Join Us On Social Media!

Pilot Boat 34.50ins

19 Posts · 11 Followers · 28 Photos · 69 Likes

Began 6 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Sheeting

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 32 Views · 0 Likes · 1 Comment

Flag

💬 Add Comment

Ive managed to fix on the bottom sheets. Still got to trim them.

What have I learned? That not easy to position clamps on hulls. Their shape and size are just not clamp friendly. Cheers.

What have I learned? That not easy to position clamps on hulls. Their shape and size are just not clamp friendly. Cheers.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Feeling stupid!

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 48 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

Many thanx to all you guys,

I’m feeling rather thick now!

I thought the skins would fit over the balsa blocks as the colours in the photo (instructions are identical! It looks like one piece from stern to prow.

I’m going to try to fit a skin today. Fingers crossed.

I’m feeling rather thick now!

I thought the skins would fit over the balsa blocks as the colours in the photo (instructions are identical! It looks like one piece from stern to prow.

I’m going to try to fit a skin today. Fingers crossed.

▲

⟩⟩

peterd

hermank

|

💬 Re: Feeling stupid!

6 months ago by 🇺🇸 thadlietz (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 47 Views · 2 Likes

Flag

|

📝 My drill bit

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 51 Views · 1 Like

Flag

💬 Add Comment

Hi Robbob,

Fret ye not. It’s a multi material drill bit.

DeWalt Multi Material Drill Bit from Toolstation.

Cut through the ply just fine.

Main difficulty was holding the hull firmly. I had to try and grip it with

one and use the hand drill either the other. This resulted in the hole being

A little off line. Fixed that with drill waggling and filing.

Fret ye not. It’s a multi material drill bit.

DeWalt Multi Material Drill Bit from Toolstation.

Cut through the ply just fine.

Main difficulty was holding the hull firmly. I had to try and grip it with

one and use the hand drill either the other. This resulted in the hole being

A little off line. Fixed that with drill waggling and filing.

▲

⟩⟩

hermank

📝 SLEC pilot boat progress.

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 53 Views · 4 Likes · 6 Comments

Flag

💬 Add Comment

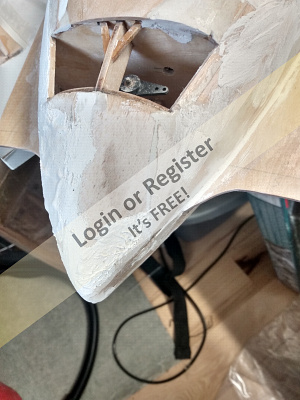

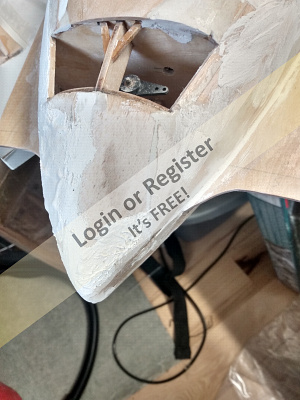

Well I have made some headway. Part assembled the cabin. Been sand the hull ready fit the skins. I’m putting that off at the moment! I’m not sure how I’m going to do it yet. Instructions says use evo stick. I’m not sure I’d position it correctly immediately and with evo I would probably be doomed. So I’m tending towards aliphatic. Be ok you think?

I also have glue the cabin structure to the hatch cover, but I’m struggling somewhat to get s flush fit all round. Still sanding away gently at it.

One query you guys might help with please. See the two balsa blocks in the images, they are to be shaped and fitted at the bow. For the life of me I cannot grasp their use or importance. Do tell if you know.

Next investigation will be preparing the ply ready for painting and how to paint. It would seem to make sense to paint parts, if different colours before joining them together I.e. cabin, deck, roofs etc.

All the best, nobody warned me the expense occurring after kit purchase! Happy days.

I also have glue the cabin structure to the hatch cover, but I’m struggling somewhat to get s flush fit all round. Still sanding away gently at it.

One query you guys might help with please. See the two balsa blocks in the images, they are to be shaped and fitted at the bow. For the life of me I cannot grasp their use or importance. Do tell if you know.

Next investigation will be preparing the ply ready for painting and how to paint. It would seem to make sense to paint parts, if different colours before joining them together I.e. cabin, deck, roofs etc.

All the best, nobody warned me the expense occurring after kit purchase! Happy days.

▲

⟩⟩

PeterL3

EdW

hermank

robbob

|

💬 Re: SLEC pilot boat progress.

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 51 Views · 6 Likes

Flag

Carved balsa wood block is often used in Classic Model Power Boat models to save the problem of wrapping plywood skins around difficult areas.

A good example of this is its use on the Vic Smeed Remora design where the same technique is also used to make the cabin roof. The balsa wood needs to be very well sealed before painting because if it should get damp or wet it will swell and spoil the look of the boat. I have always used PVA to glue the blasa wood blocks onto my model boats that use them as it allows time to position them and pin them securely in place until the glue has dried. These pictures were taken when I was building my first Remora in 1965 and I used exactly the same technique when I made my second Remora almost 60 years later. It doesn’t take much skill, but it does take a little time to sand it carefully and not take too much off at a time. The technique works very well. Hope this helps, Bob.

▲

⟩⟩

SimpleSailor

EdW

peterd

Steves-s

hermank

robbob

|

|

Login To

Remove Ads 💬 Re: SLEC pilot boat progress.

6 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 56 Views · 3 Likes

Flag

Very interesting, Robbob.

So those balsa pieces on the bow won't be further covered with wood? They'll be exposed, painted, or resin-coated directly. I've always seen [especially in static modeling] use shaped pieces of wood on the bow to facilitate attaching the strips in that point (very difficult). Of course, this saves time, it's an excellent method, even if you have to be very skilled manually, you did an excellent job. ▲

⟩⟩

Steves-s

robbob

hermank

|

|

💬 Re: SLEC pilot boat progress.

6 months ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 9 Likes

Flag

Hi Glyn.

I would recommend aliphatic glue for the skins, the use of contact adhesive would mean you have to get the skins in the right place first time otherwise you're in for a whole world of pain trying to reposition them. A tip....I have always used a heat gun on the skins to bend the ply to the approximate curvature before fixing them using lots of clamps and brass pins where required. Because the bow is a compound curve you can't bend the ply bottom skins in two directions to produce the correct shapes, hence the use of the balsa blocks for the bow. The blocks are glued in place after the skins are fitted and you carve and sand them to shape, do it slowly and carefully because if you take too much off you can't put it back on and then you'll have to use filler to rectify it! Regarding the painting, in my view this is best done when it's all assembled. I use fibreglass cloth and epoxy resin on the hull and sometimes on the cabin but you could just use several coats sanding sealer or alternatively Deluxe Materials 'Eze-Kote' for a better surface finish for paint. I hope that's helpful. Rob.

▲

⟩⟩

PeterL3

tonyb2

peterd

thadlietz

Steves-s

Rookysailor

EdW

hermank

AlessandroSPQR

|

|

💬 Re: SLEC pilot boat progress.

6 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

Sorry, Thadlietz, I didn't realize you'd already replied.

In the Build blog section, the posts aren't in the same order as in the forum. I basically agree with you. ▲

⟩⟩

hermank

|

|

💬 Re: SLEC pilot boat progress.

6 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

Hi Wolac, I think they serve (once properly shaped and glued to the bow) as a support for gluing the wooden strips in the bow area.

You could do without them, but it requires more skill and dexterity, and you can make mistakes. I think it's easier with the balsa supports. But be careful, because cutting the balsa is easy, but getting it to a correct and symmetrical shape isn't always a given. I would paint first and then finish it after assembly. Yes, extra costs always apply. ▲

⟩⟩

hermank

|

|

💬 Re: SLEC pilot boat progress.

6 months ago by 🇺🇸 thadlietz (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 54 Views · 3 Likes

Flag

The blocks typically are attached to the bow, taking grain into consideration, then carved/sanded to the required shape. Usually this method is used when there are complicated compound curves that make planking etc. very difficult. That's how I understand it🤔 it usually is not difficult to do in my limited experience. Notice the tail on my runabout top of pic...I'll attach a better one later👍

▲

⟩⟩

EdW

hermank

AlessandroSPQR

|

📝 Prop shaft

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 63 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

I’ve done the drilling for the shaft. Slides in and out ok. Bit of ferkling needed now as it’s not quite in alignment with the keel. Happy days.

▲

⟩⟩

EdW

hermank

thadlietz

|

💬 Re: Prop shaft

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 60 Views · 1 Like

Flag

I have had to make the opening for the prop shaft to pass through the keel and bulkheads many times over the years, but I have never had the luxury of doing it with a long drill bit……but I do like to idea as it could have saved me hours of work with other hand tools!

Bob. ▲

⟩⟩

hermank

|

📝 Expensive hole!

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 76 Views · 7 Likes · 4 Comments

Flag

💬 Add Comment

I have to drill a 6mm hole through the keel strengtheners. It requires an extra long drill bit. I haven’t got one, and neither as anyone I can think of asking. So I’ve got to go buy one. Annoying. Grrrrrr. 😠

The drill has to through ply laminate, and ply keel. Next thing to work out is keeping it in alignment. I have a plan, I think. Any I now have the drill bit!

)I’ve used the image, with thanks, from Robbob blog. Hope that’s ok.)

The drill has to through ply laminate, and ply keel. Next thing to work out is keeping it in alignment. I have a plan, I think. Any I now have the drill bit!

)I’ve used the image, with thanks, from Robbob blog. Hope that’s ok.)

▲

⟩⟩

PeterL3

tonyb2

EdW

robbob

hermank

thadlietz

RNinMunich

|

💬 Re: Expensive hole!

6 months ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 2 Likes

Flag

Glyn.

The bit that you have bought looks like a masonry bit which isn't best suited to use on wood! 😮 PS. No problem with you using pics from my SLEC Pilot Boat build blog 😊 Rob. ▲

⟩⟩

tonyb2

Rookysailor

|

|

Login To

Remove Ads 💬 Re: Expensive hole!

6 months ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 77 Views · 3 Likes

Flag

What is the wood and how thick? Has anyone tried to solder a drill bit into a piece of brass tubing to make it longer. Might work if the wood isn't too thick.

Lew ▲

⟩⟩

PeterL3

hermank

RodC

|

|

💬 Re: Expensive hole!

6 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 75 Views · 2 Likes

Flag

Had to buy one for my Fisherman build as I had to drill through the mahogany keel, think mine was only 5mm though.

Bit late now but what I do is file out where the prop tube is to fit along one of the doublers/strengtheners and then glue that in place and then do that with the other one ensuring that both doublers fit snugly to the keel and the prop tube passes through easily. ▲

⟩⟩

hermank

RodC

|

|

💬 Re: Expensive hole!

6 months ago by 🇬🇧 muddy (

Sub-Lieutenant) Sub-Lieutenant)✧ 77 Views · 4 Likes

Flag

Different lengths of drill bit are available from engineers suppliers, at a cost of course, I tend to use a prop shaft tube with one bush removed, this bush-less end can be cut across the face maybe twice then formed with a small file to the shape of a carpenters woodbite or ripsaw cutting edges, with the now 2 or 4 formed pointed edges bent very slightly outward to form a ringsaw shape. Sometimes with a bit of thought a twist drill can be placed down the centre of the tube to act as a drilling guide, this is best undertaken with a hand drill/brace or a very slow pistol drill, you may have to remove the device to place a new cutting edge on the tube end severel times, I have only ever used a brass tube but i,m sure a steel tube would work just as well if not better. Muddy....

▲

⟩⟩

PeterL3

hermank

zooma

RodC

|

📝 Thanks

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 86 Views · 2 Likes · 2 Comments

Flag

💬 Add Comment

Thanks ChrisF,

Point taken. I don’t know its origin, I was given it by friends son who found out I was building a model.

I’ll get another later.

Thanks again.👍

Point taken. I don’t know its origin, I was given it by friends son who found out I was building a model.

I’ll get another later.

Thanks again.👍

▲

⟩⟩

RodC

hermank

|

💬 Re: Thanks

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 85 Views · 2 Likes

Flag

Hi Wolac & PhilH,

I have bought spare pointed m4 nuts to hold the propeller on my fast flatties that use them on the end of their flex- drive shafts . Some of them are very pointed ! Try some of the online suppliers or look for spare parts for any of these fast boats with flex- drive shafts. I think I found some as spare parts from HobbyKing in the past. Being m4 threaded, they should be perfect for this application. Bob. ▲

⟩⟩

hermank

Wolac

|

|

💬 Re: Thanks

6 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 86 Views · 2 Likes

Flag

It will still do the job if it's big enough. To be honest outboard props aren't usually brass but that's what it reminds me of with the hole being where the exhaust comes out.

They are usually stainless steel or alloy but would be expensive to make for a model as they would have to be machined. ▲

⟩⟩

Wolac

hermank

|

📝 Query and update

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 85 Views · 5 Likes · 4 Comments

Flag

💬 Add Comment

Managed without hiccup to fit hatch decking. Maybe a bit of fine tuning as it tends to a little proud at one end. Just a 1mm.

As you can see from the images I have obtained a 4mm prop shaft and propeller. I think that there should be a pointy nut on the outside of the prop. There is just a hole with the threaded shaft inside.

Secondly in which order to the nuts washers and prop etc. go. Not found much info on that as yet. I did read somewhere that nylon washers maybe preferable.

I’ve reposted images. Appears they did not upload.

Getting ahead of myself but not sleeping at night trying to fathom it out!

Cheers all.

As you can see from the images I have obtained a 4mm prop shaft and propeller. I think that there should be a pointy nut on the outside of the prop. There is just a hole with the threaded shaft inside.

Secondly in which order to the nuts washers and prop etc. go. Not found much info on that as yet. I did read somewhere that nylon washers maybe preferable.

I’ve reposted images. Appears they did not upload.

Getting ahead of myself but not sleeping at night trying to fathom it out!

Cheers all.

▲

⟩⟩

hermank

RodC

EdW

PhilH

thadlietz

|

💬 Re: Query and update

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 84 Views · 3 Likes

Flag

Looking at your pictures, I am guessing that you are using one of the thin m4 stainless prop shafts from J.Perkins.

I have used one of these shafts in my Remora and it has worked very well with a standard nylon propeller . Using a nylon propeller will give you a good choice of sizes to choose from at very low cost. ….and they certainly work well enough… Bob.

▲

⟩⟩

hermank

RodC

BOATSHED

|

|

Login To

Remove Ads 💬 Re: Query and update

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 84 Views · 3 Likes

Flag

You could buy m4 stainless domed nuts from eBay.

I have used these in the past to give a nice finishing touch to hold my propellers on (also available in m5). A brass or nylon washer can run against the end of the prop shaft and a normal m4 nut can be fitted in front of this to lock against the back of the propeller as the domed nut is locked against the propeller from the outside. The end float (or “play”) between the end of the shaft and this brass or nylon washer should also be adjusted to take up any slack. A small amount of slack should be left to prevent the shaft running too tightly . This “slack” can also be adjusted in a similar way at the other end of the prop shaft inside the hull using the same technique with a plain m4 nut locked against the end of the coupling after the desired slack has been established. Bob. ▲

⟩⟩

hermank

Steve P

RodC

|

|

💬 Re: Query and update

6 months ago by 🇬🇧 PhilH (

Lieutenant Commander) Lieutenant Commander)✧ 85 Views · 3 Likes

Flag

Hi chrisf can you not buy pointed nut for the end the way you have nut washer nut is the way I would do it you don't need pointed nut on end aesthetics. But a more knowledgeable person may be along soon good luck mate don't forget it is a hobby don't take to seriously.

Philuk👍 ▲

⟩⟩

RodC

hermank

Ronald

|

|

💬 Re: Query and update

6 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 86 Views · 4 Likes

Flag

That looks more like a prop off an outboard motor. Usually those used on prop shafts are enclosed with a domed or pointed end - see one of mine.

The nut locks against the prop and then the washer goes between the nut and the prop shaft tube - brass is fine though nylon and Delrin are used as well.

▲

⟩⟩

RodC

EdW

hermank

Ronald

|

📝 No problems today,

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 87 Views · 3 Likes

Flag

💬 Add Comment

Pleased to report that I have not made a single mistake with the build today.

That’s because I haven’t had time to any work on the boat! Been baking cakes.

Tomorrow will probably be a different story. Hopefully not.

That’s because I haven’t had time to any work on the boat! Been baking cakes.

Tomorrow will probably be a different story. Hopefully not.

▲

⟩⟩

hermank

DWBrinkman

ChrisF

📝 SLEC Pilot boat

6 months ago by 🇬🇧 Wolac ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 88 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Happy days!

SLEC have happily supplied me another laser cut ply sheet containing all the parts I need to build a hatch Mk 2. So onwards I will go. It will all be plain sailing now!!!

Thank you all at SLEC.

SLEC have happily supplied me another laser cut ply sheet containing all the parts I need to build a hatch Mk 2. So onwards I will go. It will all be plain sailing now!!!

Thank you all at SLEC.

▲

⟩⟩

PeterL3

Steve P

robbob

hermank

PhilH

ChrisF

zooma

|

💬 Re: SLEC Pilot boat

6 months ago by 🇬🇧 PhilH (

Lieutenant Commander) Lieutenant Commander)✧ 88 Views · 0 Likes

Flag

Fantastic well done slec

Philuk👍 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

United Kingdom

United Kingdom