Join Us On Social Media!

Another Springer tug!!

10 Posts · 11 Followers · 71 Photos · 105 Likes

Began 6 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 4 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 A few details

4 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 33 Views · 10 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. The Springer has maidened, but wasn’t quite yet done, as I wanted to add a few details.

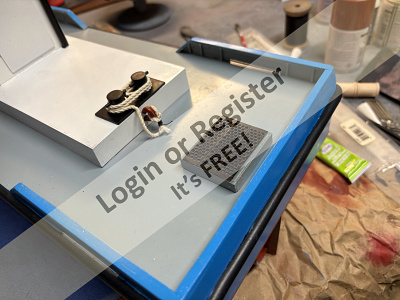

First off, I filled the gap between the push knees at the bow, as my Springer at full bore will bow bow down a little, and the bow wave will just come over the bow between the knees. Filling that space between the deck and cross bar should slow that down. The boat came in perfectly dry inside, but I did it anyway.

I also added a rub rail around the boat with the upper edge of the rail flush with the deck line.

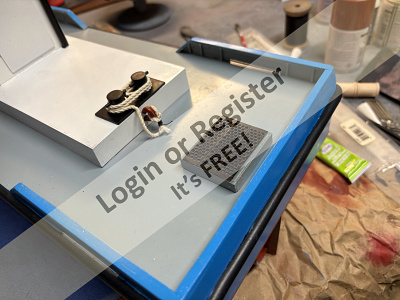

I had some metal etch step parts from my Aeronaut Pilot build left over, so I cut the end tabs off, then used them to make a grate over the rudder hatch. I had a resin bollard from my Taucher build that I glued to the aft side of the hatch, made up a rope from my stash, then took a piece of scrap plastic tree, heated it and made a pintle hook that plugs into the hatch to secure it, the eye of the rope is glued to that. Finally I made up a somewhat decent fire extinguisher from scrap parts, plastic tube and wire and mounted it on the aft corner of the wheelhouse. At this point she’s mostly done, I might build up a small winch for the forward deck.

Cash

First off, I filled the gap between the push knees at the bow, as my Springer at full bore will bow bow down a little, and the bow wave will just come over the bow between the knees. Filling that space between the deck and cross bar should slow that down. The boat came in perfectly dry inside, but I did it anyway.

I also added a rub rail around the boat with the upper edge of the rail flush with the deck line.

I had some metal etch step parts from my Aeronaut Pilot build left over, so I cut the end tabs off, then used them to make a grate over the rudder hatch. I had a resin bollard from my Taucher build that I glued to the aft side of the hatch, made up a rope from my stash, then took a piece of scrap plastic tree, heated it and made a pintle hook that plugs into the hatch to secure it, the eye of the rope is glued to that. Finally I made up a somewhat decent fire extinguisher from scrap parts, plastic tube and wire and mounted it on the aft corner of the wheelhouse. At this point she’s mostly done, I might build up a small winch for the forward deck.

Cash

▲

⟩⟩

chugalone100

premecekcz

ChrisF

BarryS

Chum444

LIBERTY CAPTAIN

RNinMunich

hermank

EdW

peterd

|

💬 Re: A few details

4 months ago by 🇺🇸 wingsounds13 (

Leading Seaman) Leading Seaman)✧ 20 Views · 3 Likes

Flag

A few simple details do make her look nicer. Well done.

J.P. ▲

⟩⟩

Cashrc

premecekcz

hermank

|

Login To

Remove Ads

Remove Ads

📝 Buttoned up and maidened!!

4 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 39 Views · 11 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. Didn’t get much done in the way of details, but got enough done Saturday to maiden the Springer Sunday. I did a MUCH better job of bonding the push knees to the hull than I did with my first attempt, however, I wanted a little more security. So I drilled the knees to accept 2 socket head screws each, then counter sunk the holes, so I could screw the knees directly into the bow, then the holes were filled. I had some rubber mat left over from my Banckerts build that I bonded to the knees with black ca. after that it was securing ballast, making a y harness for the twin 3000 mah nimh packs, and finish wiring the lights with a plug to accept an Apex RC transmitter controlled switch.

I have a video I’ll try to post here of the maiden, but suffice it to say it went well. Plenty of power, turns very well, and she stayed dry. She does have the Springer propensity to bury the bow at full power, but not dramatically. I plan to fill the space between the cross bar up front and the deck, that should keep what little water I had coming over the bow in check. I’ll do a few more details too, then she’ll be one of my “keepers”. I really like this boat!!

Cash

I have a video I’ll try to post here of the maiden, but suffice it to say it went well. Plenty of power, turns very well, and she stayed dry. She does have the Springer propensity to bury the bow at full power, but not dramatically. I plan to fill the space between the cross bar up front and the deck, that should keep what little water I had coming over the bow in check. I’ll do a few more details too, then she’ll be one of my “keepers”. I really like this boat!!

Cash

▲

⟩⟩

chugalone100

premecekcz

LIBERTY CAPTAIN

peterd

Wolle

RNinMunich

BarryS

Chum444

ChrisF

hermank

EdW

|

💬 Re: Buttoned up and maidened!!

4 months ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 34 Views · 2 Likes

Flag

Nice shakedown cruise Cash.

Good tight radius on turns and it is not top heavy. I have seen too many Springer style with so much superstructure they lean way over in turns. Enjoy the boat! Barry ▲

⟩⟩

hermank

Cashrc

|

📝 Almost done and a fudge…

4 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 53 Views · 11 Likes · 4 Comments

Flag

💬 Add Comment

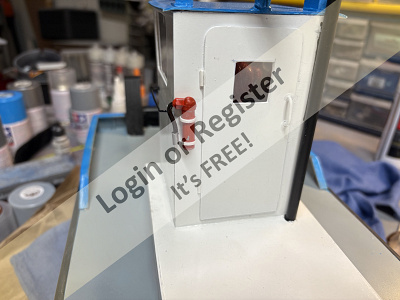

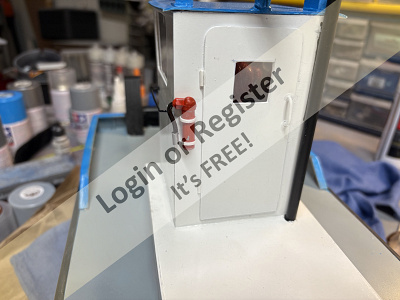

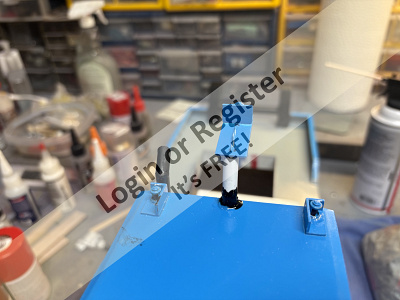

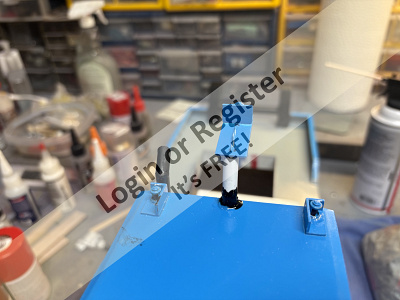

Hi y’all. Last posting I got a helpful comment from Bill saying I needed some separation between the port/starboard nav lights and the aft light. And, I thought to myself, “well, he ain’t wrong!!” So, I cobbled up a short mast with an extended platform for the aft light. Looked decent till I broke it. Now, the roof is glued on, and the main problem with the aft light is if I were able to pull the lamp out, I’ll have a Devil of a time getting the wires back thru the roof and over to the corner wiring tubes. So..I fudged it I used a larger tub split down the middle, to wrap around the damaged and repaired small tube, used a black filled ca to build up the base, made sure the whole assembly was secure, and painted it to match. Not an elegant fix but I can live with it.

I made up some simple rails with brass wires for the sides of the wheelhouse. I used the filled ca to attach, but a little of it got on the outside of the drilled hole. Looking at the mistake it looked a little like an attachment point, so I used the ca on all the rail holes to match. I like it!!

I also made up the aft hatch cover, exhaust and cabin door.

I’m hoping to maiden her this coming Sunday. My plan is to weigh her with batteries, then make up what ballast I’ll need, place it where I think it’ll be needed, then tub test her and adjust ballast there. If I can get that done this week I’ll be able to do a few more details and touch up this Saturday.

Cash

I made up some simple rails with brass wires for the sides of the wheelhouse. I used the filled ca to attach, but a little of it got on the outside of the drilled hole. Looking at the mistake it looked a little like an attachment point, so I used the ca on all the rail holes to match. I like it!!

I also made up the aft hatch cover, exhaust and cabin door.

I’m hoping to maiden her this coming Sunday. My plan is to weigh her with batteries, then make up what ballast I’ll need, place it where I think it’ll be needed, then tub test her and adjust ballast there. If I can get that done this week I’ll be able to do a few more details and touch up this Saturday.

Cash

▲

⟩⟩

chugalone100

premecekcz

RNinMunich

LIBERTY CAPTAIN

BarryS

Steves-s

Chum444

EdW

hermank

RodC

Ronald

|

💬 Re: Almost done and a fudge…

4 months ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 41 Views · 2 Likes

Flag

I think the springers are the most fun boat there is.

I had to add more ballast than I first thought to get it to sit where I was happy with it. I did see how the deck washed in some others so I extended the hatch walls up very high. I'm glad I did. You're looking good Cash, enjoy it! Barry ▲

⟩⟩

hermank

Cashrc

|

|

Login To

Remove Ads 💬 Re: Almost done and a fudge…

4 months ago by 🇺🇸 wingsounds13 (

Leading Seaman) Leading Seaman)✧ 41 Views · 2 Likes

Flag

Chum, that's what we're here for. Sometimes Cash needs a little poke and prod to do things right. 😁

J.P. ▲

⟩⟩

hermank

Cashrc

|

|

💬 Re: Almost done and a fudge…

4 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 48 Views · 2 Likes

Flag

Hi Bill. Yeah, that’s kinda the way I do it, might be a holdover from my flying days. I know that whenever I do maiden a model with detail and such still to be done…they don’t get done. So, since I usually don’t have the discipline to finish after the maiden, I complete the model before.

I really need to stay away from my kit and plans stash as I want to clean out the corner between my bench and the garage door, I can have much more storage and usable working space once that’s done. If I even open a box to look at a kit, it’s all over with but the crying and I’m back at it.🤣 You didn’t cause a problem btw, I kinda thought it didn’t look quit right but I was being a little lazy. I hate to “lick my calf over” as my dad would say😁 ▲

⟩⟩

ChrisF

hermank

|

|

💬 Re: Almost done and a fudge…

4 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 49 Views · 2 Likes

Flag

Cash, sorry for causing you grief with the nav lighting. However your solution looks like “as designed”. Well done.

You don’t seem the least bit concerned that you haven’t splashed her until completion. That’s interesting since I’m sweating that I haven’t had the Wasque 26 in the water as yet & the major build steps are complete. Everyone has their own build sequence; no right or wrong way. Looking forward to the maiden video. ▲

⟩⟩

Cashrc

hermank

|

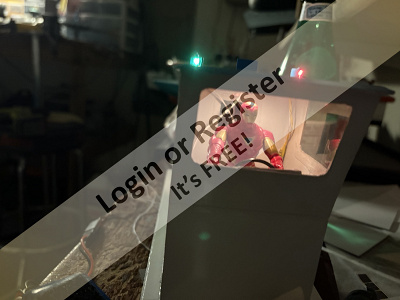

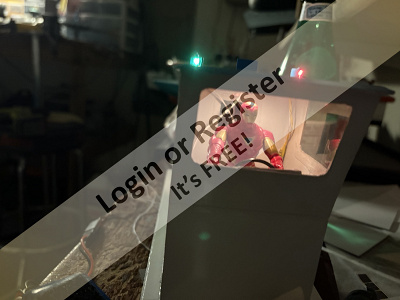

📝 Roof, pilot, lights

4 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 64 Views · 11 Likes · 4 Comments

Flag

💬 Add Comment

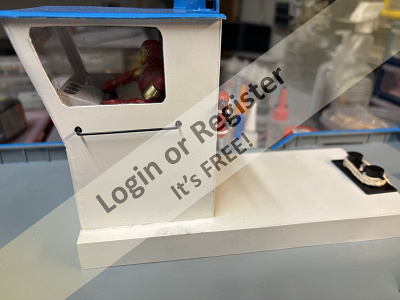

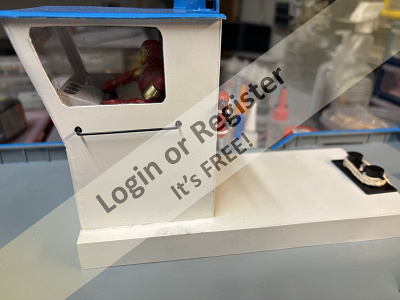

So, last week I built up a simple pilots console for the Springers cabin. Did a little measuring, realized I’d need a figure about 4 inches tall at the maximum. I was a little limited as to what I could find fairly quickly, as I want to maiden her by the end of the month, so I checked out Amazon. Tons of zombie, robots, and the like, and a few Marvel and DC superheros, as well as some Star Wars. Found one to my liking..”he’s a motorhead, a nerd, an engineer, and the smartest guy you know…ladies and gentlemen, let’s welcome to the Springers cabin, Tony Stark!! Aka, Iron Man!!!” Tony Stark is one of my favorite characters from the Marvel films, and the figure was relatively inexpensive, so win-win!!

So now she has a pilot, and needs a roof. I fabricated a roof from plasticard, and scored the sides and front to allow a little bevel. Once sanded and filled, I painted the roof to match the upper hull. I then decided that JP is right she needs lights for all the night runs we haven’t done yet. Plus, I need an interior light so Iron Man won’t be fumbling around in the dark and blow a hole thru the cabin..Y’know, safety and all that. I went thru my parts and found a fitting that looks like a modern side light with a slightly tinted lens, and used that as a cabin light fixture. All the lights are set up on one circuit.

That’s where I stand now, the roof is not glued on yet as I have a couple more interior details to make up, then the roof will be tacked on at the corners to allow it to be removed if there’s a problem with the lights. I have a couple more weekends of work to do but she’s getting closer.

Cash

So now she has a pilot, and needs a roof. I fabricated a roof from plasticard, and scored the sides and front to allow a little bevel. Once sanded and filled, I painted the roof to match the upper hull. I then decided that JP is right she needs lights for all the night runs we haven’t done yet. Plus, I need an interior light so Iron Man won’t be fumbling around in the dark and blow a hole thru the cabin..Y’know, safety and all that. I went thru my parts and found a fitting that looks like a modern side light with a slightly tinted lens, and used that as a cabin light fixture. All the lights are set up on one circuit.

That’s where I stand now, the roof is not glued on yet as I have a couple more interior details to make up, then the roof will be tacked on at the corners to allow it to be removed if there’s a problem with the lights. I have a couple more weekends of work to do but she’s getting closer.

Cash

▲

⟩⟩

chugalone100

premecekcz

Steves-s

RodC

LIBERTY CAPTAIN

GARTH

RNinMunich

Chum444

hermank

EdW

peterd

|

💬 Re: Roof, pilot, lights

4 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 60 Views · 2 Likes

Flag

Hi Bill. You’re right, but holes are drilled and parts glued and painted. If anything I’d move the aft lamp as that would be easier to do.

▲

⟩⟩

RodC

hermank

|

|

Login To

Remove Ads 💬 Re: Roof, pilot, lights

4 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 59 Views · 3 Likes

Flag

Peter’s thank you!! I was tired when I posted that and that note was a message from my doc that I screenshotted and sent to my wife. I need to slow down or be fully awake!!🤣

▲

⟩⟩

RodC

hermank

peterd

|

|

💬 Re: Roof, pilot, lights

4 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 60 Views · 3 Likes

Flag

Looking good Cash. You might want to consider moving the P & S nav lights quite a bit forward to create distance from the stern light. At least I think I am seeing a stern light in one photo.

▲

⟩⟩

RodC

Cashrc

hermank

|

|

💬 Re: Roof, pilot, lights

4 months ago by 🇦🇺 peterd (

Sub-Lieutenant) Sub-Lieutenant)✧ 67 Views · 5 Likes

Flag

Hi CashRC, There is an image there that you may want to edit out. Easy to do. Cheers

I like your action man, I needed a figure for my Baby Bootlegger and a friend had an old toy that he used to make a mould. Filled it with hot glue and painted it. Came up well.

▲

⟩⟩

chugalone100

RodC

EdW

Cashrc

hermank

|

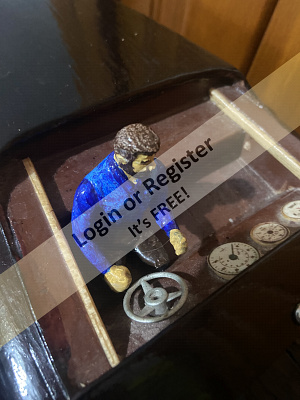

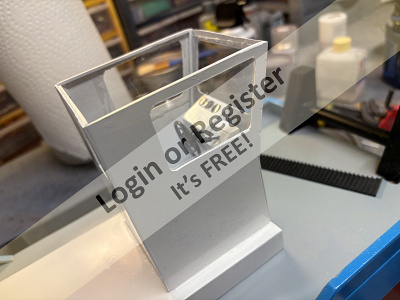

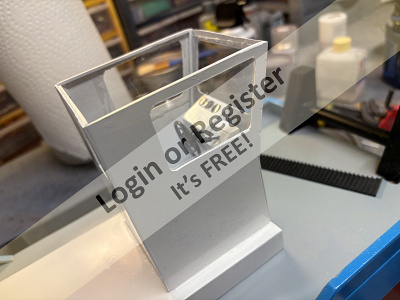

📝 Pilot house paint, glazing and pilots console

5 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 65 Views · 7 Likes

Flag

💬 Add Comment

Hi y’all. Been a week or more since last update. Got a little behind as I got my Kriegsfischkutter back in a trade with my buddy Larry, who had gotten it in a trade with me 2-3 years ago when I had only run her twice..he had added lights, did a good job but he likes to run 3 volt bulbs with an external hidden switch. I prefer 6 volt bulbs and a transmitter operated electronic switch, so changed that, and did a little touch up, she’s back in my fleet now, and never leaving-unless Larry makes me another offer I can’t refuse…🤣

So, I got the pilot house painted up, and secured to the hatch cover. At first I was going to “tint” the windows and not worry about any interior detail, but JP talked me into it, so I built up a simple console with sheet plastic and some odds and ends from my fittings stash. Now she needs a roof, a pilot, maybe lights, and some deck equipment.

Cash

So, I got the pilot house painted up, and secured to the hatch cover. At first I was going to “tint” the windows and not worry about any interior detail, but JP talked me into it, so I built up a simple console with sheet plastic and some odds and ends from my fittings stash. Now she needs a roof, a pilot, maybe lights, and some deck equipment.

Cash

▲

⟩⟩

chugalone100

RodC

RNinMunich

hermank

Chum444

EdW

peterd

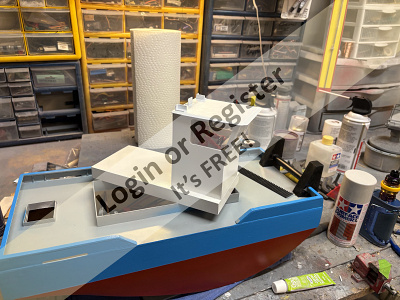

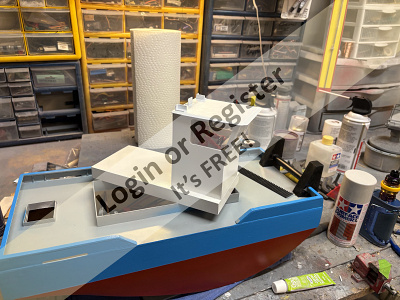

📝 Started cabin and hatch cover

5 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 70 Views · 6 Likes · 3 Comments

Flag

💬 Add Comment

Hi y’all. Got a little done this week. I built up the hatch cover using the free plasticard, very simple structure. I then agonized over what style pilot house I should do-large, small, elevated, tall…?

I decided on a simple 1-2 person house that’s just a little taller than normal. I built it up out of plasticard and reinforced the joints with 1/16 plastic strip. It’s just built up, not sanded much yet. I need to make a decision if I want to do an interior, and if I do how much detail do I want. Once I make that decision, and whether or not I want lighting, I can go ahead with paint, glazing, details and a roof.

Cash

I decided on a simple 1-2 person house that’s just a little taller than normal. I built it up out of plasticard and reinforced the joints with 1/16 plastic strip. It’s just built up, not sanded much yet. I need to make a decision if I want to do an interior, and if I do how much detail do I want. Once I make that decision, and whether or not I want lighting, I can go ahead with paint, glazing, details and a roof.

Cash

▲

⟩⟩

chugalone100

premecekcz

RodC

RNinMunich

EdW

hermank

|

💬 Re: Started cabin and hatch cover

5 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 64 Views · 3 Likes

Flag

That will make a nice little pusher tug Cash.

I like the crew cab (wheel house) too, it looks good 👍 Bob. ▲

⟩⟩

RodC

hermank

Cashrc

|

|

Login To

Remove Ads 💬 Re: Started cabin and hatch cover

5 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 71 Views · 4 Likes

Flag

I agree JP👍

😎 ▲

⟩⟩

RodC

hermank

Cashrc

Ronald

|

|

💬 Re: Started cabin and hatch cover

5 months ago by 🇺🇸 wingsounds13 (

Leading Seaman) Leading Seaman)✧ 67 Views · 4 Likes

Flag

I say that you need some interior detail. Just enough to make it look not empty. Some sort of nondescript instrument panel and basic helm. And... you DO want lighting to show off in those evening runs that we frequently have.

J.P. ▲

⟩⟩

RodC

hermank

Cashrc

RNinMunich

|

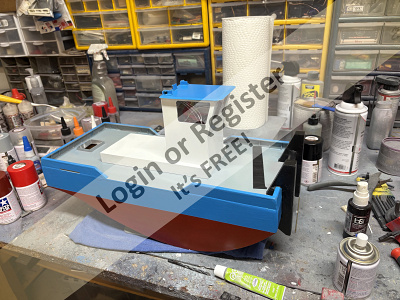

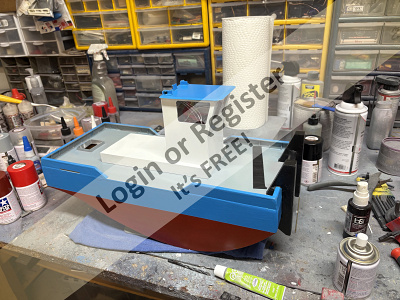

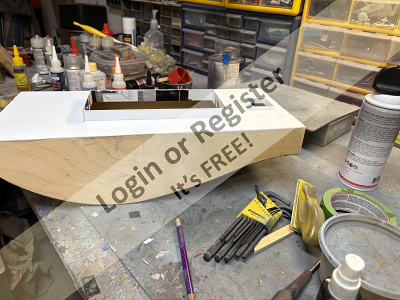

📝 Hull paint done minus touchups

5 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 77 Views · 10 Likes

Flag

💬 Add Comment

Hi y’all.I was off this past Friday so I did the fwd bulwarks supports and cap rail, built just like the aft. Once I had everything sanded I proceeded to primer and paint the hull. Not going into too much detail but since the push knees are already bonded to the hull, we’ll, there was a lot of masking tape being applied,, removed, then new tape applied elsewhere. I still have a couple of cans of French blue so I decided on a rust red bottom, upper hull and bulwarks French blue, the inner bulwarks and deck light gray,and the push knees are in black. Once everything had cured I primed and painted the Kort nozzle to match the bottom hull and reinstalled it and the prop. Now, im ready to start the hatch covers and superstructure.

Cash

Cash

▲

⟩⟩

chugalone100

premecekcz

LIBERTY CAPTAIN

Madwelshman

RodC

RNinMunich

Chum444

hermank

EdW

peterd

📝 Push knees, crossbar, fore bulwarks started aft complete

5 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 82 Views · 11 Likes

Flag

💬 Add Comment

Hi y’all. I had to fill in for my coworker last Saturday, and we ran models that Sunday, so very little work done till late this week and some this weekend. I did get the push knees made up Sunday afternoon, these consist of 6 1/8 ply parts that are laminated together and then once sanded epoxied to the bow. I also decided to add a cross bar between the knees as there is a large hole in the knees in the perfect location. I had a plastic tube that was almost a perfect fit, but I’m pretty sure it’s a polystyrene tube, and that’s one plastic that’s problematic to bond and paint, so I used some aluminum tube that’s a little smaller that the holes in the knees. I cut the tube down a bit shy of flush, then once I had it tacked in place making sure it was straight, I filled the void with scrap balsa and thick ca, the house thin balsa on the outboard sides to flush up the holes. I still have a little filling and sanding to do on the inboard joints.

I was going to do a bulwarks all round the deck, but in some pics I’ve seen of the real boats there’s a partial bulwarks forward and a partial aft, so that’s what I did. I used plasticard to make up the bulwarks, once glued in place I added 1/16 styrene supports to the aft bulwarks and then used 1/8 by 1/4 balsa for a capping rail. That’s where I’m at now, the next step is to do the same to the forward bulwarks. You’ll notice there’s a freeing port in the aft bulwarks, but none forward. My thinking is since most Springers ride a little bow high at speed, there’s more of a need aft the forward.

Cash

I was going to do a bulwarks all round the deck, but in some pics I’ve seen of the real boats there’s a partial bulwarks forward and a partial aft, so that’s what I did. I used plasticard to make up the bulwarks, once glued in place I added 1/16 styrene supports to the aft bulwarks and then used 1/8 by 1/4 balsa for a capping rail. That’s where I’m at now, the next step is to do the same to the forward bulwarks. You’ll notice there’s a freeing port in the aft bulwarks, but none forward. My thinking is since most Springers ride a little bow high at speed, there’s more of a need aft the forward.

Cash

▲

⟩⟩

chugalone100

premecekcz

LIBERTY CAPTAIN

Madwelshman

RodC

Commodore-H

RNinMunich

Chum444

EdW

hermank

peterd

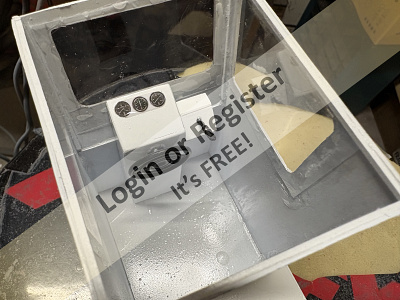

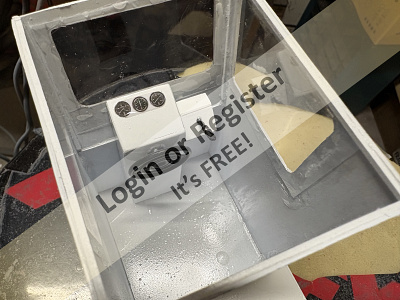

📝 3 coats of sanding sealer later, deck and coamings installed.

6 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 91 Views · 14 Likes · 1 Comment

Flag

💬 Add Comment

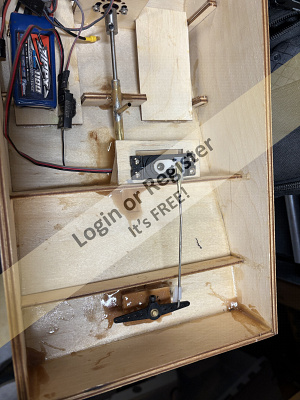

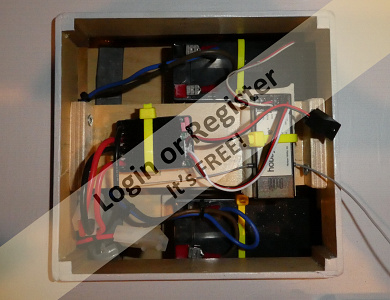

Hi y’all. I’ve decided not to glass the hull of the Springer, from what I’ve read most people don’t, so I gave her a good painting of 30 minute epoxy inside, and 3 coats of lacquer based sanding sealer outside, sanding between coats. Had to leave after each coat to let dry and get away from the fumes before I started having conversations with Elvis.🤣 Anyway, once that was done I reinstalled my equipment, same as before except I moved the esc on the fwd side of the bulkhead for easier access.

I work in a Ford dealer in Frisco Texas. We got a new battery rack from our vendor who services GM dealers as well. When the rack came in it was supplied with flat decorative panels advertising AC-Delco (GM) batteries. My boss asked if I could use the panels for building models, I took a look and said sure!!! I went home with about 6 foot by 2 foot of 2.5 mm plasticard!!

So, I had decided going in my Springers deck was going to be plastic, and my hatch/superstructure opening was going to be smaller. So, once I had everything measured to my liking, I flipped it over and laid in reinforcing wood strips, as well as outlining the hatch openings with wood to give the coaming more area to glue to. I used parts for the kit that were originally for the stock hatch and cut them down to glue to the inner hull sides, bow and transom to give the deck more gluing area, then glued it down with 15 minute epoxy. Once cured I trimmed and sanded the edges. I also test lubed my stuffing box with my little grease gun. I was able to get enough pressure that the grease oozed out of each end with the shaft installed and connected to the motor. That’s what I try to accomplish with all my boats..it’ll be easier to build a more rugged greasing tube with the soldering rig I have now.

That’s where I’m at now, I just have to design the 2 hatches and decide what wheelhouse style I want, and then start cutting plastic.

I work in a Ford dealer in Frisco Texas. We got a new battery rack from our vendor who services GM dealers as well. When the rack came in it was supplied with flat decorative panels advertising AC-Delco (GM) batteries. My boss asked if I could use the panels for building models, I took a look and said sure!!! I went home with about 6 foot by 2 foot of 2.5 mm plasticard!!

So, I had decided going in my Springers deck was going to be plastic, and my hatch/superstructure opening was going to be smaller. So, once I had everything measured to my liking, I flipped it over and laid in reinforcing wood strips, as well as outlining the hatch openings with wood to give the coaming more area to glue to. I used parts for the kit that were originally for the stock hatch and cut them down to glue to the inner hull sides, bow and transom to give the deck more gluing area, then glued it down with 15 minute epoxy. Once cured I trimmed and sanded the edges. I also test lubed my stuffing box with my little grease gun. I was able to get enough pressure that the grease oozed out of each end with the shaft installed and connected to the motor. That’s what I try to accomplish with all my boats..it’ll be easier to build a more rugged greasing tube with the soldering rig I have now.

That’s where I’m at now, I just have to design the 2 hatches and decide what wheelhouse style I want, and then start cutting plastic.

▲

⟩⟩

chugalone100

premecekcz

Madwelshman

RodC

Commodore-H

RNinMunich

GavJ

thadlietz

Chum444

zooma

SimpleSailor

hermank

EdW

peterd

|

💬 Re: 3 coats of sanding sealer later, deck and coamings installed.

6 months ago by 🇦🇺 peterd (

Sub-Lieutenant) Sub-Lieutenant)✧ 97 Views · 4 Likes

Flag

The comment made early about using a Springer is quite correct. We use one regularly to lay and retrieve buoys as well as a rescue boat.

The owner fixed two arms to the side and when using some mesh in front, it has been handy moving surface floating weed or leaves. A great workboat. I might add that our buoys are highly complex items. Approx ten inches of a pool noodle connected with a cord to an old brass tap fitting. Water is only a max one meter deep. Work well, with different colour noodle subject to turning mark. ▲

⟩⟩

RodC

Cashrc

hermank

Ronald

|

📝 Another Springer tug!!

6 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 108 Views · 14 Likes · 8 Comments

Flag

💬 Add Comment

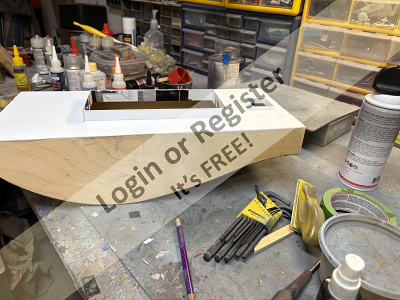

Hi y’all. Since Dickey has maidened I decided I wanted to do one more project before I attempt to overhaul my garage workshop. I’m thinking I’ll be down a month or more if I get done what I want to get done. In that vein, I’ve decided to attempt another Springer tug. Some years ago I built one before I really had ballasting down right..she ran okay, but I kept messing around with the ballast, epoxying it in, and when I tried to remove it to make changes I severely damaged the hull. So, I removed all equipment, fittings, etc and scrapped the hull. I’ve been wanting another go at it, so I ordered the Zippkits tugster, just the kit no hardware, and started to lick my calf over (old country phrase for a “do-over”)🤣

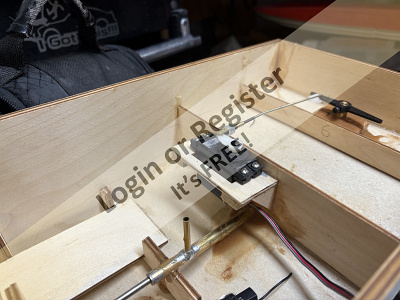

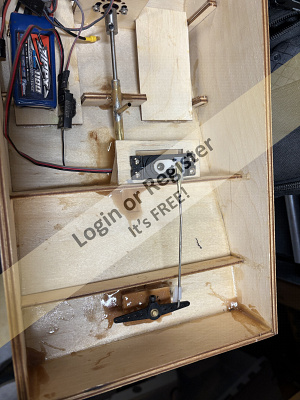

I built the hull proper per the instructions, and that’s where that ends. I’m using a 4mm shaft, the smaller Robbe/Krick Kort nozzle, and a home made stuffing box. She will be powered by my fave working boat motor, the Zippkits 650 kv outrunner fed by 2 6 cell nimh in parallel.

My stuffing box is made up of a thick wall brass tube that accepts a Traxxas 4mm i.d flanged oilite bushing. The bushing is tapped in with a hammer, and I use an old 4mm shaft to make sure the bushings stay aligned as I install the other bushing. The 1mm thick wall allows me to drill a hole the same size as the brass I’m using for an oiling tube. I’ll grind down the fitted end just a bit to get a decent, thight mechanical joint. That way when I silver solder it in place it stays put and is a good strong joint. The reason I’m so picky is that I use a mini grease gun from Horizon Hobbies, I can old it in place and pump, and I get just a wee bit of grease showing at the bushing under pressure, that way I know darn well it’s full.

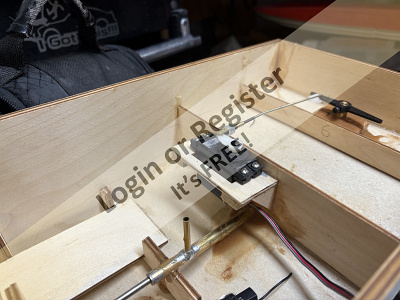

I used part of the keel parts to fit the tube, cutting it shorter to allow me to swing the Kort nozzle hard over to make it easier to change props without removing the Kort nozzle, depending on the size of the prop. I cut an oversized slot for the tube as I use solid couplers, and with the motor fitted I could get everything lined up and tack the tube in place with ca, that way I have no binding. I don’t like using universal joint couplers unless I really have to. I get my couplers from Servo City, as they are steel, use larger socket screws, and don’t have any runout. Very solid.

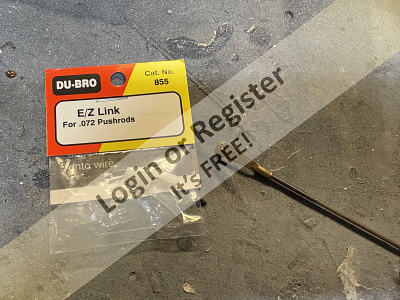

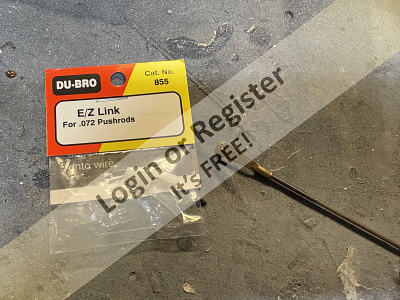

The kit uses a radio plate to to mount the servo, receiver and esc. I cut that down and built up a servo mount, and it’s installed on the same bulkhead shown in the manual, but I mounted it to the fwd side vs the aft as in the instructions. My deck opening is going to be different. I’m using Dubro pushrods, but good old Amazon was out of the ones with metal quick links, so I ordered the ones with nylon. I dug thru my junk box of hardware that I have been collecting since 95 or so, and I found gold!! A few Dubro and Sullivan threaded metal clevises, and some solder clevises too. I mounted the servo, made sure everything worked correctly, then uninstalled everything and gave the inside of the bow and transom and the bottom of the hull a coat of 30 minute epoxy.

That’s where she’s at now. I’m thing I’ll spray the rest of the inside of the hull with clear lacquer ro finish waterproofing, then I have to make a decision. I dont know if I need to glass this thing, or maybe glass the bottom and the just seal and paint the heck out of the sides, or….I’ve also heard that some people just epoxy coat the outer ull with thinned epoxy, then prime and paint. She’s gonn be a working boat, used as an emergency push boat when needed, so she needs to last…if I can get her ballasted properly this time, that is…🤣🤣

Cash

I built the hull proper per the instructions, and that’s where that ends. I’m using a 4mm shaft, the smaller Robbe/Krick Kort nozzle, and a home made stuffing box. She will be powered by my fave working boat motor, the Zippkits 650 kv outrunner fed by 2 6 cell nimh in parallel.

My stuffing box is made up of a thick wall brass tube that accepts a Traxxas 4mm i.d flanged oilite bushing. The bushing is tapped in with a hammer, and I use an old 4mm shaft to make sure the bushings stay aligned as I install the other bushing. The 1mm thick wall allows me to drill a hole the same size as the brass I’m using for an oiling tube. I’ll grind down the fitted end just a bit to get a decent, thight mechanical joint. That way when I silver solder it in place it stays put and is a good strong joint. The reason I’m so picky is that I use a mini grease gun from Horizon Hobbies, I can old it in place and pump, and I get just a wee bit of grease showing at the bushing under pressure, that way I know darn well it’s full.

I used part of the keel parts to fit the tube, cutting it shorter to allow me to swing the Kort nozzle hard over to make it easier to change props without removing the Kort nozzle, depending on the size of the prop. I cut an oversized slot for the tube as I use solid couplers, and with the motor fitted I could get everything lined up and tack the tube in place with ca, that way I have no binding. I don’t like using universal joint couplers unless I really have to. I get my couplers from Servo City, as they are steel, use larger socket screws, and don’t have any runout. Very solid.

The kit uses a radio plate to to mount the servo, receiver and esc. I cut that down and built up a servo mount, and it’s installed on the same bulkhead shown in the manual, but I mounted it to the fwd side vs the aft as in the instructions. My deck opening is going to be different. I’m using Dubro pushrods, but good old Amazon was out of the ones with metal quick links, so I ordered the ones with nylon. I dug thru my junk box of hardware that I have been collecting since 95 or so, and I found gold!! A few Dubro and Sullivan threaded metal clevises, and some solder clevises too. I mounted the servo, made sure everything worked correctly, then uninstalled everything and gave the inside of the bow and transom and the bottom of the hull a coat of 30 minute epoxy.

That’s where she’s at now. I’m thing I’ll spray the rest of the inside of the hull with clear lacquer ro finish waterproofing, then I have to make a decision. I dont know if I need to glass this thing, or maybe glass the bottom and the just seal and paint the heck out of the sides, or….I’ve also heard that some people just epoxy coat the outer ull with thinned epoxy, then prime and paint. She’s gonn be a working boat, used as an emergency push boat when needed, so she needs to last…if I can get her ballasted properly this time, that is…🤣🤣

Cash

▲

⟩⟩

EdW

GavJ

thadlietz

zooma

chugalone100

RNinMunich

Ronald

roycv

RodC

peterd

Nick Ward

Chum444

CDOGG

hermank

|

💬 Re: Another Springer tug!!

6 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 91 Views · 3 Likes

Flag

A springer tug sounds like a good thing to keep in the car to take to the lake on a quiet day to recover a stranded boat when no one else is able to help.

I have not even considered this before, but they look quite small and relatively simple to build, so I think I will start looking to find a plan or a kit. Bob. ▲

⟩⟩

peterd

RodC

RNinMunich

|

|

Login To

Remove Ads 💬 Re: Another Springer tug!!

6 months ago by 🇳🇿 Nick Ward (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 98 Views · 3 Likes

Flag

Thanks for the reply, Cash. My hull is all ply (6mm sides, 1.5mm bottom, 3mm deck, so pretty robust so I just sealed and painted the hull outside with 2 coats acrylic undercoat, sanded between coats, followed by 2 coats of Acrylic gloss colours, again sanded between coats. I had already 'soaked' the inside surfaces with thinned polyurethane varnish to really soak into the wood and also to protect the exterior grade PVA glue joints. I opt to paint inaccessible areas of the inside of the hull before side or bottom sheeting is added during the build, taking care to leave areas requiring glue completely untouched until after.

So far seems to work (I try to make sure the model is wiped down with a towel immediately after sailing, then dried out with the storage/transport case left open for 24hours in a warm room.) but I'll be honest, I think I prefer oil based gloss paints for the hull as they are more resilient; they just require a good 24+hours between coats before re-coating, and not really suitable for kitchen table builds because of the smells involved, so I'm banished to the shed whenever I do 'smelly-stuff'!😉 - I seem to remember Vic Smeed's advice regarding finishing coats on boats was to leave the paint for up to a week so it was really hard to allow a light sand to key in the final coat. I guess I was in more of a rush with my Springer, so didn't wait that long - and it WAS done on the kitchen table!😊 Can't comment on fibreglass/resin finishes as I have no experience with these.🤔 Regards, Nick ▲

⟩⟩

RodC

Cashrc

hermank

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 101 Views · 3 Likes

Flag

Nick, I like your Springer, she’s a looker!! Yep, first time I built one I really thought I had the ballast dead on, I had the plowing then I way overcompensated with aft ballast and just ruined her. This time I’m going to go in eyes wide open, and set up up a little bow high. The outrunner Zippkits sells is a good unit, ans supposedly wound by TFL for the Tugster in particular and working boat models in general. I’m using 2 7.2 6 cell Nimh packs as I just don’t want to fool around with another battery chemistry as I do lipo, nimh and LiFe, plus I have them in my stock. I’ll probably be a bit overpowered with that setup but I think she’ll be okay. We’ll find out soon enough…😁

BTW, did you glass your hull, resin it or just paint it? I’m on the fence about the finish to use. Cash ▲

⟩⟩

RodC

hermank

Nick Ward

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 101 Views · 3 Likes

Flag

Hi Rod. For most of my soldering such as light brasswork or electronics I use Kester 44 Solder Wire, 63/37. It works really well for that kind of work, and it’s a rosin core solder. I use the StayBrite for heavier work. It’s solder for use somewhere between normal soldering and brazing, a silver/tin solder.

I splurged on my birthday in January and bought a YIHUA 939D+ III EVO Digital Soldering Iron Station, a 110 watt solder station. It’s a Chinese unit, sold thru Amazon, that came with very good reviews. So far it has exceed my expectations. This unit makes short work of heavier hobby soldering work, and with a change of tips and solder it does eletronic soldering like battery plugs, LEDs, bulbs, etc nicely too. Cash ▲

⟩⟩

Ronald

hermank

RodC

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇨🇦 RodC (

Lieutenant Commander) Lieutenant Commander)✧ 107 Views · 3 Likes

Flag

Cashrc, when you say you "silver solder" it , are you referring to the silver soldering that welders sometimes do, or do you mean soldering with, say, a 40 to 60 Watt iron using electronic solder containing 3% silver??

▲

⟩⟩

Ronald

hermank

Cashrc

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇳🇿 Nick Ward (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 101 Views · 9 Likes

Flag

Hi Cash,

just saw your build log for the Springer tug. I've just finished one of these having downloaded the design from the 2015 build feature written by Colin Bishop on the Model Boats Magazine site using the basic Andy Cope sketches. I wanted it as a cheap 'rescue boat', as I had built a couple of other boats but felt I needed a back up if one of them got stranded on the local lake where I intended to sail, so their maidens were delayed until I had (relatively quickly) built the Springer (see attached photos). I intended to use RC bits I already had, but ended up buying a geared 540 motor off Ali Express turning 2300rpm at 12v, allowing me to turn a 50mm 4 bladed brass prop, plenty of grunt to push another stranded boat if necessary. I can relate to your comments about your first Springer; I'm glad I used removable lead sheet ballast as I ended up removing nearly 1/2 kg from the forward part of the hull when the maiden voyage revealed she had that typical Springer tendency to sink at the bow at higher throttle settings due to the hull shape. I'm awaiting an opportunity to sail her again after bathroom tests reveal she now sits nicely up about 3/4 inch at bow; coupled with the weight loss (now displaces around 3 1/2 kg) she should go well. I think this design is similar in size to the zippkits one. I used 2 x 1.3Ahr 12v lead gel batteries in parallel for the weight, as the current draw with the gears is very low (only around 1 amp cruising throttle) - it is, after all, a rescue boat, so hopefully doesn't need huge endurance. Springers do look cool, I think, and the robust ply construction is relatively quick and easy, so all the best for your build. 👍🤞😊 Best regards, Nick

▲

⟩⟩

chugalone100

zooma

EdW

RNinMunich

hermank

Cashrc

RodC

Ronald

peterd

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 105 Views · 3 Likes

Flag

Bill, I just make sure that everything lines up with marks on the aft hull, and that my tube is straight and the nozzle is also....and then I double check with my officially calibrated eyeball...😁 Horizontal is on center, it LOOKS like vertical is too. If I have any issues ill run a slightly smaller prop.

Cash ▲

⟩⟩

hermank

RodC

Chum444

|

|

💬 Re: Another Springer tug!!

6 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 105 Views · 3 Likes

Flag

Sounds like this is going to be a real tank Cash! Very strong indeed! I’m a devotee to single steerable Korts on tugs so I applaud your choice for propulsion. What is your alignment technique for the prop inside the Kort. I generally use a shaft centered in a plate whose diameter matches the Kort’s. I find even then I have to “eyeball” the final position.

▲

⟩⟩

RodC

Cashrc

hermank

|

United States

United States