Join Us On Social Media!

Constellation

75 Posts · 20 Followers · 745 Photos · 479 Likes

Began 9 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Do and Redo

6 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 17 Views · 5 Likes · 1 Comment

Flag

💬 Add Comment

Painted the printed grating a more oakish color, but not really matching the wood gratings I made. then I had to chop off some of the head gratings to bet the bowsprit by. Not really happy with any of that, but fixing it will have to wait as I'm gonna be traveling away from home for a bit.

I started painting the hammocks on the portside.

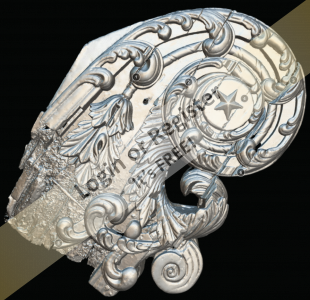

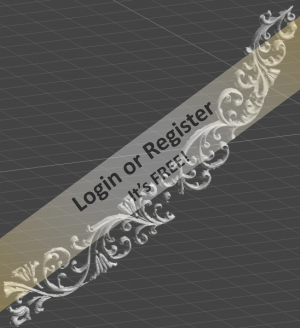

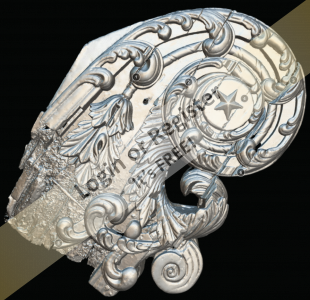

Then I found they had scanned the head ornaments on Constellation, and using screen shot of their models I got 3D files. There's a LOT of work to be done before I can print them, but I'll have 3D printed head carving for the model at last.

I started painting the hammocks on the portside.

Then I found they had scanned the head ornaments on Constellation, and using screen shot of their models I got 3D files. There's a LOT of work to be done before I can print them, but I'll have 3D printed head carving for the model at last.

▲

⟩⟩

thadlietz

stevedownunder

Ronald

RNinMunich

peterd

Login To

Remove Ads

Remove Ads

📝 Gratings and Skids

7 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 29 Views · 7 Likes

Flag

💬 Add Comment

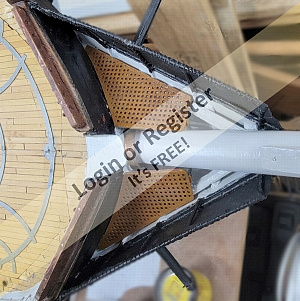

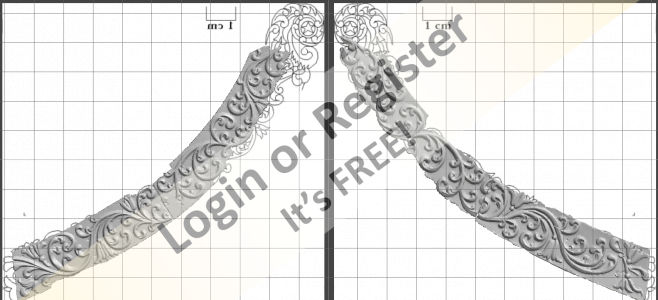

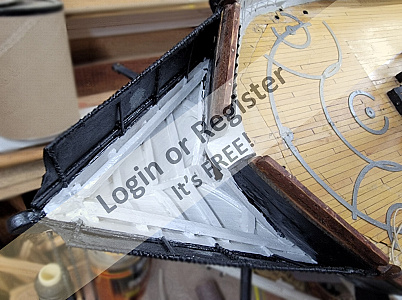

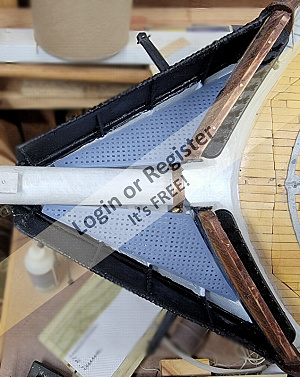

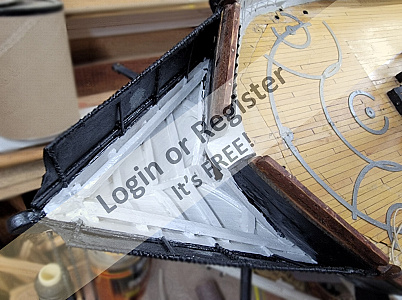

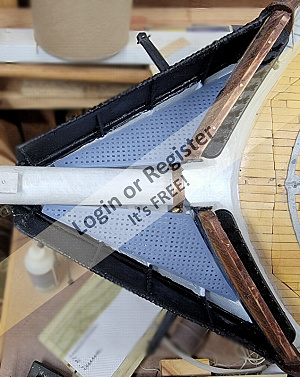

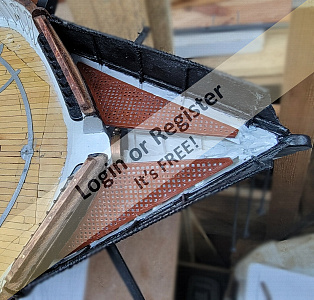

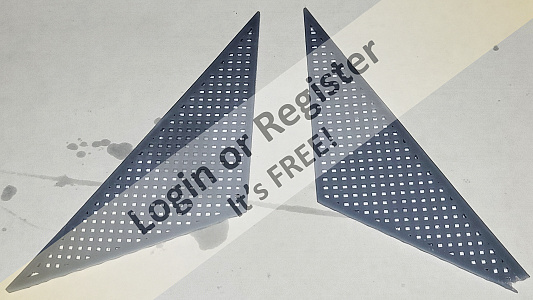

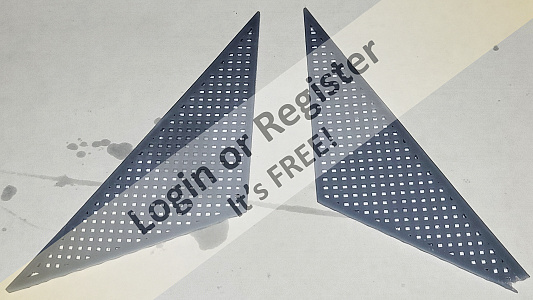

Clamps, ledgers, cleats, whatever, got installed in the head for the grating to sit on, and it all got painted. I made new templates and from them 3D models of (hopefully) better fitting gratings. Being thin and perforated, they wanted to curl, so I glued wood stiffeners to the underside, and they got primer and paint.

I installed skid rails on the sides when I could see them in the 1856 portrait the model's based on. These were cut to shape, glued, and pinned to the hull. Some primer and paint went on here too.

It's almost time to mask and properly paint the hull nice and neat.

I installed skid rails on the sides when I could see them in the 1856 portrait the model's based on. These were cut to shape, glued, and pinned to the hull. Some primer and paint went on here too.

It's almost time to mask and properly paint the hull nice and neat.

▲

⟩⟩

Ronald

Len1

hermank

EdW

thadlietz

stevedownunder

RNinMunich

📝 Remodeling the Loo

7 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 36 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Painting and clear-coating is done on the crew that's made so far, so I started looking at making gratings for the head.

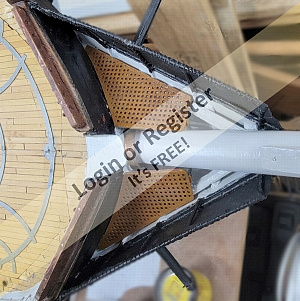

I made chipboard patterns, scanned them, and used that image as a guide to 3D modeling them. They took 4 hours to print and need some adjustment, but I need to install cleats (ledges) for them to sit on to accurately see how much adjustment is needed.

I made chipboard patterns, scanned them, and used that image as a guide to 3D modeling them. They took 4 hours to print and need some adjustment, but I need to install cleats (ledges) for them to sit on to accurately see how much adjustment is needed.

▲

⟩⟩

hermank

EdW

RNinMunich

Len1

stevedownunder

Ronald

Newby7

|

💬 Re: Remodeling the Loo

7 months ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 38 Views · 2 Likes

Flag

Fantastic!

▲

⟩⟩

hermank

stevedownunder

|

📝 Davit and Goliath

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 38 Views · 6 Likes

Flag

💬 Add Comment

I'm sure the davits had some sort of brace, most likely bolted to the hammock irons that make up the bulwarks, so I mocked something up with chipboard and the last poorly printed davits to get measurements with. I updated the 3D model with that as well as finishing the double block at the top. I replaced the ball at the tip with a ring as it appear there was a chain linking the davits together.

The slicer said it would take 3 hours and 50 minutes to print a pair, but checking the printer 2 hours in, I found it wasn't doing anything. I reset and restarted it and 4 hours later had a pair of davits.

I temporarily CAed them to the channels to see how they looked, and hung a boat from them. I think they'll serve just fine, they look right, at least. I'll drill holes in the bottoms so pins can attach them to the channels better.

The slicer said it would take 3 hours and 50 minutes to print a pair, but checking the printer 2 hours in, I found it wasn't doing anything. I reset and restarted it and 4 hours later had a pair of davits.

I temporarily CAed them to the channels to see how they looked, and hung a boat from them. I think they'll serve just fine, they look right, at least. I'll drill holes in the bottoms so pins can attach them to the channels better.

▲

⟩⟩

EdW

RNinMunich

Len1

stevedownunder

peterd

hermank

📝 More little guys

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 40 Views · 7 Likes

Flag

💬 Add Comment

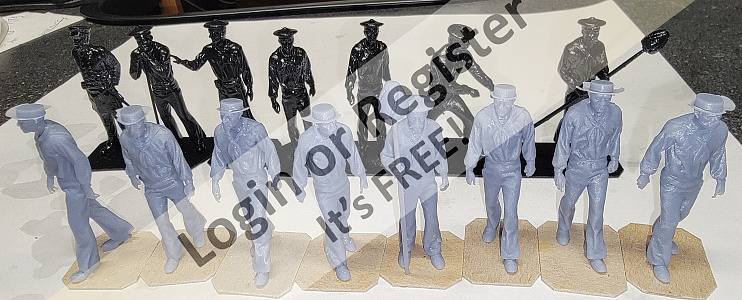

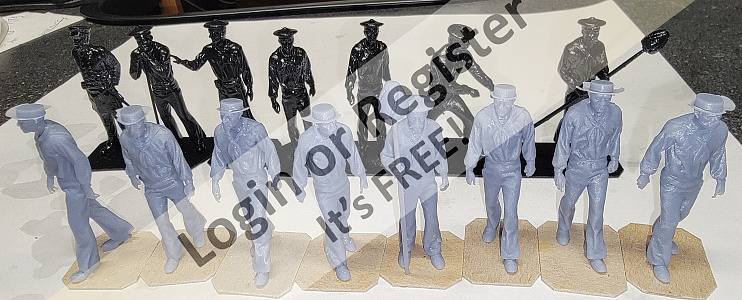

I printed the modified files, 7 straw hats, and the sponger. I made the hat brims too thin, and they didn't print well, so I made brims from paper, painted them with resin from the printer ; and hardened the resin with UV light. This batch of 15 is mostly painted, but still needs some details and touch-up.

This will make 32 crew, and I have to make guys climbing the rig, laying out on the yards, sitting around, plus some officers and Marines. I'm guessing it's going to wind up being 50 or more figure in total.

This will make 32 crew, and I have to make guys climbing the rig, laying out on the yards, sitting around, plus some officers and Marines. I'm guessing it's going to wind up being 50 or more figure in total.

▲

⟩⟩

EdW

Steves-s

Len1

hermank

stevedownunder

Fred

SimpleSailor

📝 Now in Color

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 53 Views · 11 Likes · 3 Comments

Flag

💬 Add Comment

I ordered some white, black, and blue acrylics, and paint half my little crew as soon as they came in, including Ivan.

Ivan came from a $5 kit of WWII Soviet Naval soldiers, an was the models first crewman whose job it was to be in pictures to give a sense of scale. He even survived the 2011 Earthquake!

Ivan got new paint to match the other crewmen, will remain "clean shaven," and will be posted at the helm.

I had to order more paint as I didn't have anything for things like hair colors, buckets, or casks.

Ivan came from a $5 kit of WWII Soviet Naval soldiers, an was the models first crewman whose job it was to be in pictures to give a sense of scale. He even survived the 2011 Earthquake!

Ivan got new paint to match the other crewmen, will remain "clean shaven," and will be posted at the helm.

I had to order more paint as I didn't have anything for things like hair colors, buckets, or casks.

▲

⟩⟩

Steves-s

SimpleSailor

Rookysailor

EdW

luckyduck

Len1

stevedownunder

hermank

RNinMunich

peterd

Wolle

|

💬 Re: Now in Color

8 months ago by 🇺🇸 Jerry Todd (

Sub-Lieutenant) Sub-Lieutenant)✧ 48 Views · 4 Likes

Flag

All of them are on bits of card for now, but will be attached to the deck. On stands they'd slide around as the model sailed.

Ivan is standing on a piece of clear plastic, he got his feet wet and the card came off. When he's gone sailing, he was taped down to stay with the boat. PS: I just printed a few more, though four didn't turn out. In the pic they're cleaned and PVA glued to bit of chipboard, then primed black.

▲

⟩⟩

SimpleSailor

Len1

EdW

hermank

|

|

Login To

Remove Ads |

|

💬 Re: Now in Color

8 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 55 Views · 2 Likes

Flag

Talking of buckets Jerry ...

You´re gonna need a bucket of yellow paint to do all those Minion Lower Ranks 😀 Fantastic work, museum stuff, keep it up. 😎 ▲

⟩⟩

Len1

hermank

|

📝 Bonehead Strikes Again!

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 60 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

Years ago, the lady opened the garage door while I had the full rig up, and snapped off the mizzen topmast and main mast head. I repaired it, though it was difficult as the mast and topmasts are made of white cedar and gluing end-grain does do well at all.

In a photo in the last post, in the upper left of the photo, there are some gray tubes stored up in the garage door tracks. A little over a week ago, I moved the model, with the topmasts un-shipped and t'gallants up, as in the photo, and snapped of the mizzen topmast right at the previous repair. I epoxied it back together, a little sloppily, but I was gonna clean it up later.

Instead, I went and snapped it off again, this time at the doubling. I tried to repair it again, but it was to weak to be of use.

So I made a new mizzen topmast. I don't have any more white cedar long enough, so I used bit of yellow pine from an old cabinet I scavenged some wood from. The picture shows the steps in making the new spar.

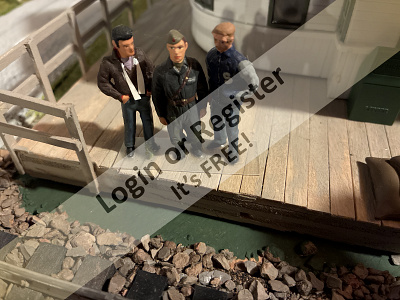

Today being a one step forward two steps back kind of day, I started painting the crew figures I 3D printed. These guys are on a portion of the 30-40 squids, marines, officers, and a cat, I plan to man the ship. I don't have the 1850's marine figures, I need to repose a few sailors, and the officer need dis-arming and reposing.

In a photo in the last post, in the upper left of the photo, there are some gray tubes stored up in the garage door tracks. A little over a week ago, I moved the model, with the topmasts un-shipped and t'gallants up, as in the photo, and snapped of the mizzen topmast right at the previous repair. I epoxied it back together, a little sloppily, but I was gonna clean it up later.

Instead, I went and snapped it off again, this time at the doubling. I tried to repair it again, but it was to weak to be of use.

So I made a new mizzen topmast. I don't have any more white cedar long enough, so I used bit of yellow pine from an old cabinet I scavenged some wood from. The picture shows the steps in making the new spar.

Today being a one step forward two steps back kind of day, I started painting the crew figures I 3D printed. These guys are on a portion of the 30-40 squids, marines, officers, and a cat, I plan to man the ship. I don't have the 1850's marine figures, I need to repose a few sailors, and the officer need dis-arming and reposing.

▲

⟩⟩

Len1

Wolle

stevedownunder

AustinG

hermank

RNinMunich

ToraDog

RossM

SimpleSailor

EdW

|

💬 Re: Bonehead Strikes Again!

8 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 60 Views · 6 Likes

Flag

My commiserations to both of you☹️

But you are not alone! I have a 1/72 Type IA U-Boat badly in need of refit and TLC. It tried to crash dive through the concrete floor of my workshop💥😭 The crash worked, the dive didn't. 😎 ▲

⟩⟩

Steves-s

Len1

stevedownunder

Jerry Todd

hermank

Ronald

|

|

💬 Re: Bonehead Strikes Again!

8 months ago by 🇺🇸 ToraDog (

Commodore) Commodore)✧ 59 Views · 5 Likes

Flag

Oh my! A compatriot of the fumble. I have deluded myself into believing that I will not make the same mistake over and over, and of course I still do.

The other day, working on assembling a new plane, on the floor, I kept reminding myself that when I stood I needed to clear the stern light which overhangs Juneau's transom. I have broken it off twice before. So when I stood up I, instead snapped off the stbd depth charge rack hanging off her stern and it shattered. Fixable, but I was not happy with myself. Your crew looks fantastic. They will add such dimension your beauty. Really amazing. ▲

⟩⟩

Len1

stevedownunder

Jerry Todd

hermank

RNinMunich

|

📝 Privacy in the Heads

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 62 Views · 6 Likes

Flag

💬 Add Comment

The screens are up, laced, and painted. The tars can have a little privacy while contemplating what that was Cookie fed them. That reminds me, I have to put in the seats and the poop-chute yet.

Well, the sheer runs the full length of the boat now.

Well, the sheer runs the full length of the boat now.

▲

⟩⟩

Len1

Wolle

SimpleSailor

EdW

hermank

stevedownunder

📝 Davit Developement

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 66 Views · 7 Likes

Flag

💬 Add Comment

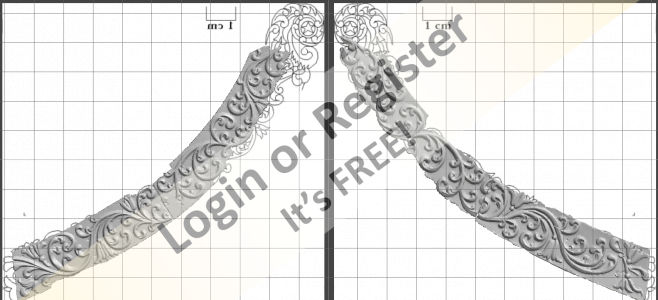

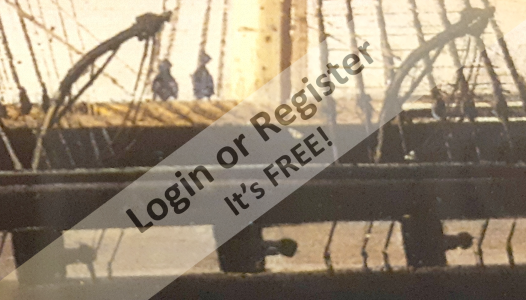

I don't have much to go on as the quarter-boat davits go. The images I have of the time frame I'm modeling the boat, are "impressionistic" at best, and I haven't been able to find technical drawings, manuals, instruction, images of other ships, photos, or anything that really shows what these davits looked like or how they were attached.

The two portraits I'm working from are the one I'm basing the model on from 1856, and one from 1860.

The davits I model previously were nothing like the paintings, so I modified it to what I show here. I printed four, two failed outright, and the two I got wouldn't be usable, but they did help with visualization.

There's some details to work out, beside building the proper double-block to replace the one I just slapped on to get a test model made. I'm there had to be some sort of bracing to the bulwark that's not shown, because the davit doesn't appear to extend below the channels to be braced against the hull.

The davits will be among the last parts to go on the model, so there's no hurry to get them done.

The two portraits I'm working from are the one I'm basing the model on from 1856, and one from 1860.

The davits I model previously were nothing like the paintings, so I modified it to what I show here. I printed four, two failed outright, and the two I got wouldn't be usable, but they did help with visualization.

There's some details to work out, beside building the proper double-block to replace the one I just slapped on to get a test model made. I'm there had to be some sort of bracing to the bulwark that's not shown, because the davit doesn't appear to extend below the channels to be braced against the hull.

The davits will be among the last parts to go on the model, so there's no hurry to get them done.

▲

⟩⟩

Len1

EdW

jbkiwi

hermank

Ronald

stevedownunder

SimpleSailor

📝 Tarpaulin

8 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 66 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

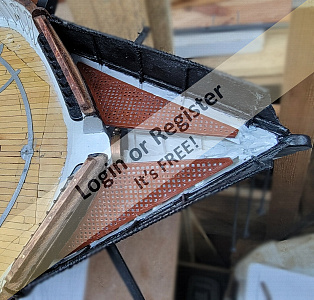

The tarp that goes over the frames I made from some Supplex (cloth I use for my sails) with strips of wood hemmed/glued into the bottom and aft ends. It's left a little long at the top and will get trimmed after it's installed. It was spray-painted black, front and back - two coats.

The reinforced edges are glued to the top-rail of the head and the hull, and the loose part is pulled over the rail and CAed to hold it. It's then laced with Dacron sail thread along the top rail and forward end. The whole thing will get another coat of paint brushed on, but first I have to get the port side to this point.

The reinforced edges are glued to the top-rail of the head and the hull, and the loose part is pulled over the rail and CAed to hold it. It's then laced with Dacron sail thread along the top rail and forward end. The whole thing will get another coat of paint brushed on, but first I have to get the port side to this point.

▲

⟩⟩

Len1

hermank

stevedownunder

SimpleSailor

|

💬 Re: Tarpaulin

8 months ago by 🇨🇦 RossM (

Captain) Captain)✧ 71 Views · 2 Likes

Flag

Don't tell me it is BLACK PEARL SUPPLEX!!😉

▲

⟩⟩

Len1

hermank

|

United States

United States

Recruit)

Recruit)