Join Us On Social Media!

BYMS 2079

9 Posts · 11 Followers · 123 Photos · 72 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 1 year ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 finishing BYMS 2079

1 year ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 29 Views · 1 Like · 1 Comment

Flag

💬 Add Comment

The last major item to construct was the bridge.

With so much deck equipment, mast, davits and other fittings being susceptible to being knocked or broken I built a travelling/storage box for BYMS2079.

In the end the build took 7 months, though I was working on other projects at the same time. This is the most complex and detailed build that I've done to date, have found that I'm comfortable working at 1:48.

The next build will be the HMS Medway Queen, also in 1:48 so it will be great to have the two minesweepers on the water together.

With so much deck equipment, mast, davits and other fittings being susceptible to being knocked or broken I built a travelling/storage box for BYMS2079.

In the end the build took 7 months, though I was working on other projects at the same time. This is the most complex and detailed build that I've done to date, have found that I'm comfortable working at 1:48.

The next build will be the HMS Medway Queen, also in 1:48 so it will be great to have the two minesweepers on the water together.

▲

⟩⟩

Brightwork

|

💬 Re: finishing BYMS 2079

12 months ago by 🇺🇸 Hhager2 (

Sub-Lieutenant) Sub-Lieutenant)✧ 15 Views · 2 Likes

Flag

Excellent model. Similar to my MSCO 49 Lorikeet I served on. I used the Calypso kit and bashed it back to its roots. Your details far exceed mine. Very accurate. I’m not sure I saw the otters on the stern. They help keep sweep lines at a depth. Mag n the wenches look so real. The topside cabinet was where I was helmsman most times. Otherwise repairing radar n comms. My uncle was navigator usually topside open deck. He was also signalman. We all had multiple roles. I once ran ship from Newport RI to Long Island sound in a hurricane. I’m steering n ship is bouncing. I have radar I’m watching because you can’t see anything n it was at night. Before entering the sound which was calmer water, I realized I’m alone. I’m hanging onto a large wheel watching radar I didn’t notice everyone left n were puking in the head. I guess I was too scared to throw up? Amazing how much of a beating that ship can take.

▲

⟩⟩

RNinMunich

neilw

|

Login To

Remove Ads

Remove Ads

📝 BYMS 2079 (continued)

1 year ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 30 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

Just realised I've not updated this build blog for some time!

I've found all the pics I took during the build so time for a few updates.

With the rear deck finished I moved over to building various deck fittings, most of these came from Sirmar but needed assembling, finishing and painting.

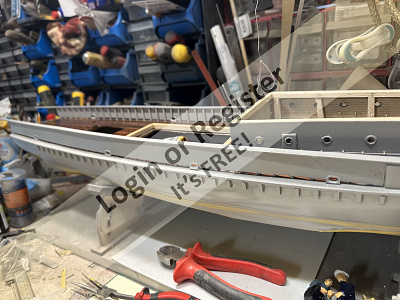

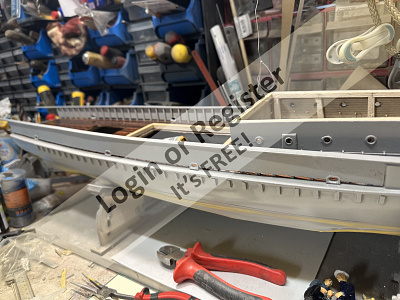

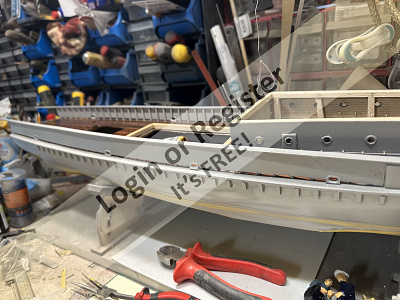

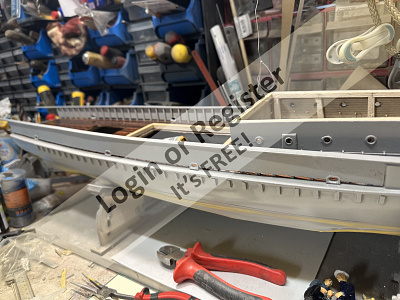

The bulwarks needed finishing with the top rail, steamed over a former to get the correct curve. With this done it was time to add all the fittings to the rear deck.

With the rear deck complete it was time to add the foredeck. This was the same as the rear deck - a thin ply subdeck with a laid deck of 2mm x 1mm mahogany with very thin plasticard used to simulate the caulking.

Once the foredeck was in place it needed a few coats of varnish before the armaments, mast, stanchions and other fittings could be added.

Getting to look like a proper ship, just needs the bridge to be built.

I've found all the pics I took during the build so time for a few updates.

With the rear deck finished I moved over to building various deck fittings, most of these came from Sirmar but needed assembling, finishing and painting.

The bulwarks needed finishing with the top rail, steamed over a former to get the correct curve. With this done it was time to add all the fittings to the rear deck.

With the rear deck complete it was time to add the foredeck. This was the same as the rear deck - a thin ply subdeck with a laid deck of 2mm x 1mm mahogany with very thin plasticard used to simulate the caulking.

Once the foredeck was in place it needed a few coats of varnish before the armaments, mast, stanchions and other fittings could be added.

Getting to look like a proper ship, just needs the bridge to be built.

▲

⟩⟩

BarryS

AlessandroSPQR

EdW

|

💬 Re: BYMS 2079 (continued)

1 year ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 17 Views · 1 Like

Flag

Looking great with all those fiddle bits.

Barry 👍 ▲

⟩⟩

neilw

|

📝 BYMS 2079, never mind the bulwarks

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 55 Views · 4 Likes

Flag

💬 Add Comment

Have been plugging away with 2079, thought did get distracted by the Nile River Gunboat for a while.

The main deck is finished and now has several coats of varnish, not the authentic look but I want something to break up the never ending sea of grey paint.

Before varnishing and the fitting of the bulwarks I built the first level of the superstructure, figuring that without the bulwarks fitted I'd have more access to fit the sides, rear panel and hand rail. The doors and portholes came as part of fittings more Sirmar, the hand rail uses brass handrail stanchions and 1mm brass rod, all painted grey.

With the 1st level of the superstructure built it was time to fit the bulwarks. I'd removed the old bulwarks as these were part of the moulding and didn't extend far enough aft, the moulding was also an irregular thickness so would throw any vertical supports out of alignment. I used the old GRP bulwarks as templates to make a pair of 1.5mm ply bulwarks.

At this point I made a mistake in cutting and fitting 38 vertical supports to each of the new bulwarks, when I offered them up to the deck I released I'd have to do so much fine filing of each support to get the right length to match the curve of the deck. Decide to treat that as a learning experience and recut the the bulwarks.

For version 2 I fitted the 4 closed fairleads in each bulwark, I created a template of the fairlead then transferred this to each fairlead position on both bulwark sides, cut out the shape for the fairleads, fitted them and then painted the bulwarks before gluing them in place to the deck. The glue contact points were the base of each fairlead, the base of the rear vertical support I'd added and the front edge of the bulwark, where it meets the moulding.

Now the bulwarks were attached to the deck I added the 38 vertical supports. These were fitted 12mm apart using a ply block as a spacer.

Once the vertical supports were all glued in place I was able to finally varnish the deck.

The only remaining part the bulwarks to be fitted now was the handrail / capping rail. This sits on top of the bulwark sides and vertical supports and follows the curve of the fo'c'sle.

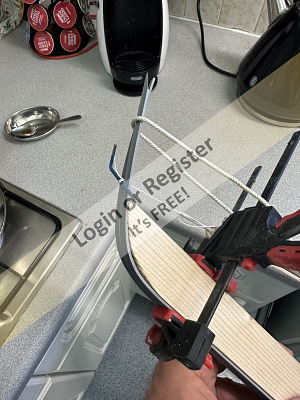

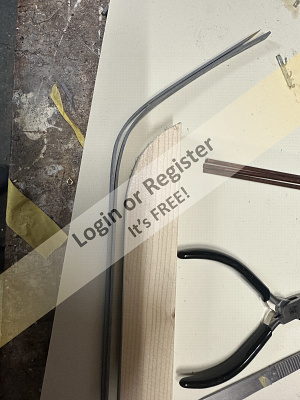

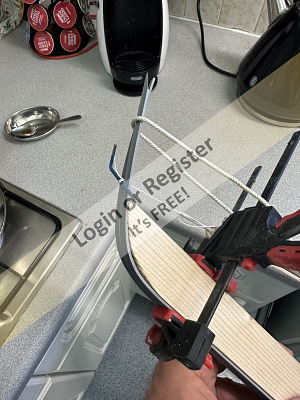

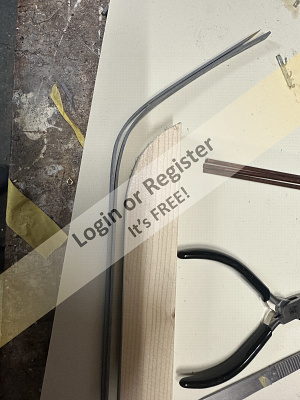

I used obechi strip for the hand rail and didn't want any joins in it so decide to steam it using a former of the fo'c'sle curve. Luckily a recent power cut had meant I had to find the stove top kettle that could consistently produce steam. The pictures show the painted obechi strip being steamed using a Spanish windlass to pull the strip against the former as it becomes pliable from the steam. I left the strip on the former over night and found the steamed curve was perfect.

Gluing the hand rail into place was very straightforward and brings and end to this part of the build. I need to do some small bits of paint correction to the bulwarks but the next stage will be the fitting of the foredeck and building upwards.

I now have all the parts built for the rear deck and engine room cover - I'll post details and pics about them a little later.

The main deck is finished and now has several coats of varnish, not the authentic look but I want something to break up the never ending sea of grey paint.

Before varnishing and the fitting of the bulwarks I built the first level of the superstructure, figuring that without the bulwarks fitted I'd have more access to fit the sides, rear panel and hand rail. The doors and portholes came as part of fittings more Sirmar, the hand rail uses brass handrail stanchions and 1mm brass rod, all painted grey.

With the 1st level of the superstructure built it was time to fit the bulwarks. I'd removed the old bulwarks as these were part of the moulding and didn't extend far enough aft, the moulding was also an irregular thickness so would throw any vertical supports out of alignment. I used the old GRP bulwarks as templates to make a pair of 1.5mm ply bulwarks.

At this point I made a mistake in cutting and fitting 38 vertical supports to each of the new bulwarks, when I offered them up to the deck I released I'd have to do so much fine filing of each support to get the right length to match the curve of the deck. Decide to treat that as a learning experience and recut the the bulwarks.

For version 2 I fitted the 4 closed fairleads in each bulwark, I created a template of the fairlead then transferred this to each fairlead position on both bulwark sides, cut out the shape for the fairleads, fitted them and then painted the bulwarks before gluing them in place to the deck. The glue contact points were the base of each fairlead, the base of the rear vertical support I'd added and the front edge of the bulwark, where it meets the moulding.

Now the bulwarks were attached to the deck I added the 38 vertical supports. These were fitted 12mm apart using a ply block as a spacer.

Once the vertical supports were all glued in place I was able to finally varnish the deck.

The only remaining part the bulwarks to be fitted now was the handrail / capping rail. This sits on top of the bulwark sides and vertical supports and follows the curve of the fo'c'sle.

I used obechi strip for the hand rail and didn't want any joins in it so decide to steam it using a former of the fo'c'sle curve. Luckily a recent power cut had meant I had to find the stove top kettle that could consistently produce steam. The pictures show the painted obechi strip being steamed using a Spanish windlass to pull the strip against the former as it becomes pliable from the steam. I left the strip on the former over night and found the steamed curve was perfect.

Gluing the hand rail into place was very straightforward and brings and end to this part of the build. I need to do some small bits of paint correction to the bulwarks but the next stage will be the fitting of the foredeck and building upwards.

I now have all the parts built for the rear deck and engine room cover - I'll post details and pics about them a little later.

▲

⟩⟩

EdW

Scratchbuilder

BarryS

Colin H

📝 A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 120 Views · 16 Likes · 8 Comments

Flag

💬 Add Comment

It has been a while since I updated the blog. I've been on holiday so popped into the Royal Naval Patrol Service Museum in Lowestoft and came away with lots of information about BYMS, enough to make me rethink a lot of the fittings. I'm now including a lot more detail that was missing form the plans, I'll update the blog with progress later about how far I've come in making a load of deck detail and fittings.

I had hoped to be writing about completing the main deck and installing many fittings but I've had to rethink the deck material.

Before going on holiday I'd fitted the deck beams so they were flush with the gunwale and bought a sheet of Laser engraved deck lines on 1.5mm (1/16") x 300mm x 1100mm Birch Ply. This gave the visual effect of 2mm wide planks, meaning the full size planks would have been approximately 100mm or 4" wide.

When I returned from holiday I started to fit the deck main deck piece, started off by fitting it into the fo'c'sle, and the plan was to fix it in place to the deck beams then trim around to fit it flush with the hull.

Before I fixed it in place I realised I didn't like the deck plank effect as after I applied a coat of varnish to the deck I found the the lines were too feint and the timber had a prominent birds eye grain.

I also didn't like the fact it sat on the gunwale and there would be an obvious step of 1.5mm at the forward edge of the deck; the entire deck should be flush with the gunwale whereas I had the frames flush to it. I also realised that one sheet of the deck lined ply would not be enough to do both the main deck and the foredeck as I'd mismeasured by 10mm so even if I decided to keep the deck lined ply I'd have to buy another sheet.

Additionally, I think the 2mm wide planks should have been 3mm wide to simulate 150mm/6" planks, there was only one outcome - a rethink of the deck and a return to my original plan, to fit a thin subdeck and glue thin strips of timber for the planks and use thin plasticard to simulate the caulking. The 0.25mm (10 thous) black pasticard, scales up to give a simulated 12.5mm (1/2") of caulking.

After several large mugs of tea I removed all the deck beams and fitted a new set that are about 1.6mm below the gunwale.

A quick order to Cornwall Model Boats and I received some 0.8mm ply and a tube full of 1m x 3mm x 1mm mahogany strips along with some 0.25mm thick plasticard sheets. This cost about the same as another sheet of the Deck lined ply, I'd have needed this if I had decided to continue with that approach so the change in material costs about the same, but will take considerably longer to fit. Fortunately I had some 0.8mm ply in the workshop so didn't need to buy a full sheet.

The subdeck went in easily as I made card templates to help with a snug fit. The next part is taking a long time.

I have to cut each plank to correct length then glue a thin strip of the plasticard to one edge. Once the superglue has dried I trim the lower edge of the plasticard so it is flush with the underside of the plank. The plank is the glued to the subdeck, with the plasticard flush to the previous plank.

The full length planks require three lengths of plasticard carefully butted together, I found I have to wait for the first piece of plasticard to adhere before gluing on the next plasticard strip.

This is a very time intensive and fiddly process, I've found I can prepare a maximum of 4 planks a day then glue them to the subdeck the next day. The main deck will take about 50 planks so there's still a lot to do.

The last pic shows a section that I sanded down and applied some white spirit to see what it would like once varnished, I know the darker colour isn't to everyone's taste but I think it will make a nice contract to the grey colour that will be applied to that most of the fittings and superstructure.

I've been building lots of the deck fittings and superstructure while sorting the deck - have a load of progress pics I'll upload in the next few days,

I had hoped to be writing about completing the main deck and installing many fittings but I've had to rethink the deck material.

Before going on holiday I'd fitted the deck beams so they were flush with the gunwale and bought a sheet of Laser engraved deck lines on 1.5mm (1/16") x 300mm x 1100mm Birch Ply. This gave the visual effect of 2mm wide planks, meaning the full size planks would have been approximately 100mm or 4" wide.

When I returned from holiday I started to fit the deck main deck piece, started off by fitting it into the fo'c'sle, and the plan was to fix it in place to the deck beams then trim around to fit it flush with the hull.

Before I fixed it in place I realised I didn't like the deck plank effect as after I applied a coat of varnish to the deck I found the the lines were too feint and the timber had a prominent birds eye grain.

I also didn't like the fact it sat on the gunwale and there would be an obvious step of 1.5mm at the forward edge of the deck; the entire deck should be flush with the gunwale whereas I had the frames flush to it. I also realised that one sheet of the deck lined ply would not be enough to do both the main deck and the foredeck as I'd mismeasured by 10mm so even if I decided to keep the deck lined ply I'd have to buy another sheet.

Additionally, I think the 2mm wide planks should have been 3mm wide to simulate 150mm/6" planks, there was only one outcome - a rethink of the deck and a return to my original plan, to fit a thin subdeck and glue thin strips of timber for the planks and use thin plasticard to simulate the caulking. The 0.25mm (10 thous) black pasticard, scales up to give a simulated 12.5mm (1/2") of caulking.

After several large mugs of tea I removed all the deck beams and fitted a new set that are about 1.6mm below the gunwale.

A quick order to Cornwall Model Boats and I received some 0.8mm ply and a tube full of 1m x 3mm x 1mm mahogany strips along with some 0.25mm thick plasticard sheets. This cost about the same as another sheet of the Deck lined ply, I'd have needed this if I had decided to continue with that approach so the change in material costs about the same, but will take considerably longer to fit. Fortunately I had some 0.8mm ply in the workshop so didn't need to buy a full sheet.

The subdeck went in easily as I made card templates to help with a snug fit. The next part is taking a long time.

I have to cut each plank to correct length then glue a thin strip of the plasticard to one edge. Once the superglue has dried I trim the lower edge of the plasticard so it is flush with the underside of the plank. The plank is the glued to the subdeck, with the plasticard flush to the previous plank.

The full length planks require three lengths of plasticard carefully butted together, I found I have to wait for the first piece of plasticard to adhere before gluing on the next plasticard strip.

This is a very time intensive and fiddly process, I've found I can prepare a maximum of 4 planks a day then glue them to the subdeck the next day. The main deck will take about 50 planks so there's still a lot to do.

The last pic shows a section that I sanded down and applied some white spirit to see what it would like once varnished, I know the darker colour isn't to everyone's taste but I think it will make a nice contract to the grey colour that will be applied to that most of the fittings and superstructure.

I've been building lots of the deck fittings and superstructure while sorting the deck - have a load of progress pics I'll upload in the next few days,

▲

⟩⟩

Peejay

Colin H

AlessandroSPQR

Graham93

SimpleSailor

RNinMunich

jbkiwi

hermank

EdW

River Rat

Rogal118

DWBrinkman

chugalone100

Scratchbuilder

BarryS

Doogle

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 68 Views · 3 Likes

Flag

Found the solution to fairing the deck. Plasticard and CA is a very hard material, visited the proper boat building tool boxes, I used some of these small planes for bevelling the 100+ ribs on the 100 year old sailing canoes restoration, forgot I had them. Ideal for the 3mm planks with 0.25mm ‘caulking’.

Deck still needs some work but I have the apertures sorted for the winch, engine room vents/funnel and a hatch for the battery.

▲

⟩⟩

Doogle

Scratchbuilder

hermank

|

|

Login To

Remove Ads 💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 Doogle (

Vice Admiral) Vice Admiral)✧ 68 Views · 2 Likes

Flag

She's looking really good neilw 👍👍

▲

⟩⟩

neilw

AlessandroSPQR

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 77 Views · 3 Likes

Flag

That’s the main deck planking done. At least the foredeck planking is a few months away.

Now the clean-up and cutting the forward aperture to get access to battery compartment. 10 thou plasticard and HV CA have combined to give a very hard surface to sand. Have decided to start on the forward superstructure and fo’c’sle sub deck before fitting the bulwarks as I’ll have better access and the bulwarks won’t be there to get dinged.

▲

⟩⟩

hermank

Colin H

Doogle

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 87 Views · 4 Likes

Flag

Had a couple of days away from the BYMS, thought I’d better not spend my wedding anniversary in the workshop. Have been busy sorting through the last auction purchases, but have managed to clean up some of the latest planking, fitted a couple more and have what I hope is the last batch in prep.

▲

⟩⟩

Colin H

Doogle

RNinMunich

Scratchbuilder

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 93 Views · 4 Likes

Flag

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 104 Views · 4 Likes

Flag

Seem to be speeding up, can now prep 6 planks at a time, found the trick is to cut the plasticard strips wider (4mm or 5mm) as this stops them from curling up so glueing them to the plank edge is now straight forward, swearing has stopped and the number of plastic gloves needed has decreased.

Have developed my paring skills to take off the extra plasticard from the edge that gets glued to the sub deck, don’t want to tempt fate but over half way there on the main deck and have 6 planks in prep and 6 needing paring as decided to have a day off today from fitting them. Probably another 3 or 4 sessions required to finish the main deck. I’ll have to do the same to the foredeck but that’s months away.

▲

⟩⟩

Colin H

Scratchbuilder

EdW

Doogle

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 119 Views · 2 Likes

Flag

Hi Bill

I’ll be glad when it is over, seems the past week has been spent bent over the deck planks, probably another week to go until the main deck is finished. ▲

⟩⟩

Colin H

Scratchbuilder

|

|

💬 Re: A purchasing mistake and now lots of planking.

2 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 118 Views · 1 Like

Flag

Neil.

A very comprehensive informative write up. Looking good 👍 Regards Bill. ▲

⟩⟩

neilw

|

📝 First trials

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 133 Views · 6 Likes · 4 Comments

Flag

💬 Add Comment

I wanted to test the effectiveness of the rudders and ESC while seeing how much ballasting would be required so I took the hull to the lake today. My father and I use Fridays as a testing day as the lake is usually quiet so we can make lots of mistakes without an audience. The other boat you can see in the video is his tug project, now successfully ballasted.

Have to say I was very pleased with the manoeuvrability of the boat, was thinking I might need to fit a mixer for the steering but she turns nicely just using the the rudders as they are so i wont bother with a mixer.

She need ballasting towards the bow, but there's enough buoyancy to cope with the superstructure and fittings. Very impressed with the lack of wash, I'm using a 3S with twin 365 motors rated at 6V-15V. Think it will only need a 2S as I was using very little throttle.

Have to say I was very pleased with the manoeuvrability of the boat, was thinking I might need to fit a mixer for the steering but she turns nicely just using the the rudders as they are so i wont bother with a mixer.

She need ballasting towards the bow, but there's enough buoyancy to cope with the superstructure and fittings. Very impressed with the lack of wash, I'm using a 3S with twin 365 motors rated at 6V-15V. Think it will only need a 2S as I was using very little throttle.

▲

⟩⟩

DWBrinkman

flaxbybuck

Scratchbuilder

DuncanP

Colin H

Doogle

|

💬 Re: First trials

2 years ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 126 Views · 0 Likes

Flag

The waterline and movement look good in your trials video. Don't forget to keep the superstructure as light as possible 😉

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: First trials

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 133 Views · 1 Like

Flag

Bill, it is indeed Canon Teign Falls. Nice and quiet now the kids have gone back to school!

▲

⟩⟩

Scratchbuilder

|

|

💬 Re: First trials

2 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 126 Views · 0 Likes

Flag

Hi Neil.

Looks really good I have to say. Is that lake Canonteign? Regards Bill. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: First trials

2 years ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 126 Views · 3 Likes

Flag

The best bit about a mixer is slowly spinning the boat on its axis!

Roy ▲

⟩⟩

neilw

Doogle

Colin H

|

📝 The first cut is the deepest

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 139 Views · 7 Likes · 4 Comments

Flag

💬 Add Comment

Decided to tackle the part of the build that I wasn't looking forward to. I'd made the decision to extend the topsides to close to the transom, however before thinking of extending the topsides I'd have to cut the scuppers. The article by Brian Peach in the May 1996 edition of Marine Modelling suggests, as they are marked on the moulding, to drill a series of holes and complete with a file.

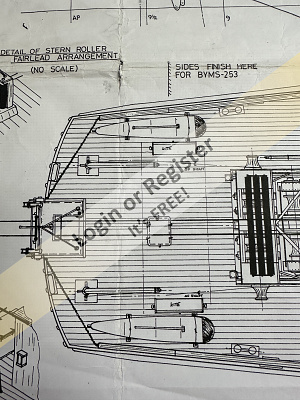

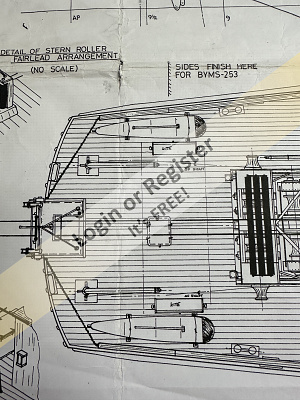

I made the decision to move the topsides completely with the plan to replace them with new topsides that extend to the transom (I'll use the old ones as a template to get the correct sheerline). The topsides will be attached to the deck by about 40 triangular bracing pieces - see the pics of the plans.

I invested in some Dremel EZ Speedclic Cutting wheels, put on the appropriate safety gear and had both topsides removed in about a minute - very impressed with the Speedclic discs. I'm glad I took this approach as the moulding of the topsides was of varying thickness so when the supports would have been added they would not have been in a straight line without having to do a lot of fairing to get the topsides to uniform thickness. I'll be using 1.5mm ply for the replacement topsides.

With the topsides removed I took the opportunity to get some paint on the hull, black under the waterline and I found that Hycote produce a Polar Grey for Ford cars, this is the shade of grey I was looking for.

The paint is too glossy at the moment but I'll flatten it back later.

I've made a start on the internal fit out. Rudders and motors are installed and tested, and I've trimmed the transom to the correct shape. With those large scuppers it made sense to get the correct deck camber so flush deck beams were fitted with thin balsa laminated to the beams and the desired camber filed and sanded into the correct shape.

I've made a temporary deck to check the camber and to work out the position of the various openings.

Will be leaving the hull alone for the while as the next part of the build is to make up the LL Sweep Reel and Four Drum Sweep Winch using the items bought from Sirmar

I made the decision to move the topsides completely with the plan to replace them with new topsides that extend to the transom (I'll use the old ones as a template to get the correct sheerline). The topsides will be attached to the deck by about 40 triangular bracing pieces - see the pics of the plans.

I invested in some Dremel EZ Speedclic Cutting wheels, put on the appropriate safety gear and had both topsides removed in about a minute - very impressed with the Speedclic discs. I'm glad I took this approach as the moulding of the topsides was of varying thickness so when the supports would have been added they would not have been in a straight line without having to do a lot of fairing to get the topsides to uniform thickness. I'll be using 1.5mm ply for the replacement topsides.

With the topsides removed I took the opportunity to get some paint on the hull, black under the waterline and I found that Hycote produce a Polar Grey for Ford cars, this is the shade of grey I was looking for.

The paint is too glossy at the moment but I'll flatten it back later.

I've made a start on the internal fit out. Rudders and motors are installed and tested, and I've trimmed the transom to the correct shape. With those large scuppers it made sense to get the correct deck camber so flush deck beams were fitted with thin balsa laminated to the beams and the desired camber filed and sanded into the correct shape.

I've made a temporary deck to check the camber and to work out the position of the various openings.

Will be leaving the hull alone for the while as the next part of the build is to make up the LL Sweep Reel and Four Drum Sweep Winch using the items bought from Sirmar

▲

⟩⟩

EdW

flaxbybuck

Doogle

chugalone100

BarryS

Colin H

Scratchbuilder

|

💬 Re: The first cut is the deepest

2 years ago by 🇺🇸 Hhager2 (

Sub-Lieutenant) Sub-Lieutenant)✧ 125 Views · 0 Likes

Flag

Great job What your doing looks familiar as I did my deck sort of like the way you did.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: The first cut is the deepest

2 years ago by 🇬🇧 Doogle (

Vice Admiral) Vice Admiral)✧ 127 Views · 1 Like

Flag

Looking forward to seeing your next blog, 😀 coming along nicely 👌

▲

⟩⟩

neilw

|

|

💬 Re: The first cut is the deepest

2 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 132 Views · 2 Likes

Flag

Neil.

Looking really good. Nice to see you have Darth Vader(pic3) as your assistant,but good to see him wearing protective gear. Looking forward to the next installment. Regards Bill. ▲

⟩⟩

neilw

Doogle

|

|

💬 Re: The first cut is the deepest

2 years ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 128 Views · 1 Like

Flag

You are certainly doing a commendable job on her!

Barry ▲

⟩⟩

neilw

|

📝 It will look worse before it gets better

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 148 Views · 12 Likes · 4 Comments

Flag

💬 Add Comment

With some decisions made about the hull I managed to get started.

Seem to have gathered a small library about Minesweepers, thank to World of Books, eBay and a couple of glasses of red wine.

Was good to find a chapter about the BYMS in 'Out sweeps!' that mentions that the BYMS had their growing pains and the Admiralty developed a long list of modifications needed to the original design. I suspect the extension of the gunwales/topsides to the stern and the additional blocks under the rubbing strake were among these modifications as I've seen both features in several images of a BYMS.

The last week or so has been spent making holes in the hull or adding bits to the hull.

The first bit of surgery was fitting the rudders, 'A' brackets and prop shafts. I opened my now large box of BYMS fittings and realised the 'A' brackets I'd bought some time ago were over scale, very clunky and I didn't like them. Time to learn how to make them myself, so I bought some brass tube and bar and spent a happy few hours experimenting until I got an identical pair of 'A' brackets that I couldn't pull apart.

The Sirmar hull has small indentations marking the centre positions for the rudder shafts, prop shafts and A Brackets so drilling the relevant holes and opening up the apertures for the prop shafts was straightforward. The rudders are off-the-shelf, and nearly the same size as those on the plan, I reduced the length of the rudder shaft tubes and shaft length. The tubes were bonded in using West Epoxy with a filleting blend added, used to same for A Brackets and Prop shaft tubes.

The pics show this before any cleaning up so it will look neater soon. I also added a bulkhead as felt the unsupported prop shaft tubes were liable to getting knocked when working in the hull, it will also provide a barrier should any water get in the rear section. The last job on this part of the internal fit out was to install a platform to support the twin motors.

Time now to tackle the hull changes. The bilge keels were straightforward as the plans showed the location and size of them so a pair were made from Obechi strips, these are currently slightly thicker than required as I'll sand them to shape later on.

With the bilge keels fitted the next job on the list was to add the blocks under the rubbing strake, luckily I have a decent photo of 2079 showing the location of all 37 blocks so I was able to work out the start and finish position of the run of blocks and could work out the gap between them. They needed to be the same depth as the rubbing strake (1/8") and I found I had a number of lengths of 1/8" x 1/8" Obechi so used a simple jig to cut about 90 blocks, knowing I'd lose/drop some of them at some point.

The gap between the blocks was 12.49mm so I used a spacer block of this width to position the next block and checked the gap with a vernier gauge. Have to say it was a fiddly but satisfying task, I used Everbuild HV CA glue as this gave me a few seconds to position each block before the glue cured.

With all 74 blocks fitted I sprayed a coat of grey primer as this highlighted any excess CA used to glue the blocks and any excess epoxy used to attach the bilge keels. I'll clean any excess glue from the blocks and keels when do the final tidy up of the epoxy used for the prop shaft tubes and 'A' brackets.

Am considering this grey primer as the final hull colour as I can use a cutting compound to smooth the finish and spray a matt clear coat on top.

Seem to have gathered a small library about Minesweepers, thank to World of Books, eBay and a couple of glasses of red wine.

Was good to find a chapter about the BYMS in 'Out sweeps!' that mentions that the BYMS had their growing pains and the Admiralty developed a long list of modifications needed to the original design. I suspect the extension of the gunwales/topsides to the stern and the additional blocks under the rubbing strake were among these modifications as I've seen both features in several images of a BYMS.

The last week or so has been spent making holes in the hull or adding bits to the hull.

The first bit of surgery was fitting the rudders, 'A' brackets and prop shafts. I opened my now large box of BYMS fittings and realised the 'A' brackets I'd bought some time ago were over scale, very clunky and I didn't like them. Time to learn how to make them myself, so I bought some brass tube and bar and spent a happy few hours experimenting until I got an identical pair of 'A' brackets that I couldn't pull apart.

The Sirmar hull has small indentations marking the centre positions for the rudder shafts, prop shafts and A Brackets so drilling the relevant holes and opening up the apertures for the prop shafts was straightforward. The rudders are off-the-shelf, and nearly the same size as those on the plan, I reduced the length of the rudder shaft tubes and shaft length. The tubes were bonded in using West Epoxy with a filleting blend added, used to same for A Brackets and Prop shaft tubes.

The pics show this before any cleaning up so it will look neater soon. I also added a bulkhead as felt the unsupported prop shaft tubes were liable to getting knocked when working in the hull, it will also provide a barrier should any water get in the rear section. The last job on this part of the internal fit out was to install a platform to support the twin motors.

Time now to tackle the hull changes. The bilge keels were straightforward as the plans showed the location and size of them so a pair were made from Obechi strips, these are currently slightly thicker than required as I'll sand them to shape later on.

With the bilge keels fitted the next job on the list was to add the blocks under the rubbing strake, luckily I have a decent photo of 2079 showing the location of all 37 blocks so I was able to work out the start and finish position of the run of blocks and could work out the gap between them. They needed to be the same depth as the rubbing strake (1/8") and I found I had a number of lengths of 1/8" x 1/8" Obechi so used a simple jig to cut about 90 blocks, knowing I'd lose/drop some of them at some point.

The gap between the blocks was 12.49mm so I used a spacer block of this width to position the next block and checked the gap with a vernier gauge. Have to say it was a fiddly but satisfying task, I used Everbuild HV CA glue as this gave me a few seconds to position each block before the glue cured.

With all 74 blocks fitted I sprayed a coat of grey primer as this highlighted any excess CA used to glue the blocks and any excess epoxy used to attach the bilge keels. I'll clean any excess glue from the blocks and keels when do the final tidy up of the epoxy used for the prop shaft tubes and 'A' brackets.

Am considering this grey primer as the final hull colour as I can use a cutting compound to smooth the finish and spray a matt clear coat on top.

▲

⟩⟩

cyril413

EdW

chugalone100

jbkiwi

flaxbybuck

hermank

RNinMunich

Doogle

boatmam

dave976

Colin H

Scratchbuilder

|

💬 Re: It will look worse before it gets better

2 years ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 132 Views · 0 Likes

Flag

Like the explanation and photos. Keep it up ! 😉

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: It will look worse before it gets better

2 years ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 133 Views · 2 Likes

Flag

Looking good. I like minesweepers, dont see as many of them as other WWII warships. Keep at it, looking forward to splash day.

Cash ▲

⟩⟩

neilw

RNinMunich

|

|

💬 Re: It will look worse before it gets better

2 years ago by 🇬🇧 Doogle (

Vice Admiral) Vice Admiral)✧ 139 Views · 2 Likes

Flag

A great start, looking forward to seeing how your build progresses

▲

⟩⟩

Scratchbuilder

neilw

|

|

💬 Re: It will look worse before it gets better

2 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 139 Views · 4 Likes

Flag

Neil

Great start and brilliant explanation of what your doing 👍👍 Regards Bill. ▲

⟩⟩

RNinMunich

Doogle

Colin H

neilw

|

📝 A bit more research

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 152 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

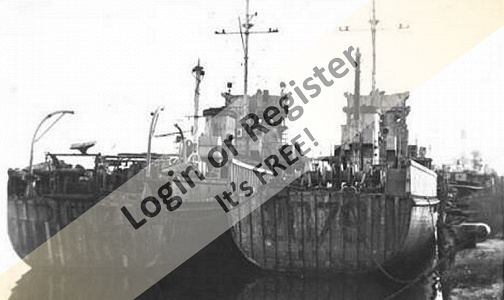

Having made the decision to build the BYMS as 2079 I've been focussing on the research side of the build. Luckily there's a BYMS Facebook Group, when I posted to this group I had a reply from someone involved with the Royal Navy Patrol Service Association Museum in Lowestoft. Turns out they have the bell from 2079 and a collection of photographs of various ships including BYMSs. I'm heading up to Norfolk and Suffolk next month so will be visiting the museum to see what I can find.

There's also a very informative website detailing the activities of the Royal Navy Base Wildfire, Sheerness and Minesweeper Base Wildfire III, Queenborough. The Wildfire site has a pager about each BYMS and I came across a photo of 2079 that shows the addition of what looks look wooden fenders below the scuppers and rubbing strake, highlighted in picture.

I'd not seen them on any pics of BYMS so was wondering if they are a later addition. I was then sent a photo of another BYMS showing the same addition to the hull. They are a later addition to some BYMSs but have decided that as they were fitted on 2079 then my model will also have them fitted.

Looking at the plans, they show that the BYMS hull also had bilge keels, so 2079 will have to have those fitted.

Having spent a fair bit of time looking at various photos of BYMSs it looks like most of them had the topsides extending to the transom, so the decision to extend the topsides has been made.

It now looks like the next stage of the build is to add the hull appendages and to extend the topsides, I'll get on with that after I've fitted the rudders, props and motor mounts.

There's also a very informative website detailing the activities of the Royal Navy Base Wildfire, Sheerness and Minesweeper Base Wildfire III, Queenborough. The Wildfire site has a pager about each BYMS and I came across a photo of 2079 that shows the addition of what looks look wooden fenders below the scuppers and rubbing strake, highlighted in picture.

I'd not seen them on any pics of BYMS so was wondering if they are a later addition. I was then sent a photo of another BYMS showing the same addition to the hull. They are a later addition to some BYMSs but have decided that as they were fitted on 2079 then my model will also have them fitted.

Looking at the plans, they show that the BYMS hull also had bilge keels, so 2079 will have to have those fitted.

Having spent a fair bit of time looking at various photos of BYMSs it looks like most of them had the topsides extending to the transom, so the decision to extend the topsides has been made.

It now looks like the next stage of the build is to add the hull appendages and to extend the topsides, I'll get on with that after I've fitted the rudders, props and motor mounts.

▲

⟩⟩

cyril413

Colin H

dave976

Doogle

Scratchbuilder

RNinMunich

hermank

BarryS

chugalone100

|

💬 Re: A bit more research

2 years ago by 🇬🇧 neilw (

Lieutenant Commander) Lieutenant Commander)✧ 150 Views · 3 Likes

Flag

thanks Hhager2

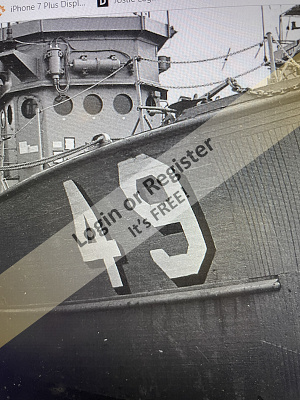

Your great pics show some of the differences between the YMS and the BYMS, especially the stern area. The pic of 2079 moored inboard of 2157 show how the topsides come right to the transom. I think the YMS and some BYMS had the aft section of the topside as a canvas or removable section. I need to find earlier pics of BYMS when they came out of the yards to see if this was a featured as built or a later addition. Impressed with the screen capture from the Minesweeper movie - I've just ordered a DVD of it, for the grand sum of £2.59, can see the pause button is going to get a lot of use.

▲

⟩⟩

EdW

Colin H

dave976

|

|

💬 Re: A bit more research

2 years ago by 🇺🇸 Hhager2 (

Sub-Lieutenant) Sub-Lieutenant)✧ 142 Views · 5 Likes

Flag

It looks like the MSCO u build by using Billings Calypso. Which was originally a mine sweeper. I bashed it back to its roots Try finding USN MSCO 49 or one of its other sisters. Lorikeet my uncle was navigator n chief I was a seaman under him. I got to know every inch over 4 years. It was stationed on Hudson River on NJ side. My model pic it billing ship and my mini model of it. The pics are all I have but there is a blueprint pic. Maybe it will help you I may have pics I made when on the ship. Any questions feel free to ask.

▲

⟩⟩

cyril413

RNinMunich

Colin H

dave976

Scratchbuilder

|

📝 BYMS 2079

2 years ago by 🇬🇧 neilw ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 177 Views · 14 Likes · 7 Comments

Flag

💬 Add Comment

This is going to be a long project, never attempted anything smaller than 1:30, so a 1:48 project is going to be fun.

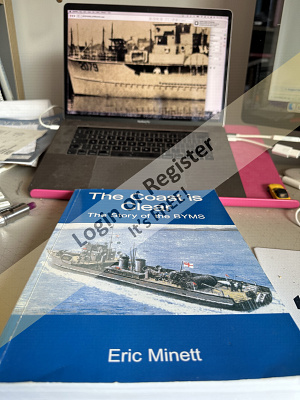

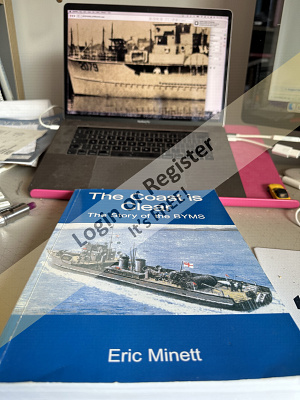

It all started with me finding a copy of Eric Minett's book 'The Coast is Clear: The Story of the BYMS' in a local charity shop. I'd never heard of the British Yard Minesweeper (BYMS) but on reading the book found it very interesting, especially the mine sweeping ahead of the D-Day landings.

I posted about the book on here and nickthesteam very kindly offered me a Sirmar hull, all the plans and some fittings. I've just finished my last large build, the RAF Crash Tender (just waiting for the last few fittings to arrive then I'll get some pics and video of her afloat), so the BYMS came to the top of the project list.

I'd contacted Barry at Sirmar and bought some more fittings and spent a while collecting props, shafts, motors, rudders etc.

I've also been doing a fair bit of research into the BYMS and decided I want to build one that has some sort of local connection. As I'm originally from the East Coast of the UK with family links to the Lowestoft area I found that Minesweeping Flotilla 163 was based at Lowestoft and Great Yarmouth in 1943 and the ships of this flotilla were BYMS 2036, 2040, 2057, 2079, 2080, 2161, 2167, 2194.

Additionally 2079 was one of the first ships in the D-Day Landings and has a very interesting history, so the decision was made to build a model of 2079. The first stage of model building is complete, knowing what will be built!

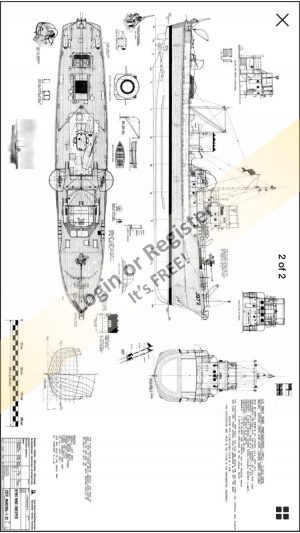

My purchases included a set of three plans

1 x 1:48 detailed drawing of BYMS 2172 (previously designated as J972 and YMS 172)/BYMS 2253 (previously designated as known YMS 253)

2 x non-scale drawings of the YMS 419. These are very detailed and heavily annotated.

In theory there should be little difference between the American YMS and the BYMS as they were all made in the same shipyards, however I have discovered an issue in both the drawings and the hull moulding.

All the drawings show the topsides end some distance before the transom and that the topsides for BYMS 2253 finish further forward than for other vessels. The hull moulding has the top sides ending before the transom, however various photographs of the majesty of BYMS show the topsides continuing to the transom (including those of BYMS 2079).

I suspect the America BYS had the topsides stopping before the transom, BYMS 2253 has them set further forward but the majority of BYMS had the topsides continue to the transom. The Simar moulding would be fine I was to build a model of BYMS 2172 or BYMS 2253, but as this will be 2079 some additional material will be required.

So, a little bit of topside lengthening is required before the first major job of cutting the scuppers. I'll fit the rudders, shafts and motors first. Can't seeing this being a quick build but I'll update as and when progress is made.

It all started with me finding a copy of Eric Minett's book 'The Coast is Clear: The Story of the BYMS' in a local charity shop. I'd never heard of the British Yard Minesweeper (BYMS) but on reading the book found it very interesting, especially the mine sweeping ahead of the D-Day landings.

I posted about the book on here and nickthesteam very kindly offered me a Sirmar hull, all the plans and some fittings. I've just finished my last large build, the RAF Crash Tender (just waiting for the last few fittings to arrive then I'll get some pics and video of her afloat), so the BYMS came to the top of the project list.

I'd contacted Barry at Sirmar and bought some more fittings and spent a while collecting props, shafts, motors, rudders etc.

I've also been doing a fair bit of research into the BYMS and decided I want to build one that has some sort of local connection. As I'm originally from the East Coast of the UK with family links to the Lowestoft area I found that Minesweeping Flotilla 163 was based at Lowestoft and Great Yarmouth in 1943 and the ships of this flotilla were BYMS 2036, 2040, 2057, 2079, 2080, 2161, 2167, 2194.

Additionally 2079 was one of the first ships in the D-Day Landings and has a very interesting history, so the decision was made to build a model of 2079. The first stage of model building is complete, knowing what will be built!

My purchases included a set of three plans

1 x 1:48 detailed drawing of BYMS 2172 (previously designated as J972 and YMS 172)/BYMS 2253 (previously designated as known YMS 253)

2 x non-scale drawings of the YMS 419. These are very detailed and heavily annotated.

In theory there should be little difference between the American YMS and the BYMS as they were all made in the same shipyards, however I have discovered an issue in both the drawings and the hull moulding.

All the drawings show the topsides end some distance before the transom and that the topsides for BYMS 2253 finish further forward than for other vessels. The hull moulding has the top sides ending before the transom, however various photographs of the majesty of BYMS show the topsides continuing to the transom (including those of BYMS 2079).

I suspect the America BYS had the topsides stopping before the transom, BYMS 2253 has them set further forward but the majority of BYMS had the topsides continue to the transom. The Simar moulding would be fine I was to build a model of BYMS 2172 or BYMS 2253, but as this will be 2079 some additional material will be required.

So, a little bit of topside lengthening is required before the first major job of cutting the scuppers. I'll fit the rudders, shafts and motors first. Can't seeing this being a quick build but I'll update as and when progress is made.

▲

⟩⟩

EdW

dave976

Stephen T

RNinMunich

chugalone100

Doogle

Wolle

BarryS

jumpugly

marky

Nickthesteam

roycv

Colin H

Scratchbuilder

|

💬 Re: BYMS 2079

2 years ago by 🇺🇸 Hhager2 (

Sub-Lieutenant) Sub-Lieutenant)✧ 142 Views · 2 Likes

Flag

Pic 7 is way diff. The floats were further firward. The rear cut out of the side railing was fir the otters. These allowed you to use the hoist to get it n its cable over the side. So pic 7 shows flite there n otters missing. They are a squat metal thing with loovers painted white. Anyway I think you will do all right with what’s out there. Wish I had that hull the billing was a pain in reconstructing back to Msco minesweeper coastal oceangoing. The big reel in middle aft is an electrified cable that senses magnetic distortions. The floats look like wingtank of a plane hold cable cutters and the others maintain its depth. We did sweeps and found the placed exercise ones then blew them up. The guns on the sides had a platform where half would fold down. The bridge topside had a canvas cover sometimes I drove the ship in a hurricane once. Everyone was puking so I had the radar, engine speed n steering all alone until we got from Newport to LI Sound. Ship sailed smooth but was battered by sea.

▲

⟩⟩

neilw

Peejay

|

|

Login To

Remove Ads 💬 Re: BYMS 2079

2 years ago by 🇬🇧 dave976 (

Captain) Captain)✧ 152 Views · 3 Likes

Flag

Should make a nice scale model and I am pleased to see that you are basing your model on an actual vessel. Sirmar made some good mouldings and yours is no exception. Possible that a previous owner made some modifications to the hull to build a different vessel. Should be easily rectified. Will be an interesting build blog as you proceed.

dave976 ▲

⟩⟩

Peejay

Scratchbuilder

Doogle

|

|

💬 Re: BYMS 2079

2 years ago by 🇺🇸 chugalone100 (

Lieutenant Commander) Lieutenant Commander)✧ 160 Views · 4 Likes

Flag

Very slick looking ship.

This will be a great build to follow.😎 ▲

⟩⟩

Peejay

Doogle

Scratchbuilder

neilw

|

|

💬 Re: BYMS 2079

2 years ago by 🇬🇧 Doogle (

Vice Admiral) Vice Admiral)✧ 164 Views · 4 Likes

Flag

Another interesting build to follow. All the best. At this rate, I'll be so busy with following builds and finishing mine, when I can go back to work I wont have the time for it 😁

▲

⟩⟩

Peejay

RNinMunich

neilw

Scratchbuilder

|

|

💬 Re: BYMS 2079

2 years ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 163 Views · 2 Likes

Flag

Nice prints.

This will be interesting to follow! Barry ▲

⟩⟩

Peejay

neilw

|

|

💬 Re: BYMS 2079

2 years ago by 🇬🇧 roycv (

Fleet Admiral) Fleet Admiral)✧ 168 Views · 3 Likes

Flag

Hi what chance! I am just listening to "In Dangers hour" by Douglas Reeman.

It is an audio book from local library. Set on a minesweeper operating in the Channel, ending up on D.Day. Roy ▲

⟩⟩

Peejay

neilw

Nickthesteam

|

|

💬 Re: BYMS 2079

2 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 173 Views · 3 Likes

Flag

Neil.

Looking forward to following this one. This is right up my street 👍👍 Regards Bill. ▲

⟩⟩

Peejay

Nickthesteam

neilw

|

United Kingdom

United Kingdom