Join Us On Social Media!

The Marlin Cabin Cruiser (Vintage Model Works)

27 Posts · 21 Followers · 216 Photos · 314 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 11 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

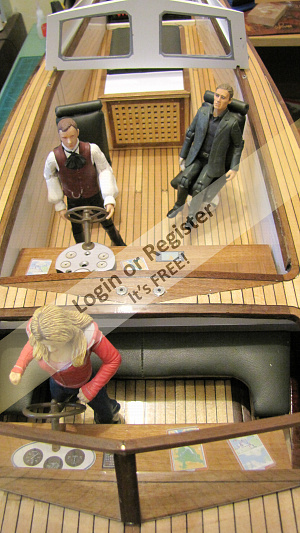

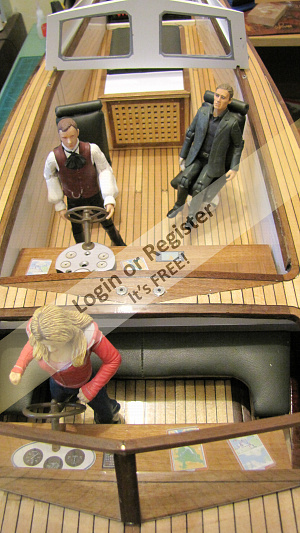

📝 Final pictures

11 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 82 Views · 18 Likes · 10 Comments

Flag

💬 Add Comment

The build is now complete and we are waiting for the maiden voyage to take place at the earliest opportunity Its been an interesting build with plenty of problems to be solved, but in all the kit is a comprehensive package, supplying a full box of materials covering all the build requirements. The plans are self-explanatory to the intermediate builder leaving nothing to chance.

I have during the build made quite a few deviations from plan such as planking and general additional woodwork, lighting and internal fittings.

My overall comment is that it’s a great kit to build and makes a wonderful model.

Next project is to finish the Inga IV

I have during the build made quite a few deviations from plan such as planking and general additional woodwork, lighting and internal fittings.

My overall comment is that it’s a great kit to build and makes a wonderful model.

Next project is to finish the Inga IV

▲

⟩⟩

Madwelshman

DuncanP

GaryLC

Rookysailor

RNinMunich

Ronald

robbob

Len1

River Rat

Fred

Doogle

hermank

stevedownunder

Scratchbuilder

MouldBuilder

ToraDog

chugalone100

ChrisG

|

💬 Re: Final pictures

11 months ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 55 Views · 2 Likes

Flag

Once again thanks for the comments.

I'm glad to see your still with us Rob Ill watch out for your build ▲

⟩⟩

robbob

Scratchbuilder

|

|

Login To

Remove Ads 💬 Re: Final pictures

11 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 50 Views · 1 Like

Flag

"it won't be anywhere near as good as yours."

Somehow, judging from your own Build Blogs, I doubt that Robbob😉 You set the bar pretty high yourself. Looking forward to your Marlin build. New workshop? Who's a lucky boy then😁 Blog on Man😎 ▲

⟩⟩

Scratchbuilder

|

|

💬 Re: Final pictures

11 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 54 Views · 2 Likes

Flag

"Plus its much more entertaining and encouraging than a just a "Like""

Hear hear Michael👍 Interaction is the lifeblood of a forum. I've followed all your Builds with awe.😮 The Marlin blog has been yet yet another Master Class with a splendid result. Particularly impressed by your attention to details and skill in their execution. Your innovative control panel design I shall attempt to emulate in my Sea Scout, whose cockpit is somewhat desolate at the moment! Looking forward to your next instalment of - "This is how it's done folks". All the best, Doug😎 ▲

⟩⟩

ChrisG

Scratchbuilder

|

|

💬 Re: Final pictures

11 months ago by 🇬🇧 robbob (

Admiral) Admiral)✧ 66 Views · 4 Likes

Flag

Tremendous job Mike.

I've been following your build with very keen interest and you certainly have set the benchmark for this model. I fear that when I get back to building mine, hopefully as soon as my new workshop is finished!, it won't be anywhere near as good as yours. Congratulations😀👍👍 Robbob. ▲

⟩⟩

Doogle

RNinMunich

stevedownunder

Scratchbuilder

|

|

💬 Re: Final pictures

11 months ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 65 Views · 3 Likes

Flag

Mike.

Totally agree with your thoughts re people joining in. We all have different ideas and I certainly enjoy it when members ask questions or give advice be it good or indifferent on my posts. Good luck with the Inga IV. Regards Bill. ▲

⟩⟩

RNinMunich

stevedownunder

ChrisG

|

|

💬 Re: Final pictures

11 months ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 67 Views · 5 Likes

Flag

Many thanks for your kind words and support through this build.

I'm not sure whether people realise how beneficial a conversation about a build is not only to the builder but also to others who may be struggling with some part of a build which seems to some an easy fix but to others its a revelation. So please take the time to comment with your thoughts about somebodies build, you never know it may just help someone to see the solution. Plus its much more entertaining and encouraging than a just a "Like" Ill get on with the next build now ▲

⟩⟩

jbkiwi

RNinMunich

stevedownunder

ChrisG

Scratchbuilder

|

|

💬 Re: Final pictures

11 months ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 70 Views · 2 Likes

Flag

Another great job Mike, keen to see the official launching.👍👍

JB ▲

⟩⟩

stevedownunder

ChrisG

|

|

💬 Re: Final pictures

11 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 63 Views · 2 Likes

Flag

That's a stunning build, looking forward to seeing her afloat on the maiden voyage.

▲

⟩⟩

stevedownunder

ChrisG

|

|

💬 Re: Final pictures

11 months ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 72 Views · 2 Likes

Flag

Mike.

Wholehearted congratulations on a super build. First class as always. What’s next? Regards Bill. ▲

⟩⟩

ChrisG

stevedownunder

|

|

💬 Re: Final pictures

11 months ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 69 Views · 2 Likes

Flag

Perfect as always Mike. You really have made a super job on this build. Looking forward to the trials. Must trial Dusseldorf one day.😬

▲

⟩⟩

stevedownunder

ChrisG

|

Login To

Remove Ads

Remove Ads

📝 Deck fittings

11 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 84 Views · 11 Likes · 1 Comment

Flag

💬 Add Comment

The deck fittings are minimal consisting of forward and rear cleats with bollards front and rear. These were all scratch made from brass, and are pinned and epoxied to the deck. Although this takes a lot of time it’s a most satisfying part of a build for me as I consider myself a builder not a sailor.

▲

⟩⟩

GaryLC

RNinMunich

robbob

jbkiwi

MouldBuilder

Colin H

Scratchbuilder

stevedownunder

Len1

ChrisG

Doogle

|

💬 Re: Deck fittings

11 months ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 85 Views · 2 Likes

Flag

Beautiful looking fittings Mike,

Cheers, Stephen. ▲

⟩⟩

AlessandroSPQR

GaryLC

|

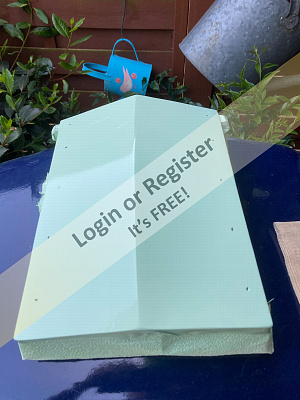

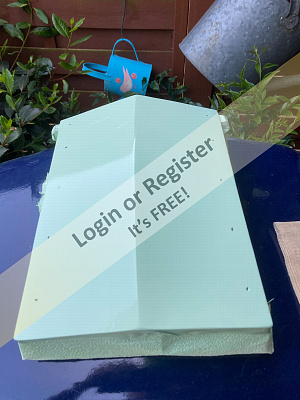

📝 Windscreen

11 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 90 Views · 19 Likes · 3 Comments

Flag

💬 Add Comment

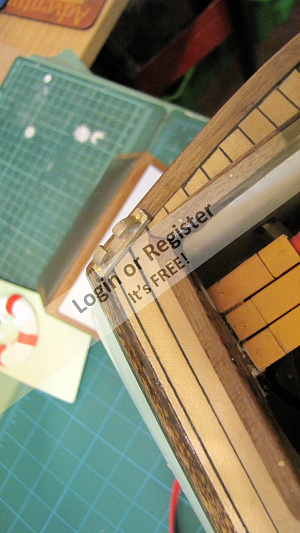

The front cabin has a windscreen, which is made from clear plastic sheet, which is supplied in the kit, this was roughly the correct shape. To bend the piece at the right angles I heated a piece of 2mm rod and held the bend line over it but not touching until it was pliable I then bent it to the correct angle drawn on a plan. I I felt that the sheet now the correct shape needed some solid surround. To match the rest of the boats wood it needed to be made from a dark wood such as walnut. I cut square sections 5 x 5 mm and then cut a 1mm slot along its length.

This was then cut into required pieces to slot onto the plastic I cut the screen in half to make it easier to put a central pillar in. the sides presented an issue in that they are curved, so a profile was cut out and carefully a slot was cut into the curve.

The whole assembly was glued together with the assistance of a metal jig and CA and then 1.0 mm pins secure it to the deck

This was then cut into required pieces to slot onto the plastic I cut the screen in half to make it easier to put a central pillar in. the sides presented an issue in that they are curved, so a profile was cut out and carefully a slot was cut into the curve.

The whole assembly was glued together with the assistance of a metal jig and CA and then 1.0 mm pins secure it to the deck

▲

⟩⟩

robbob

jbkiwi

GaryLC

MouldBuilder

Len1

River Rat

Peejay

Rookysailor

AustinG

Ronald

stevedownunder

Scratchbuilder

flaxbybuck

Colin H

pressonreguardless

Doogle

hermank

ChrisG

RNinMunich

|

💬 Re: Windscreen

11 months ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 78 Views · 5 Likes

Flag

This is what modelling is all about ! Finding solutions to making things and pursuing ideas to a successful conclusion.

I applaud your determination and patience to produce one small part of a boat that many will glance at without a second thought as to how it was made, or indeed just how long it took in the planning and execution. Only a true modeller will recognise and appreciate what you have achieved. Well done. 😉 ▲

⟩⟩

stevedownunder

River Rat

Ronald

RNinMunich

Scratchbuilder

|

|

Login To

Remove Ads 💬 Re: Windscreen

11 months ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 86 Views · 2 Likes

Flag

Nice Job on the windscreen, Mike👍👍

Trev ▲

⟩⟩

stevedownunder

Scratchbuilder

|

|

💬 Re: Windscreen

11 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 82 Views · 6 Likes

Flag

Super job Michael👍

Where there's a will ...! Been wondering how to add a windscreen to my Sea Scout, might try that. Had been thinking of brass or ally U channel, but that's a real pig to accurately bend without distortion. There's nothing like a good jig, As Granny used to say while jigging around her parlour to the radio, with glass of Eggnog in her hand. God bless her.😉 Cheers, Doug 😎 ▲

⟩⟩

robbob

stevedownunder

MouldBuilder

Ronald

Colin H

hermank

|

📝 22 Painting

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 105 Views · 12 Likes

Flag

💬 Add Comment

The cabin cruiser needs to be painted as soon as possible so it can properly harden for a few weeks. I use cellulose paints (a left over mind set from spraying cars) This Cruiser will have a first coat of etch primer followed by 4 coats of standard grey primer with any filling and smoothing in between coats.

The whole hull will first be sprayed with a white gloss and will receive three to four coats, I prefer to give a number of thin coats this avoids the chances of any runs, which always cause problems, as they need to harden before being flattened.

The hull has been left to harden four a week; it is now hard enough to turn back on its stand. I now need to draw the water line around the hull. I do this by levelling the hull according to the “plans water line” and then using a height gauge with a pencil attached instead of the scriber I pencil a line around the whole hull.

Next masking the lower half of the hull leaving the area to be painted a very light green, again a number coats are applied to give a good depth of paint. The cabin also gets a coat of the green paint, having been painted white on the inside

I will now leave the paint to harden for 2-3 weeks before attempting to finally polish it to a high sheen.(hopefully)

The whole hull will first be sprayed with a white gloss and will receive three to four coats, I prefer to give a number of thin coats this avoids the chances of any runs, which always cause problems, as they need to harden before being flattened.

The hull has been left to harden four a week; it is now hard enough to turn back on its stand. I now need to draw the water line around the hull. I do this by levelling the hull according to the “plans water line” and then using a height gauge with a pencil attached instead of the scriber I pencil a line around the whole hull.

Next masking the lower half of the hull leaving the area to be painted a very light green, again a number coats are applied to give a good depth of paint. The cabin also gets a coat of the green paint, having been painted white on the inside

I will now leave the paint to harden for 2-3 weeks before attempting to finally polish it to a high sheen.(hopefully)

▲

⟩⟩

robbob

MouldBuilder

Len1

RNinMunich

Graham93

Scratchbuilder

jbkiwi

boatmam

hermank

Doogle

pressonreguardless

Colin H

📝 21 Cabin rear

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 106 Views · 16 Likes · 1 Comment

Flag

💬 Add Comment

The cabin has a rear section which when built as a fixed unit would have made it strong and rigid. However as I’m building a removable cabin I will have to add some additional 4x4 stiffeners around the sides and across the end so when its removed it remain rigid. The sides have what I think would be Chrome trim (4 strips) these are made of wood and have been painted along with the rest of cabin and then have been covered with adhesive aluminium foil ( the old fashioned tape used on window alarm systems) its worked well and looks the part.

▲

⟩⟩

robbob

MouldBuilder

jbkiwi

ChrisG

Doogle

Graham93

River Rat

RNinMunich

flaxbybuck

Wolle

hermank

stevedownunder

Len1

pressonreguardless

chugalone100

Colin H

|

💬 Re: 21 Cabin rear

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 110 Views · 0 Likes

Flag

Interesting to see use made of the adhesive aluminium foil. I bought some years ago and have not used it yet, but I do have a project on the go, so ...... mm!? 😉

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

📝 20 Cabin Front continued

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 123 Views · 17 Likes · 9 Comments

Flag

💬 Add Comment

The cabin is now complete and the electrics have been added, this comprises of navigation lights, internal cabin lights which are powered through 3mm bullet connectors 4 in all 1 neg and 3 positive all operated through RC switches.

All the windows have Perspex inserts and will need an chrome look surround. these are made from 1mm styrene sheet, I pencilled around the window profiles and cut the external profile (the easy bit) I then drilled 4mm holes at each of the corners.

Next I made a simple jig which would allow me to mill the internal profile by hand, first setting the 3mm thickness and a couple of pins to stop the sheet lifting each piece was moved around cutting away the centre using a 2mm slot drill.

A final deburr and light surface sand (1200 grit) to make sure the chrome pen adheres well. these will be applied on final assembly.

All the windows have Perspex inserts and will need an chrome look surround. these are made from 1mm styrene sheet, I pencilled around the window profiles and cut the external profile (the easy bit) I then drilled 4mm holes at each of the corners.

Next I made a simple jig which would allow me to mill the internal profile by hand, first setting the 3mm thickness and a couple of pins to stop the sheet lifting each piece was moved around cutting away the centre using a 2mm slot drill.

A final deburr and light surface sand (1200 grit) to make sure the chrome pen adheres well. these will be applied on final assembly.

▲

⟩⟩

robbob

ChrisG

PeteJev

RNinMunich

Scratchbuilder

flaxbybuck

River Rat

stevedownunder

Graham93

Len1

pressonreguardless

MouldBuilder

Doogle

hermank

chugalone100

Wolle

Colin H

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 103 Views · 1 Like

Flag

(how did you do that without causing the plastic to burr ?😉)

The plastic is 1mm thick so can easily be cut with scissors I did this just shy of the line. I next finished the profile using the disc sander with a fine grit disc, this does leave a burr, but this is easily removed by using a scalpel, drawing at an angle of 45 degrees across the edge of the piece which easily removes the burr leaving a nicely chamfered smooth edge. ▲

⟩⟩

stevedownunder

|

|

Login To

Remove Ads 💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 116 Views · 2 Likes

Flag

I was particularly interested to see your method of producing window frames from plastic sheet. You say you cut the external profile first, but how did you do that without causing the plastic to burr ?😉

▲

⟩⟩

stevedownunder

Scratchbuilder

|

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 113 Views · 4 Likes

Flag

Thanks for all the nice comments, Colin H (type of drill/mill) Although I have a full size milling machine for this very delicate work a super high speed miniature drilling machine is the best option using a 1.5 mm slot drill the direction of cut is cutting into the material from left to right so the cutting force pushes the work against the wooden stop

▲

⟩⟩

ChrisG

stevedownunder

Scratchbuilder

Wolle

|

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 126 Views · 1 Like

Flag

Hi Mike,

Beautiful work as is normal for you. You may already know this, I believe that painting a gloss black before the chrome improves the chrome finish, might be worth a try on some scrap. Cheers, Stephen. ▲

⟩⟩

AlessandroSPQR

|

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 118 Views · 0 Likes

Flag

Super job as usual Mike. 😃

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 120 Views · 1 Like

Flag

Lovely bit of milling on such flimsy material, what is your drill/mill machine.

And do you use a pull cut or push cut. Cheers Colin. ▲

⟩⟩

pressonreguardless

|

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 120 Views · 0 Likes

Flag

Impressive work there 👍

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 121 Views · 0 Likes

Flag

I love your work. Very meticulous details.

It will be a “Super Model”.😎 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: 20 Cabin Front continued

1 year ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 123 Views · 0 Likes

Flag

Mike.

As always great detain and craftsmanship 👍 Regards Bill. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

📝 20 Cabin front

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 144 Views · 16 Likes · 3 Comments

Flag

💬 Add Comment

The cabin is best constructed on the body of the boat weather you are having it fixed or detachable, in my case I went for detachable. This presents additional problems if you want to have illumination in and on the cabin. In my previous model – The (Vintage Model Works Police Boat) I also had illumination on the removable cabin and this is achieved by using 2.5 mm bullet connectors, the socket is epoxied into the deck and the pins are epoxied into the cabin.

The cabin needs navigation lights, internal lights and a mast light this means I need 4 connections one will be a negative with 3 lives the 3 lights will be wired through RC switches. There are two pins at the front and two in the rear section of the cabin.

Now that’s sorted we can start to build the wooden parts of the cabin, first to be glued are the five pieces that form the periphery of the cabin sides, these have been strengthened with 4x4 framework glued to each piece.

Now the sides are set we can assemble the roof first gluing a centre spare in place to ensure we have a curved roof.

You may have noticed that the deck is in the process of been varnished, and looks a bit rough at this point. We have given two coats rubbing down between, we will have a further four coats to apply before an acceptable “depth and smoothness” is achieved.

The cabin needs navigation lights, internal lights and a mast light this means I need 4 connections one will be a negative with 3 lives the 3 lights will be wired through RC switches. There are two pins at the front and two in the rear section of the cabin.

Now that’s sorted we can start to build the wooden parts of the cabin, first to be glued are the five pieces that form the periphery of the cabin sides, these have been strengthened with 4x4 framework glued to each piece.

Now the sides are set we can assemble the roof first gluing a centre spare in place to ensure we have a curved roof.

You may have noticed that the deck is in the process of been varnished, and looks a bit rough at this point. We have given two coats rubbing down between, we will have a further four coats to apply before an acceptable “depth and smoothness” is achieved.

▲

⟩⟩

Wolle

pressonreguardless

Scratchbuilder

chugalone100

jbkiwi

robbob

AndyN

flaxbybuck

Madwelshman

Graham93

MouldBuilder

stevedownunder

RNinMunich

hermank

River Rat

Colin H

|

💬 Re: 20 Cabin front

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 123 Views · 0 Likes

Flag

Hi JB yes its still in progress but very slowly, I've had a lot of other things going on over the last few months but hopefully back on the case now. I've, just finished spraying the hull of this and the other blog of the Inga IV I have running in parallel.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: 20 Cabin front

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 125 Views · 2 Likes

Flag

Hi Mike, how are you getting on with this,-still working on it?

▲

⟩⟩

stevedownunder

Scratchbuilder

|

|

💬 Re: 20 Cabin front

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 126 Views · 1 Like

Flag

I'm well impressed !😉

▲

⟩⟩

stevedownunder

|

📝 19 Bow protector

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 147 Views · 13 Likes · 1 Comment

Flag

💬 Add Comment

As you will all be aware, the most vulnerable part of any craft is the bow and is often the area that gets damaged resulting in difficult repairs. This was something that happened to one of my boats --(carrying it down a flight of stairs).

To minimise the possibility of damage I fabricated a cover made from brass sheet that follows the profile of the bow and over onto the deck area, this will have an illuminated bow light built into this protector. The piece is made from two fabricated parts, which will be silver soldered together, polished and finally epoxied to the bow. The final picture I will save until assembly.

To minimise the possibility of damage I fabricated a cover made from brass sheet that follows the profile of the bow and over onto the deck area, this will have an illuminated bow light built into this protector. The piece is made from two fabricated parts, which will be silver soldered together, polished and finally epoxied to the bow. The final picture I will save until assembly.

▲

⟩⟩

MouldBuilder

hermank

River Rat

Westwind

Graham93

Scratchbuilder

flaxbybuck

RNinMunich

stevedownunder

Brightwork

Colin H

robbob

pressonreguardless

|

💬 Re: 19 Bow protector

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 141 Views · 2 Likes

Flag

I have been watching your progress on this Marlin model and been greatly impressed with your modelling skills. This latest piece, the bow 'fender' is such a good idea, and your execution of it is flawless.

Well done. Looking forward to completion😉 ▲

⟩⟩

hermank

Scratchbuilder

|

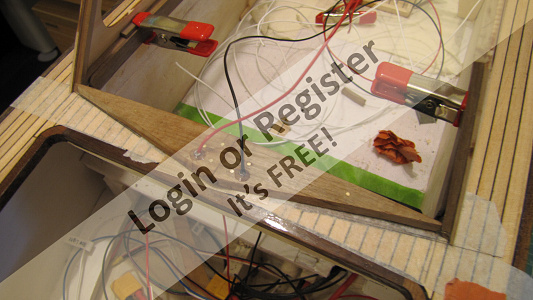

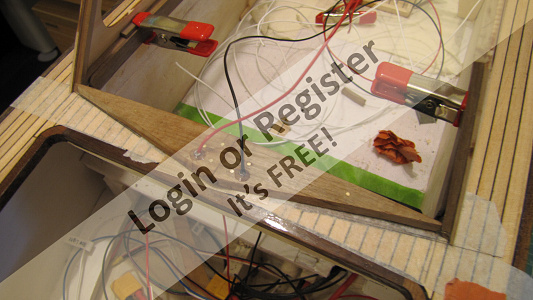

📝 18 Dash board

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 148 Views · 13 Likes · 2 Comments

Flag

💬 Add Comment

The internal cabin has a compartment, which serves as a battery cover (page 15) and a visual dashboard with dials and steering wheel. I wanted to add some detail and interest on the boat so the dashboard is to be illuminated. The body of the unit is made from 6mm black Perspex, there are 9 dials to be illuminated with different colour LEDs. They will all be powered by 6V so they all need to have different resisters wired in then they will all be terminated to a single terminal block to which 6V can be applied. The holes drilled for each LED will be countersunk to the same diameter of each dial on the laminated paper picture; this countersink was then painted with a mirror finish pen to enhance the illumination.

The holes are transferred to the wooden cabinet to allow the wires to pass through.

The holes are transferred to the wooden cabinet to allow the wires to pass through.

▲

⟩⟩

MouldBuilder

hermank

DuncanP

pressonreguardless

River Rat

Rookysailor

RNinMunich

Graham93

stevedownunder

jbkiwi

Colin H

Scratchbuilder

robbob

|

💬 Re: 18 Dash board

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 146 Views · 1 Like

Flag

The gauges are just pictures copied from internet, I then just use Microsoft Word to arrange them in the positions I want.

Then print them and finally laminate ▲

⟩⟩

stevedownunder

|

|

💬 Re: 18 Dash board

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 149 Views · 2 Likes

Flag

Hi Mike

The gage setup looks great. Where did you get the gages, they look very authentic. Trev ▲

⟩⟩

stevedownunder

hermank

|

📝 17 Motor cover (completed)

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 154 Views · 12 Likes · 1 Comment

Flag

💬 Add Comment

Although the motor is a nice looking piece of mechanical propulsion it has a fan on it that could cause injury, and in the real craft it is covered.

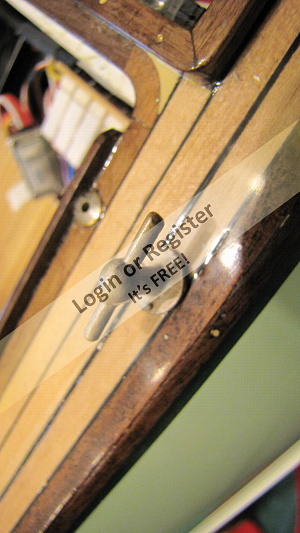

I decided to make something similar to the one I made for the police boat, which required a cover with an air intake at one end and an exit at the other to keep the motor cool in a confined space. Using some 2mm ply I made two side profiles that would cover the motor and fan, this was framed with 4mm sq timber to give attachment points for the top and ends. The end had incorporated a grating, which I made from bamboo; I found this close-grained wood was ideal to stay intact when cutting the small slots and then cutting into log lengths, this gives pieces that can be made into any size required

The wooden outer frame will be varnished wood (walnut) and the panels will be white, made from white plasticard inserts, the top panel will have a soft leather padded seat in light olive. (what colour will the hull be?)

The box when compete will be held in place by small magnets which had proved very successful on other boats, this requires a same size bottom frame to be attached to the deck with the magnet inserts

I decided to make something similar to the one I made for the police boat, which required a cover with an air intake at one end and an exit at the other to keep the motor cool in a confined space. Using some 2mm ply I made two side profiles that would cover the motor and fan, this was framed with 4mm sq timber to give attachment points for the top and ends. The end had incorporated a grating, which I made from bamboo; I found this close-grained wood was ideal to stay intact when cutting the small slots and then cutting into log lengths, this gives pieces that can be made into any size required

The wooden outer frame will be varnished wood (walnut) and the panels will be white, made from white plasticard inserts, the top panel will have a soft leather padded seat in light olive. (what colour will the hull be?)

The box when compete will be held in place by small magnets which had proved very successful on other boats, this requires a same size bottom frame to be attached to the deck with the magnet inserts

▲

⟩⟩

hermank

pressonreguardless

River Rat

GaryLC

flaxbybuck

Madwelshman

stevedownunder

jbkiwi

Colin H

Scratchbuilder

RNinMunich

robbob

|

💬 Re: Motor cover

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 143 Views · 1 Like

Flag

I was particularly interested in hearing about your use of bamboo. It is such a wonderful material having great strength. It is little used in this country (UK) but in other parts of the world they use little else. In China I was amazed to see bamboo scaffolding used on buildings 10 or 12 storeys high.😉

▲

⟩⟩

mturpin013

|

United Kingdom

United Kingdom