Join Us On Social Media!

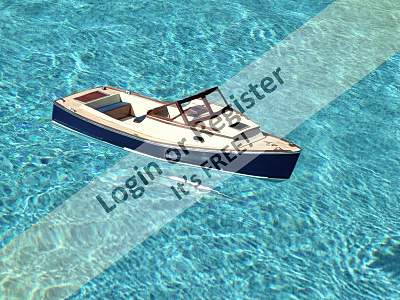

Lindsay M a scratch built Wasque 26 ft

27 Posts · 11 Followers · 54 Photos · 199 Likes

Began 8 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 15 days ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 South Florida Boatyard re-opens

15 days ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 31 Views · 9 Likes · 7 Comments

Flag

💬 Add Comment

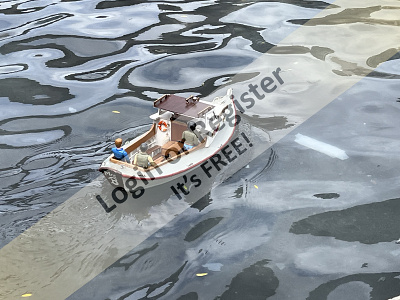

Warm enough to send the Lindsay M on her maiden voyage.

- I thought it would be too slow…it was.

- Limited rudder throw looked like turning radius

would be excessive…it wasn’t

- No leaks expected…none showed up.

- I thought it would be too slow…it was.

- Limited rudder throw looked like turning radius

would be excessive…it wasn’t

- No leaks expected…none showed up.

▲

⟩⟩

Mike Stoney

Ronald

LewZ

hermank

AlessandroSPQR

chugalone100

DWBrinkman

jumpugly

ChrisF

|

💬 Re: South Florida Boatyard re-opens

14 days ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 24 Views · 2 Likes

Flag

|

|

Login To

Remove Ads 💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 22 Views · 1 Like

Flag

Thank you Lew. It has been uncharacteristically cool in Naples also. Not complaining though; still single digit low temps at home on Cape Cod.

My sailing has been limited to the condo community’s pool. It’s a small community & everyone is very interested in the boats, how they were built, how they work, & seeing them run. I only launch when no one is in the pool & make it clear I will beach it whenever someone wants to get it in the water. My boats are not fast. I understand there is a park a few miles from here where folks sail. I intend to check it out but haven’t as yet, ▲

⟩⟩

hermank

|

|

💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 29 Views · 2 Likes

Flag

Chum... you are a little south of me. Been a little too cool up here (Tampa Bay area) especially for MB meets. Had a few tank meets though. Glad you first run was a success. Where do you sail?

Lew ▲

⟩⟩

Chum444

hermank

|

|

💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 28 Views · 2 Likes

Flag

Thank you DWB. It’s been a fun build. I always enjoy it when the builder, in this case, CW Hood of Marblehead, Ma, gets involved. They provided me with the lines & other much appreciated advice to complete the build.

No’gators, or falling iguanas today! 😂 ▲

⟩⟩

hermank

AlessandroSPQR

|

|

💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 DWBrinkman (

Commodore) Commodore)✧ 27 Views · 3 Likes

Flag

Chum,

Great boat! It looks fantastic on the water. Those (manmade) Florida Caribbean Seas are beautiful, and no worry about Gators! Dave ▲

⟩⟩

hermank

AlessandroSPQR

Chum444

|

|

💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 29 Views · 2 Likes

Flag

Thank you Jump. I’ve got a few things to straighten out it I’m happy with the maiden splash.

▲

⟩⟩

hermank

AlessandroSPQR

|

|

💬 Re: South Florida Boatyard re-opens

15 days ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 34 Views · 3 Likes

Flag

She's a Beauty Chum!!!!!

😊 ▲

⟩⟩

hermank

AlessandroSPQR

Chum444

|

Login To

Remove Ads

Remove Ads

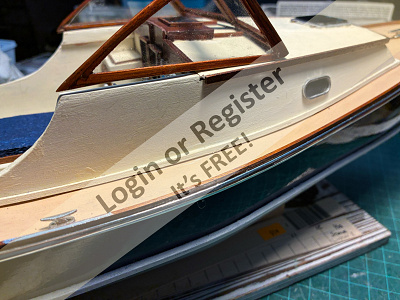

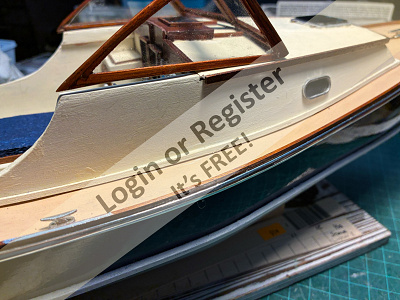

📝 A bit more final finishing.

2 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 55 Views · 8 Likes · 3 Comments

Flag

💬 Add Comment

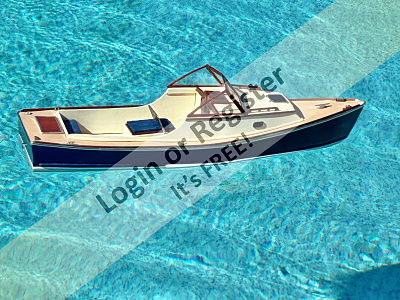

Most of final details completed prior to shipping boat to Florida for maiden voyage.🤞🤞🤞

Then finish up punch list.

Then finish up punch list.

▲

⟩⟩

Mike W

DWBrinkman

chugalone100

hermank

Ronald

PhilH

EdW

RNinMunich

|

💬 Re: A bit more final finishing.

2 months ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 53 Views · 1 Like

Flag

Ah, time to break the ice. None here. 10 days to go until Christmas and I was outside in a tee shirt running tanks. Next week is boats.

Lew Clearwater, Florida ▲

⟩⟩

hermank

|

|

Login To

Remove Ads 💬 Re: A bit more final finishing.

2 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 53 Views · 1 Like

Flag

Thank you Phil. The boat will go to Florida with the builder who escapes the New England winters for three months. In the past my wife & I enjoyed the snow & winter sports but age caught up with us so skiing is no longer an option.

As mentioned earlier in this thread I usually do the maiden voyage early in the build. But rehabbing from knee surgery prevented that. So I will use the large test tank ( the condo association’s pool) for the first splash. Thus the crossed fingers. ▲

⟩⟩

hermank

|

|

💬 Re: A bit more final finishing.

2 months ago by 🇬🇧 PhilH (

Lieutenant Commander) Lieutenant Commander)✧ 48 Views · 2 Likes

Flag

Being nosey why are you shipping it to florida boat looks good mate

Philuk👍 ▲

⟩⟩

hermank

BOATSHED

|

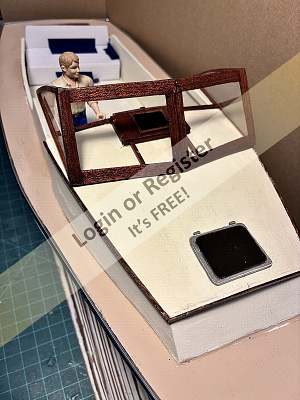

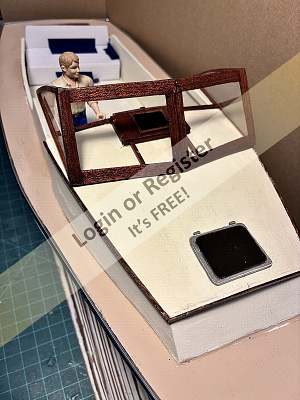

📝 Details, details, details

3 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 59 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

The helm.

Looking aft at the cockpit

Motor box & stern seat.

Overall view of cockpit,

Clamshell vents for circulating air thru bilge.

Cabin porthole.

Cleat & fairleads on foredeck.

Looking aft at the cockpit

Motor box & stern seat.

Overall view of cockpit,

Clamshell vents for circulating air thru bilge.

Cabin porthole.

Cleat & fairleads on foredeck.

▲

⟩⟩

Ronald

Mike W

chugalone100

ChrisF

PhilH

EdW

AlessandroSPQR

hermank

|

💬 Re: Details, details, details

3 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 53 Views · 2 Likes

Flag

I really like this Chum setup.

▲

⟩⟩

hermank

Chum444

|

📝 Continuing with details

4 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 73 Views · 11 Likes · 6 Comments

Flag

💬 Add Comment

- Trunk cabin hatch & companionway hatch to

cabin in place.

- Chrome rub rail & stern hatch, access to

rudder post, added.

- Companionway doors installed. Helm details

started.Typical tight fit on 26 ft boat.

cabin in place.

- Chrome rub rail & stern hatch, access to

rudder post, added.

- Companionway doors installed. Helm details

started.Typical tight fit on 26 ft boat.

▲

⟩⟩

Mike W

chugalone100

zooma

AlessandroSPQR

Ronald

peterd

robbob

hermank

EdW

thadlietz

jumpugly

|

💬 Re: Continuing with details

4 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 64 Views · 2 Likes

Flag

Those boats look some fine Ronald. Do you have build logs for them herein? Tx for the info for figures; they’re never easy to find.

▲

⟩⟩

hermank

Ronald

|

|

Login To

Remove Ads |

|

💬 Re: Continuing with details

4 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 73 Views · 1 Like

Flag

The 3m77 will cure permanently after 20 minutes or so. However, there’s a product called Easy Tack by Krylon that’s supposedly removable.. Amazon wants 20 bucks, probably get it cheaper in some other stores.

Cash ▲

⟩⟩

hermank

|

|

💬 Re: Continuing with details

4 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 73 Views · 3 Likes

Flag

Thank you Cash. I used Elmer’s which was impossible to peal off the frames. Do you know if the glue you referenced is still on the market.?

Even though I glued the frame drawings to the ply I have to be a LOT more careful cutting them out. I thought I was being precise but not. For next scratch build I will probably contract for laser cutting. Bill ▲

⟩⟩

hermank

Cashrc

jumpugly

|

|

💬 Re: Continuing with details

4 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 73 Views · 4 Likes

Flag

Got a look at this late. She’s looking real nice Bill, good work on a great subject. I like how you cut the frames out with the plan’s attached. That is some old school building. I did something similar when I was building old timer model airplanes, I’d use 3M77 to glue the patterns to wood, then peel them off before I permanently glued the part in place. I like your work sir.

Cash ▲

⟩⟩

hermank

jumpugly

RodC

Chum444

|

📝 Continuing progress

5 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 79 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

I’ve been making the cockpit sole, etc removable to provide access to running gear & bilge. This all because the 26’s bottom has not yet been wetted so I have no idea what might be amiss & require fixing or replacement

Spray rails glued & pinned to hull.

Decided on a bit of color change for deck.

Cockpit details begun; the fun stuff.

Owner anxious for first boat ride.

Spray rails glued & pinned to hull.

Decided on a bit of color change for deck.

Cockpit details begun; the fun stuff.

Owner anxious for first boat ride.

▲

⟩⟩

Ronald

peterd

EdW

hermank

|

💬 Re: Continuing progress

5 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 79 Views · 1 Like

Flag

Thank you Bob. The windscreen proved to be quite a challenge given that it took over 30 pieces to construct. Should have constructed a fixture…..oh well!

On another note I hope your offset rudder solves your Kommander handling issue. Watching your video I see you were not running as fast as I had assumed. The wake also looked flat as it should. Tells me that prop walk(torque) is the issue assuming your prop is a right hand prop. Hopefully I’m wrong but offsetting the rudder will reduce/solve the diving problem in right turns but will show up somewhere else. The reduced & asymmetrical water pressure on the rudder may make left turns a problem. Left turn radius could become impossibly large & tracking straight may be difficult. Anyway I’ll be watching to see how you make out.🤞 ▲

⟩⟩

hermank

|

|

💬 Re: Continuing progress

5 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 80 Views · 1 Like

Flag

That is coming along very nicely - I do like the windscreen shape that you have made.

I made something "similar" for the Chris Craft Corvette that I restored and I am thinking about making something like it for my Swordsman to replace the plain wrap-around screen too. Bob. ▲

⟩⟩

hermank

|

📝 Some progress

5 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 81 Views · 6 Likes

Flag

💬 Add Comment

Well, it’s been tack glue, marking fit pieces to fit, remove, cut, re-tack glue to check fit, & repeat! For next scratch build I need to improve cutting accuracy for bulkheads, gunnel support, etc. Same for applying epoxy sealer in hull interior. Kind of slopped epoxy blobs onto gluing surfaces. *#*”#!

Photos

Sprayed cockpit sides with ammonia based

window cleaner, clamped to gunnel, & left to sit

overnight. Will reduce tensile stress on joints

when finally glued in place.

Motor box fabricated. Servo will be hidden by

removable aft seat.

Owner is anxious for a boat ride but yard

schedule indicates that is in the distance.

Photos

Sprayed cockpit sides with ammonia based

window cleaner, clamped to gunnel, & left to sit

overnight. Will reduce tensile stress on joints

when finally glued in place.

Motor box fabricated. Servo will be hidden by

removable aft seat.

Owner is anxious for a boat ride but yard

schedule indicates that is in the distance.

▲

⟩⟩

Ronald

chugalone100

EdW

LeeA

thadlietz

hermank

📝 Windscreen

6 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 85 Views · 8 Likes · 2 Comments

Flag

💬 Add Comment

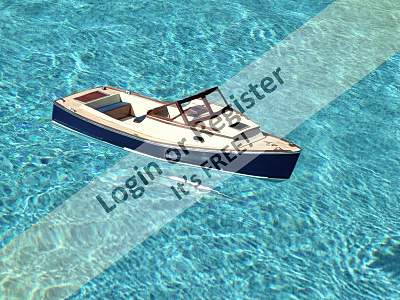

Finally can see the light at the end of the tunnel! So far, excluding the windows, the windscreen required 34 pieces to construct. Maybe one more sanding with 500 grit paper & one more coat of gloss clear. Then the windows & figuring out how to attach the screen to the hull in a way that is removable with the trunk cabin.

▲

⟩⟩

chugalone100

premecekcz

thadlietz

hermank

EdW

AlessandroSPQR

Commodore-H

jumpugly

|

💬 Re: Windscreen

6 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 84 Views · 3 Likes

Flag

I like the hull line and the color you chose, Chum.

▲

⟩⟩

LeeA

hermank

Chum444

|

|

💬 Re: Windscreen

6 months ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 84 Views · 3 Likes

Flag

Very sharp Chum!

👍👍👍 ▲

⟩⟩

hermank

AlessandroSPQR

Chum444

|

📝 Windscreen

6 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 88 Views · 8 Likes

Flag

💬 Add Comment

So far a week’s work on the windscreen. Fiddly work with 18 individual pieces & more to come. Gaining on it!

▲

⟩⟩

Ronald

chugalone100

premecekcz

hermank

Commodore-H

EdW

jumpugly

thadlietz

📝 Windscreen fabrication

6 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 92 Views · 8 Likes · 2 Comments

Flag

💬 Add Comment

The next gating item in my modified build sequence is the windscreen. Its exact size, shape, & location determines how I fabricate the trunk cabin roof. Specifically how much of it can be made removable to access the motor, ESC, the drive coupling. The more course mahogany grain renders it much less flexible than basswood for bending.

▲

⟩⟩

EdW

hermank

Commodore-H

jumpugly

ChrisF

PhilH

thadlietz

AlessandroSPQR

|

💬 Re: Windscreen fabrication

6 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 89 Views · 2 Likes

Flag

Phil,

Fortunately the pieces I am using are small in cross section so they can be bent (carefully) after a quick soaking in ammonia based window cleaner. The two side pieces are the main challenge. The next issue is how to attach it to the hull so it is has some structural integrity to prevent it from being easily knocked off. The glazing will provide some rigidity but not to the degree that satisfies me. Haven’t thought this one through as yet. ▲

⟩⟩

hermank

AlessandroSPQR

|

|

💬 Re: Windscreen fabrication

6 months ago by 🇬🇧 PhilH (

Lieutenant Commander) Lieutenant Commander)✧ 92 Views · 2 Likes

Flag

Hi one of those many problems we have to over come I'm modeling ,could you use other wood type with saple veneer over when bent to shape?.

Philuk👍 ▲

⟩⟩

hermank

Chum444

|

📝 No maiden voyage as yet.

6 months ago by 🇺🇸 Chum444 ( Commodore)

Commodore)

Commodore)

Commodore)✧ 95 Views · 6 Likes

Flag

💬 Add Comment

Since I don’t want to get kicked off the property that has my test pond I have to wait until the residents have mostly finished their use of the beach. That has gotten me out of sync with my usual build sequence.

I’ve been working toward cockpit templates for future construction. Photo shows a bit of how the finished cockpit will look. Cutting card stock much easier than wood or styrene. One thing becomes apparent; the engine cover box mock-up is oversized.

I’ve been working toward cockpit templates for future construction. Photo shows a bit of how the finished cockpit will look. Cutting card stock much easier than wood or styrene. One thing becomes apparent; the engine cover box mock-up is oversized.

▲

⟩⟩

Ronald

EdW

thadlietz

AlessandroSPQR

hermank

jumpugly

United States

United States