Join Us On Social Media!

Brushless motor sync problems

2 Posts · 6 Followers · 0 Photos · 15 Likes

Began 1 year ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 12 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Brushless Motor

12 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 35 Views · 3 Likes

Flag

💬 Add Comment

Some weeks have passed and I have had one or two opportunities to further test and experiment with the power train set-up.

With the three fuses between motor and ESC removed I carried out trials using a watt meter, and different size props. The motor is rated at 50 amps max. and 870 watts max.power. The ESC is rated at 90 amps.

X40 prop pulled 25amps and 492 watts.

S45 prop pulled 21 amps and 419 watts.

X45 prop pulled 31 amps and 594 watts.

S50 prop pulled 27 amps and 505 watts.

All these values are safely within the parameters of the motor and ESC. I did not have the X50 or 55 sizes with me, but they should be next to test. In the original set up I was using an X55, and fuses between motor and ESC when they melted and the motor went out of sync.

In all the above cases I checked every component after fast running to see how cool or hot they had become, and the only heat detected was very slight warmth in the cables between motor and ESC, and a hint of warmth in the ESC. No problems arose.

I am pleased that the early issues have been resolved, and thank you one and all for your input without which I would have been floundering !

I can now look forward to years of enjoyment on the water. 😉

With the three fuses between motor and ESC removed I carried out trials using a watt meter, and different size props. The motor is rated at 50 amps max. and 870 watts max.power. The ESC is rated at 90 amps.

X40 prop pulled 25amps and 492 watts.

S45 prop pulled 21 amps and 419 watts.

X45 prop pulled 31 amps and 594 watts.

S50 prop pulled 27 amps and 505 watts.

All these values are safely within the parameters of the motor and ESC. I did not have the X50 or 55 sizes with me, but they should be next to test. In the original set up I was using an X55, and fuses between motor and ESC when they melted and the motor went out of sync.

In all the above cases I checked every component after fast running to see how cool or hot they had become, and the only heat detected was very slight warmth in the cables between motor and ESC, and a hint of warmth in the ESC. No problems arose.

I am pleased that the early issues have been resolved, and thank you one and all for your input without which I would have been floundering !

I can now look forward to years of enjoyment on the water. 😉

▲

⟩⟩

Razor1955

stevedownunder

Len1

📝 Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 127 Views · 12 Likes · 43 Comments

Flag

💬 Add Comment

Can anyone help me with this issue please.

Cabin cruiser 1m long; 4240 x 740 brushless motor; 5S lipo; 55mm prop.

Cruised happily for 15 mins, then made noise (not dissimilar to slipping coupling) and powered down to a stop. Would then only creep along. On inspection found all three fuse holders and 25A fuses had melted, but fuses not blown. The motor was not hot, nor was the ESC. Out of water seemed to operate OK. It was suggested that the prop might be too large, and caused the motor to go out of sync after a while.

So, what do you think might be happening ?

😉

Cabin cruiser 1m long; 4240 x 740 brushless motor; 5S lipo; 55mm prop.

Cruised happily for 15 mins, then made noise (not dissimilar to slipping coupling) and powered down to a stop. Would then only creep along. On inspection found all three fuse holders and 25A fuses had melted, but fuses not blown. The motor was not hot, nor was the ESC. Out of water seemed to operate OK. It was suggested that the prop might be too large, and caused the motor to go out of sync after a while.

So, what do you think might be happening ?

😉

▲

⟩⟩

Razor1955

Commodore-H

stevedownunder

GaryLC

Doogle

Peejay

hermank

johnf

Trident73

Len1

AlessandroSPQR

cenbeth

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 37 Views · 4 Likes

Flag

Thanks DG.

To answer Doug and Isaac's points. One factor that I had omitted to include is the displacement which is 8.5Kg. ie it is a heavy boat. My wish was to make this boat seriously fast, but not like one of the super-fast electrics. Lastly, I am trying to take things one step at a time. In my last note you will have seen that I have prepared 'links' to use in place of the three motor fuses. I acknowledge there is good reason to remove these fuses, and this could be my next step. By changing just one item at a time I would expect to determine whether this item helps or not. Whilst you had provided information on this issue Doug, much of it was way over my head. And, I had no prior knowledge of your expertise. My approach to problem solving is to ask 'why ?' five times. Old fashioned maybe, but it still relevant. The questions raised by this blog demonstrate the difficulties in selecting appropriate equipment in the power chain. With the lack of clear or simple advice on this topic I used this forum to gather information, but have to allow that there are always differences of opinion. Thank you all for your interest and input. 😉 ▲

⟩⟩

Razor1955

Len1

hermank

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 40 Views · 2 Likes

Flag

Heartily agree Isaac👍

I'm also deeply disappointed that, despite all the informed and qualified advice that he received in this thread, he still insists on using the 3 fuses in the motor leads☹️ What possible "scientific" advice he could have been given to justify that is beyond me (an electrical/electronic engineer with over 40 years experience). Cheers, Doug😎 ▲

⟩⟩

Len1

jbkiwi

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇺🇸 Isaac (

Lieutenant) Lieutenant)✧ 41 Views · 2 Likes

Flag

Recall me questioning your use of 5S battery?

In my opinion a 3S battery for that size boat is all you need. I think the over voltage of the 5S battery has overwhelmed the ESC and it went into some sort of defensive mode and cut the power to the motor. Isaac ▲

⟩⟩

Len1

RNinMunich

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 43 Views · 3 Likes

Flag

DG - from what I know of the 800 and 850 motors the first is low revving (4280 rpm) whilst the 850 is higher revving at 8310 rpm. I have seen the 800 used for tugs and similar slow moving craft that require lot of torque.

I used an 850 in a Sea Queen powered at 12v with lots of NiMH batteries and a 50X prop. Its speed was quick but not fast. It will be interesting to see how your 800 performs. Good luck 😉 ▲

⟩⟩

Razor1955

Cpt-Pugwash

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 46 Views · 1 Like

Flag

DG - what are your motor specifications ? (just curious) 😉

▲

⟩⟩

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 49 Views · 4 Likes

Flag

Hello DGoss99 and thank you for your input.

I will try to answer your questions. 1. I left the 3 motor fuses in place. The fuses are 25Amp. 2. I should have mentioned the main breaker is rated at 40 amps, and the ESC at 90 amps. 3. I have not measured the rpm. The motor specification gives the no load rpm as 13690. 4. I have not checked the maximum speed of the boat. That will come next. From observations I would say it is around 18 - 20 mph. (Quite fast enough for me, and close to the speed limit on the tarn.) Thanks for your interest, and let me know if you have any other queries. 😉 ▲

⟩⟩

Razor1955

AlessandroSPQR

hermank

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 54 Views · 8 Likes

Flag

Hello all,

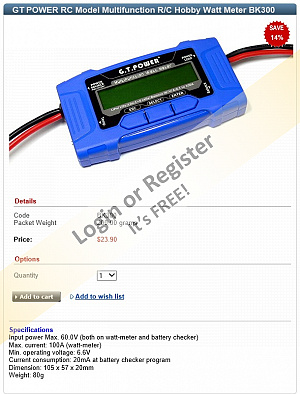

This morning I borrowed a watt meter to find out more about my boat set-up. By finding out the amps and watts when at full throttle I have compared these figures with the specification of my motor to see whether I can safely increase (or should decrease) the size of my prop. My motor spec says max 50 amps, max 870 watts. With an X40 prop I drew 25 amps, 492 watts. With a 45 prop I drew 21 amps, 419 watts. With an X45 prop I drew 31 amps, 594 watts. The performance of the boat with the X45 prop was most satisfactory, and when back on the bench all components were either cold or only just warm, so all appeared to be well. At 31 amps and 594 watts the motor is running well within its capabilities, so this is the prop I have decided to keep in place. I already know that the X55 prop caused the motor to stall so there seemed little point in repeating the trial with this prop size. Having successfully completed this trial I feel confident in being able to ascertain the correct prop size for any boat and will, accordingly, purchase a meter myself. I have seen them advertised from around £10. 😉 ▲

⟩⟩

Razor1955

stevedownunder

Peejay

Len1

Trident73

Cpt-Pugwash

hermank

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 67 Views · 3 Likes

Flag

Thanks so much Flaxbybuck.

▲

⟩⟩

Peejay

hermank

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 66 Views · 4 Likes

Flag

Hello Alessandro, and thank you for your latest submission. You raise some interesting points and I now hope to be able to answer some of these.

One or two club members at LBMBC have given me information that should help me understand how I can adjust the load on the motor to extract the best performance. I will report back when I have test results. 😉 ▲

⟩⟩

Peejay

hermank

Len1

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 66 Views · 5 Likes

Flag

Hello to all naval modelers and ship lovers.

I am very happy that this discussion has been resumed and expanded, perhaps it had been closed too abruptly. It is too interesting and instructive, therefore it is worth analyzing it well and hearing all the opinions. For me it was very instructive and I have to thank all of you but especially Flaxbybuck. Flaxbybuck was very precise and meticulous (from the beginning of the work) in choosing and assembling the various components (for a brushless solution). He started from scratch. He evaluated the best way to protect the model and the various components (very expensive or quite expensive, depending on the point of view). He looked for information that at the beginning was very little, then increased with the finding of some problems. In any case he wisely left the possibility of modifying the protection with or without fuses without costs and work times. From his work (commendable), from the valuable and useful comments of the members of this forum and from information acquired externally, I have arrived at these final considerations: These final considerations should not be understood (at least for me) as definitive conclusions, they are always subject to possible changes and I ask myself (and you) still some questions. The problem can be divided into two main branches: 1. Can the fuses on the three phases of the brushless motor (between esc and motor) create problems for the operation of the motor itself? If so, why? 2. Are the fuses on the three phases of the brushless motor (between esc and motor) completely useless? Or is their usefulness less than the problems they create? 1. First topic: "Can the fuses on the three phases of the brushless motor (between the esc and the motor) create problems for the operation of the motor itself? If so, why?" 1A. Problems directly caused by the introduction of fuses. From what I have been able to find, fuses do not directly create problems for the operation of the motor. On this aspect, I have reread what many members of the group said (after the failure and not before), and I have acquired information from external sources. 1B. Problems indirectly caused by the introduction of fuses. To insert fuses, it often happens that poor quality connectors are used (both in terms of conductors and insulators). In this case, introducing high (relatively high) contact resistances, with high currents, can create various problems (including those described by Flaxbybuck). Fuses inserted with good quality connectors do not create problems. The second test by Flaxbybuck (which however also reduced the diameter of the propeller and therefore the strain on the motor) seems to confirm this. However, Flax was very far-sighted and astute and has prepared everything to return to the fuseless configuration, should further tests advise him to do so. Thinking that the effort and work of finding a high quality connection (with very low contact resistances) is useless and not worth it is an excellent observation but it is part of the second theme (not this one). I am curious to know if anyone believes that the fuse could be directly responsible for the malfunction of a brushless motor even in ideal conditions (with perfect connections and without introducing high contact resistances). In that case I would like to have technical details that explain it. 2. Second topic: "Are the fuses on the three phases of the brushless motor (between the ESC and the motor) completely useless? Or is their usefulness less than the problems they create? The most widespread opinion on this forum is that: the three fuses on the three power cables of a brushless motor are useless. It is a widespread opinion even outside of this forum. The main reasons are essentially three: 1. It is not believed that there is any potential danger for the motor; 2. The danger could exist but there are already protections; 3. The fuse between the ESC and the battery is already sufficient. In this case we must ask ourselves the following questions: What do we want to protect? Is what we want to protect already protected? The first answer is that I want to protect the motor (especially if it is very expensive). In my opinion, the dangers exist (I have heard many reports of motors going up in smoke) and are due to overcurrents caused, in turn, by: excessive friction on the propeller shaft; partial or total blockages of the propeller due to vegetation or dirt; foreign objects that get stuck; excessive load due to the size of the propeller, etc. Etc. Consider that many electric motors used in ships are engines created for airplanes (as in the specific case we are talking about). The second answer is yes. (At least from what I recently learned also in this forum). Apparently the best ESCs for brushless motors can be set to protect the motor by setting a limit current (which does not exceed the maximum current of the electric motor). Or they interrupt the power supply when the temperature rises too much beyond a certain threshold. I have never made or checked these settings, but I know that many ESCs do not have these protections. So, in these cases (where the motor protections are absent) could fuses be useful? At this point another question arises: Does the fuse between the ESC and the battery (which we all said is certainly useful) also protect the motor? Well, I am not so sure about this. In other words, are we sure that the currents circulating in the ESC-battery circuit are the same as those circulating in the electric motor-ESC circuit? I don't think so, precisely because they are two separate circuits. If it is true that you never see fuses on brushless motors, I answer that it is also true that you constantly hear brushless motors smoking. Surely there were errors in the initial setup but I wonder: if there had been fuses would those motors have been saved? I think so but it is just my personal opinion. Who knows if the inexperienced modeler had found broken fuses (instead of the motor) he could have thought: "I did something wrong, I have to change elements of the setup". He would have arrived at the correct solution (perhaps by burning many fuses) after many tests without burning the motor. Maybe (but I repeat maybe) those who carelessly use a propeller that is too big, at least in the testing phase, could save the motor by burning the fuses during the tests. Of course it is better to take measurements and buy suitable measuring instruments, or it is better (depending on the philosophy of the modeler) to follow already known and consolidated setups, spending a lot on quality. I also make another consideration (about the fact that you never see fuses on brushless motors), brushless motors were originally used for airplanes. It is clear that a fuse on an airplane is counterproductive. On a ship, no. I repeat, in my opinion, a ship stuck in the middle of a lake can be salvaged. Instead, a fire in the middle of a lake is irreparable. A broken engine is worse than an intact ship that needs to be brought back to shore because it has a broken fuse. I hope I have translated sufficiently. ▲

⟩⟩

Razor1955

Commodore-H

Peejay

Len1

flaxbybuck

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Cpt-Pugwash (

Midshipman) Midshipman)✧ 75 Views · 5 Likes

Flag

Flaxby.. You have done this all this pretty much by the book. As I commented before, I would replace the 3 blade fuses in the Motor Phases with links as they are an extra single point of failure and maybe a liability rather than a help. The 40A breaker on the Battery Positive will serve to protect the motor.

I say protect the motor, because the motor you have chosen is the weakest link on the propulsion chain (if in fact there is a weak link!) What you have there is an 850W motor, which at 5s will get really pissy if you exceed 42ish amps (850w/20v = 42.5 amp) The battery will give you virtually unlimited current and the ESC will pop at about 100A Peak so that leaves the motor at risk should you stall the Prop and give the throttle some welly! The 40amp breaker may protect you but I would go lower say 35amp (as they trip slowly) or even remove this if you don't want it to trip just because it feels like it and leave your vessel stranded somewhere. (BTW - 850W on a 1M scale boat is a LOT of push! - for more push get a bigger motor) The above is all theoretical as there will be wiggle room in most of the components. On the big Electric Helis we have no trips or fuses. The biggest failing items are the batteries as they do work hard and get hot.. You can't water cool anything on a Heli!! Just so you know where you are, to start (as is suggested elsewhere in this thread) you should invest a recording Watt Meter and you'll know exactly where you stand on the power consumption front. As far as your battery care regime goes, you are over and above with your handling. Remember, never drop them and if you do, quarantine them out doors for a day or two to make sure they are OK. Last thing.. NEVER let the batteries get too hot to hold after a run. If they do, you need higher capacity battery, a smaller prop or LESS throttle!!! WATT METER.... ▲

⟩⟩

Razor1955

Peejay

hermank

Len1

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 71 Views · 3 Likes

Flag

Thanks for the info DGoss.

Not having any previous experience of handling large lipo batteries I asked people reading this site for their recommendations. The majority response appeared to favour fuses on each of the three motor leads, in addition to one on the battery. There were some responses that favoured no fuses on the motor but I did not fully understand all the information supporting this, and opted for using fuses. I have to admit that I still do not understand the technicalities of this, so would appreciate any information that throws light on the subject. You may have noted that I have prepared three 'links' that can be used in place of the fuses. These can be easily installed and the fuses removed. Are there any tests you can suggest that would demonstrate fuses are not needed ? I am happy to try out any suggestions provided they are sensible, and can be supported either by science or by experience. My concern has always been to protect the motor and ESC from becoming damaged. I do not know precisely how damage might occur but imagine from 'spikes' or overloading. I always charge my batteries out of the boat. I slow balance charge before use, then 'store' charge after use. 😉 ▲

⟩⟩

Razor1955

Peejay

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 71 Views · 2 Likes

Flag

Fuses ?

I asked the question whether to use a fuse or fuses and the best information received suggested a total of four fuses, viz. one between battery and ESC, then three between ESC and motor. I have installed a 40A circuit breaker for the first case, and 25A fuses (standard blade car fuses) for the three between ESC and motor. This installation seems to offer the highest level of protection and, using a 5S lipo battery for the first time I was anxious to install the best protection possible. 😉 ▲

⟩⟩

Peejay

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 77 Views · 2 Likes

Flag

Hi Flaxbybuck, we're actually the ones who have you to thank.

First of all thank you for this latest report and I'm glad everything is working. Secondly, thank you for allowing us to analyze in depth all the technical problems relating to a set-up with a brushless motor. ▲

⟩⟩

Doogle

stevedownunder

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 75 Views · 6 Likes

Flag

So, today I was back on the water for further trials to see whether my brushless motor problems have been rectified.

Firstly, I renewed all three fuse holders and fuses (same 25A rating). Secondly, I prepared three 'jump' leads that can take the place of the fuses should the need arise. (It did not) Third. I changed the 55X prop for a 40X. At the end of today's trials, which appeared to be successful, I found the following: 1. There were no obvious problems or breakdowns. 2.The motor was quite hot, but not so hot that I could not hold it. In my book that is OK. (Nb the motor is cooled by a fan) 3. All cables, fuseholders, ESC and battery were cold with no signs of having been hot. 4. The top speed was slightly less than before. Before settling on this prop size I will experiment with other sizes. Thanks again for all your suggestions and help without which I would not have been able to make such an informed decision about how to deal with the problem. 😉 ▲

⟩⟩

Razor1955

Peejay

Doogle

stevedownunder

AlessandroSPQR

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 89 Views · 8 Likes

Flag

Wow, what a response from you ! I never expected such a detailed consideration of my problem.

After careful inspection, personal research, plus consideration of all your posts, I have reached a conclusion. In my view the cause of the problem (motor 'stalling') was overloading which causes the motor to go out of sync. So a smaller prop is needed. Melting of the fuse holders is a secondary issue caused by poor contact of the fuses manifest when subjected to a large current. Initially I will see whether replacing the fuses and holders is sufficient; if not, then I might remove these three fuses altogether. Thank you all for helping me with this issue. Your help has been invaluable. I will keep you posted ! (Don't hold your breath because I never rush these things.) 😉

▲

⟩⟩

Peejay

stevedownunder

IanL1

johnf

Len1

MartinW

AlessandroSPQR

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 102 Views · 5 Likes

Flag

Great thoughts ChrisF, thank you so much for your input and sharing your experience.

▲

⟩⟩

Peejay

hermank

stevedownunder

ChrisF

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 ChrisF (

Commodore) Commodore)✧ 105 Views · 8 Likes

Flag

Thanks RN (Edit: overlapped with your last comment) for the detailed reply as that is along the lines of what I I was going to say but less succinctly and without the important calculations. Electric/electronics isn't my area of expertise so I tend to rely on logic and common sense which serves me well most of the time.

Alessandro - I'm sure that fuses, holders and connections could be manufactured to meet the requirements to allow fusing of the individual three cables but certainly for RC model use they appear not to be - I think a search would be fruitless? The main reason being cost as you would be approaching the cost of the thing i.e. the motor, that you are seeking to protect. The motor is usually the cheapest of the major components so why bother, especially when you could be introducing further and more likely risks? My understanding is that the main thing you want to avoid in a model boat is a fire and why a fuse, if installed, is between the battery and ESC. My brief online search didn't bring up any agreement on fitting fuses in the motor cables and usually the opposite. The flying lads in the main won't use fuses at all, especially if using a BEC as control of the plane will be lost. If the motor stalls because of say weed then it could overheat and be damaged but most folks would come off the throttle and as said before decent ESCs have thermal and overload protection. Cheap ones may not but that's always a risk when using cheaper components. Carry out your tests to satisfy your curiosity and understanding (nothing wrong with that) but it isn't really going to help modellers as we aren't going to do it, that is install fuses in the motor cables. FBs experience has been good in a way because it has highlighted the pitfalls of doing so. Chris ▲

⟩⟩

Razor1955

Peejay

hermank

Doogle

stevedownunder

Len1

AlessandroSPQR

RNinMunich

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 101 Views · 5 Likes

Flag

Thanks Lew, agreed.👍

This topic has been beaten to death. No further comment on my part. Cheers, All, Doug😎 ▲

⟩⟩

Peejay

hermank

stevedownunder

LewZ

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 103 Views · 6 Likes

Flag

Good morning to all naval modelers.

Thanks Doug for all the clarifications. Thank you also for your indulgence in unfortunate translations (I often don't understand well and don't make myself understood). "So if we're just talking about contact issues, I agree." Thank you. That IMHO is the issue here. Perfect, it's clear you were referring to connections. I agree with all of you. I note that, based on your experience (ChrisF, Doug, Trident73, JBkiwi, Stevedownunder, GaryLC), you do not believe that a connection with a fuse can have suitable characteristics (no matter how well it is maintained) for managing a brushless motor. This is very important and I must take it into due consideration. "gold is preferred to copper in these cases (mobile connections), not because it is less resistive (or more conductive) than copper but because it is almost immune to oxidation and corrosion." Both reasons actually. Just a quick clarification here: not for both reasons but only for the oxidation and corrosion issue. This is a very common mistake (even the best people make it), many think that gold is less resistive than copper (i.e. more conductive). Not so copper is less resistive (more conductive) than gold. On the podium in the first three places of the classic metal conductors the ranking is as follows: 1) Silver, 2) Copper, 3) Gold. Thanks also for the explanation on how the brushless motor works, it's what I've seen and read on many Youtube videos on the subject (I'll put the links at the end so as not to cut the text). I was excessively succinct and this may have generated some misunderstandings. DC power supply, I meant that we use the current from a battery and not the alternating current from the mains. It will certainly never start with a positive and a negative, you need a special driver or an ESC that distributes square-type alternating currents (which attract and repel the magnets at the same time). But this was clear from what I wrote immediately afterwards, however you were right to clarify it. By rotation I meant the rotational sequence that the currents have within the various windings (see the video). All your clarifications are perfectly reflected in the various informative films on the functioning of the brushless motor but the most important problem has not been answered: I'm not sure that, in the event that one of the three cables is interrupted, the system will continue to provide alternating voltages (as you are convinced)." I'm not sure either. But my gut feeling is that the ESC would do it's best to carry on with the feedback it gets from the remaining two connections. With considerable stuttering and loss of power. Which corresponds to the symptoms that FB reported. Yes, I hope to have time to carry out some tests on this matter because this can be very important for us model makers (even if I had no intention of using brushless for my models). It is only out of pure curiosity that I want to delve deeper into the problem. --------------------------------------------------------------------------------- Ok, so far we have talked about topics relating to the Flaxybybuck problem and related to RC naval modelling. From this point on I will talk about the other topics that deviated a bit from the main topic. I'm only doing this for accuracy but if you want Doug we can continue in private if this bothers other users. "It has absolutely nothing to do with the device which caused the fault in the first place. Your example puts the cart before the horse." Why do you write like this? I did not say this. I wrote (but sorry if I wasn't clear) that a protection device (fuse, circuit breaker, motor protector, etc. etc.) not only prevents fires but also saves the system (i.e. the wiring and other electrical equipment) . I gave the example of a thermomagnetic circuit breaker-differential circuit breaker, because they are devices that have (or should have) all in their own electrical panel, even a minimalist one. The circuit breaker certainly protects you from a possible fire but it also protects the cables and the pure differential. If they come into direct contact with phase and neutral we are in the presence of a short circuit therefore we will have a very large current intensity, for example 4000 Ampere (they remain below the threshold of 4500 Ampere of a common single-phase apparatus). In this case it is true that we avoided a fire by promptly opening the circuit (magnetic protection). However, there are overload situations (currents that are not short circuit but still higher than the capacity of the electrical cables and other equipment in the panel) which do not generate fires but, in the long run, damage the conductors, insulation and other equipment in the electrical panel. . In this case the thermomagnetic switch (thermal part, usually a bimetallic plate) intervenes following a timing that takes into account how much we are exceeding the threshold current, saving the electrical system from damage (not a fire). Likewise the fuses. Some types of fuses are installed not only to protect against fires but also to protect the motor and the network from overcurrents (logically there is not only a fuse to protect the motor but also other devices, such as a motor protector for example). "NOT specifically to protect the devices they are connected to." I didn't agree with this. Instead, I believe that fuses are also used to protect the devices to which they are connected. This is what I meant to say, sorry if I wasn't clear earlier.

▲

⟩⟩

Razor1955

Peejay

hermank

Doogle

stevedownunder

Len1

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 103 Views · 5 Likes

Flag

Doug, thanks for the advanced "skip" warning. Seems like there is enough words posted on this topic to write a book.

Also seems to me that for scale model boats powering a model is not that difficult. Basically supplying power to a motor through an ESC Seems simple enough. I placed my engineering days behind me and use simple math and logic to get this to work. My only complicated part is getting the combination of prop and motor RPM right for the desired performance (speed and low heating). My simple method Seems to have worked for me and my model fleet. Perhaps if someone is interested in getting absolute peak performance these wordy posts might be of interest. KISMIF ! Lew Florida ⛱️, USA 🇺🇸 ▲

⟩⟩

Doogle

stevedownunder

Len1

RNinMunich

hermank

|

|

Login To

Remove Ads 💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 104 Views · 6 Likes

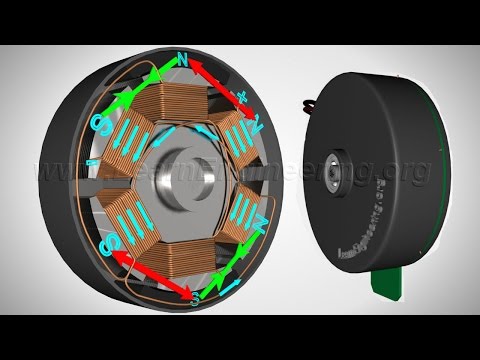

Flag

Oh dear. I thought we had already put this topic to bed!🙄

My dear Alessandro, I am giving you the benefit of the doubt, in that you may have some troubles / ambiguities with the translations back and forth. I will deal with the comments in your epistle in order of appearance. (Sorry shipmates but this may get a bit long! Electrically well versed readers have permission to skive off this lecture😁) "So much so that I specified that you need to tighten the connection well and make sure there is no play." This implies a screw connection, or worse a clip or crimp connection. ON NO ACCOUNT should these be used on high load (current) wiring. You can never be sure of the true contact area. The smaller the area of contact the greater the chance of causing a hot spot at high currents, e.g. 25 to 50A as we have here. The current density problem! Also these connector types are seldom (if ever) available gold plated. Thus being susceptible to corrosion in a damp (marine🙄) environment. Not to mention coming loose under vibration or due to heating / cooling cycle effects. "If, however, you think that the fuse creates problems because the metal foil causes greater resistance (when you refer to the 1st and 3rd Ohm's laws, V=R*I, P=V*I or P=R*I* I ) because of its subtlety, then I disagree. Allow me to disagree, no pretensions on my part just to reason." "metal foil fuse" This may be a translation problem. A slow blow fuse consists of a straight solid wire. A quick blow fuse is a coil under tension. "In other words, I find it difficult to believe that the greater resistance caused by the fuse foil creates such a significant Joule effect. Fuses would no longer have any reason to exist if they were capable of melting plastics before melting them." My remarks re heating were specifically directed at the connections of the fuse holder. The fact that the fuse itself did not blow means that the current was less than 25A. But high enough to create heat in a bad connection. Say I=20A and R=0.5Ω. P=I²R --> 800W.😮 "I take it for granted that a new connector does not yet have oxide and corrosion." 'In this the most perfect of all perfect worlds.' Perhaps. But my experience in our real world is that most non gold plated connectors are already lightly corroded on opening the packet, and need cleaning before use and protecting (e.g. WD40) in use. Pull out any spade connector (e.g. auto type fuses) and see where it is dull, most of it, and where it is shiny, very little showing the few points of real contact. "gold is preferred to copper in these cases (mobile connections), not because it is less resistive (or more conductive) than copper but because it is almost immune to oxidation and corrosion ." Both reasons actually. "So if we're just talking about contact issues, I agree." Thankyou. That IMHO is the issue here. "Nothing about the correct section of the cables, but I don't think that is the cause." In this case probably not. This was simply part of my general advice on safe installations. "Regarding this statement: "Most folks don't realize that fuses are fitted to protect wiring from overheating and causing fires. NOT specifically to protect the devices they are connected to." Sorry but I don't completely agree with you. ... I can refer to civil electrical systems (the one in your house): fuses and circuit breakers serve to prevent fires but also "specifically" to safeguard the system (consisting of cables and various devices)." That is exactly my point Alessandro. A house system consists of many circuits which are protected by fuses / circuit breakers of various values according to the use of the circuit; lighting, power sockets, high power 3 phase for cookers. If a device on a power socket circuit develops a fault causing an overload the fuse or breaker on that circuit pops to prevent a fire in the cabling and the fault dragging the whole house system down. It has absolutely nothing to do with the device which caused the fault in the first place. Your example puts the cart before the horse. "I don't know the brushless motor well enough. I certainly know, in general terms, the operating principle. It is a direct current electric motor because it is powered by direct current ..." NO it is not! If it was you could power it by directly connecting it to a battery (PSU). But how? Which two wires would you connect to + and - of the source? Or would you use two batteries in parallel with a centre tap for the 3rd wire? Try it if you like I'd be most interested to hear how it goes. " ... but in fact it works with different alternating currents (not sinusoidal but mostly square)." Now you're getting it😀 Partly! True the battery provides DC power to the ESC, but not to the motor. The ESC receives a decoded pulse train (as you say 'almost square') from the RC receiver. So far the same as a brushed motor setup. BUT! (There's always a BUT.😉) In the case of a brushless motor the ESC needs instruction from the motor what to do with this pulse train. It receives this instruction, in the most common brushless motors, by monitoring the EMF feedback from each connecting wire of the motor. As you know, when you energise (apply a voltage) a coil it generates both an electric and magnetic field. When you remove the energising voltage these fields collapse and send their energy back into the supply wires in the form of a Back EMF pulse. This tells the ESC which coil of the stator was last energised and thus which is the next one in sequence. Other, more expensive, brushless motors have sensors built in which provide this position information. Never been down this alley, so far haven't seen any reason to, so I don't know precisely how it works but I assume that it requires an ESC capable of digesting the info from the sensor. Maybe other members can enlighten me. Never stop learning👍 "These currents that create the rotating magnetic fields are generated by the ESC (in our case) ..." The magnetic fields do not rotate. The fields are static and the coils generating them are built into the stator of the motor; in an Outrunner the inner part, in an Inrunner the outer part like the can of a brushed motor. Whichever, the magnetic fields generated by the stator coils act against the permanent magnets in the rotating part thus driving the motor round. "I'm not sure that, in the event that one of the three cables is interrupted, the system will continue to provide alternating voltages (as you are convinced)." I'm not sure either. But my gut feeling is that the ESC would do it's best to carry on with the feedback it gets from the remaining two connections. With considerable stuttering and loss of power. Which corresponds to the symptoms that FB reported. Be interested to hear the result of your experiment Alessandro. Cheers all, I warned you this post could get a bit long😉 (Even though I left some detail out, such as pulse train type and coding/decoding PPM or PWM😉) Doug😎 ▲

⟩⟩

Razor1955

hermank

stevedownunder

Len1

ChrisF

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇦🇺 stevedownunder (

Commodore) Commodore)✧ 110 Views · 7 Likes

Flag

Hi Flaxbybuck,

I haven't read all the responses so I may be repeating what other people have said. I personally would say the problem is a bad joint or another way of saying that is a high resistance joint, as Gary has said and this has caused excessive heat that melted the fuse holder. Fun fact, as copper is heated it becomes resistive, a bad electrical joint will cause heat, this situation only gets worse while current is still being applied. I personally would not have any fuses on the output side of the ESC, if one fuse blew you would be running your 3 phase motor with only 2 phases, this is really bad for 3 phase/brushless motors. As others have said I wouldn't have any fuse even on the input/battery side, if you feel you must have then a thermal overload is not a bad choice as once it cools down you will be able to start the motor again. Cheers, Stephen. ▲

⟩⟩

Len1

GaryLC

SimpleSailor

hermank

AlessandroSPQR

jbkiwi

RNinMunich

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 125 Views · 4 Likes

Flag

Hi there, and having read your problem, although electric motors is not my strong point I would like to offer you my opinion on what happened and why. First off as you mention the boat was behaving quite normally and all was well, then a strange noise from the boat and a reduction in speed as it limped home with little or no power. I think your fuse holders were the cause of the problem, and I think the vibration loosened the fuse termination screws sufficiently to cause a very high resistance joint, which heated up the terminations enough to melt the fuse holders. The fact the fuses didn't blow means the rating is set far too high, and you were lucky nothing burned and the motor and escapement unharmed. So you could invest in porcelain fuses that will definitely, fix the problem on a long term lasting basis. Happy boating, regards, Gary.

▲

⟩⟩

Len1

hermank

AlessandroSPQR

stevedownunder

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 105 Views · 5 Likes

Flag

Hello everyone, let me say that it is a real pleasure to talk to you about these topics.

However, there is a lot to say and learn from you so let's proceed in order. I have a lot to learn about brushless motors because, unlike synchronous and asynchronous AC motors, I didn't study them at school. However, unfortunately I forgot too many things even about what I studied. Everything I will write is to submit it to your scrutiny and to give Flaxybybuck a more precise idea of what to do. First Doug and ChrisF. First of all, thank you for your explanations, always very enlightening. Yes, I confirm that I wrote the last message before reading yours. You actually explain the cause very well. However, this explanation, which is fully shared by ChrisF and Trident73, refers to the problem of connections. The fuse itself would not cause any problem. The fact is that it introduces new junctions (further junctions), which are of mediocre quality such as the faston type and those are the real problem. If that's the point then I totally agree. So much so that I specified that you need to tighten the connection well and make sure there is no play. I take it for granted that a new connector does not yet have oxide and corrosion. If, however, you think that the fuse creates problems because the metal foil causes greater resistance (when you refer to the 1st and 3rd Ohm's laws, V=R*I, P=V*I or P=R*I* I ) because of its subtlety, then I disagree. Allow me to disagree, no pretensions on my part just to reason. It is true that a small current causes a greater Joule effect, i.e. heat, in fact it depends on the square of the current and it is no coincidence that we transport electrical energy by raising the voltage up to 380,000 Volts and more to reduce the current for the same power . However, it is also true that the metal foil of the fuse, as long as a certain current is not flowing through it, does not generate a high temperature, certainly not so high as to melt the plastic of the connectors. In other words, I find it difficult to believe that the greater resistance caused by the fuse foil creates such a significant Joule effect. Fuses would no longer have any reason to exist if they were capable of melting plastics before melting them. You rightly say that you prefer gold-plated connectors. In this regard I want to remind you (you teach me) that gold is preferred to copper in these cases (mobile connections), not because it is less resistive (or more conductive) than copper but because it is almost immune to oxidation and corrosion . So if we're just talking about contact issues, I agree. I really like your analysis: "the problem most likely lies in the only component that failed. The fact that neither motor or ESC overheated confirms that they were not under stress." I agree with you even if it's not always true, sometimes a mosfet burns but the cause was a malfunction of the chip that controlled it, however this time the fact that the electric motor and ESC are not overheated is in your favor. Nothing about the correct section of the cables, but I don't think that is the cause. Regarding this statement: "Most folks don't realize that fuses are fitted to protect wiring from overheating and causing fires. NOT specifically to protect the devices they are connected to." Sorry but I don't completely agree with you. I'm definitely wrong, but I want to explain my reasons even if this goes a bit outside the main topic (don't get angry Flaxybybuck). I remember many diagrams of fuses and other devices of motor systems in the electrotechnical field (precisely to protect the engines themselves), but apart from this I can refer to civil electrical systems (the one in your house): fuses and circuit breakers serve to prevent fires but also "specifically" to safeguard the system (consisting of cables and various devices). The regulations in Italy, which implement the European ones, define, for example, the circuit breaker as a device which has the purpose of safeguarding the electrical system, unlike the differential switch which has the purpose of protecting people from indirect contact. So it is true that the circuit breaker protects us from fires (magnetic part for short circuits and thermal part for overloads) but it is also true that it protects the equipment. In fact, a (pure) differential with Idn current of 30 mA but maximum capacity of 16A must be protected by a circuit breaker of the same value for overloads, therefore a C16 (C curve of 16 A). This is due to Italian legislation. Sorry for the digression, now I return to the original riverbed. For Trident73. I liked all your interventions, especially the suspicion that a screw may have slipped into the armature of the brushless motor, but your last message made me think a lot. You could be right and if I don't recognize it right away it's only because I want to be sure. "Imagine a situation where one fuse blows and the other two don't. They would not save anything and the ESC would still send signals to some of the windings causing a rapid stuttering of the motor and probably “magic smoke” to escape the ESC". I don't know the brushless motor well enough. I certainly know, in general terms, the operating principle. It is a direct current electric motor because it is powered by direct current but in fact it works with different alternating currents (not sinusoidal but mostly square). These currents that create the rotating magnetic fields are generated by the ESC (in our case), which must know the position and synchronize. I'm not sure that, in the event that one of the three cables is interrupted, the system will continue to provide alternating voltages (as you are convinced). As soon as I have time I want to do some experiments but, actually, it's a pretty big risk. Compared to the risk of overheating due to the propeller jamming (which I never underestimate because it has often happened to me), for example due to vegetation, this risk could be more serious. You made an excellent point. Logically these doubts come to me about the brushless motor, on the brushed I have no doubts about the use of fuses. Sorry for the bad translation, I hope you understood something of what I wanted to say. ▲

⟩⟩

Razor1955

Len1

hermank

GaryLC

Peejay

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 ChrisF (

Commodore) Commodore)✧ 111 Views · 6 Likes

Flag

Alessandro - I simplified my mention of the motor leads by just saying that the motor relied on accurate timing from the ESC which RNinMunich kindly expanded on with his detailed description. And also his mention that the leads should all be the same length with good quality, preferably gold connecters. It would be very difficult to ensure that amount of uniformity if introducing fuses and almost certainly the resistance would vary from lead to lead.

You are right that when identifying problems that you should only change one thing at a time but I was pretty confident it was the introduction of the fuses that was causing the problem. And so seeing as I considered the prop to be too big for the model it should be changed anyway, not so much for it being the cause of the problem. I did say that brushless motors can turn big props and as has been said there was no warming of the battery, ESC or motor so there didn't appear to be a problem because of the prop size as such but it wasn't helping. I was going to mention the motor rpm which I calculated a bit less at 13690 unloaded which when loaded would be 10952 (80%). It is a little high for a planing hull cruiser and I reckon would still perform well on a 4S. But once the electrical issues have been rectified the 5S should be Ok as long as the throttle hand is restrained or Tx limited! Good luck with the changes FB. Chris ▲

⟩⟩

Razor1955

Len1

hermank

Peejay

RNinMunich

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 107 Views · 6 Likes

Flag

Ciao Alessandro.

Ref "Why should a fuse affect the operation of a brushless motor? I'm asking you because a fuse (with current flowing below the threshold) should behave like a normal electrical contact from an electrical point of view. If there is no oxide, corrosion or false contact there should be no problems. " I can only assume that you wrote this before reading my post! (Starting with "Absolutely JB, ...") Cheers, Doug😎 " If there is no oxide, corrosion or false contact .." THAT IMHO is exactly the problem here. Why else would the fuse holder fail but motor and ESC not? ▲

⟩⟩

Razor1955

Len1

AlessandroSPQR

ChrisF

Peejay

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Trident73 (

Sub-Lieutenant) Sub-Lieutenant)✧ 122 Views · 7 Likes

Flag

Hi Alessandro, i just saw in your message that the three fuses are on the three motor wires between the motor and esc. I had not realised that until now. I had assumed they were battery side between the esc and battery, although I guess that would not do much... I would still say definitely to get rid of them (just my opinion). Imagine a situation where one fuse blows and the other two dont. They would not save anything and the ESC would still send signals to some of the windings causing a rapid stuttering of the motor and probably “magic smoke” to escape the ESC

▲

⟩⟩

Cpt-Pugwash

Len1

AlessandroSPQR

ChrisF

Peejay

hermank

RNinMunich

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 109 Views · 4 Likes

Flag

Hi Trident73 and Jbkiwi, sorry if I didn't include you but I only noticed your messages after writing mine.

Consider what I wrote to ChrisF in my last message to you too. I see that all three of you are against the three fuses on the three electric motor cables. This makes the discussion much more interesting and stimulating because when you have different opinions you compare and you can always learn something. I'm curious to see if removing the three fuses will solve the problem (leaving all other conditions unchanged, including the diameter of the propeller). As already said, I can change my mind, admit the mistake and thank you for having learned something, but in the meantime I would like to ask you a question. Why should a fuse affect the operation of a brushless motor? I'm asking you because a fuse (with current flowing below the threshold) should behave like a normal electrical contact from an electrical point of view. If there is no oxide, corrosion or false contact there should be no problems. ▲

⟩⟩

Len1

Peejay

ChrisF

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 108 Views · 6 Likes

Flag

Flaxby,

Ditch the fuses and holders in the motor leads. Use the bullet connectors provided on the motor and ESC. Preferably gold plated. And make sure that they are a good tight fit. Cheers, Doug😎 ▲

⟩⟩

Cpt-Pugwash

Len1

AlessandroSPQR

Peejay

hermank

Trident73

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 108 Views · 6 Likes

Flag

Absolutely JB👍

My first thought, as a former test engineer, was the problem most likely lies in the only component that failed. The fact that neither motor or ESC overheated confirms that they were not under stress. All the comments referring to the connections are correct IMHO. Even a small current due to resistance of a poor connection (e.g. intermittent or dry joint) can cause high heat to be be generated. V=IR, P=IV --> =I²R. 🔥 NOTHING should be added to the motor leads on a brushless motor, as it provides feedback info to the ESC of the current position of the motor rotor coils in relation to the stator coils. Thus enabling the ESC to work out which stator coil should receive the next voltage pulse. Any interference with the motor leads can affect this. Also ensure that the ESC leads are at least the same wire gauge as those supplied on the motor, and the total length of each of the 3 wires are the same. A smaller wire gauge has more resistance and increases the chance of overheating. My 2 Euro-cents worth😉 Cheers All, Happy brushless sailing🤞 😎 PS Most folks don't realise that fuses are fitted to protect wiring from overheating and causing fires. NOT specifically to protect the devices they are connected to. ▲

⟩⟩

AlessandroSPQR

Peejay

ChrisF

hermank

Len1

Trident73

|

|

Login To

Remove Ads 💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 109 Views · 4 Likes

Flag

Hi ChrisF, I'm very interested in this discussion and your opinion matters a lot to me.

I would like to retrieve the old post to read what was said about him at the time. Unfortunately I haven't succeeded yet. Can you put the link in this topic, so we can reread what was written? However I remember some things. I'm definitely still in favor of fuses, anyway. If sized well, with just a few cents they save very expensive equipment if not the entire boat. But this is another matter. In this specific case I understand that you prefer (if you really have to install fuses) to only place one on the battery side. I accept your opinion but I don't think that additional protection (downstream as well as upstream) causes a problem. At most one of the two could be superfluous but I don't think it is harmful. I still believe today in the validity of the protection both between the ESC and the battery and between the ESC and the electric motor (logically by adequately calibrating the size of the fuses), for various reasons that I have already described, however I am ready to change my mind and admit that I was wrong. One can certainly argue about the very low size of the fuse (25 Ampere compared to the 50 Ampere declared for the motor) but the fuse did not break. Using an undersized fuse generally means not making the most of the equipment you are protecting (if it breaks first), but it certainly does not mean not protecting it adequately. Your ideas and suggestions are very inspiring to me and I am willing to admit that the three fuses may have caused their motor to malfunction as long as this is demonstrated unequivocally. For this reason, if Flaxybybuck wanted to carry out the same tests by removing the three fuses after the engine, it would have to do so with the same 55 mm propeller. I mean you have to change one variable at a time to find the cause of the problem. If we remove the fuses and at the same time reduce the diameter of the propeller, if the problem were resolved we would not understand whether this was due to the removed fuses or the reduced propeller. I also reiterate that it is very important (where possible) to carry out measurements. To give a certain answer and arrive at reasoned conclusions, we should check how much current passes between the ESC and the battery and how much current passes in the motor cables (between the ESC and the motor). ▲

⟩⟩

Peejay

ChrisF

Len1

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Trident73 (

Sub-Lieutenant) Sub-Lieutenant)✧ 122 Views · 5 Likes

Flag

Another Q, sorry…. Are you using good quality silicone insulated wire (eg such as the stuff on your ESC and Motor) to hook up your fuses, and do they have good quality soldered joints to the fuse holder terminals?

▲

⟩⟩

Peejay

RNinMunich

Len1

hermank

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Trident73 (

Sub-Lieutenant) Sub-Lieutenant)✧ 122 Views · 5 Likes

Flag

Another thought (this has bitten me in the past). Double check your motor mounting screws are not protruding too far into the back of the motor case and touching any of the windings.

Also, make sure your system knows where your top of throttle is. Usually this is done by connecting the battery with the transmitter OFF then turning ON the transmitter with the throttle set to MAX. After the first ‘beep’ lower the throttle and you should hear normal startup tones. Goes without saying to stay clear of the prop while you do this in case it starts. Also some ESC brands may have different procedures for calibration of the throttle range ▲

⟩⟩

Peejay

Len1

hermank

AlessandroSPQR

jbkiwi

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Trident73 (

Sub-Lieutenant) Sub-Lieutenant)✧ 121 Views · 5 Likes

Flag

Just personal preference but in a brushless setup I have never used a fuse, assuming that you have spare capacity in the esc and that the battery has the ‘c’ rating to deliver the necessary current it should not be necessary.

One other thought springs to mind - might be worth double checking that no foreign object (screw / washer etc ) has found its way into the motor can and stuck to one of the magnets on the rotating can. That would induce noise, balance issues and other problems… 🤔 ▲

⟩⟩

Peejay

Len1

hermank

AlessandroSPQR

jbkiwi

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 109 Views · 7 Likes

Flag

Hi FB, firstly,- remove the fuses from the 3 motor wires,! as if one fuse has a loose connection, it will get hot, and the motor will be trying to run with less power on that winding (out of sync sound) and causing the other 2 to load up and get hot. If you are going to use a fuse in the system, it should be before the ESC.

With a 740kv motor, the prop speed with a 5s will be around 15,100 rpm (unloaded) with a full battery (assuming the battery is 20c) which is probably too much for that motor with the 55mm prop The Aerodrive from HK - max 50A - in reality a safe 25A cont ). Start with a 25mm prop, - working your way up till you get to a reasonable safe amperage loaded. As Trident said, the best investment you can make (using LiPos especially) is a Watt meter such as the examples pictured (the GT Power one is the best, HK doesn't sell the pictured one any more, but there are similar ones branded differently,- the last 3 only measures amps, watts and volts and Watt hours. 1 and 2 measure cell voltages on LiPo and Life batteries - (have plugs for balance leads) and can balance cells as well. A bit hard to find now, but the other 3 are available on Ali Express and EBay. These can all stop you from making expensive mistakes. I have 3 and use them religiously when setting up new models, and have never had a problem in around 14yrs of running electrics. As suggested,- as an alternative, try it on a 4s LiPo which will lower the stress on the motor, ie motor is slower but can handle a larger prop. With brushless motors, as a general rule, the higher the KV and the bigger the battery (V) the smaller the prop, and vice versa) same for boats. Most people don't realize, that if your model is a bit slow on say a 4s 20c LiPo, instead of buying a 5s and maybe maxing out your motor, you can increase your performance by buying a 4s 60c (or higher) battery, which will give you similar performance to a 5s 20c. JB

▲

⟩⟩

stevedownunder

Peejay

Len1

hermank

RNinMunich

AlessandroSPQR

Trident73

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 ChrisF (

Commodore) Commodore)✧ 112 Views · 8 Likes

Flag

I was concerned at the number of fuses you have and still am. Different folks have different views but personally I side with the those that say only one fuse is needed and that should be in the positive lead between the battery and escape.

I don't see why you feel the need to have a fuse in each or any of the battery wires and I'm leaning to this as being where the problem lies. My reasoning being that even though the motor manufacturer has sized the cables for the design current I do think sometimes there isn't a lot of leeway and given that you are quite likely introducing resistance with the fuse/fuseholder and the added joints and this resistance is causing heat build-up and the melting. Also brushless motors rely on precise timing from the ESC to run and again the fuses might be causing a problem here? I don't use fuses at all in my builds (I may use one at some point when I'm using the boats more often) as in my case I consider the risk quite low - we don't have a weed problem and I also oversize my motor and ESC (no water-cooling at all) along with smaller props so that components aren't working that hard. If I was racing I'd fit one but I don't think my bought plastic race boats have one, I'll have to check. But they are built to a price and not as precious as my builds! So, if it was me I'd remove the three fuses to the motor and try with the smaller prop. Your ESC has a good rating and its own protection. Fuse size needs more discussion as I've seen it mentioned that it should lie between the max. current of the motor (50amps in your case?) and below that of the ESC of 90amps. 5 to 10 amps lower is mentioned but that is with lower amp ESC's so I think one closer to the motor rating would be better - this isn't an area I know much about so caution on that and see what others think about a safe fuse rating. Edit: just remembered that you have 40amp breaker between the battery and ESC and no problems with that so that value would seem to be fine particularly as it is lower than the motor rating as well as that of the ESC. One other thing. If you are going to do an extended dry run make sure the top bearing has sufficient lubrication and that the bottom bearing is running in water. For less mess and resistance leave the prop off! Chris ▲

⟩⟩

stevedownunder

Peejay

Len1

RNinMunich

hermank

AlessandroSPQR

jbkiwi

Trident73

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 104 Views · 4 Likes

Flag

Thank you for your response Alessandro. Very helpful.

Unless I receive further and better information my proposed actions at this stage are : 1. Replace the fuse holders and fuses. 2. Recharge the battery 3. Replace the prop with a smaller size, say 45mm 4. Bench test 5. Water test. Bon voyage ! 😉 ▲

⟩⟩

Peejay

Len1

hermank

AlessandroSPQR

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 110 Views · 5 Likes

Flag

Hi Flaxybybuck, thanks for this information.

I had searched for previous topics in which you had already included these indications and diagrams but I couldn't find them. I don't even remember if they were in the "builds", the "forum" or other sections. You gave a detailed report and now I understand a little more, also thanks to the precious interventions of ChrisF and Trident73. Nonetheless, I am very surprised at what happened to you. It has never happened to me, nor have I ever heard of a fuse holder that melts but the fuse remains intact. I'm sorry that this inconvenience has occurred to you, however you can learn a lot from these problems (the diagnosis of which is very complicated). So thank you for sharing it and letting us participate. To understand well I would have to have the naval model and the components at hand and see for myself, but I will try to make some hypotheses. 1. The strange case of the fuse. If the fuse had broken we could have established that its size was too small, so we could have gradually chosen a higher one (30, 35, 40 Ampere up to the maximum allowed by the electric motor). But this is not the case, unfortunately. Yet the fuse holder melted. Let us therefore start from this fact. At the moment I can only think of two causes for this effect (but if I think about it I could identify others). One of these causes is an overcurrent, high enough to melt the insulating plastic material (if I understand correctly this happened) but not too high to break the fuse. Unless the fuse is of such poor quality I don't think the insulating materials can melt before the metal foil. I would rule out this hypothesis. The other cause can be slow contact which does not break the metal foil but, due to the sparks, can melt or deform the plastic. In this case, however, you should also notice signs of small burns, a small blackened part. 2. Probable causes of the overcurrent. It's true, the first thought of an electrical overcurrent is a load that is too large which can be traced back to an oversized propeller. The first suspect is certainly the propeller but it is not one hundred percent certain that that is the cause. If I remember correctly (from studies done when I was young), three-phase synchronous electric motors, if subjected to an excessive load on the axis, began to slip and lose synchronism. I am not an expert in brushless DC motors but I believe that, for this problem, there are many similarities. I will try to do some research on this. Indeed, reducing the diameter of the propeller could solve the problem (it could). 3. Other Hypotheses. The engine may be factory defective. 4. Tests to be carried out. 4a. Check the fuse holders and fuses, see if there are any blackening symptoms of burns. Maybe take some photos and show us. 4b. Reset fuses and melted parts (replace identical fuses). Tighten the fuse faston connectors well (they must not be loose). 4c. Do a test run with the RC model out of the water (with the hold open). I'm sorry but you have to be patient, so go beyond twenty minutes and set the stick to maximum if nothing happens. Observe at regular intervals what is happening in the hold. 4d. Repeat the test in the bathtub (with the hold open), not in the pond where you can't see what's happening. Analyze the noises and sources carefully. Tests 4c and 4d would be better done with the aid of adequate instrumentation, to measure electrical currents and temperatures. I don't insist on this point because I understand that it can be an expensive instrumentation. Above 10 Amperes, for measurements of electric current intensity, the common multimeter is no longer sufficient but a current clamp (much more expensive) is needed. Furthermore, a multimeter that can also measure temperatures exceeds twenty/thirty euros. In this regard, I would take into consideration Trident73's excellent advice regarding the purchase and use of a modeling Wattmeter (I'm seriously thinking of purchasing one too). I have no idea how much it might cost. If the problem occurs immediately, within fifteen minutes, repeat the test (after letting everything cool down) putting a 35 mm propeller. If the problem is solved like this you can leave this diameter or also test the 40 mm and 45 mm ones. ▲

⟩⟩

Razor1955

Peejay

Len1

hermank

flaxbybuck

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 106 Views · 4 Likes

Flag

Thanks for your responses guys. Here is a bit more information.

Set-up. Motor - Turnigy SK3 4240 740Kv (fan cooled) with 25A standard size spade fuse on each of the three leads. (between motor and ESC) Lipo - 5000mAh, 5S with 40A current breaker (between battery and ESC) ESC - Turnigy Marine ESC 90A (water cooled) Prop - 55mm on M4 prop shaft. Operation Approx 15 minutes in open water. Only operated at half forward speed (scared of what might happen if to go any faster). Maybe half the time was spent cruising around at slow speeds and half the time up to half throttle, but then for limited duration. What happened ? Sudden noise from boat which sounded a bit like a slipping coupling. The boat immediately slowed to near stop. Carefully opening the throttle just one notch the boat would creep forwards, but as soon as the throttle was opened more then the noise would start and the boat would slow down. Back on the dockside Carried out the following checks. 1. Prop clear of any weeds etc 2. Normal 'clearance' in the prop shaft (ie. prop shaft clear to run freely in the prop tube ) 3. Prop shaft cool. 4. All grub screws securing the coupling were tight. (Coupling not slipping) 5. Motor (fan cooled) was just warm. 6. ESC was cool. 7. Battery was cool. All cells registered 3.85V. 8. Main circuit breaker had not triggered. 9. All three fuse holders and fuses were partly melted, but the fuses had not blown. 10. Motor seemed to operate normally whilst out of the water. I think that was all ! 😉 ▲

⟩⟩

Razor1955

Peejay

Len1

hermank

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 Trident73 (

Sub-Lieutenant) Sub-Lieutenant)✧ 131 Views · 7 Likes

Flag

Best investment i ever made when i got into brushless for planes was to buy a watts up meter. Connect inline between battery and ESC and it shows you the power output of your system (Watts) and importantly, current draw (A) The fact that your fuse holders have melted tells you the system is under stress and way too much heat is being released. Without knowing the amps (current draw) I would suggest going with a smaller prop and a smaller battery. 5s (~18v) is a lot of power, were you running around at the top of the throttle range for that 15 minutes? Was the ESC very hot? Was the propshaft free running or was it locking up under load, as that would also generate heat in the system.

▲

⟩⟩

Razor1955

Peejay

Len1

flaxbybuck

hermank

AlessandroSPQR

ChrisF

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇬🇧 ChrisF (

Commodore) Commodore)✧ 127 Views · 6 Likes

Flag

Bit of a funny one that. As Alessandro says we could do with more information.

Slowing down like that can be indicative of the LiPo low-voltage protection cutting in - what's the Mah of the battery as if it's say less than 4000 you won't get much run time? But the damaged fuse holders suggests another problem and a worrying one. Are the connections to the fuse holders sound as loose connections could cause overheating and erratic power supply which could get worse as things heat up. 55mm prop is a bit big for a boat of that size, I'd probably use 45mm but brushless motors can turn big props. I prefer to go for a smaller prop that allows the motor to rev higher and more freely rather than risk overloading it. You're using 25 amp fuses but what ESC are you using? If Allessandro is right about the motor it looks as though max. amps is 50 so you want to be using a 60amp ESC or greater. You could then use higher rated fuses. Talking of which, one fuse is usually used so where are you fitting them? Whilst I can see you are using 5S because the kv of the motor is relatively low I must admit I get a bit twitchy with higher voltages! I usually use 3S though I do intend to use 4S in my Fairey Swordsman 33 which is a similar size to your cruiser. Give us some more info. and we can give it some more thought! Chris ▲

⟩⟩

Peejay

Len1

flaxbybuck

hermank

AlessandroSPQR

Trident73

|

|

💬 Re: Brushless motor sync problems

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 130 Views · 4 Likes

Flag

Hi Flxybybuck.

I wanted to wait for a few messages to better understand the problem but since no one has written yet, I'll try to help you. But first I would like to understand this part: "On inspection found all three fuse holders and 25A fuses had melted, but fusees not blown." Sorry, the translator leads me astray, provides a contradictory and meaningless translation that he doesn't make me understand. I didn't understand what happened to the fuses. Is the fuse broken? If you used the car ones with Faston connectors, you should see the metal blade, is it broken or intact? Another question: ESC and motor are not damaged. Did I get it right? However, now nothing is moving anymore. It's correct? Some pictures would help. Is this the motor? ▲

⟩⟩

Peejay

flaxbybuck

Trident73

Len1

|

United Kingdom

United Kingdom