along, but in the case of my boat I had to construct this from scratch. I chose to do this with sheet plastic which, with patience, turned out OK.

Making the engine covers was a little more complicated than making a simple box, but not much more. Patience both with the assembly and painting was key to getting a reasonable result. 😉

▲

⟩⟩

RodC

AlessandroSPQR

Fred

River Rat

Doogle

RNinMunich

chugalone100

Colin H

Scratchbuilder

|

💬 Re: Sea Plane Tenders 8

10 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 94 Views · 4 Likes

Flag

Great photos 📸, enjoying seeing your build as it progresses 👍

▲

⟩⟩

AlessandroSPQR

Scratchbuilder

River Rat

Colin H

|

|

💬 Re: Sea Plane Tenders 8

10 months ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 96 Views · 4 Likes

Flag

Flaxbybuck.

Really impressive work on your part. Great photographs as well. Regards Bill. ▲

⟩⟩

AlessandroSPQR

River Rat

Colin H

RNinMunich

|

📝 Sea Plane Tenders 7

11 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 103 Views · 10 Likes

Flag

💬 Add Comment

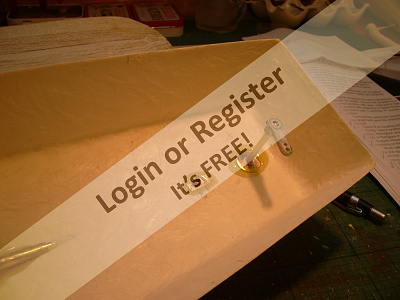

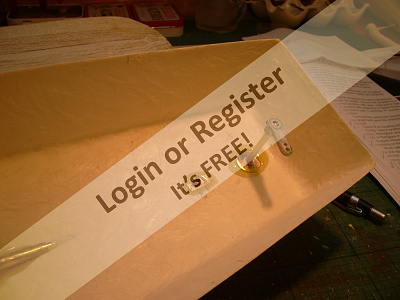

You may recall that this project started with my buying the Deans Marine SPT441 kit and wanting to make a plank on frame model of it at the same time. So here are a few shots of progress being made on the Deans boat.

The slot for the prop shaft was first cut and filed smooth, and a hole drilled for the rudder shaft. These items were held in place temporarily (with blue tac or similar stuff) whilst epoxy resin was poured in and allowed to cure. The tac was then removed, the boat turned over and resin applied to the external surface.

The Deans prop tube support, rudder and rudder yolk were discarded and I made new ones from brass sheet and rod and soldered them together. The oiling tube was also added. This was done by first shaping the tube end to fit snugly over the prop tube, holding the two in place and soldering them, then drilling the tube by inserting a drill bit down the oiling tube being careful to only drill into the prop tube, and not right the way through !

The motor, coupling and prop shaft were put in place before gluing the motor mount into place. Both boats can be seen being progressed together.

Work on the hull then involved gluing the internal gunwales, the deck beams, the radio shelf and battery holder into place. In addition, a solid bulkhead was made and glued into place just forward of the RC shelf. This was to create a buoyancy chamber.

In the next photos the motor, radio control gear, battery and deck are put into place temporarily to ensure that everything is placed correctly and will be accessible when the boat is complete.

Close up shots show the oiling tube, then the seating for the rudder servo.

When I was happy that all was ready I glued the deck down, assisted by weights and tape. In the final shot the rubbing strips were being added. To bend the plastic around the bow gentle heat was applied, then dipping in hot water. This formed a permanent curve and made gluing the rest to the hull much easier. With these strips and the lifting points glued on the hull was virtually complete. 😉

The slot for the prop shaft was first cut and filed smooth, and a hole drilled for the rudder shaft. These items were held in place temporarily (with blue tac or similar stuff) whilst epoxy resin was poured in and allowed to cure. The tac was then removed, the boat turned over and resin applied to the external surface.

The Deans prop tube support, rudder and rudder yolk were discarded and I made new ones from brass sheet and rod and soldered them together. The oiling tube was also added. This was done by first shaping the tube end to fit snugly over the prop tube, holding the two in place and soldering them, then drilling the tube by inserting a drill bit down the oiling tube being careful to only drill into the prop tube, and not right the way through !

The motor, coupling and prop shaft were put in place before gluing the motor mount into place. Both boats can be seen being progressed together.

Work on the hull then involved gluing the internal gunwales, the deck beams, the radio shelf and battery holder into place. In addition, a solid bulkhead was made and glued into place just forward of the RC shelf. This was to create a buoyancy chamber.

In the next photos the motor, radio control gear, battery and deck are put into place temporarily to ensure that everything is placed correctly and will be accessible when the boat is complete.

Close up shots show the oiling tube, then the seating for the rudder servo.

When I was happy that all was ready I glued the deck down, assisted by weights and tape. In the final shot the rubbing strips were being added. To bend the plastic around the bow gentle heat was applied, then dipping in hot water. This formed a permanent curve and made gluing the rest to the hull much easier. With these strips and the lifting points glued on the hull was virtually complete. 😉

▲

⟩⟩

RodC

BOATSHED

Fred

RNinMunich

Scratchbuilder

AlessandroSPQR

Trident73

Colin H

dave976

Doogle

📝 Sea Plane Tenders 6

11 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 101 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

Planking of the sides was easier than the bottom, there being fewer planks that needed patterns making. You may notice that at the bow a few short planks were put in place. These cut out the need for shaping full length planks. My method with the planking was to steam or wet the balsa in hot water to facilitate the sharper bends near the bows, and glue just the bow portion into place. When the glue was set the remainder of each plank was pinned and glued into place. I found this much easier than trying to pin (or clamp) and glue each plank for its full length.

When the planking was all completed I had to create an even smooth surface over the whole boat. Initially I attempted to do this by 'plastering' the whole side with filler but I got a bit too enthusiastic with the filler when doing the first side leaving a lot of rubbing down to be done just to get back to the high points of balsa. With subsequent sides I was more prudent with the filler and put on just enough.

The next step was to encase the hull with glass fibre. To help with this stage I made temporary frames that would allow me to hold the hull without touching it, or to clamp it down onto a table top. The workshop was heated to around 22 degrees Centigrade to help the whole process.

I selected a very light fibreglass 'tissue' and used Halford's Isopon polyester resin. First the tissue was cut into pieces, one piece for each of the five 'sides'. Resin was brushed onto the hull and each tissue piece gently but accurately laid into place, and then stippled with a stiff brush to remove air bubbles and encourage resin to come to the surface. Sideways strokes with the brush were avoided because the tissue would disintegrate and become totally unmanageable. Additional resin was either poured on or applied with the stippling brush where insufficient resin had come to the surface to form an unbroken layer. Whilst this worked sufficiently well I made a mental note to thin the resin with isopropanol alcohol when doing this in the future.

Once the fibreglass was completely cured and dried I rubbed off all the high spots with a coarse grade of wet and dry paper, then applied car body filler to the surface and rubbed it down (wet). Two types of sanding block were used for this, a cork block with a convex shaped back face, and a sponge sanding block. I found using the cork block was quicker and easier than the sponge, giving a greater degree of control over the sanding. The car body filler was a blue green colour, and the photos show how much of this was removed in the sanding process, in places all of it.

At this point I was able to drawer some comparisons with the Deans Marine model which I had been progressing alongside the home build. 😉

When the planking was all completed I had to create an even smooth surface over the whole boat. Initially I attempted to do this by 'plastering' the whole side with filler but I got a bit too enthusiastic with the filler when doing the first side leaving a lot of rubbing down to be done just to get back to the high points of balsa. With subsequent sides I was more prudent with the filler and put on just enough.

The next step was to encase the hull with glass fibre. To help with this stage I made temporary frames that would allow me to hold the hull without touching it, or to clamp it down onto a table top. The workshop was heated to around 22 degrees Centigrade to help the whole process.

I selected a very light fibreglass 'tissue' and used Halford's Isopon polyester resin. First the tissue was cut into pieces, one piece for each of the five 'sides'. Resin was brushed onto the hull and each tissue piece gently but accurately laid into place, and then stippled with a stiff brush to remove air bubbles and encourage resin to come to the surface. Sideways strokes with the brush were avoided because the tissue would disintegrate and become totally unmanageable. Additional resin was either poured on or applied with the stippling brush where insufficient resin had come to the surface to form an unbroken layer. Whilst this worked sufficiently well I made a mental note to thin the resin with isopropanol alcohol when doing this in the future.

Once the fibreglass was completely cured and dried I rubbed off all the high spots with a coarse grade of wet and dry paper, then applied car body filler to the surface and rubbed it down (wet). Two types of sanding block were used for this, a cork block with a convex shaped back face, and a sponge sanding block. I found using the cork block was quicker and easier than the sponge, giving a greater degree of control over the sanding. The car body filler was a blue green colour, and the photos show how much of this was removed in the sanding process, in places all of it.

At this point I was able to drawer some comparisons with the Deans Marine model which I had been progressing alongside the home build. 😉

▲

⟩⟩

RodC

AlessandroSPQR

Fred

RNinMunich

Trident73

Colin H

chugalone100

hermank

Doogle

Scratchbuilder

|

💬 Re: Sea Plane Tenders 6

11 months ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 102 Views · 1 Like

Flag

Nice looking hull. Good pre finish.

I love the painting attachment. 😎 ▲

⟩⟩

AlessandroSPQR

|

|

💬 Re: Sea Plane Tenders 6

11 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 102 Views · 1 Like

Flag

Looking great, very informative on what looks like a great build taking shape 😀

▲

⟩⟩

AlessandroSPQR

|

📝 Sea Plane Tenders 5

11 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 106 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

With the motor, prop shaft and rudder shaft installed it was time to turn my attention to the planking.

After an additional plank each side of the keel I then looked at the sides, in particular at the bulkheads and their accuracy. In spite of taking pains to maintain accuracy from drawing board to build it was obvious that the bulkheads needed adjusting for the side planking.

Using a thin lath I was able to determine which bulkheads needed attention, then glue additional balsa on. Initially these added strips were thicker than necessary, but were then carefully sanded down until the correct profile was reached. The thickness added varied from zero to 2mm.

This may not sound much, but on a small model like this it would make a very noticeable difference to the shape of the hull, so it was important that the profile looked symmetrical and true.

Planking then continued to the bottom. Most planks needed to be shaped before being glued into place, so cardboard patterns were made and tested in place before cutting the balsa and gluing it on. The side planks adjoining the chine needed the most pronounced shape. This can be seen in the photos.

Eventually the bottom planking was completed and I took stock of the build to date. Clearly quite a bit of filling would be needed ! 😉

After an additional plank each side of the keel I then looked at the sides, in particular at the bulkheads and their accuracy. In spite of taking pains to maintain accuracy from drawing board to build it was obvious that the bulkheads needed adjusting for the side planking.

Using a thin lath I was able to determine which bulkheads needed attention, then glue additional balsa on. Initially these added strips were thicker than necessary, but were then carefully sanded down until the correct profile was reached. The thickness added varied from zero to 2mm.

This may not sound much, but on a small model like this it would make a very noticeable difference to the shape of the hull, so it was important that the profile looked symmetrical and true.

Planking then continued to the bottom. Most planks needed to be shaped before being glued into place, so cardboard patterns were made and tested in place before cutting the balsa and gluing it on. The side planks adjoining the chine needed the most pronounced shape. This can be seen in the photos.

Eventually the bottom planking was completed and I took stock of the build to date. Clearly quite a bit of filling would be needed ! 😉

▲

⟩⟩

AlessandroSPQR

Fred

hermank

Rookysailor

RNinMunich

chugalone100

Scratchbuilder

Colin H

Doogle

|

💬 Re: Sea Plane Tenders 5

11 months ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 105 Views · 5 Likes

Flag

It's a real pleasure to watch your progress and craftsmanship as your model starts to come alive.

Great work, keep it up shipmate. Cheers Colin. ▲

⟩⟩

AlessandroSPQR

hermank

Rookysailor

RNinMunich

Scratchbuilder

|

|

💬 Re: Sea Plane Tenders 5

11 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 106 Views · 1 Like

Flag

Looks like she's coming along nicely 👌. Well done 👏

▲

⟩⟩

AlessandroSPQR

|

📝 Sea Plane Tenders 4

11 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 118 Views · 13 Likes · 1 Comment

Flag

💬 Add Comment

The next step was to position the motor. I had chosen a small brushless, an A2212, 1000KV and planned using a Rabaesch coupling. I turned up an aluminium alignment tool on the lath. The length is identical to the coupling, and the ends drilled out 3.2mm for the motor and 4mm for the prop shaft. (Photo 1) This simple tool allows accurate positioning of the motor, metal mount and balsa bulkhead to which it is attached. By connecting all together the bulkhead can be accurately positioned and glued into place. (Photo 2)

Once this is done the planking can continue (Photo 3) but before going too far I completed the mounting of the rudder servo by gluing small blocks into place. A rudder yolk was fashioned from brass sheet soldered to a brass collar. When I was happy that the servo could operate without the yolk snagging on anything I bent thin wire connecting rods ensuring that the two rods are parallel and of equal length. (Photos 4,5 and 6)

Getting perfect alignment of the prop tube, motor and rudder is critical in such a small boat so I took my time, checked and rechecked everything before glue or filler had set. It was also necessary to think ahead several stages to ensure construction could continue in successive stages without having to undo any work already done. Not so easy when there are no instructions to follow, but not impossible.

Once this is done the planking can continue (Photo 3) but before going too far I completed the mounting of the rudder servo by gluing small blocks into place. A rudder yolk was fashioned from brass sheet soldered to a brass collar. When I was happy that the servo could operate without the yolk snagging on anything I bent thin wire connecting rods ensuring that the two rods are parallel and of equal length. (Photos 4,5 and 6)

Getting perfect alignment of the prop tube, motor and rudder is critical in such a small boat so I took my time, checked and rechecked everything before glue or filler had set. It was also necessary to think ahead several stages to ensure construction could continue in successive stages without having to undo any work already done. Not so easy when there are no instructions to follow, but not impossible.

▲

⟩⟩

AlessandroSPQR

Fred

hermank

chugalone100

Scratchbuilder

PeteJev

stevedownunder

RNinMunich

ChrisG

Len1

Doogle

Norway

Colin H

|

💬 Re: Sea Plane Tenders 4

11 months ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 126 Views · 2 Likes

Flag

A great method of mounting the transmission, making sure of a smooth silent drive, also doing it at this stage makes it so much easier to see and have access whilst mounting the bulkhead.

The same goes for the rudder installation, great stuff ▲

⟩⟩

AlessandroSPQR

RNinMunich

|

📝 Sea Plane Tenders 3

12 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 125 Views · 14 Likes

Flag

💬 Add Comment

Having just returned from a 3 week holiday in France I am trying to catch up with everything.

SPT 409 had reached the stage where the bulkheads and chine rails had been fitted.

Pic 1 - The stern post and transom in place. Strengthening pieces added to allow the prop and rudder tubes to pass through the keel.

Pic 2 - chine rails in place. The forward section shows how the chine rails are formed into a tight curve using solid sheet cut to shape.

Pic 3 - The first plank being held whilst glue sets

Pic 4 - The first two planks in place, one each side of the keel. Note how the planks overlap at the bow, alternating right over left, left over right etc.

Pic 5 - The rudder tube is glued into place with epoxy. Note the added bracket to support the top end of the rudder tube.

Pic 6 - The rudder tube is now positioned with a lump of blue tack. This allows adjustments to be made to ensure it is precisely aligned whilst being glued.

Pic 7 - the bow section is fitted with solid blocks of balsa that are sanded to profile.

Pic 8 - The prop tube is set in place with Ronseal High Performance wood filler. This is a two part resin filler not dissimilar to car body filler but better suited to using with wood. This hardens in about 10 minutes when the blue tack is removed and the underside filled.

Pic 9 - the internal end of the prop tube is encased and filled with Ronseal and the area tidied up after.

SPT 409 had reached the stage where the bulkheads and chine rails had been fitted.

Pic 1 - The stern post and transom in place. Strengthening pieces added to allow the prop and rudder tubes to pass through the keel.

Pic 2 - chine rails in place. The forward section shows how the chine rails are formed into a tight curve using solid sheet cut to shape.

Pic 3 - The first plank being held whilst glue sets

Pic 4 - The first two planks in place, one each side of the keel. Note how the planks overlap at the bow, alternating right over left, left over right etc.

Pic 5 - The rudder tube is glued into place with epoxy. Note the added bracket to support the top end of the rudder tube.

Pic 6 - The rudder tube is now positioned with a lump of blue tack. This allows adjustments to be made to ensure it is precisely aligned whilst being glued.

Pic 7 - the bow section is fitted with solid blocks of balsa that are sanded to profile.

Pic 8 - The prop tube is set in place with Ronseal High Performance wood filler. This is a two part resin filler not dissimilar to car body filler but better suited to using with wood. This hardens in about 10 minutes when the blue tack is removed and the underside filled.

Pic 9 - the internal end of the prop tube is encased and filled with Ronseal and the area tidied up after.

▲

⟩⟩

AlessandroSPQR

Fred

hermank

chugalone100

boatmam

mturpin013

Norway

River Rat

RNinMunich

Colin H

dave976

neilw

Doogle

marky

📝 Sea Plane Tenders 2

1 year ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 135 Views · 13 Likes · 1 Comment

Flag

💬 Add Comment

During the planning stage I was mindful of the need to keep weight to a minimum, so I decided to use a 2.5mm ply deck, and balsa sheet for planking, 1/16" if memory serves. The bulkheads are 1/4" balsa.

For younger viewers there are 25.4mm to 1". Some materials are still sold in imperial sizes, eg 5/32" (which equals 4mm.) This works well enough for timber, but not metals where the small differences can make a significant difference to the fit, eg.when fitting prop shafts to prop tubes.

The next stage was to find a suitable base board upon which the boat would be made. I found a piece of melamine faced chipboard which served the purpose being nicely flat, and strong enough to resist any forces that might arise during construction.

After marking out and cutting the deck it was securely held down to the baseboard with screwed battens.

The keel member was cut out from 6mm ply. Thinner pieces of ply were attached each side of the keel to form the slot for the prop tube and glued into place. I generally used waterproof PVA wood adhesive for these parts.

The eagle eyed will have noticed the slots cut into the bulkheads and the keel which is to house two pieces together whilst keeping their integrity.

The last photo shows the principle bulkheads in place and attached to the deck and the keel. The battens have been re-positioned to lie each side of one of the bulkheads. Small blocks have been glued to the transom and mid section bulkhead to accept the chine rails. Forward of this bulkhead the chines are formed from ply. This is so the sharp curve towards the bows can be achieved.

At the stern the transom has been reinforced with a post, and pieces glued each side of the keel ready to accept the rudder tube. Note that the keel member at the bows has been roughly shaped to the cross section profile.

Everything has to be prepared in readiness for planking at this stage so there is quite a bit of checking and adjusting. This is a small boat, just 21 x 6.5" so accuracy is very important. A lot of time was spent checking and rechecking dimensions and symmetry. More of this later. 😉

For younger viewers there are 25.4mm to 1". Some materials are still sold in imperial sizes, eg 5/32" (which equals 4mm.) This works well enough for timber, but not metals where the small differences can make a significant difference to the fit, eg.when fitting prop shafts to prop tubes.

The next stage was to find a suitable base board upon which the boat would be made. I found a piece of melamine faced chipboard which served the purpose being nicely flat, and strong enough to resist any forces that might arise during construction.

After marking out and cutting the deck it was securely held down to the baseboard with screwed battens.

The keel member was cut out from 6mm ply. Thinner pieces of ply were attached each side of the keel to form the slot for the prop tube and glued into place. I generally used waterproof PVA wood adhesive for these parts.

The eagle eyed will have noticed the slots cut into the bulkheads and the keel which is to house two pieces together whilst keeping their integrity.

The last photo shows the principle bulkheads in place and attached to the deck and the keel. The battens have been re-positioned to lie each side of one of the bulkheads. Small blocks have been glued to the transom and mid section bulkhead to accept the chine rails. Forward of this bulkhead the chines are formed from ply. This is so the sharp curve towards the bows can be achieved.

At the stern the transom has been reinforced with a post, and pieces glued each side of the keel ready to accept the rudder tube. Note that the keel member at the bows has been roughly shaped to the cross section profile.

Everything has to be prepared in readiness for planking at this stage so there is quite a bit of checking and adjusting. This is a small boat, just 21 x 6.5" so accuracy is very important. A lot of time was spent checking and rechecking dimensions and symmetry. More of this later. 😉

▲

⟩⟩

AlessandroSPQR

chugalone100

mturpin013

Norway

dave976

boatmam

Scratchbuilder

RNinMunich

Fred

hermank

MouldBuilder

Colin H

Doogle

|

💬 Re: Sea Plane Tenders 2

1 year ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 133 Views · 1 Like

Flag

Looks like a good start, will keep watching with interest 👍

▲

⟩⟩

AlessandroSPQR

|

United Kingdom

United Kingdom