Join Us On Social Media!

36" Thames River Police Launch by Robbob

46 Posts · 18 Followers · 403 Photos · 668 Likes

Began 7 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 " Constructing the box"

6 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 60 Views · 8 Likes · 10 Comments

Flag

💬 Add Comment

"Re: Constructing 'The Box'

11 hours ago by Skydive130 ( Warrant Officer)

"I have just taken delivery of this kit, and the joy opening the box and getting that wafting smell of fresh wood, nothing like it!

Having check the excellent quality laser cut wood against the parts list, it seems that the basic box built first is now supplied as 6mm and 5mm ply instead of balsa. Can I presume this is a change to the test kit? I am not worried about the extra weight, less ballast at the end.

My only other issue now is trying to source the HobbyKing SK3 840kv motor you have used in your beautiful model as it’s currently out of stock in the Uk and EU, living only 3 miles from HobbyKing UK means I can order and sometimes pick up same day. Does anyone else have an suitable alternative recommendations for the motor if I cannot source an SK3. I could order from HobbyKing in HK as showing in stock, but the postage is high?"

Hi Skydive130

I have moved this to the end of my blog so that others can see it easily.

Yes, I understand that the box is now all ply construction, I doubt if the added weight will be any problem at all.

Re: the HK motor, speak to Mike at VMW I'm sure that he or his colleague Alan can suggest a suitable alternative.

Good luck with the build and ......Please Do A Build Blog 😁👍.

Robbob.

11 hours ago by Skydive130 ( Warrant Officer)

"I have just taken delivery of this kit, and the joy opening the box and getting that wafting smell of fresh wood, nothing like it!

Having check the excellent quality laser cut wood against the parts list, it seems that the basic box built first is now supplied as 6mm and 5mm ply instead of balsa. Can I presume this is a change to the test kit? I am not worried about the extra weight, less ballast at the end.

My only other issue now is trying to source the HobbyKing SK3 840kv motor you have used in your beautiful model as it’s currently out of stock in the Uk and EU, living only 3 miles from HobbyKing UK means I can order and sometimes pick up same day. Does anyone else have an suitable alternative recommendations for the motor if I cannot source an SK3. I could order from HobbyKing in HK as showing in stock, but the postage is high?"

Hi Skydive130

I have moved this to the end of my blog so that others can see it easily.

Yes, I understand that the box is now all ply construction, I doubt if the added weight will be any problem at all.

Re: the HK motor, speak to Mike at VMW I'm sure that he or his colleague Alan can suggest a suitable alternative.

Good luck with the build and ......Please Do A Build Blog 😁👍.

Robbob.

▲

⟩⟩

Jay

tonyb2

Martin555

hmsnostalgia

RNinMunich

Skydive130

BOATSHED

Missouri

|

💬 Re: " Constructing the box"

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 5 Likes

Flag

LOL..😂🤣

When ya gotta go...ya gotta go! ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

RNinMunich

Ianh

|

|

Login To

Remove Ads 💬 Re: " Constructing the box"

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 4 Likes

Flag

|

|

💬 Re: " Constructing the box"

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 5 Likes

Flag

Hi Doug.

I don't think putting crew figures on boats is always necessary to make a model more realistic, if not done really well they can make a good 'scale model' look more like a 'toy boat'. Having said that, Sy's Atlantic 21 will look fantastic, and its single crew man is a legitimate use of a figure, and I know Sy will make him look the part too. In the case of Bionic Bill, HE is the prominent feature of the model and although made from an actual toy figure Graham has brought him (and Ben of course) to life very realistically. The superbly engineered boat they sit in with all its hidden mechanisms is almost secondary, and it's the boat that is scaled to the figures, not t'other way round. Just my personal thoughts ....😁 Rob. ▲

⟩⟩

Jay

hmsnostalgia

Ianh

RNinMunich

Martin555

|

|

💬 Re: " Constructing the box"

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

"No, I decided not to add any crew figures to any of my models"

So you are the Master of the Ghost Ships! Great shame Rob, a crew brings a boat / ship to life! Imagine Graham's rowboat without Bill, or Martin's submarine without his little mariners!🤔 Or my Sea Scout without the Police er Ladies😉 Cheers, Doug 😎

▲

⟩⟩

Martin555

robbob

|

|

💬 Re: " Constructing the box"

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 4 Likes

Flag

Hi hmsnostalgia.

No, I decided not to add any crew figures to any of my models because unless they are to the true scale of the model and in a natural looking pose I don't believe that they ever look very realistic. Robbob. ▲

⟩⟩

AlessandroSPQR

Jay

tonyb2

hmsnostalgia

|

|

💬 Re: " Constructing the box"

6 years ago by 🇬🇧 hmsnostalgia (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 56 Views · 2 Likes

Flag

Nice to see your craft on the water, have you decided whether to add any crew ?.

▲

⟩⟩

tonyb2

robbob

|

|

💬 Re: " Constructing the box"

6 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 9 Likes

Flag

Hello Sy.

I've only just seen your update on your boat, it must have been while I was on me holibobs! and you certainly have made a magnificent job of it too 👍👍 And to see that you have incorporated some of the build features that I did is very pleasing as well and you have my absolute approval. Interestingly, I have just returned from the International Model Boat Show in Warwickshire where I made a point of visiting the Wicksteed Park Model Boat Club stand to see Roger Clements and his restoration of an original Veron Thames Police Launch that I used as a benchmark along with the 'photos of the model in the NMM for the detailing of my model. I hope she sails as well as mine does when you have the maiden voyage, I have included some 'photos of my model's first sea trials. Kind Regards. Rob.

▲

⟩⟩

AlessandroSPQR

Jay

tonyb2

Mike Stoney

RNinMunich

Colin H

hmsnostalgia

jbkiwi

Missouri

|

|

💬 Re: " Constructing the box"

6 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 58 Views · 7 Likes

Flag

Hi again, just thought I’d show a few pics of my build as it nears completion if I may? It’s been a thoroughly enjoyable build thus far and looking forward to getting her on the water in the next couple of weeks. Just a few more details to make and add, a bit more varnish and good to go! I did build some lead into the hull fore, aft and sides under the hull box and between the outer sheets, guesstimated The weight and after a bath ballast test, it’s about spot on.

Most of the details are scratch built including the anchor made from bits of plasticard, anchor chain is just 20p of cheap necklace from a charity shop. All instrument dials, throttle quadrant again scratch built from plasticard with instrument gauges from a freebie given out in RCM&E a few years ago! However, I have and I hope you don’t mind, used a lot of the ideas in your build which I have read front to back so many times to gleam hints and tips.

▲

⟩⟩

AlessandroSPQR

tonyb2

Mike Stoney

RNinMunich

Colin H

hmsnostalgia

robbob

|

|

💬 Re: " Constructing the box"

6 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 9 Likes

Flag

Hi Sy.

Thank you very much for your very kind words about my build blog.😁 I've not added any ballast to mine yet but if I need to it will be through the fore and aft hatches that I incorporated into my model as there's no other means of access to the innards. To be honest I have not yet put it in the 'test tank' (bath 😉) to check how she sits in the water and the accuracy of the waterline. As regards the prop, mine is currently a 40mm 2 blade S type but until I do some sea trials I won't know the current draw or how she performs. Alan at VMV would definitely be able to advise you on the best 3 blade prop to use. As for the Build Blog, it can be as brief or as comprehensive as you are prepared to make it and it's certainly not compulsory but other modellers, including myself, really like to see how a build progresses, and I can tell you from my own experience that the help, encouragement and praise that you get from those that read it makes the effort very worthwhile. If you can, do take 'photos as you work so that even if you don't do a blog during the construction you can still do one afterwards, and the pictures will be invaluable in bringing your words to life. I didn't start my blogs until I was at least halfway through the build and I had enough material to post consistently and regularly, but that was my choice. Anyway, I quite enjoy writing.......and I probably ramble on a bit too much too......so I'll leave it there. Happy Building. Robbob. ▲

⟩⟩

AlessandroSPQR

Jay

tonyb2

hmsnostalgia

Missouri

Geoffrhoose

Martin555

Skydive130

RNinMunich

|

|

💬 Re: " Constructing the box"

6 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 57 Views · 2 Likes

Flag

Many thanks for your reply Robbob. I decided to order the motor from Hong Kong after all, I need a few other bits, so postage justified. I may do a build blog, but I very much doubt there is anyway I could improve on your blog, it’s a superb read!

Have you needed to add any ballast on yours? My concern would be trying to add ballast after deck is fitted as there would be limited opportunity to put in any lead unless feeding it through fore and aft hatches. I’m hoping the extra weight in the ply box will be sufficient to get her on the water line without ballast especially as the waterline is quite low on the hull? One last question if I may? I would like to go the brass prop route as I do in all my boats, what size do you suggest, presuming 3-blade and using exactly the same set-up as your motor, esc and lipo combo? Kind regards Sy ▲

⟩⟩

tonyb2

Martin555

|

Login To

Remove Ads

Remove Ads

📝 The Display Stand

6 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 65 Views · 15 Likes · 5 Comments

Flag

💬 Add Comment

With the annual club exhibition coming up I made a display stand for the boat, the construction is just the same as the one I made for my RAF Crash Tender.

I had to make some card templates of the hull at the bow and stern to get the end panels the right shape and transferred these to a pair of drawings allowing for a strip of 10mm thick neoprene foam to cushion the hull.

The end panels were cut from 10mm ply and the side rails are 8mm softwood set into the end panels and just glued and pinned.

After a thorough rub down I gave the stand three coats of a Mahogany stain before fitting the self- adhesive neoprene strips.

I had a pair of engraved brass plaques made up with a description of the boat, one for each side and Mike Cummings at Vintage Model Works very kindly supplied some VMW stickers to go on each side 👍 and there are some Model-Boats.com stickers on there too 👍😀.

I’m just contemplating the construction of a transport and storage case for this model and a recent thread on this site has been very helpful in highlighting some strong but lightweight plastics that may do the job.

I had to make some card templates of the hull at the bow and stern to get the end panels the right shape and transferred these to a pair of drawings allowing for a strip of 10mm thick neoprene foam to cushion the hull.

The end panels were cut from 10mm ply and the side rails are 8mm softwood set into the end panels and just glued and pinned.

After a thorough rub down I gave the stand three coats of a Mahogany stain before fitting the self- adhesive neoprene strips.

I had a pair of engraved brass plaques made up with a description of the boat, one for each side and Mike Cummings at Vintage Model Works very kindly supplied some VMW stickers to go on each side 👍 and there are some Model-Boats.com stickers on there too 👍😀.

I’m just contemplating the construction of a transport and storage case for this model and a recent thread on this site has been very helpful in highlighting some strong but lightweight plastics that may do the job.

▲

⟩⟩

Jay

tonyb2

Mike Stoney

Colin H

hmsnostalgia

DaveWhittaker

RNinMunich

MouldBuilder

JOHN

rolfman2000

Rookysailor

BOATSHED

Missouri

jbkiwi

Martin555

|

💬 Re: The Display Stand

6 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 57 Views · 1 Like

Flag

Stunning model finished off with an equally good stand.

I can only dream of constructing something of this quality. Perfect. ▲

⟩⟩

BOATSHED

|

|

Login To

Remove Ads 💬 Re: The Display Stand

6 years ago by 🇬🇧 Rookysailor (

Commodore) Commodore)✧ 57 Views · 2 Likes

Flag

Love the colour and the finish, complements the boat.

Peter😐 ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Display Stand

6 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Sets the boat off nicely!

▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Display Stand

6 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 57 Views · 2 Likes

Flag

Will be doing the same for the boys boat when were back from holiday, Ill post some pics of boat and stand ASAP. Nice easy design and looks the part.

▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Display Stand

6 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Very nice indeed, really looks the part.

Well done. Martin555. ▲

⟩⟩

tonyb2

BOATSHED

|

📝 The Instrument Panel.

6 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 63 Views · 12 Likes · 4 Comments

Flag

💬 Add Comment

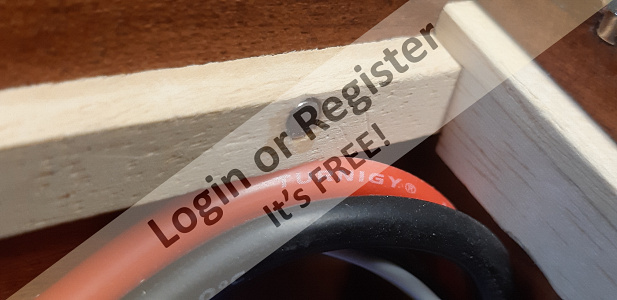

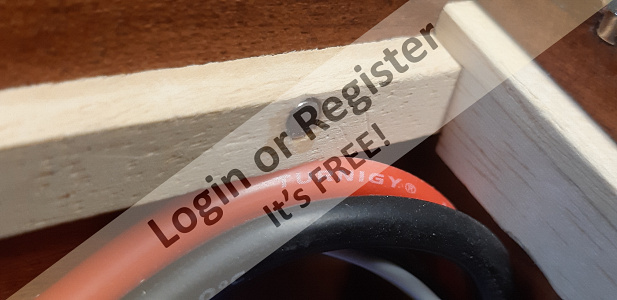

I decided that an instrument panel would enhance the appearance of the ‘Steering Wheel’ power switch so I made up a panel to go around the switch onto which I could put some dials and a throttle control.

In my previous blog update I discounted using the very nice but pricey BECC transfers and looked for an alternative, Doug (RNinMunich) kindly sent me a .pdf of some instruments but the resolution was very poor when printed out. So after a bit of Googling I found a picture of some real commercially made instruments that was quite high resolution, and importantly, printed very nicely even when scaled down to the sizes I needed. I used a premium glossy photo paper in my Canon Pixma printer for this.

The panel was made from some 2.0mm ply from the scrap box with the edges bevelled for neatness and after two coats of Teak stain they were ready to have the dials applied.

The dials were cut out from the printed sheet as best as possible with a new scalpel blade, not easy I might add, as they are so small that you can’t really make a continuous circular cut so it was a case of nibbling round the edges until it was an acceptable shape. That was a test for my old eyes 🤓 I can tell you.

The edges of the dials were blackened with a black ‘Sharpie’ pen before sticking down onto the panel with a light smear of canopy glue.

The throttle control is just an offcut of Obeche carved and shaped and with a short piece of styrene tube and a pin head for the lever, painted in gunmetal grey it doesn’t look too bad. I used a small white ball headed pin in the final assembly.

The instrument panel was given two coats of satin lacquer to protect the dials before the throttle control was stuck down and then the whole piece glued down onto the battery cover, and I also painted the aluminium switch panel black so it was less conspicuous through the slot.

I had arranged the height of the wheel so that the battery cover can only be removed with the switch on the off position as a safety consideration. Also there’s room inside the battery box for a low voltage alarm attached to the battery balance connector too.

Viewed through the cabin window the instrument panel looks quite acceptable and it all helps to disguise the purpose of the steering wheel and the switch can be accessed easily through the sliding cabin window without removing the cabin.

Quite pleased with that 😁

In my previous blog update I discounted using the very nice but pricey BECC transfers and looked for an alternative, Doug (RNinMunich) kindly sent me a .pdf of some instruments but the resolution was very poor when printed out. So after a bit of Googling I found a picture of some real commercially made instruments that was quite high resolution, and importantly, printed very nicely even when scaled down to the sizes I needed. I used a premium glossy photo paper in my Canon Pixma printer for this.

The panel was made from some 2.0mm ply from the scrap box with the edges bevelled for neatness and after two coats of Teak stain they were ready to have the dials applied.

The dials were cut out from the printed sheet as best as possible with a new scalpel blade, not easy I might add, as they are so small that you can’t really make a continuous circular cut so it was a case of nibbling round the edges until it was an acceptable shape. That was a test for my old eyes 🤓 I can tell you.

The edges of the dials were blackened with a black ‘Sharpie’ pen before sticking down onto the panel with a light smear of canopy glue.

The throttle control is just an offcut of Obeche carved and shaped and with a short piece of styrene tube and a pin head for the lever, painted in gunmetal grey it doesn’t look too bad. I used a small white ball headed pin in the final assembly.

The instrument panel was given two coats of satin lacquer to protect the dials before the throttle control was stuck down and then the whole piece glued down onto the battery cover, and I also painted the aluminium switch panel black so it was less conspicuous through the slot.

I had arranged the height of the wheel so that the battery cover can only be removed with the switch on the off position as a safety consideration. Also there’s room inside the battery box for a low voltage alarm attached to the battery balance connector too.

Viewed through the cabin window the instrument panel looks quite acceptable and it all helps to disguise the purpose of the steering wheel and the switch can be accessed easily through the sliding cabin window without removing the cabin.

Quite pleased with that 😁

▲

⟩⟩

Jay

tonyb2

Mike Stoney

hmsnostalgia

DaveWhittaker

BOATSHED

Missouri

JOHN

Colin H

Martin555

jbkiwi

RNinMunich

|

💬 Re: The Instrument Panel.

6 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 3 Likes

Flag

What a cracking idea. Well done and thanks for letting us all know about it.

Cheers Colin. 👍 ▲

⟩⟩

tonyb2

BOATSHED

Martin555

|

|

Login To

Remove Ads 💬 Re: The Instrument Panel.

6 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Superbly done Rob.

Really looks the parts. Well done. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Instrument Panel.

6 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 60 Views · 6 Likes

Flag

Hi John.

That's a good tip and well worth considering for the future👍👍. Thanks. Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

Colin H

Martin555

|

|

💬 Re: The Instrument Panel.

6 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 60 Views · 8 Likes

Flag

Nice job Rob!

If I might offer a suggestion which might make it easier to make gauge panels for future projects. To save trying to cut around tiny prints, (fingers/eyes don't work so well with age) what others do with aircraft dashes etc is to drill through the dash panel with a spur drill (pictured) of the appropriate size for the particular gauge, against a piece of hardwood, after marking the hole positions on masking tape applied firmly to the panels' face (to prevent damaging the face). You get a nice accurate hole which you can edge seal and blacken, thereby giving 'depth' to your gauge cluster. You can then roughly cut the prints to size and position/glue them on a backing panel and spray with clear, or sandwich them between some thin acetate sheet, the backing plate and your dash panel. Probably selling snow to Inuits, but others might be able to use the method. John B

▲

⟩⟩

tonyb2

Colin H

MouldBuilder

BOATSHED

Geoffrhoose

RNinMunich

Martin555

robbob

|

📝 The Battery Cover

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 67 Views · 17 Likes · 6 Comments

Flag

💬 Add Comment

The switch and battery box is a sub-assembly that can be easily removed for repair or modification, and the ‘steering wheel’ power switch works really well but it all needs to be concealed in an enclosure that’s in keeping with the rest of the boat.

Firstly I built up a framework on the walls and floor around the battery box to support an enclosure, this was designed with a sloping top panel to make it look more like a control and instrument panel than just a box. The obeche strips were angled and bevelled and just superglued in place.

The enclosure was then built up on this framework to get the shape and angles right and all the internal edges reinforced with obeche strip with some bracing pieces at each end to add rigidity.

A slot was cut into the top panel to allow for the throw of the power switch and the edges of this were also reinforced with some more obeche strip.

Some external framing detail was added and also a handle to assist with removal as the 4mm diameter neodymium magnets that were set into the framing hold it very firmly in place. I uses a total of 6 pairs of these magnets and I now think that 4 pairs would have been more than sufficient and hence the need for a sturdy handle to get a good grip!

(I did a count up of how many magnets are on this model and in total there are 42 of varying sizes 😲)

Three of coats of Teak stain were applied to all the bare wood to finish it off.

I may add some ‘instrumentation’ detail on the top panel around the steering wheel and possibly a throttle control just as a finishing detail.

BECC do some nice round decals and bezels for this but they’re a bit pricey for just the few that I need so this extra detail might be an unnecessary extravagance!

The last thing to make is a presentable looking display stand for exhibition and display so it’s off to the drawing board to sketch something out ✍🤓.

Firstly I built up a framework on the walls and floor around the battery box to support an enclosure, this was designed with a sloping top panel to make it look more like a control and instrument panel than just a box. The obeche strips were angled and bevelled and just superglued in place.

The enclosure was then built up on this framework to get the shape and angles right and all the internal edges reinforced with obeche strip with some bracing pieces at each end to add rigidity.

A slot was cut into the top panel to allow for the throw of the power switch and the edges of this were also reinforced with some more obeche strip.

Some external framing detail was added and also a handle to assist with removal as the 4mm diameter neodymium magnets that were set into the framing hold it very firmly in place. I uses a total of 6 pairs of these magnets and I now think that 4 pairs would have been more than sufficient and hence the need for a sturdy handle to get a good grip!

(I did a count up of how many magnets are on this model and in total there are 42 of varying sizes 😲)

Three of coats of Teak stain were applied to all the bare wood to finish it off.

I may add some ‘instrumentation’ detail on the top panel around the steering wheel and possibly a throttle control just as a finishing detail.

BECC do some nice round decals and bezels for this but they’re a bit pricey for just the few that I need so this extra detail might be an unnecessary extravagance!

The last thing to make is a presentable looking display stand for exhibition and display so it’s off to the drawing board to sketch something out ✍🤓.

▲

⟩⟩

Jay

tonyb2

Ygagnon

hmsnostalgia

DaveWhittaker

MouldBuilder

BOATSHED

Geoffrhoose

Colin H

mturpin013

Missouri

jugge

rolfman2000

RNinMunich

jacko

jbkiwi

Martin555

|

💬 Re: The Battery Cover

5 years ago by 🇬🇧 drspock (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 58 Views · 2 Likes

Flag

Well played Sir!

Doc ▲

⟩⟩

tonyb2

Martin555

|

|

Login To

Remove Ads 💬 Re: The Battery Cover

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 6 Likes

Flag

Maiden voyage will be very soon and if she veers off to a magnetic north heading I'll know I've definitely overdone the magnets 🤣

Rob. ▲

⟩⟩

tonyb2

Jay

Martin555

hmsnostalgia

BOATSHED

RNinMunich

|

|

💬 Re: The Battery Cover

7 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 3 Likes

Flag

"don't go near any powerful magnets"

Don't take it on The Tube Rob, she'll get ripped apart !😮😭 😁😎 ▲

⟩⟩

tonyb2

Martin555

BOATSHED

|

|

💬 Re: The Battery Cover

7 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 58 Views · 3 Likes

Flag

Nice work Rob, but don't go near any powerful magnets or it'll be ripped from you hands or worse still sail off into the distance.

▲

⟩⟩

Martin555

BOATSHED

RNinMunich

|

|

💬 Re: The Battery Cover

7 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 3 Likes

Flag

Nicely hidden!

▲

⟩⟩

tonyb2

Martin555

BOATSHED

|

|

💬 Re: The Battery Cover

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Hi Robbob,

Excellent workmanship yet again. You really have a boat to be really proud of. It is a pleasure to look at it. Keep up the good work. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

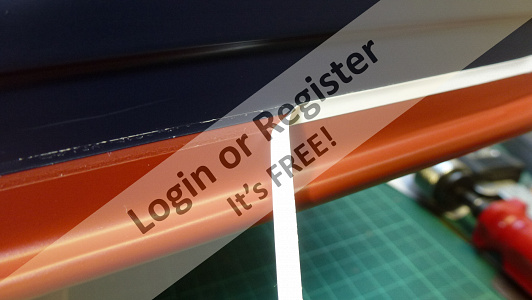

📝 The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 64 Views · 14 Likes · 17 Comments

Flag

💬 Add Comment

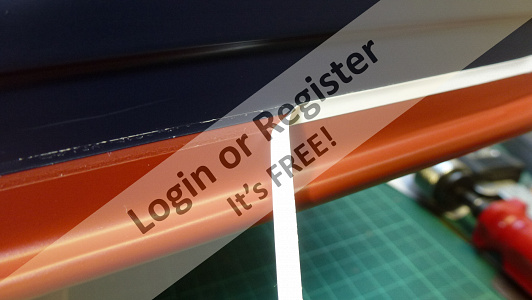

I don’t know what it is about successfully applying a white waterline to a hull that gives me so much grief.

I had problems with getting a good result with my Crash Tender and similarly with this model too.

The common denominators are;

1. Me.

2. The hull.

3. Trimline Tape.

On both occasions I’ve used this tape it has refused to adhere properly where it crosses the spray rails and on this occasion it also lifted in lots of places along the hull sides so that when the finishing lacquer was sprayed on it got behind the tape, lifted it more, and looked awful 😞 and this was despite meticulous cleaning and keying of the surface before application.

Without meaning to do an injustice to the product I suspect that it’s just the way I was applying it and perhaps I had greater expectations of the product.

Consequently I had to remove all of the tape and flat down the step in the lacquer coat 😠 and consider another approach, perhaps masking tape and white paint or an alternative tape.

I decided to persist with the ‘tape’ method so I found a seller on eBay that could supply very thin PVC car body ‘coachlining’ tape in any colour or width to order, so I bought 10 metres of 4mm in white for just a couple of quid.

What a difference!😊

This stuff went on beautifully straight, sticks like the proverbial and has stayed firmly in place over all of the contortions of the spray rails and hull.

Furthermore when the hull was re-lacquered with a clear satin finish it behaved impeccably….success at last.😀👍

I had problems with getting a good result with my Crash Tender and similarly with this model too.

The common denominators are;

1. Me.

2. The hull.

3. Trimline Tape.

On both occasions I’ve used this tape it has refused to adhere properly where it crosses the spray rails and on this occasion it also lifted in lots of places along the hull sides so that when the finishing lacquer was sprayed on it got behind the tape, lifted it more, and looked awful 😞 and this was despite meticulous cleaning and keying of the surface before application.

Without meaning to do an injustice to the product I suspect that it’s just the way I was applying it and perhaps I had greater expectations of the product.

Consequently I had to remove all of the tape and flat down the step in the lacquer coat 😠 and consider another approach, perhaps masking tape and white paint or an alternative tape.

I decided to persist with the ‘tape’ method so I found a seller on eBay that could supply very thin PVC car body ‘coachlining’ tape in any colour or width to order, so I bought 10 metres of 4mm in white for just a couple of quid.

What a difference!😊

This stuff went on beautifully straight, sticks like the proverbial and has stayed firmly in place over all of the contortions of the spray rails and hull.

Furthermore when the hull was re-lacquered with a clear satin finish it behaved impeccably….success at last.😀👍

▲

⟩⟩

Jay

tonyb2

hmsnostalgia

DaveWhittaker

MouldBuilder

BOATSHED

mturpin013

Colin H

Geoffrhoose

Rookysailor

Missouri

JOHN

Martin555

rolfman2000

|

💬 Re: The Waterline/Boot Topping.

6 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 3 Likes

Flag

Hi hmsnostalgia.

It all turned out OK in the end, and a lesson learned on the way. Cheers.👍 Robbob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

|

|

Login To

Remove Ads 💬 Re: The Waterline/Boot Topping.

6 years ago by 🇬🇧 hmsnostalgia (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 56 Views · 2 Likes

Flag

Always more than one way eh !!, I should think even very experienced builders get stuck, a build blog is great for beginners and 'old hands' alike !!, great work Robbob !!. 👍😊👌😀

▲

⟩⟩

tonyb2

robbob

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 57 Views · 2 Likes

Flag

CRash tender going slow and your right the boys freeman is nearly finished, good job its his Birthday in two weeks.

however still been doing a bit hoses now finished. I must get going with the painting, I have all the paints as per your recommendations, so with weather prospects being better maybe its time to get going ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 4 Likes

Flag

Hi Mike.

IMHO it's much better stuff than the Trimline tape when you have to go over awkward shapes. How's the Crash Tender coming along?, I've not seen any updates recently. I suspect the Freeman 22 for the lad is taking a priority😀. Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 57 Views · 3 Likes

Flag

Rob sent of for some 4mm trim you recommended and it arrived today and I was impressed with the inclusion of application instructions. I will try it first on the Freeman 22 I am building for my Grandson.

▲

⟩⟩

tonyb2

BOATSHED

robbob

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 4 Likes

Flag

Good to hear that you're contemplating doing a blog👍.

Looking forward to seeing how you're tackling the re-furb. Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 57 Views · 2 Likes

Flag

I have it in mind to do a blog, but don’t simply want to repeat material in some of the excellent blogs on this site covering Crash Tender builds, including yours. I’d want to cover details not in existing blogs. I’m currently waiting on parts from China before I’ll have anything new to show.

▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 4 Likes

Flag

If they are waterslide decals you'll definitely need to lacquer over them.

Self adhesive vinyl decals would probably be OK but I'd still do 2 coats of lacquer over the whole hull anyway. Why not do a blog on this build /refurb? Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 57 Views · 2 Likes

Flag

Yes, in a couple of days time. Even though they say it isn’t necessary, I don’t like the idea of not sealing all the decals.

▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 4 Likes

Flag

Hi Graham.

Well done! but keep an eye on it and make sure it doesn't lift. Will you be lacquering over it? Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 57 Views · 2 Likes

Flag

I managed to fit the Trimline tape together with the rest of the decals. The tape didn't want to stick properly where it folded over the spray rails, so I tried heating it carefully with a hot air paint stripper and then pressing it into place while warm. That seems to have done the trick and it still looks to be OK this morning. A hair dryer would have been safer (cooler) but I don't have one and I didn't dare 'borrow' one from my wife!🤣

▲

⟩⟩

tonyb2

BOATSHED

|

|

Login To

Remove Ads 💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Good luck.

I hope it goes well for you. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

I am glad that you managed to sort it out. Well done.

I never though of using tape, I have always painted mine. Thanks for the idea. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 5 Likes

Flag

Hi Graham93

Good luck with the Trimline tape, it may well work fine for you. Do leave it on for a few days to see if it lifts before spraying any lacquer over it though. Particularly where it crosses over the spray rails at the bow, if it shows any signs of lifting bail out and use the vinyl tape from Stripeworld. Keeping my fingers crossed for you 🤞😉🤞 Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

Martin555

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 58 Views · 3 Likes

Flag

Thanks Robbob. Very timely. I’m planning to add Trimline to my Crash Tender later today. At least I now know where to go for a recommended alternative if it doesn’t go well.

Wish me luck ▲

⟩⟩

tonyb2

BOATSHED

Martin555

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 60 Views · 8 Likes

Flag

Hi Dave.

Here's a link to the eBay site for 'Stripeworld' as requested 😁. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

rolfman2000

RNinMunich

BOATSHED

Rookysailor

Martin555

|

|

💬 Re: The Waterline/Boot Topping.

7 years ago by 🇬🇧 rolfman2000 (

Warrant Officer) Warrant Officer)✧ 76 Views · 4 Likes

Flag

Glad it came right for you on the second attempt Robbob. Please can you share a link for the pinstriping tape off Ebay, obviously or the seller which would probably be better, as we contact him for whatever width we needed.

Best wishes, Dave W 😊 ▲

⟩⟩

tonyb2

hmsnostalgia

BOATSHED

Martin555

|

📝 The Roof Spray Deflector.

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 65 Views · 15 Likes · 4 Comments

Flag

💬 Add Comment

The final piece of cabin detail to add was a spray deflector rail.

Making the piece was reasonably easy as it just involved shaping a length of obeche strip into a triangular section and then gently steaming and bending it to as much as a curvature as possible without snapping it.

Because the roof is also a convex shape the strip had to be further shaped while held in a bent form to flatten the centre slightly so that it would sit correctly on the roof over its length.

When I was happy with the shape and fit I stained the piece with two coats of Teak stain.

Fixing the piece down onto the roof was the bit that worried me most as I couldn’t drill any holes for retaining studs as I had done with other roof details for fear of splitting it and so superglueing it directly to the roof was the only way, and I had to get it right first time. 😓

For this part I had to enlist another pair of hands 🙌 to ensure it stuck down properly first time so after choreographing and rehearsing the action a few times I applied a very thin bead of superglue to the part, bent it to the required curvature and placed the ends on the corners of the roof and then rotated the piece down onto the painted surface of the roof at which point the other hands pushed it down firmly in place and held for a minute or more until the bond was complete.

Much to my relief 😊 it was a successful process and I was then able to trim the ends back with a sharp blade and paint the cut ends with a bit of Teak stain😁

The cabin is completed…….finally.😊

Making the piece was reasonably easy as it just involved shaping a length of obeche strip into a triangular section and then gently steaming and bending it to as much as a curvature as possible without snapping it.

Because the roof is also a convex shape the strip had to be further shaped while held in a bent form to flatten the centre slightly so that it would sit correctly on the roof over its length.

When I was happy with the shape and fit I stained the piece with two coats of Teak stain.

Fixing the piece down onto the roof was the bit that worried me most as I couldn’t drill any holes for retaining studs as I had done with other roof details for fear of splitting it and so superglueing it directly to the roof was the only way, and I had to get it right first time. 😓

For this part I had to enlist another pair of hands 🙌 to ensure it stuck down properly first time so after choreographing and rehearsing the action a few times I applied a very thin bead of superglue to the part, bent it to the required curvature and placed the ends on the corners of the roof and then rotated the piece down onto the painted surface of the roof at which point the other hands pushed it down firmly in place and held for a minute or more until the bond was complete.

Much to my relief 😊 it was a successful process and I was then able to trim the ends back with a sharp blade and paint the cut ends with a bit of Teak stain😁

The cabin is completed…….finally.😊

▲

⟩⟩

Jay

tonyb2

hmsnostalgia

DaveWhittaker

Puddle-pirate

RNinMunich

BOATSHED

Geoffrhoose

MouldBuilder

mturpin013

Missouri

figtree7nts

rolfman2000

Colin H

Martin555

|

💬 Re: The Roof Spray Deflector.

7 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 58 Views · 3 Likes

Flag

That is a super looking boat. The detail is extraordinary. It looks just like the real thing. Hope I can do something like that one day.😉

▲

⟩⟩

tonyb2

hmsnostalgia

BOATSHED

|

|

Login To

Remove Ads 💬 Re: The Roof Spray Deflector.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 4 Likes

Flag

Hi Mike.

Well, the model isn't 100% finished yet, I have still to 'box in' the battery and power switch and most importantly do the 'Sea Trials'. So I have a few more blog updates to do yet. What's next?..........no idea🤔 I'm open to offers if someone wants a prototype built up and blogged 😉 Perhaps I'll take a break from model building for a short while and just enjoy playing with them 😁 Rob. ▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: The Roof Spray Deflector.

7 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 57 Views · 2 Likes

Flag

Whats Next ?

▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: The Roof Spray Deflector.

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

She certainly looks good well done.

Fantastic workmanship. Something to be really proud of. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

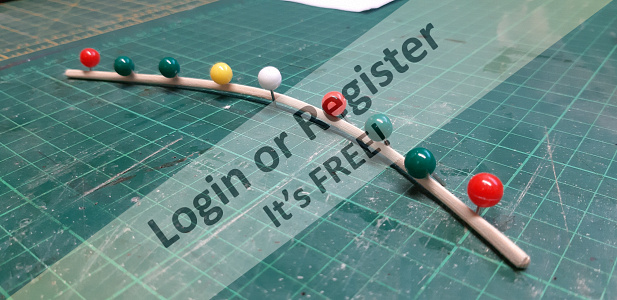

📝 Cabin Grab Handles.

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 64 Views · 14 Likes · 3 Comments

Flag

💬 Add Comment

There are a couple of grab handles on the front and rear of the cabin roof that I thought I’d like to add to my model.

Making them from wood seemed rather difficult so I made them from some plasticard rod that I heated and bent over a former to the right size and shape. They were then rubbed down with an abrasive to roughen the surface so that the wood stain that I’ve used elsewhere would stick properly and two coats of Teak stain did the trick.

Superglueing them directly to the cabin would not be a very firm fixing so I drilled some 2.5m holes correctly spaced so that the handles could be pushed into place and I used some canopy glue as a fixing so that any excess glue could be wiped away easily.

When the glue had set I gave the handles a final coat of stain using a very fine brush, a steady hand and an old pair of eyes 🤓.

Just the spray deflector on the roof to fit now.

Making them from wood seemed rather difficult so I made them from some plasticard rod that I heated and bent over a former to the right size and shape. They were then rubbed down with an abrasive to roughen the surface so that the wood stain that I’ve used elsewhere would stick properly and two coats of Teak stain did the trick.

Superglueing them directly to the cabin would not be a very firm fixing so I drilled some 2.5m holes correctly spaced so that the handles could be pushed into place and I used some canopy glue as a fixing so that any excess glue could be wiped away easily.

When the glue had set I gave the handles a final coat of stain using a very fine brush, a steady hand and an old pair of eyes 🤓.

Just the spray deflector on the roof to fit now.

▲

⟩⟩

tonyb2

Jay

hmsnostalgia

DaveWhittaker

BOATSHED

Geoffrhoose

Commodore-H

Colin H

RNinMunich

Missouri

MouldBuilder

mturpin013

Martin555

rolfman2000

|

💬 Re: Cabin Grab Handles.

7 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Handcuffs Dave!!!? 😮

The bind moggles 😁 ▲

⟩⟩

tonyb2

BOATSHED

|

|

Login To

Remove Ads 💬 Re: Cabin Grab Handles.

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Very nice handy work.

Well done. Martin. ▲

⟩⟩

tonyb2

BOATSHED

|

|

💬 Re: Cabin Grab Handles.

7 years ago by 🇬🇧 rolfman2000 (

Warrant Officer) Warrant Officer)✧ 75 Views · 4 Likes

Flag

And here was I thinking there was no more detail you could put on, apart from a pair of furry dice and a pair of handcuffs, you've done it again Robbob. Nicely reported and photo illustrated again. Best wishes, Dave W 😊

▲

⟩⟩

RNinMunich

tonyb2

BOATSHED

Martin555

|

📝 Brass Cabin Trim.

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 65 Views · 14 Likes · 8 Comments

Flag

💬 Add Comment

A rather nice feature on the NMM model are some brass trims on the rear pillars of the cabin and I found a ‘photo of one of the real boats that clearly shows the trims so I decided to add these to my model too.

The brass sheet I used for this is only 0.3mm thick and can be fairly easily be cut by scoring heavily with a strong knife blade and then snapping. The cut edges show no sign of deformation and are easily smoothed and finished with a file.

The strips are about 6mm wide and each strip was trimmed to fit the upper part of the cabin pillars and the lower curved portion formed by careful bending over a suitably sized former.

They are held in place with a few spots of superglue and after a final cleaning with fine emery paper were brush painted with a couple of coats of clear lacquer.

The brass sheet I used for this is only 0.3mm thick and can be fairly easily be cut by scoring heavily with a strong knife blade and then snapping. The cut edges show no sign of deformation and are easily smoothed and finished with a file.

The strips are about 6mm wide and each strip was trimmed to fit the upper part of the cabin pillars and the lower curved portion formed by careful bending over a suitably sized former.

They are held in place with a few spots of superglue and after a final cleaning with fine emery paper were brush painted with a couple of coats of clear lacquer.

▲

⟩⟩

Jay

tonyb2

hmsnostalgia

DaveWhittaker

BOATSHED

Colin H

Commodore-H

Geoffrhoose

MouldBuilder

jbkiwi

Missouri

Martin555

RNinMunich

rolfman2000

|

Login To

Remove Ads 💬 Re: Brass Cabin Trim.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 4 Likes

Flag

😆

▲

⟩⟩

Jay

Missouri

tonyb2

hmsnostalgia

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

I must remember the 'grab handles' as well then😮😉

▲

⟩⟩

BOATSHED

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 6 Likes

Flag

Thanks Doug.

Don't forget the handcuffs for your Sea Scout. Apparently they're quite 'En Vogue' 😉 ▲

⟩⟩

Jay

Missouri

tonyb2

hmsnostalgia

BOATSHED

RNinMunich

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

Excellent Rob👍

Think I'll do that to 'tart up' my Sea Scout a little. 😉 KUTGW. Cheers, Doug 😎 ▲

⟩⟩

BOATSHED

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

Another nice touch!

▲

⟩⟩

BOATSHED

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 5 Likes

Flag

Thanks Martin.

I'm going to add a little bit more cabin detail soon, there's a curved spray deflector on the roof and some grab handles on the rear edge, you can see them in the NMM 'photo. Rob. ▲

⟩⟩

Jay

Missouri

tonyb2

hmsnostalgia

BOATSHED

|

|

💬 Re: Brass Cabin Trim.

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

Hi Robbob,

Nice touch, That is a really super model. Excellent workmanship. Well done. Martin. ▲

⟩⟩

BOATSHED

robbob

|

📝 The Rudder

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 62 Views · 13 Likes · 1 Comment

Flag

💬 Add Comment

I did consider making my own rudder from brass tube, rod and sheet but I realised that a standard commercially available rudder could be easily modified to simulate the rudder type used on the real boat.

I ordered a ‘large’ size standard rudder from ModelBoatBits along with the prop shaft and prop that were needed for the model and then set about modifying the rudder.

As the blade of the rudder is held in a slot in the rudder post by a couple of small 'rivets' it was an easy job to just punch them out and separate the parts. The rudder blade was then rotated 90 degrees and a single new hole drilled through to fix the blade in the new position.

I re-shaped the blade a little to more of a rounded profile before fixing it back onto the shaft with the original rivets. I also used a small piece of brass rod to fill the exposed original rivet hole and all the parts were soft soldered together.

The new rivet was filed down flush with the blade and the whole part burnished and finished with a coat of clear lacquer.

I ordered a ‘large’ size standard rudder from ModelBoatBits along with the prop shaft and prop that were needed for the model and then set about modifying the rudder.

As the blade of the rudder is held in a slot in the rudder post by a couple of small 'rivets' it was an easy job to just punch them out and separate the parts. The rudder blade was then rotated 90 degrees and a single new hole drilled through to fix the blade in the new position.

I re-shaped the blade a little to more of a rounded profile before fixing it back onto the shaft with the original rivets. I also used a small piece of brass rod to fill the exposed original rivet hole and all the parts were soft soldered together.

The new rivet was filed down flush with the blade and the whole part burnished and finished with a coat of clear lacquer.

▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

Geoffrhoose

Colin H

Commodore-H

Missouri

mturpin013

Elsrickle

Martin555

Rookysailor

RNinMunich

|

💬 Re: The Rudder

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 1 Like

Flag

A Nice neat rudder.

Well done. Martin. ▲

⟩⟩

BOATSHED

|

📝 The Battery Box & Power Switch

7 years ago by 🇬🇧 robbob ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 63 Views · 15 Likes · 6 Comments

Flag

💬 Add Comment

I wanted to install a main power switch on the model so that the battery could be pre-installed and connected ready for the lake but at the same time the battery needed to be easily replaceable at the lakeside. The problem I faced was where I could fit and conceal a switch for this, and have it easily accessible too.

The answer, I decided, was to disguise the switch as a cabin feature that I intended to include in the model detailing anyway, and the boats steering wheel was the ideal candidate.

I started by sketching out a design that would incorporate a battery box and switch as a complete sub-assembly and with a workable design I began by constructing the battery box from 3mm ply.

The switch mounting was formed from 1.2mm aluminium plate for which I made up a card template to determine the right size and angle of bends required to obtain the ‘slope’ of the top panel. Once formed and drilled the switch plate was fixed to another ply panel on one end of the box and fixed in place with screws.

I found the XT60 connector mounting PCB on the Hobbyking site and it is perfect for my needs so the alloy mounting plate was drilled with clearance holes for the connecting pins and the heat shrink tubing that further insulates the soldered connections, and the PCB is fixed to the plate with a couple of M3 screws and nuts.

The switch is rated at 12v 25A and I disassembled it to remove the operating toggle so that I could remove the taper on the shaft and reduce it to a 4mm diameter to take a brass tube that forms the new steering column.

The plastic steering wheel was picked up from the SHG stand at the Thornbury model show and is a perfect scale for the boat and it’s a perfect fit inside the brass tube too.

The switch contacts were bent to give some clearance for the wiring. A cautionary note with these switches, don’t solder any wires directly to them as the heat from the iron will also melt and deform the plastic case too. This causes the internal contacts to move and lose their firm ‘snap’ contact and potentially compromise the switch rating. I discovered this very quickly but thankfully I had ordered two switches, as they are not expensive, so I had an immediate replacement that was then wired with spade connectors.

The switch assembly was finished with another XT60 connector that mates with the power cable that goes back to the ESC via a 15A blade fuse. The whole switch and battery assembly is fixed to the deck floor with three woodscrews and so the whole assembly is removable for maintenance or modification if required.

When I glazed the cabin I made the port sliding window movable (but with an end retaining stop) so that I could quickly access the ‘Steering Wheel’ switch without having to remove the cabin from the boat. A battery change will involve that but as the whole cabin is retained by six small but very powerful neodymium magnets this is very quick and simple matter anyway.

The whole battery box and switch will later be ‘boxed in’ with a false control panel with a throttle control and dials, and this will also be on magnetic retainers, with the battery section as a separate removable part for an easy battery change.

All of these features I had considered and planned at an early stage and so implementing them was quite straightforward.🤔🤓

Getting closer to completion now, along with the control panel cover I need to re-shape the brass rudder and also fix the waterline tape problem that has really annoyed me!😡 More on that in a later update.😁

The answer, I decided, was to disguise the switch as a cabin feature that I intended to include in the model detailing anyway, and the boats steering wheel was the ideal candidate.

I started by sketching out a design that would incorporate a battery box and switch as a complete sub-assembly and with a workable design I began by constructing the battery box from 3mm ply.

The switch mounting was formed from 1.2mm aluminium plate for which I made up a card template to determine the right size and angle of bends required to obtain the ‘slope’ of the top panel. Once formed and drilled the switch plate was fixed to another ply panel on one end of the box and fixed in place with screws.

I found the XT60 connector mounting PCB on the Hobbyking site and it is perfect for my needs so the alloy mounting plate was drilled with clearance holes for the connecting pins and the heat shrink tubing that further insulates the soldered connections, and the PCB is fixed to the plate with a couple of M3 screws and nuts.

The switch is rated at 12v 25A and I disassembled it to remove the operating toggle so that I could remove the taper on the shaft and reduce it to a 4mm diameter to take a brass tube that forms the new steering column.

The plastic steering wheel was picked up from the SHG stand at the Thornbury model show and is a perfect scale for the boat and it’s a perfect fit inside the brass tube too.

The switch contacts were bent to give some clearance for the wiring. A cautionary note with these switches, don’t solder any wires directly to them as the heat from the iron will also melt and deform the plastic case too. This causes the internal contacts to move and lose their firm ‘snap’ contact and potentially compromise the switch rating. I discovered this very quickly but thankfully I had ordered two switches, as they are not expensive, so I had an immediate replacement that was then wired with spade connectors.

The switch assembly was finished with another XT60 connector that mates with the power cable that goes back to the ESC via a 15A blade fuse. The whole switch and battery assembly is fixed to the deck floor with three woodscrews and so the whole assembly is removable for maintenance or modification if required.

When I glazed the cabin I made the port sliding window movable (but with an end retaining stop) so that I could quickly access the ‘Steering Wheel’ switch without having to remove the cabin from the boat. A battery change will involve that but as the whole cabin is retained by six small but very powerful neodymium magnets this is very quick and simple matter anyway.

The whole battery box and switch will later be ‘boxed in’ with a false control panel with a throttle control and dials, and this will also be on magnetic retainers, with the battery section as a separate removable part for an easy battery change.

All of these features I had considered and planned at an early stage and so implementing them was quite straightforward.🤔🤓

Getting closer to completion now, along with the control panel cover I need to re-shape the brass rudder and also fix the waterline tape problem that has really annoyed me!😡 More on that in a later update.😁

▲

⟩⟩

Jay

tonyb2

hmsnostalgia

BOATSHED

Colin H

samc

rolfman2000

Geoffrhoose

JOHN

MouldBuilder

Missouri

Rookysailor

mturpin013

RNinMunich

Martin555

|

💬 Re: The Battery Box & Power Switch

7 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 2 Likes

Flag

No worries robbob, I've done exactly the same (18 planes and 5 boats- no 6 coming up) so needed to standardize plugs (same with JST plugs all female going out) but I've found that occasionally you end up with a space you just can't get your fingers in to pull the plugs apart without breaking something. The seaplane tender i'm doing at the moment will hopefully be all 'plug and play' (motors included) as I have the space to do it in.

John ▲

⟩⟩

BOATSHED

robbob

|

|

Login To

Remove Ads 💬 Re: The Battery Box & Power Switch

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 6 Likes

Flag

Hi jbkiwi.

I've standardised on XT60 connectors on all my models, batteries and chargers for maximum flexibility and interchangability, also there's a wide range of mounting options and accessories for them from HobbyKing. The MT60 & MT30 motor connectors are great and there's also the XT30 and XT90 range for smaller and larger current demands too. The batteries are a snug but not tight fit in the battery box and I've not experienced any LiPo battery swelling problems (yet)😀🤞 ▲

⟩⟩

Jay

Missouri

tonyb2

hmsnostalgia

BOATSHED

jbkiwi

|

|

💬 Re: The Battery Box & Power Switch

7 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 57 Views · 3 Likes

Flag

Nice battery box idea. Just a thought though, the Deans type connectors are a lot smaller than the XT60s (50%) an a lot easier to get apart in a confined space (especially in emergencies) I had to do a one side fixed method in one of my planes due to lack of room using XT60s, as there was no way to grip and separate both. There is a tool available to separate them apparently, (I was thinking of modding a pair of circlip pliers) XT 60s are more for high amp use (eg 30A plus), also the Deans are brown which would not clash with your woodwork, should you need to leave one exposed (although I can't imagine you leaving the battery box lidless ! PS don't have the battery box too tight as sometimes the batteries (although supposed to be the same specs) can come a few mm larger, also in case the battery 'puffs' as it degrades. Heat shouldn't be a problem but is something to think about.

▲

⟩⟩

RNinMunich

BOATSHED

robbob

|

|

💬 Re: The Battery Box & Power Switch

7 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 57 Views · 2 Likes

Flag

That is a really clever solution.

Love the quality of the woodwork and finish as well. Gives us all a benchmark to try to achieve. ▲

⟩⟩

BOATSHED

robbob

|

|

💬 Re: The Battery Box & Power Switch

7 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 59 Views · 6 Likes

Flag

Hi Martin.

Yes, I've been looking at your Cottesmore blog.👍👍 I'm glad to hear that you've taken inspiration from my own solution to hiding switches. Rob. ▲

⟩⟩

Jay

Missouri

tonyb2

hmsnostalgia

BOATSHED

Martin555

|

|

💬 Re: The Battery Box & Power Switch

7 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 58 Views · 3 Likes

Flag

Hi Robbob,

Excellent I like it, very clever. Well done. As you may have read in my blog on Cottesmore I plan on changing things around so that I don't have to move the superstructure to switch it on and off. You have now given me in idea of how I could make my switch using the aft winch. Thank you. Martin. ▲

⟩⟩

DaveWhittaker

BOATSHED

robbob

|

United Kingdom

United Kingdom