Join Us On Social Media!

Dumas #1206 Little Shelley Foss Build

7 Posts · 11 Followers · 58 Photos · 48 Likes

Began 1 year ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 2 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Little Shelley Foss first float

2 months ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 25 Views · 6 Likes · 3 Comments

Flag

💬 Add Comment

This past Memorial day weekend the Admiral an I went to the local park “duck pond” for the first outing with the Little Shelley Foss.

The Admiral insisted on a photo op with the tug in hand before its maiden voyage.

The tug run very well and I was quite pleased with the performance despite running into exposed logs, as the pond is shallow due to lack of rain the past few months!😎

The Admiral insisted on a photo op with the tug in hand before its maiden voyage.

The tug run very well and I was quite pleased with the performance despite running into exposed logs, as the pond is shallow due to lack of rain the past few months!😎

▲

⟩⟩

Len1

IanL1

RNinMunich

AlessandroSPQR

AustinG

Wolle

|

💬 Re: Little Shelley Foss first float

2 months ago by 🇺🇸 cjanik001 (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 13 Views · 1 Like

Flag

I have to admit the captain was preoccupied with running his own video of the event, and not watching over the bow. 😊 The Admiral actually caught the incident on record.

Anyway, had we several inches or rain the past week, now the pond is higher covering the snags. ▲

⟩⟩

Len1

|

|

Login To

Remove Ads 💬 Re: Little Shelley Foss first float

2 months ago by 🇳🇿 IanL1 (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 15 Views · 2 Likes

Flag

Great video. Not sure about the skipper running aground???? Anyway no damage so don't need to dock. Cheers and well done. Ian👍

▲

⟩⟩

Len1

AlessandroSPQR

|

|

💬 Re: Little Shelley Foss first float

2 months ago by 🇮🇹 AlessandroSPQR (

Rear Admiral) Rear Admiral)✧ 28 Views · 1 Like

Flag

Nice navigation, runs decisively and with exuberant power.

But he fires that captain, how did he not see those obstacles in the middle of the sea? ahahahahahaha. ▲

⟩⟩

Len1

|

Login To

Remove Ads

Remove Ads

📝 Little Shelley Foss Update, conclusion

5 months ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 40 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

I just posted her in my Harbor, so I guess I need to finish out the blog.

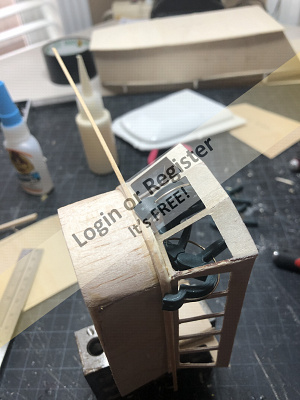

The last posting showed the hull completed and ready for paint. Finishing the superstructure was straight forward gluing up everything except for the very top plastic roof, where I installed magnets so that it could be removable, and a small video camera can be place within to give a captains view. The black cube within the cabin is the camera. Hopefully this will give some interesting video on the water.

Now the hard part, putting holes in the completed hull for the prop tubes!!! I soldered 5/16" brass tubes at the proper angle to flat brass plate and epoxied to the hull both inside and out.

The prop shafts are 1/4" stainless steel threaded for the props. I purchased 5/16" to 1/4" oil lite bushings for the water end, and at the motor end of the tubes installed ball bearings within. The prop shafts needed to be machined down slightly so that the ball bearings would slide onto them. There is a picture of my milling machine (drill press and file). Chuck in the shaft, and lightly hold a file against the shaft and a block of wood while the drill press is turning. Checking frequently for a perfect fit.

Installing electronics, motors, and wiring. I chose to operate the rudders using two smaller servos connected to the same channel via a "Y" connector, as there was no space for a larger one with the linkage to connect the rudders together. Seems to work well, at least in drydock.

Hand rails and upper pilot house details were part of the kit. All other detail parts, port holes, doors, fire hoses are from Harbor Models. The stairways between decks are scratch built using styrene bits.

I used rattle can primer paint on the inside and outside of the hull to seal the bare wood. I painted the color using acrylic hobby paint, and sealed with rattle can clear, giving it at least three separate coats for a good waterproof seal.

All in all it was a fun build, The quality of the wood within the Dumas kit was not optimum, but it was usable.

The last posting showed the hull completed and ready for paint. Finishing the superstructure was straight forward gluing up everything except for the very top plastic roof, where I installed magnets so that it could be removable, and a small video camera can be place within to give a captains view. The black cube within the cabin is the camera. Hopefully this will give some interesting video on the water.

Now the hard part, putting holes in the completed hull for the prop tubes!!! I soldered 5/16" brass tubes at the proper angle to flat brass plate and epoxied to the hull both inside and out.

The prop shafts are 1/4" stainless steel threaded for the props. I purchased 5/16" to 1/4" oil lite bushings for the water end, and at the motor end of the tubes installed ball bearings within. The prop shafts needed to be machined down slightly so that the ball bearings would slide onto them. There is a picture of my milling machine (drill press and file). Chuck in the shaft, and lightly hold a file against the shaft and a block of wood while the drill press is turning. Checking frequently for a perfect fit.

Installing electronics, motors, and wiring. I chose to operate the rudders using two smaller servos connected to the same channel via a "Y" connector, as there was no space for a larger one with the linkage to connect the rudders together. Seems to work well, at least in drydock.

Hand rails and upper pilot house details were part of the kit. All other detail parts, port holes, doors, fire hoses are from Harbor Models. The stairways between decks are scratch built using styrene bits.

I used rattle can primer paint on the inside and outside of the hull to seal the bare wood. I painted the color using acrylic hobby paint, and sealed with rattle can clear, giving it at least three separate coats for a good waterproof seal.

All in all it was a fun build, The quality of the wood within the Dumas kit was not optimum, but it was usable.

▲

⟩⟩

EdW

AlessandroSPQR

Wolle

Commodore-H

Len1

boatmam

BarryS

|

💬 Re: Little Shelley Foss Update, conclusion

5 months ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 39 Views · 1 Like

Flag

I am glad to see you finish the project. I have enjoyed watching the progress.

Shelley is a great looking gal! I suppose you have already a new project in mind. It seems like we can never overcome this obsession. Barry ▲

⟩⟩

Len1

|

📝 Little Shelley Foss...slow But Sure!!

11 months ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 52 Views · 3 Likes

Flag

💬 Add Comment

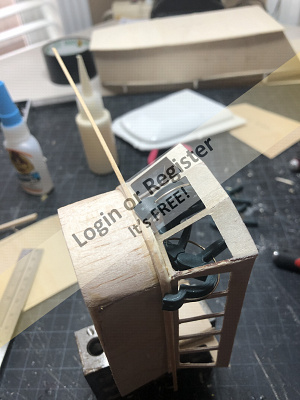

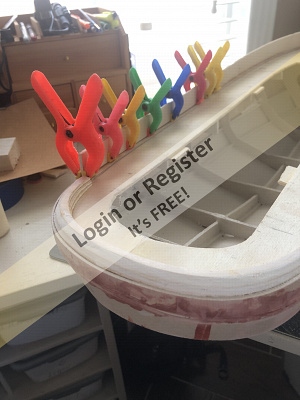

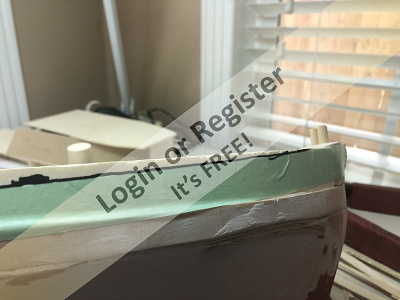

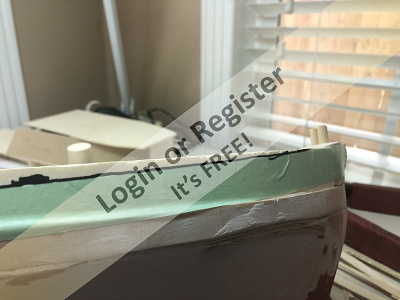

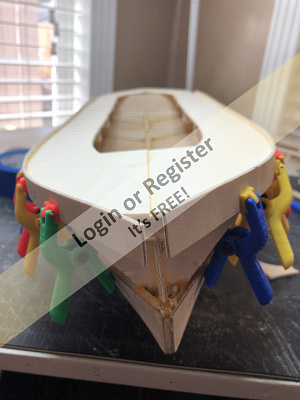

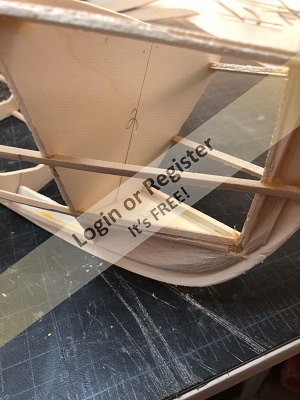

Well, starting back after the clean-up has taken awhile longer then expected. That, and the 47 days of triple digit heat in Southeast Texas hasn't helped, however I did manage to get the final planks installed and formed the solid balsa bow block. Since there is no sanding or painting inside, I had to sweat it out in the outdoor shed😴! Attaching the planks at the bow created a problem since no clamps were able to secure while the glue was setting. I therefore used brute force and secured the planks with a well placed screw or two into the balsa bow block. This worked quite nicely, and the screws came out without an issue.

The top of the deck is next on the agenda with the bulwark base and bulwarks. The stern has three sections which are glued together, and then filed to form a slope towards the rear. The wood material in the kit for these parts was not the best, and some of the pieces had to be glued back together, the die cutting process actually crushed the plywood. After assembly and forming the slope, it was glued to the stern of the boat along with the bulwark bases.

The bulwark nose block on the bow is formed out of a solid balsa block. The kit came with a pine block for the solid pieces, however I decided to go with the balsa for ease in cutting and shaping. I cut the long upright bulwark sides in half for better attachment. I also used super glue to get a quick hold since there was limited grip for clamps.

Once both bulwark sides were in place, I used painting tape to eyeball the slope between the stern bulwark and the bow. Then using a marker along the outer edge of the tape put a cut line. Using a very new and sharp x-acto blade, I carefully scored the lines edge to get a nice smooth groove, and with additional scores of the blade finally cutting through the plywood.

There are a few more odds and ends left for the upper deck, and then final filling and sanding.

The top of the deck is next on the agenda with the bulwark base and bulwarks. The stern has three sections which are glued together, and then filed to form a slope towards the rear. The wood material in the kit for these parts was not the best, and some of the pieces had to be glued back together, the die cutting process actually crushed the plywood. After assembly and forming the slope, it was glued to the stern of the boat along with the bulwark bases.

The bulwark nose block on the bow is formed out of a solid balsa block. The kit came with a pine block for the solid pieces, however I decided to go with the balsa for ease in cutting and shaping. I cut the long upright bulwark sides in half for better attachment. I also used super glue to get a quick hold since there was limited grip for clamps.

Once both bulwark sides were in place, I used painting tape to eyeball the slope between the stern bulwark and the bow. Then using a marker along the outer edge of the tape put a cut line. Using a very new and sharp x-acto blade, I carefully scored the lines edge to get a nice smooth groove, and with additional scores of the blade finally cutting through the plywood.

There are a few more odds and ends left for the upper deck, and then final filling and sanding.

▲

⟩⟩

EdW

Wolle

chugalone100

📝 Dumas #1206 Little Shelley Foss cont.

1 year ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 60 Views · 4 Likes

Flag

💬 Add Comment

Well I guess I'm getting better with posting sooner! The Admiral informed me that I needed to clean up the dry dock because we are expecting some upper brass (daughter) and a few V.I.P's (grandsons) later on this week, hence the urgency of getting this post out sooner.

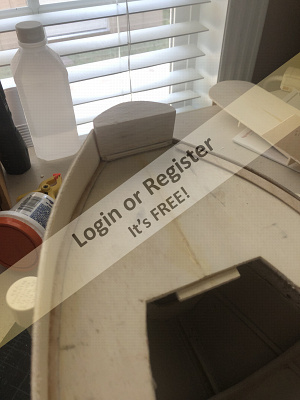

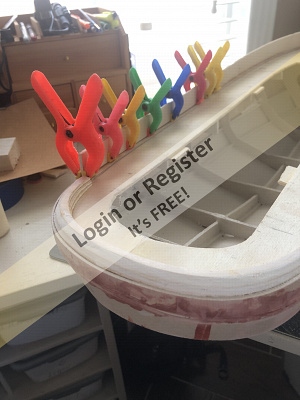

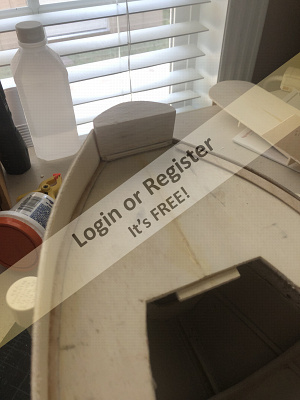

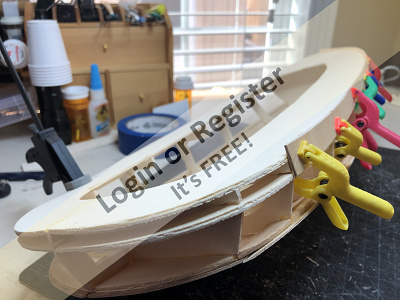

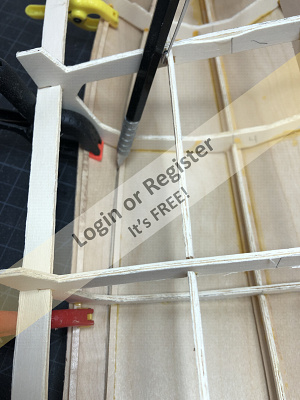

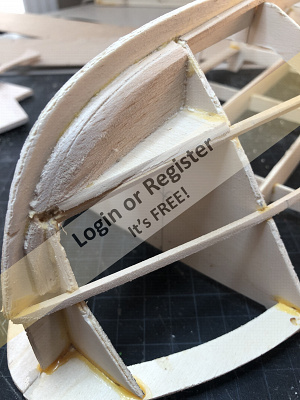

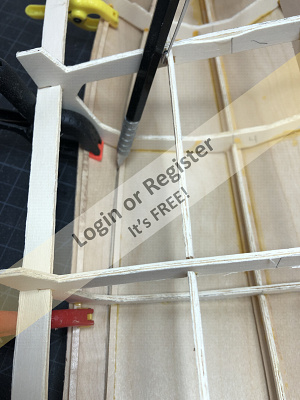

After getting the first two sections of planks on the hull, the instructions switch to gluing the deck down onto the hull structure. In preparation, the small tabs on the bulkheads are cut and sanded to match the crown of the deck as seen in the first picture on the right side compared to the left. I marked with a pencil and then cut with a razor saw.

Since the deck is in four pieces, I placed the outer decking on the hull, and marked where the inside cutout for the inner deck would be, and made sure my glue didn't go past these marks. When the outer deck was dry, I cut most of the bulkheads through only leaving 2 on each side uncut so the inner deck could be glued. When that dried, I cut the remaining bulkheads to remove the inner deck with the bulkhead bracing glued to the bottom of the inner decking.

chugalone100 asked what glue I used. There is a picture of the brand which I have used for the past several builds with very good luck so far. My models are stored in the garage, which is not humidity controlled, in Southeast Texas as well ☀️🔥, and I haven't experienced any delamination of the glue on the previous models. This brand also has a level III glue in the green label which claims to be waterproof. I will switch to that when this runs out. The remaining pictures show adding the #4 planking on the sides and rear, as well as adding the #3 planking to the rear. The #3 side planking will need to wait until after the VIP's visit.

After getting the first two sections of planks on the hull, the instructions switch to gluing the deck down onto the hull structure. In preparation, the small tabs on the bulkheads are cut and sanded to match the crown of the deck as seen in the first picture on the right side compared to the left. I marked with a pencil and then cut with a razor saw.

Since the deck is in four pieces, I placed the outer decking on the hull, and marked where the inside cutout for the inner deck would be, and made sure my glue didn't go past these marks. When the outer deck was dry, I cut most of the bulkheads through only leaving 2 on each side uncut so the inner deck could be glued. When that dried, I cut the remaining bulkheads to remove the inner deck with the bulkhead bracing glued to the bottom of the inner decking.

chugalone100 asked what glue I used. There is a picture of the brand which I have used for the past several builds with very good luck so far. My models are stored in the garage, which is not humidity controlled, in Southeast Texas as well ☀️🔥, and I haven't experienced any delamination of the glue on the previous models. This brand also has a level III glue in the green label which claims to be waterproof. I will switch to that when this runs out. The remaining pictures show adding the #4 planking on the sides and rear, as well as adding the #3 planking to the rear. The #3 side planking will need to wait until after the VIP's visit.

▲

⟩⟩

EdW

Wolle

chugalone100

Scratchbuilder

📝 Dumas #1206 Little Shelley Foss cont.

1 year ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 78 Views · 13 Likes · 3 Comments

Flag

💬 Add Comment

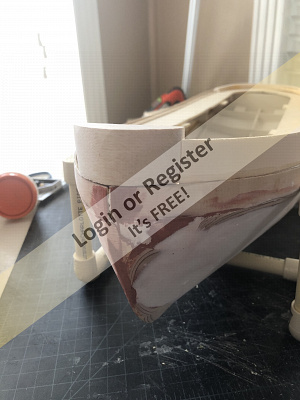

Wow. eleven days goes by fast when you are having fun! First I want to thank BarryS for the

link to the other forum and build blogs. A Picture is worth a thousand words, and a hundred pictures even better!!!

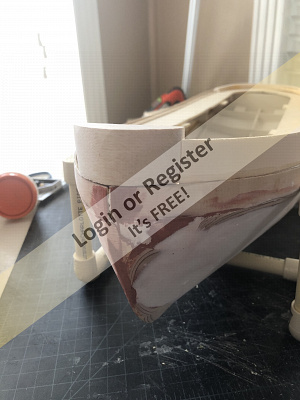

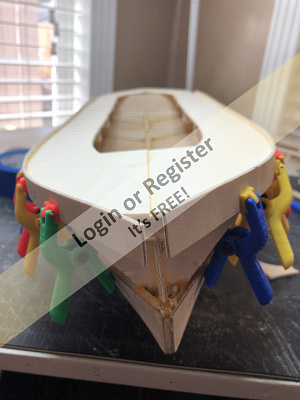

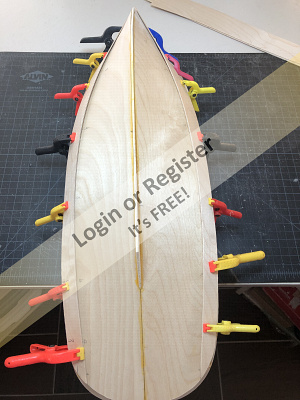

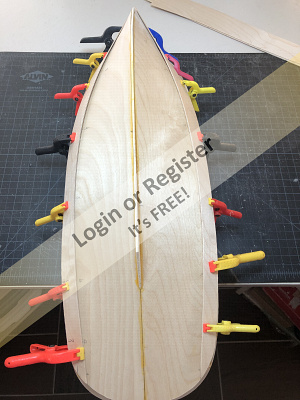

After reading the forums and looking at the pictures, I gained the confidence that planking with plywood could be accomplished if I took my time and was careful. I initially thought about just carving the lower bow section from balsa, but decided to actually add some sheet balsa, gluing to the bottom of the stringer, and adding some sheet to the keel for gluing support.

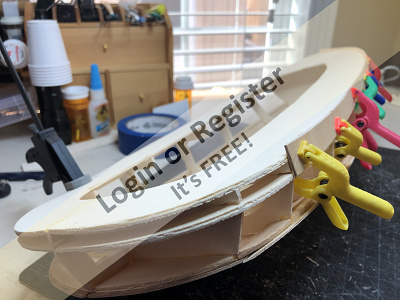

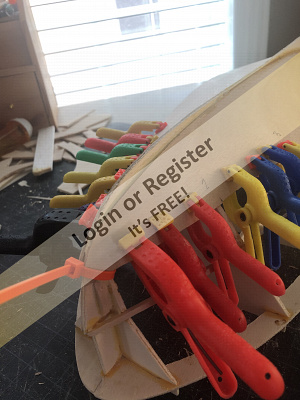

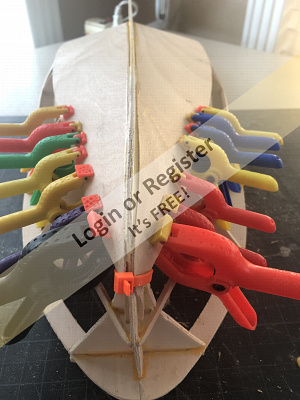

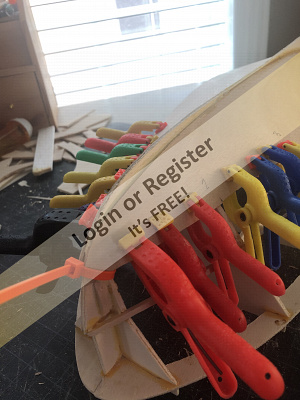

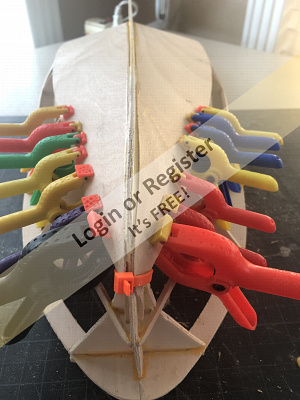

Before gluing any of the planking, I clamped the initial bottom plank matching along the keel from the stern to bulkhead #3. With this fitted, I then marked along the top of the stinger inside the hull with a pencil to make the cut line for each piece. once cut and re-fitted to the hull, I glued each bottom plank starting from the stern and working to the number 5 bulkhead.

Once that had dried, I then glued and clamped both sides to attach Bulkheads 4 and 3.

Now the fun began.😐 The plywood needed to be formed more closely to fit the keel toward the bow. I carefully clipped away the ply with diagonal cutters on each side and smoothing with sandpaper until I got the desired fit on each side. Then glued both sides down, and held the foremost part of the bow with a well placed tie wrap.

The second sheet plank was done in a similar fashion, dry fitting the sheets with clamps, marking the stringer line, and cutting and sanding for a smooth fit before gluing in small steps from stern to bow.

This now completes steps 7 of 33 on the Dumas instructions.

link to the other forum and build blogs. A Picture is worth a thousand words, and a hundred pictures even better!!!

After reading the forums and looking at the pictures, I gained the confidence that planking with plywood could be accomplished if I took my time and was careful. I initially thought about just carving the lower bow section from balsa, but decided to actually add some sheet balsa, gluing to the bottom of the stringer, and adding some sheet to the keel for gluing support.

Before gluing any of the planking, I clamped the initial bottom plank matching along the keel from the stern to bulkhead #3. With this fitted, I then marked along the top of the stinger inside the hull with a pencil to make the cut line for each piece. once cut and re-fitted to the hull, I glued each bottom plank starting from the stern and working to the number 5 bulkhead.

Once that had dried, I then glued and clamped both sides to attach Bulkheads 4 and 3.

Now the fun began.😐 The plywood needed to be formed more closely to fit the keel toward the bow. I carefully clipped away the ply with diagonal cutters on each side and smoothing with sandpaper until I got the desired fit on each side. Then glued both sides down, and held the foremost part of the bow with a well placed tie wrap.

The second sheet plank was done in a similar fashion, dry fitting the sheets with clamps, marking the stringer line, and cutting and sanding for a smooth fit before gluing in small steps from stern to bow.

This now completes steps 7 of 33 on the Dumas instructions.

▲

⟩⟩

EdW

Wolle

hermank

flaxbybuck

boatmam

pressonreguardless

Doogle

chugalone100

ChrisG

MouldBuilder

Scratchbuilder

RodC

BarryS

|

💬 Re: Dumas #1206 Little Shelley Foss cont.

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 70 Views · 0 Likes

Flag

It's coming along nicely.

Thanks for all the photos CJ - I always enjoy seeing photos of other people's boat building, especially the initial hull building stage that you have just shown us. All those clamps ! And they are a devil to get to stay where you want them, aren't they ? Good luck with the rest of the build 😉 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Dumas #1206 Little Shelley Foss cont.

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 75 Views · 0 Likes

Flag

Cjanik

Your model is coming up very nicely. I red all of your building progress but I missed you mentioning what type of glue are you using.😎 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Dumas #1206 Little Shelley Foss cont.

1 year ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 78 Views · 2 Likes

Flag

OK good to see it is coming right along now.

I was looking at the clamps and thinking I have a basket full of all different types and sizes of clamps. Sometimes I still can't find one that fits the bill just right! I am glad to see the link was helpful. Keep up the good work and post so we can follow the progress. Barry ▲

⟩⟩

Doogle

Scratchbuilder

|

📝 Dumas #1206 Little Shelley Foss

1 year ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 99 Views · 0 Likes · 1 Comment

Flag

💬 Add Comment

Thank you all for the likes, as well as the link to the other build post with photos. I need to look at this on an actual computer rather than this cell phone screen when I get more time today.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

|

💬 Re: Dumas #1206 Little Shelley Foss

1 year ago by 🇨🇦 RodC (

Lieutenant) Lieutenant)✧ 99 Views · 2 Likes

Flag

I find plank-on-frame (or sheet-on-frame, for that matter) more than a bit intimidating. I had bought a small boat kit off Amazon, messed the planking up horribly. This failure tells me I lack the experience & manual dexterity for a built up hull.

I have on hand a DUMAS PT109 which i am reluctant to even start. Might offer it for sale within my club (Metro Marine Modellers of Toronto/southern Ontario fame) From now on I am only buying kits with molded hulls, preferably one-piece rather than two halves like the DUMAS military tug. I do have a BILLINGS African Queen kit on hand (ABS hull, one-piece) and I hav the DUMAS great lakes freighter, no longer available, which is styrene sheet over frame. A member has very kindly 3D-printed me a Clyde Puffer out of ABS filament. It's in 3 pieces as it's a bit under 30" LOA. Lots of room to get both of my hands inside the hull thru a huge deck hatch!! Currently assembling a twin-engine ZIPPKITS Springer tug. ▲

⟩⟩

Scratchbuilder

Homdadream67

|

📝 Dumas #1206 Little Shelley Foss Build

1 year ago by 🇺🇸 cjanik001 ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 118 Views · 15 Likes · 6 Comments

Flag

💬 Add Comment

Hello,

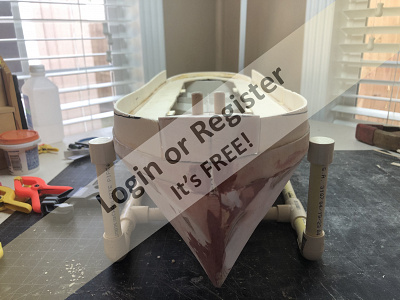

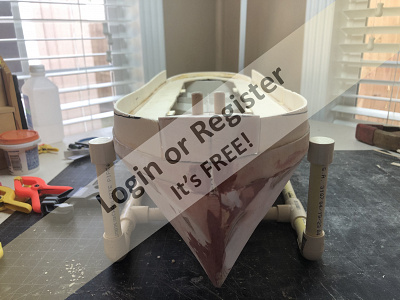

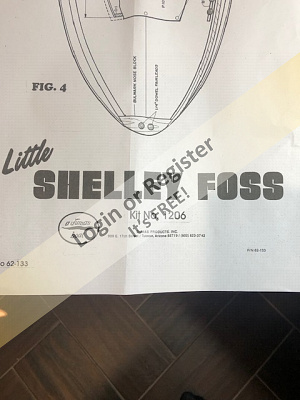

I purchased this kit for myself for Fathers Day this past June. This is actually my first commercial kit to construct, as all others in my harbor were scratch built. Since retiring my Beaver Tug boat some time ago, actually, it got sent to the scrap heap, my harbor has been looking for a replacement. At 24" long, this fits well with the other models I have made. Also, my Admiral (wife) won't allow anything larger.

The kit comes with all the wood for the vessel, railing, metal stanchions, other cast metal details like horn, lights etc. What it does not include are the running gear parts including stuffing tubes, props shafts and rudders. I held off purchasing this additional kit because I had been gifted a Dumas Trojan some years ago. While the Trojan was not very well built, I was able to remove many of the running gear parts from it before sending it to the scrap heap.

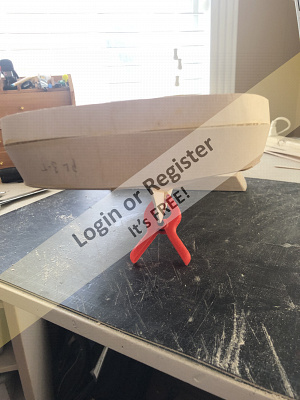

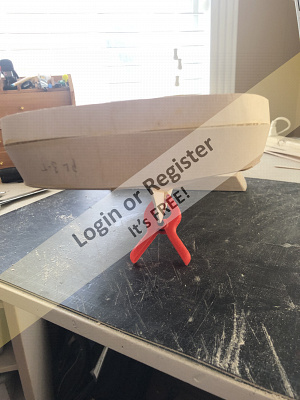

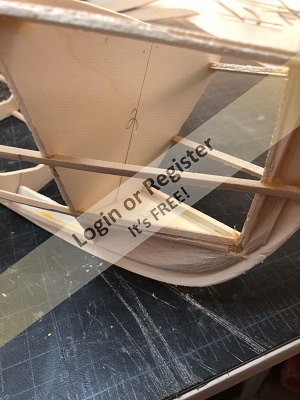

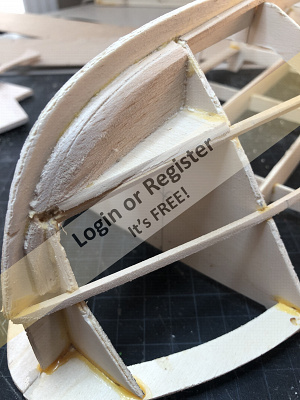

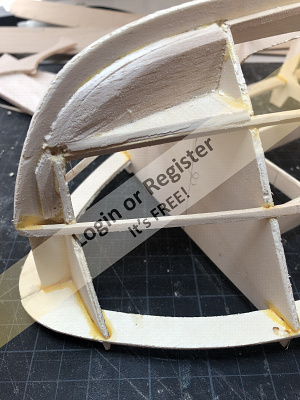

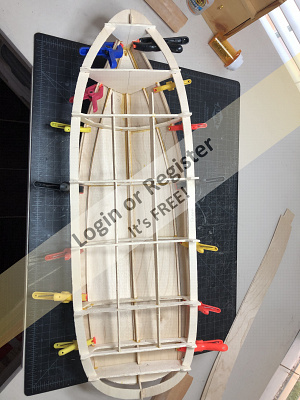

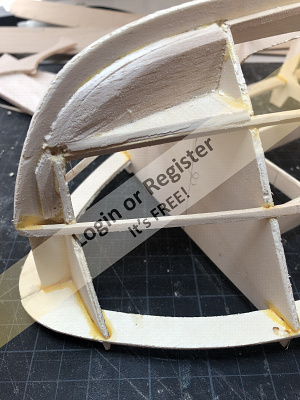

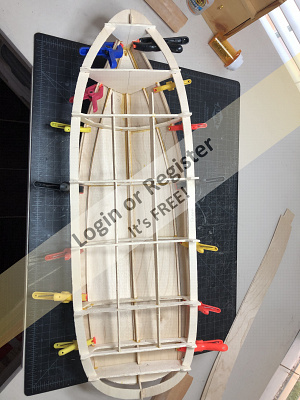

As you can see from the pictures, I have already constructed the hull skeleton. The pieces are removed with ease from the die cutting. I did have to use a hobby knife on some of the more thinner frame pieces to avoid breaking them, but for the most part everything came out clean and with minimum cleanup.

As far as instructions, they seem to be lacking. There is a 33 step, 2 sheet written instruction sheet, a parts I.D. sheet, along with a full size drawing of the boat exterior showing locations of the hull and superstructure details. There isn't a lot of visual details, so you must read the instruction text, and figure it out for yourself. To Dumas' credit, they did make this disclaimer in their write-up that instructions are minimal, and recommended for more advanced modelers.

I am at the stage now, where I need to plank the hull. The planking comes in 4 - 1/16" plywood sheets cut to fit the curvature of the hull on each side. I have never planked a hull with plywood before, only with strip wood. The ply seems to be sort of stiff, and will not conform to the hull without some serious bending and clamping. I need to ask this question, or maybe search other build blogs as to how to best accomplish this task.

Can thin plywood be wetted, (or soaked) in water so that it becomes more plyable and easier to clamp while being glued? or will this just warp the hull once it dries back out!

Hopefully, I will find my answer after searching the blogs, or a fellow follower will provide the answer. 😊

That's all for now, hope you enjoy reading the blog.

I purchased this kit for myself for Fathers Day this past June. This is actually my first commercial kit to construct, as all others in my harbor were scratch built. Since retiring my Beaver Tug boat some time ago, actually, it got sent to the scrap heap, my harbor has been looking for a replacement. At 24" long, this fits well with the other models I have made. Also, my Admiral (wife) won't allow anything larger.

The kit comes with all the wood for the vessel, railing, metal stanchions, other cast metal details like horn, lights etc. What it does not include are the running gear parts including stuffing tubes, props shafts and rudders. I held off purchasing this additional kit because I had been gifted a Dumas Trojan some years ago. While the Trojan was not very well built, I was able to remove many of the running gear parts from it before sending it to the scrap heap.

As you can see from the pictures, I have already constructed the hull skeleton. The pieces are removed with ease from the die cutting. I did have to use a hobby knife on some of the more thinner frame pieces to avoid breaking them, but for the most part everything came out clean and with minimum cleanup.

As far as instructions, they seem to be lacking. There is a 33 step, 2 sheet written instruction sheet, a parts I.D. sheet, along with a full size drawing of the boat exterior showing locations of the hull and superstructure details. There isn't a lot of visual details, so you must read the instruction text, and figure it out for yourself. To Dumas' credit, they did make this disclaimer in their write-up that instructions are minimal, and recommended for more advanced modelers.

I am at the stage now, where I need to plank the hull. The planking comes in 4 - 1/16" plywood sheets cut to fit the curvature of the hull on each side. I have never planked a hull with plywood before, only with strip wood. The ply seems to be sort of stiff, and will not conform to the hull without some serious bending and clamping. I need to ask this question, or maybe search other build blogs as to how to best accomplish this task.

Can thin plywood be wetted, (or soaked) in water so that it becomes more plyable and easier to clamp while being glued? or will this just warp the hull once it dries back out!

Hopefully, I will find my answer after searching the blogs, or a fellow follower will provide the answer. 😊

That's all for now, hope you enjoy reading the blog.

▲

⟩⟩

MouldBuilder

flaxbybuck

RodC

Graham93

Doogle

Colin H

hermank

BarryS

Double Rum

Nickthesteam

River Rat

pressonreguardless

chugalone100

Wolle

Scratchbuilder

|

💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 84 Views · 2 Likes

Flag

As others have said, wetting or steaming ply is not advisable because it may delaminate. I would try heating the ply, not violently such as with a blow torch, but more gently such as putting it in the oven. If possible trial it at 120 degrees, then progressively warmer and test the results. Good luck !😉

▲

⟩⟩

RNinMunich

pressonreguardless

|

|

Login To

Remove Ads 💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 106 Views · 1 Like

Flag

Here is a link that might help along the way.

▲

⟩⟩

Colin H

|

|

💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 112 Views · 1 Like

Flag

Steaming works with solid wood, not with plywood it can cause delamination of the plys

Trev ▲

⟩⟩

Nickthesteam

|

|

💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇨🇦 AustinG (

Chief Petty Officer 1st Class) Chief Petty Officer 1st Class)✧ 113 Views · 3 Likes

Flag

Be carefull bending any wood. It can split if not careful. I would suggest steaming and apply carefully.

AustinG ▲

⟩⟩

MouldBuilder

Nickthesteam

RNinMunich

|

|

💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 115 Views · 2 Likes

Flag

Hi cj

I don't think wetting plywood is a good idea. I would just bend it to the framing. Just make sure you do both sides at the same sitting, I also have found the Dumas instructions to need interpretation. Best of Luck👍👍 Trev ▲

⟩⟩

MouldBuilder

Nickthesteam

|

|

💬 Re: Dumas #1206 Little Shelley Foss Build

1 year ago by 🇩🇪 Wolle (

Commander) Commander)✧ 116 Views · 1 Like

Flag

An interesting project, I'd be happy to look over your shoulder

▲

⟩⟩

Nickthesteam

|

United States

United States