Join Us On Social Media!

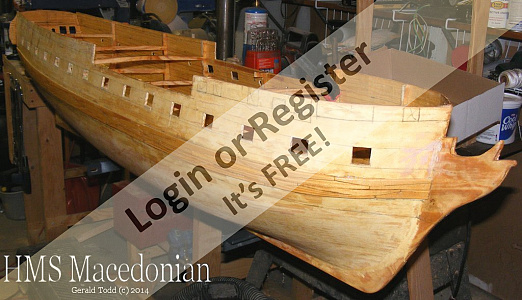

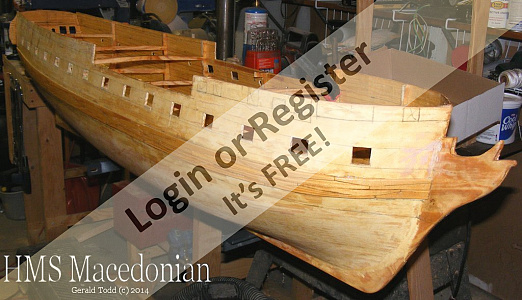

HMS Macedonian: a working RC model in 1:36 scale

14 Posts · 7 Followers · 115 Photos · 113 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 12 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 More details

12 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 19 Views · 2 Likes

Flag

💬 Add Comment

Modeled and printed some gunport lids, cat head cat faces (note these are 1cm sqare, so won't have much detail), and one of 7 sizes of deadeyes.

It might get warm enough to paint a little, or it might blizzard, depends on which channel you watch.

It might get warm enough to paint a little, or it might blizzard, depends on which channel you watch.

▲

⟩⟩

Peejay

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Guns and then some

12 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 3 Likes

Flag

💬 Add Comment

All the guns and carriages needed are printed, a some extras. Also made the ship's wheel from the 3D model of Constellation's wheel.

There's still a bunch of things to model and print; blocks, gunport lids,hearts, bullseyes, fairleads, crew, anchors, and a lot of other stuff.

There's still a bunch of things to model and print; blocks, gunport lids,hearts, bullseyes, fairleads, crew, anchors, and a lot of other stuff.

▲

⟩⟩

Peejay

RNinMunich

luckyduck

📝 Great Guns

12 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 32 Views · 6 Likes

Flag

💬 Add Comment

▲

⟩⟩

Peejay

luckyduck

jumpugly

RNinMunich

hermank

Ray

📝 Printing the Capstan

12 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 35 Views · 6 Likes

Flag

💬 Add Comment

I "test-printed" the capstan and the section of the disks where the sockets for the capstan bars were didn't print. The hole in the bottom capstan didn't go all the way through. So I reworked the disk section of both the upper and lower capstans and printed it again. This time it printed - mostly. The hole in the bottom printed over again (haven't figured that one out) and there were a couple of flaw around some of those sockets (which I'll putty up when paint time comes) It's usable at least and I'm marking it done.

▲

⟩⟩

Peejay

RNinMunich

luckyduck

hermank

Chuck

jumpugly

📝 Capstan

1 year ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 38 Views · 5 Likes

Flag

💬 Add Comment

With the guns done but for printing them, the next item (that my skill set can manage) is the capstan.

I based it on a drawing down-loaded from the National Maritime Museum of the Neptune's Main Capstan as taken off in Depford Yard in 1796.

To save on resin I modeled the main pillar hollow and the spar-deck capstan is removable from the gun-deck one to facilitate installation when the time comes. The length of the pillar under the upper capstan may need to be adjusted to fit it to the model one the decks go in.

So, the thing's nearly done, it still needs pawls and some other details. Since it's something that could be used on other's models, the STL will get posted on Thingiverse when it's done.

I based it on a drawing down-loaded from the National Maritime Museum of the Neptune's Main Capstan as taken off in Depford Yard in 1796.

To save on resin I modeled the main pillar hollow and the spar-deck capstan is removable from the gun-deck one to facilitate installation when the time comes. The length of the pillar under the upper capstan may need to be adjusted to fit it to the model one the decks go in.

So, the thing's nearly done, it still needs pawls and some other details. Since it's something that could be used on other's models, the STL will get posted on Thingiverse when it's done.

▲

⟩⟩

Peejay

RNinMunich

hermank

Chuck

Mike Stoney

📝 Test prints

1 year ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 47 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Test printed a few of each gun, need to tweak the supports and angles, and wait for a new bottle of resin, then I'll start full production

▲

⟩⟩

Peejay

RNinMunich

hermank

Mike Stoney

MartyV

jumpugly

SimpleSailor

|

💬 Re: Test prints

1 year ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 46 Views · 3 Likes

Flag

They are awesome Terry!!!

▲

⟩⟩

Peejay

hermank

Mike Stoney

|

📝 Guns! Guns! Guns!

1 year ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 51 Views · 8 Likes

Flag

💬 Add Comment

The 3D modeling software I've used since the early 90's isn't really up to task for making the ornate carvings need for Macedonian's stern, or Constellation's head, and learning Blender ; but I'm pretty good now at making cannons. 😉

Macedonian's battery will consist of 22 carronades on the spar-deck and 28 long 18 pounder guns on the gun-deck, plus 2 or 4 18 pdr chasers probably. I started these a while back and had some basic models made up that needed finishing. Winter keeps me out of the shop, so it's 3D Modelling Season!

The pictures show the models in Anim8or, the modeling software I use; In the "slicer" which slices them into strata for printing, and some of the photos I used as guides; 18 pounders of HMS Unicorn and carronades of HMS Trincomalee.

As I type, the models are printing and the STL files are available on my Thingiverse page:

Macedonian's battery will consist of 22 carronades on the spar-deck and 28 long 18 pounder guns on the gun-deck, plus 2 or 4 18 pdr chasers probably. I started these a while back and had some basic models made up that needed finishing. Winter keeps me out of the shop, so it's 3D Modelling Season!

The pictures show the models in Anim8or, the modeling software I use; In the "slicer" which slices them into strata for printing, and some of the photos I used as guides; 18 pounders of HMS Unicorn and carronades of HMS Trincomalee.

As I type, the models are printing and the STL files are available on my Thingiverse page:

▲

⟩⟩

RNinMunich

hermank

Mike Stoney

SimpleSailor

MouldBuilder

EdW

Peejay

jumpugly

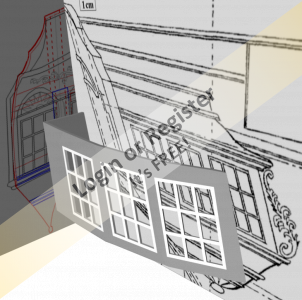

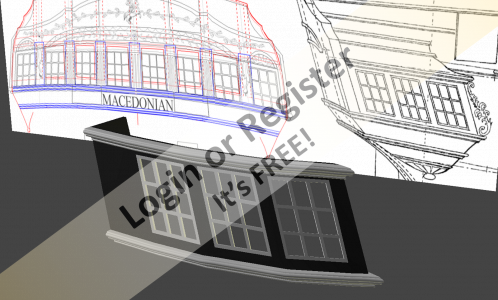

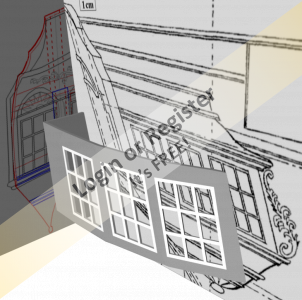

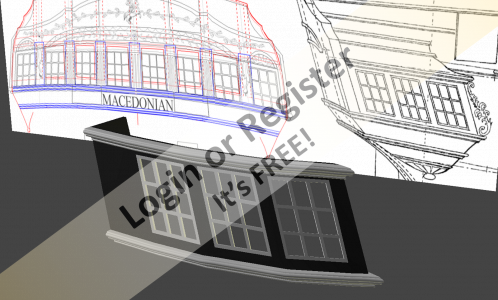

📝 The Stern and Quarter Galleries

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 10 Likes

Flag

💬 Add Comment

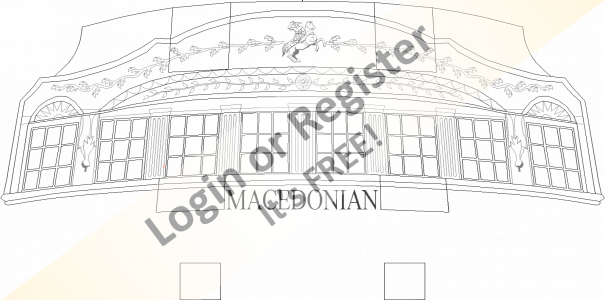

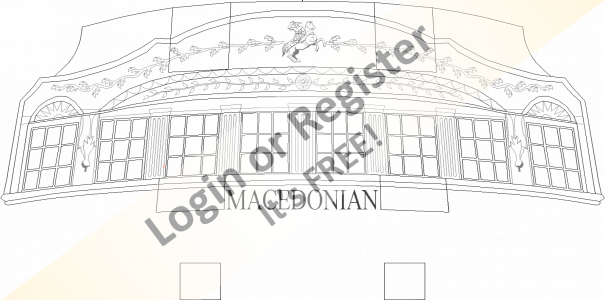

I was working on the stern and quarter galleries separately, but reconciling the sides with the back was making my brain itch, so I made it all one model, which helped, and didn't.

To create a base to work from, I'm going to 3D model the aft 15cm or so of the physical hull down to the waterline, hoping that will make it all the right size and fit.

The transom at the widest part is about 27cm across and some 10cm tall, which won't fit in the printer, so I'll be dividing it into parts that"ll assemble on the model's wooden transom, with the quarter galleries as separate pieces.

To create a base to work from, I'm going to 3D model the aft 15cm or so of the physical hull down to the waterline, hoping that will make it all the right size and fit.

The transom at the widest part is about 27cm across and some 10cm tall, which won't fit in the printer, so I'll be dividing it into parts that"ll assemble on the model's wooden transom, with the quarter galleries as separate pieces.

▲

⟩⟩

RNinMunich

hermank

Chuck

Mike Stoney

EdW

Len1

Colin H

Ronald

Peejay

jumpugly

📝 Macedonian: More details and 3D printing

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 73 Views · 15 Likes · 1 Comment

Flag

💬 Add Comment

There's always long gaps in working on my models. Life just gets in the way for long periods sometimes. Poor Macedonian is always in third place for attention behind Constellation and Pride of Baltimore. But, every now and then, I devote myself to Macedonian alone, and even get some work done.

As my next way-point, I would really like to get the hull to the point of painting, but there's a lot to get onto it before that can happen.

One item are the channels. These I made of aircraft plywood, but I feel they may be too thin, and maybe the wrong shape in cross-section. So I moved onto the quarter galleries. I decided to build them up right on the hull, but I'm not to happy with those either.

I ground the edge of a utility blade to make a scraper to shape the moldings with, but the pine is just too soft to get the appearance I want, so I'm going to pull that off when I find better wood to make them from.

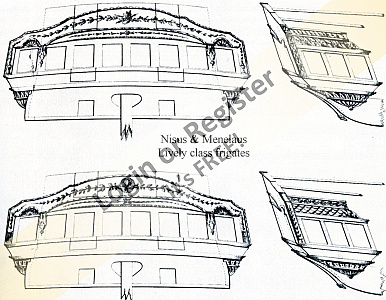

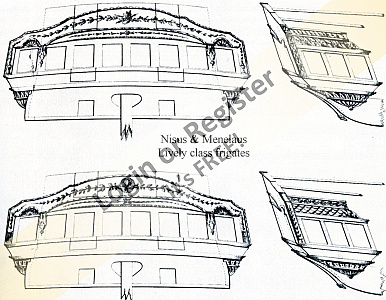

I have no solid evidence how Macedonian actually looked, in particular, her stern. In paintings there are no two alike, nor is any useful detail shown. Where you can see it, such as in Gardner's paintings of her fight with the United States, you can see much and what's visible is generic at best. I do have sketches of two other Lively class ship's stern decorations, so based on those, and the styles of other frigate sterns I could find pictures of, I developed my own Alexander the Great themed stern. At this point, I'm heavily leaning towards 3D printing the entire transom, moldings, carvings, window frames, and all; including the quarter galleries. I'll print it in several parts and simply epoxy right onto the existing wooden transom, which needs to be thicker anyway.

Moving to the bow, Macedonian's alleged "original" figurehead exist today at the US Naval Academy in Annapolis Maryland. I say alleged because compared to other figureheads of British warships, this one looks more like a caricature of actor Michael J. Pollard.

Years ago, someone digitally scanned the figurehead, contacted me, and offered to 3D print a model for a mere $300 US. I felt that was a bit much for a 6 or 7cm tall bust, so I passed. When I was able to 3D print myself, I contacted them again hoping to get a copy of the STL file, but they hemmed and hawed about copyrights and other nonsense (I think they actually lost the file). So, while the figurehead at the Naval Academy may actually be Macedonian's figurehead, I figure it was damaged in the fight with United States, and the American sailor that repaired it, put his own "touches" to the job. Basically, I don't think it originally looked like that. Online, I found a 3D file from someone who scanned a bust of Alexander the Great in a museum in Europe somewhere. I know of several figureheads said to be based on classical statues, and this one was the same general style as the figurehead and around early enough for someone to have sketched it back then for the carver to reference, ie; I think this is probably closer to what the Macedonian's figurehead looked like before the big American frigate bow-raked her and took off a big chunk of his head.

Speaking of 3D printing... I got into resin printing with the intent purpose of making parts for ship models. The figurehead, decorative carvings, guns, crew figures and so on. I originally bought 5 3D printed 18 pounder Blomefield guns, and 5 32 pounder Carronades with the intention of making molds and casting the rest needed in resin. Having a printer of my own means I can print all the guns I need myself.

The trick to 3D printing is having the digital 3D model to print - you can't print a letter till you type it. You can see a lot of stuff's been printed for Constellation over in that build-blog. Here, so far, besides a test print of Alex's head, and a couple of guns, I made and printed the ship's stove.

I learned that from the 1780's to 1810, the most common type of stove on British warships was the Brodie type, which supplanted what was known as the Firehearth. In 1810 stoves by Lamb & Nicholson were taking over in place of the Brodies; but I have yet to find any information; drawing, photos, models, or even a description of a L&N stove. Macedonian was launched in June of 1810 and I'm sure her stove was requisitioned well before then, so was most probably a Brodie type. Anyway, that's the course I steered. In The Arming and Fitting of English Ships of War by Brian Lavery, on page 198, was a chart showing stove dimensions for various ships based on gun rating and I based my model on the sizes for a 38 gun frigate. (The figures in the pic with the stove are Constellation's crew, and not 1812 period)

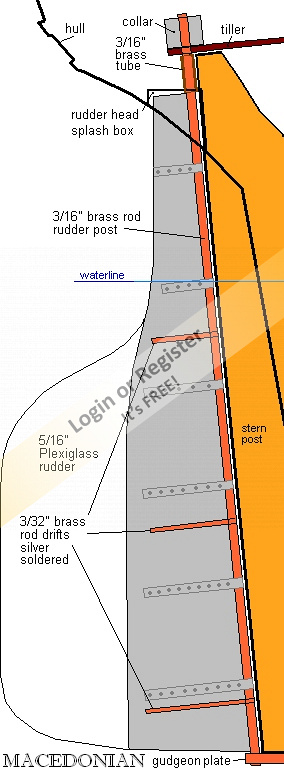

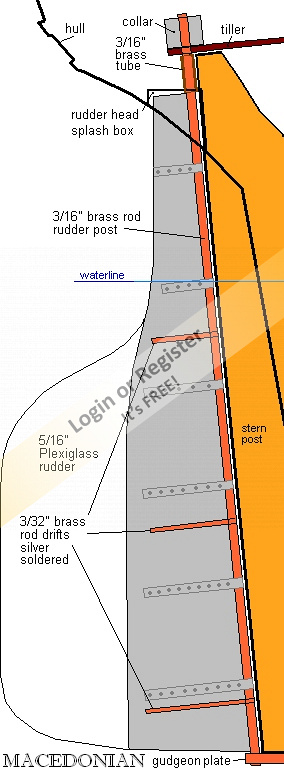

The drawing of the rudder attached here, shows how it will be made from Plexiglass and brass rod. The "extension" to increase it's area is left clear, and is not removable, though the entire rudder IS removable. Side pieces in the shape of the scale rudder are glued to either side, and will be coppered like the bottom.

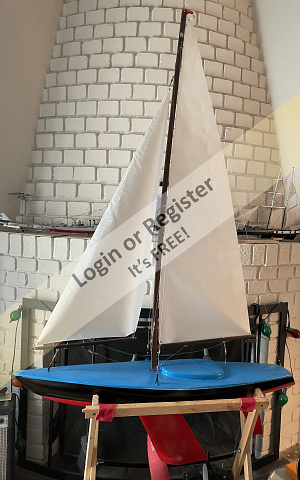

The hull's be taken out on display a couple of times, one time even getting in the pool for her first ever swim.

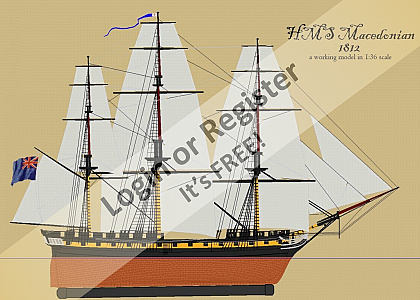

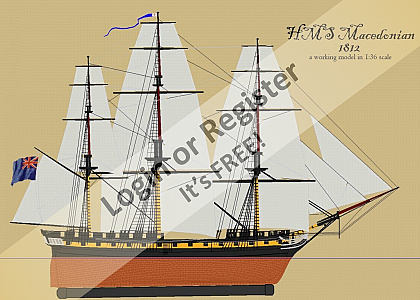

Another attached drawing shows her sail plan based on a drawing of another frigate, proportion-wise. Her external ballast is also shown. Constellation uses a 2 inch ID PVC pipe filled with 000 lead shot and weighing about 42 pounds for ballast. It's held to the model by 2 5/16" stainless steel threaded rod inside aluminum tubes in the hull. I need to install such tubes in Macedonian, and the plan is to place them so she can use Constellation's ballast, though I may make Macedonian her own so the two models can sail together.

As for the sails and rig. History of the American Sailing Navy has spar dimensions for Macedonian taken in 1818. Obviously this is how the Americans re-rigged her to their standard, and not how she was rigged before her capture, so, for me, they're meaningless. I haven't found any direct reference for her spars and sails, or for any other Lively class frigate either, but I have some "standard" numbers for different rates of ships. The problem there is it's dated a decade before the Lively's and even 38 gun ships were a little smaller than the Lively class boats then. I've plugged these numbers into a spread sheet, and came up with something of a compromise between Steel's 38 and 40 gun ships specs and Trincomalee, a Leda class 38 existing in Hartlepool today. So far, I've made the built-up lower masts for the model, save the bowsprit.

There will be a lot of 3D printed items going into the model; all of her guns, boats, fittings, carvings, crew figures, figurehead, and anything else I can think of and can manage to digitally model myself.

As my next way-point, I would really like to get the hull to the point of painting, but there's a lot to get onto it before that can happen.

One item are the channels. These I made of aircraft plywood, but I feel they may be too thin, and maybe the wrong shape in cross-section. So I moved onto the quarter galleries. I decided to build them up right on the hull, but I'm not to happy with those either.

I ground the edge of a utility blade to make a scraper to shape the moldings with, but the pine is just too soft to get the appearance I want, so I'm going to pull that off when I find better wood to make them from.

I have no solid evidence how Macedonian actually looked, in particular, her stern. In paintings there are no two alike, nor is any useful detail shown. Where you can see it, such as in Gardner's paintings of her fight with the United States, you can see much and what's visible is generic at best. I do have sketches of two other Lively class ship's stern decorations, so based on those, and the styles of other frigate sterns I could find pictures of, I developed my own Alexander the Great themed stern. At this point, I'm heavily leaning towards 3D printing the entire transom, moldings, carvings, window frames, and all; including the quarter galleries. I'll print it in several parts and simply epoxy right onto the existing wooden transom, which needs to be thicker anyway.

Moving to the bow, Macedonian's alleged "original" figurehead exist today at the US Naval Academy in Annapolis Maryland. I say alleged because compared to other figureheads of British warships, this one looks more like a caricature of actor Michael J. Pollard.

Years ago, someone digitally scanned the figurehead, contacted me, and offered to 3D print a model for a mere $300 US. I felt that was a bit much for a 6 or 7cm tall bust, so I passed. When I was able to 3D print myself, I contacted them again hoping to get a copy of the STL file, but they hemmed and hawed about copyrights and other nonsense (I think they actually lost the file). So, while the figurehead at the Naval Academy may actually be Macedonian's figurehead, I figure it was damaged in the fight with United States, and the American sailor that repaired it, put his own "touches" to the job. Basically, I don't think it originally looked like that. Online, I found a 3D file from someone who scanned a bust of Alexander the Great in a museum in Europe somewhere. I know of several figureheads said to be based on classical statues, and this one was the same general style as the figurehead and around early enough for someone to have sketched it back then for the carver to reference, ie; I think this is probably closer to what the Macedonian's figurehead looked like before the big American frigate bow-raked her and took off a big chunk of his head.

Speaking of 3D printing... I got into resin printing with the intent purpose of making parts for ship models. The figurehead, decorative carvings, guns, crew figures and so on. I originally bought 5 3D printed 18 pounder Blomefield guns, and 5 32 pounder Carronades with the intention of making molds and casting the rest needed in resin. Having a printer of my own means I can print all the guns I need myself.

The trick to 3D printing is having the digital 3D model to print - you can't print a letter till you type it. You can see a lot of stuff's been printed for Constellation over in that build-blog. Here, so far, besides a test print of Alex's head, and a couple of guns, I made and printed the ship's stove.

I learned that from the 1780's to 1810, the most common type of stove on British warships was the Brodie type, which supplanted what was known as the Firehearth. In 1810 stoves by Lamb & Nicholson were taking over in place of the Brodies; but I have yet to find any information; drawing, photos, models, or even a description of a L&N stove. Macedonian was launched in June of 1810 and I'm sure her stove was requisitioned well before then, so was most probably a Brodie type. Anyway, that's the course I steered. In The Arming and Fitting of English Ships of War by Brian Lavery, on page 198, was a chart showing stove dimensions for various ships based on gun rating and I based my model on the sizes for a 38 gun frigate. (The figures in the pic with the stove are Constellation's crew, and not 1812 period)

The drawing of the rudder attached here, shows how it will be made from Plexiglass and brass rod. The "extension" to increase it's area is left clear, and is not removable, though the entire rudder IS removable. Side pieces in the shape of the scale rudder are glued to either side, and will be coppered like the bottom.

The hull's be taken out on display a couple of times, one time even getting in the pool for her first ever swim.

Another attached drawing shows her sail plan based on a drawing of another frigate, proportion-wise. Her external ballast is also shown. Constellation uses a 2 inch ID PVC pipe filled with 000 lead shot and weighing about 42 pounds for ballast. It's held to the model by 2 5/16" stainless steel threaded rod inside aluminum tubes in the hull. I need to install such tubes in Macedonian, and the plan is to place them so she can use Constellation's ballast, though I may make Macedonian her own so the two models can sail together.

As for the sails and rig. History of the American Sailing Navy has spar dimensions for Macedonian taken in 1818. Obviously this is how the Americans re-rigged her to their standard, and not how she was rigged before her capture, so, for me, they're meaningless. I haven't found any direct reference for her spars and sails, or for any other Lively class frigate either, but I have some "standard" numbers for different rates of ships. The problem there is it's dated a decade before the Lively's and even 38 gun ships were a little smaller than the Lively class boats then. I've plugged these numbers into a spread sheet, and came up with something of a compromise between Steel's 38 and 40 gun ships specs and Trincomalee, a Leda class 38 existing in Hartlepool today. So far, I've made the built-up lower masts for the model, save the bowsprit.

There will be a lot of 3D printed items going into the model; all of her guns, boats, fittings, carvings, crew figures, figurehead, and anything else I can think of and can manage to digitally model myself.

▲

⟩⟩

RNinMunich

hermank

Ray

Chuck

Mike Stoney

SimpleSailor

Colin H

roycv

EdW

Len1

Kennybeck

GaryLC

jumpugly

Peejay

AlessandroSPQR

|

💬 Re: More details and 3D printing

2 years ago by 🇺🇸 Hhager2 (

Sub-Lieutenant) Sub-Lieutenant)✧ 65 Views · 6 Likes

Flag

Impressive research n ship. You must have lots of patience. I build planes as well and military ships but even a plastic HMS Victory 1:180 scale is frustrating enough. Pic part built not painted yet I can’t wait for rigging frustration. Masts not glued in nor rear deck. It’s just a kit I bought to keep me from getting bored while visiting Hollywood. Like my Rc sail boat better.

▲

⟩⟩

Peejay

hermank

Chuck

Mike Stoney

Colin H

EdW

|

📝 Macedonian: Wale Ho!

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 74 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

I made a technical screw-up here. The main wale should be "anchor-stock" planked; additional wales, are "top and butt" planked. I don't know why, but I used top and butt planks for Macedonian's wales, and was mostly done before I realized my error. I'll just have to hang my head and take it when some rivet-counter comes along and berates me for it.

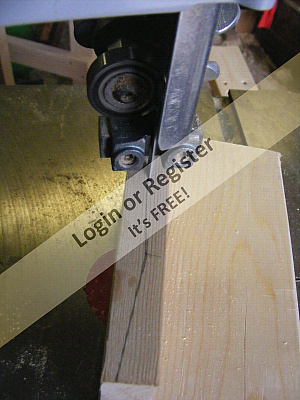

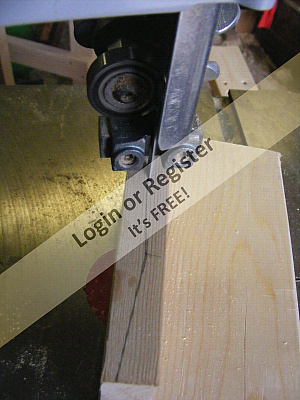

At any rate... Back to the old white pine again, where I sawed out the shape from the edge of the board, then sliced off the planks, one by one. These got applied to the hull with gel CA. At the hard bends, like in the bow, they are dipped in ammonia and clamped in a makeshift jig to bend them to shape. It's not difficult, but I went through a lot of latex gloves working with CA, and since I'm not a fan of jig-saw puzzles, it was a bit tedious. On this model the wales are mostly decorative, added because the real ship had them and without them you'd think something was missing, even if you didn't know what.

Once the wales were on, they were puttied, sanded, planed, and epoxied. A friend and I were building a boat in my yard then, and the hull got a bit of epoxy brushed on, or poured into the nooks and crannies in the hull when ever there was some left over.

I cut out the gunports in the usual way, drill a hole big enough for a sabre-saw blade to fit into and go to town with the saw, carefully.

The hull is only as thick as it's planking, which is an issue at the gun ports and such. Basically I need to frame around the gunports not only to get the right hull thicknesses, but some of tis framing peeks into the port, forming a ledge for the gunport lids to close against.

That's another of those puzzles I'm not so fond of, and I haven't determined yet how I'm going to go about it. The shape of the hull is what comes into play here, so I have to cut the side pieces for each gunport to shape; clamp an ammonia-dipped wood piece in place to take the shape, or even 3D print gunport frames custom made to fit each one. When I figure it out, I'll be sure to post that adventure here for you to follow. 😉

All this started back in the middle of November of 2011. The last picture ( I hope that's where it is) is a close-up of the fore-foot of the hull taken in early October, 2012. Being a wood hull, and kept out in my unheated/uncooled shop, the wood will move with temperature and humidity. If you look closely at the photo, there's a dark line along a seam - a crack! This is why I glass my hulls, at least on the outside, and coat them in resin on the inside. If any wood in the hull gets wet, it will swell, when, if it dries, it will shrink. This will cause seams to open, things to come loose, plywood to delaminate, mold and rot to take hold, and turn all your hard work to trash.

Glass cloth is to resin what rebar is to concrete. A wood hull like this doesn't need glass cloth to play that part, the planking is structural enough for that on it's own, but wood "moves" more than glass, and so the glass acts a bit like shrink-wrap, holding the wood to it's job. Plainly put - paint ain't enough!

Also, when ever something is going through the hull, like a prop-shaft for instance, I drill the hole over-sized and fill it with epoxy. When that's set-up, drill the proper sized hole in the epoxy. This way there's no bare wood that water can get too. This model will get holes drilled through the keel for rods that will hold the external ballast to the hull; that will be done in just the manner described.

At any rate... Back to the old white pine again, where I sawed out the shape from the edge of the board, then sliced off the planks, one by one. These got applied to the hull with gel CA. At the hard bends, like in the bow, they are dipped in ammonia and clamped in a makeshift jig to bend them to shape. It's not difficult, but I went through a lot of latex gloves working with CA, and since I'm not a fan of jig-saw puzzles, it was a bit tedious. On this model the wales are mostly decorative, added because the real ship had them and without them you'd think something was missing, even if you didn't know what.

Once the wales were on, they were puttied, sanded, planed, and epoxied. A friend and I were building a boat in my yard then, and the hull got a bit of epoxy brushed on, or poured into the nooks and crannies in the hull when ever there was some left over.

I cut out the gunports in the usual way, drill a hole big enough for a sabre-saw blade to fit into and go to town with the saw, carefully.

The hull is only as thick as it's planking, which is an issue at the gun ports and such. Basically I need to frame around the gunports not only to get the right hull thicknesses, but some of tis framing peeks into the port, forming a ledge for the gunport lids to close against.

That's another of those puzzles I'm not so fond of, and I haven't determined yet how I'm going to go about it. The shape of the hull is what comes into play here, so I have to cut the side pieces for each gunport to shape; clamp an ammonia-dipped wood piece in place to take the shape, or even 3D print gunport frames custom made to fit each one. When I figure it out, I'll be sure to post that adventure here for you to follow. 😉

All this started back in the middle of November of 2011. The last picture ( I hope that's where it is) is a close-up of the fore-foot of the hull taken in early October, 2012. Being a wood hull, and kept out in my unheated/uncooled shop, the wood will move with temperature and humidity. If you look closely at the photo, there's a dark line along a seam - a crack! This is why I glass my hulls, at least on the outside, and coat them in resin on the inside. If any wood in the hull gets wet, it will swell, when, if it dries, it will shrink. This will cause seams to open, things to come loose, plywood to delaminate, mold and rot to take hold, and turn all your hard work to trash.

Glass cloth is to resin what rebar is to concrete. A wood hull like this doesn't need glass cloth to play that part, the planking is structural enough for that on it's own, but wood "moves" more than glass, and so the glass acts a bit like shrink-wrap, holding the wood to it's job. Plainly put - paint ain't enough!

Also, when ever something is going through the hull, like a prop-shaft for instance, I drill the hole over-sized and fill it with epoxy. When that's set-up, drill the proper sized hole in the epoxy. This way there's no bare wood that water can get too. This model will get holes drilled through the keel for rods that will hold the external ballast to the hull; that will be done in just the manner described.

▲

⟩⟩

RNinMunich

Chuck

Mike Stoney

SimpleSailor

Colin H

EdW

hermank

Peejay

|

💬 Re: Wale Ho!

2 years ago by 🇨🇦 RossM (

Captain) Captain)✧ 72 Views · 2 Likes

Flag

Thanks for the heads-up about through-hull holes, and glass cloth

▲

⟩⟩

Peejay

Mike Stoney

|

United States

United States