Join Us On Social Media!

Racing Sparrow

15 Posts · 15 Followers · 104 Photos · 117 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 2 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Maiden voyage

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 114 Views · 8 Likes · 4 Comments

Flag

💬 Add Comment

▲

⟩⟩

Doogle

Madwelshman

AndyB

robbob

jbkiwi

stevedownunder

peterd

philcaretaker

|

💬 Re: Maiden voyage

6 months ago by 🇬🇧 Boiler Bri (

Able Seaman) Able Seaman)✧ 29 Views · 1 Like

Flag

Hi. Not too sure what’s going on here. I have been emailed this, yet it’s two years old. ??

Brian ▲

⟩⟩

EdW

|

|

Login To

Remove Ads 💬 Re: Maiden voyage

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 105 Views · 2 Likes

Flag

Hi Phil,

There was a problem on the website earlier this week which prevented the picture loading. Now fixed thanks to Stephen (Fireboat) Graham93 ▲

⟩⟩

philcaretaker

stevedownunder

|

|

💬 Re: Maiden voyage

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 95 Views · 1 Like

Flag

Looks great on the water Graham,

The first of many sailing sessions to come. 👍 Cheers, Stephen. ▲

⟩⟩

Graham93

|

|

💬 Re: Maiden voyage

2 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 108 Views · 0 Likes

Flag

Hi Graham - Link ok but photo not taken ????

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

Login To

Remove Ads

Remove Ads

📝 Sail making

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 129 Views · 11 Likes · 12 Comments

Flag

💬 Add Comment

The sails are made from 50 micron polyester drafting film, often referred to as 'Mylar'.

The jib is made in one piece, the main is assembled from four pieces stuck together with 12mm double sided tape.

Using a full sized drawing of each sail, the film was taped on top and the outline of the sail traced onto the film. Coloured vinyl tape was added to reinforce the positions of each attachment point. Once one side was complete, the sail was turned over and reinforcement tape added to the other side. Only once all the reinforcements were in place were the sails trimmed to their final size with a sharp knife, thus also trimming the reinforcement tape.

Metal eyelets were added to each attachment point using the tools which came with the eyelets.

Finally, the completed sails were tied to the rigging points - ready for its first outing.👍👍

The jib is made in one piece, the main is assembled from four pieces stuck together with 12mm double sided tape.

Using a full sized drawing of each sail, the film was taped on top and the outline of the sail traced onto the film. Coloured vinyl tape was added to reinforce the positions of each attachment point. Once one side was complete, the sail was turned over and reinforcement tape added to the other side. Only once all the reinforcements were in place were the sails trimmed to their final size with a sharp knife, thus also trimming the reinforcement tape.

Metal eyelets were added to each attachment point using the tools which came with the eyelets.

Finally, the completed sails were tied to the rigging points - ready for its first outing.👍👍

▲

⟩⟩

hermank

flaxbybuck

Griss

Rookysailor

Mike Stoney

AndyB

stevedownunder

philcaretaker

Colin H

robbob

dave976

|

Login To

Remove Ads 💬 Re: Sail making

6 months ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 29 Views · 0 Likes

Flag

Can you show us the method you used to tie the sails to the mast and booms please. I would be most interested to see this as there are a number of different ways of doing it, some more complicated than others. Thanks 😉

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Sail making

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 114 Views · 1 Like

Flag

Hi Andy,

Thanks, I'm pleased with it so far. I'm not into racing. I just enjoy sailing for fun and don't want to get into competitive sailing. Graham93 ▲

⟩⟩

AndyB

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 114 Views · 0 Likes

Flag

Hi Michael,

That picture was taken at the lakeside BEFORE its maiden voyage - as I stated in the post 'ready for it's first outing' 😀 Graham93 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Sail making

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 107 Views · 1 Like

Flag

Watched the video of your boat sailing

Looks great and sails really well Will/can you race it? Are there similar designs to compete against? ▲

⟩⟩

Graham93

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 121 Views · 1 Like

Flag

Come on Graham that last picture looks as if it may have been taken at the lake side, have you had a sneaky sail without pictures😜

▲

⟩⟩

stevedownunder

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 121 Views · 1 Like

Flag

I think you will find turpentine substitute will dissolve double sided glue

▲

⟩⟩

stevedownunder

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 roycv (

Rear Admiral) Rear Admiral)✧ 106 Views · 1 Like

Flag

Hi I think I might try a hair dryer thanks for the advice, I can't shorten or anything as it is a scale sail fitted to the mast. Will not be in UK til next week so let you know how it goes.

Cheers Roy ▲

⟩⟩

stevedownunder

|

|

💬 Re: Sail making

2 years ago by 🇺🇸 Black Shoe (

Sub-Lieutenant) Sub-Lieutenant)✧ 123 Views · 2 Likes

Flag

Sorry to jump in so late, but it may be worth a try to use a heat gun, (hair dryer, or maybe even an iron on low heat) to soften the tapes glue. Then gently peel the layers away and replace the offending area.

▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 128 Views · 1 Like

Flag

Hi Roy,

A difficult problem to overcome. You could try to find a solvent to soften the glue. Acetone would be my suggestion. Try ‘nail varnish remover’ which contains acetone. Test first that it doesn’t damage the Mylar, but I don’t think it will. An alternative, easier solution would be to cut the seam out of the sail and remake it. This would shorten the sail by the seam width, which would probably not be noticeable. Graham93 ▲

⟩⟩

stevedownunder

|

|

💬 Re: Sail making

2 years ago by 🇬🇧 roycv (

Rear Admiral) Rear Admiral)✧ 119 Views · 1 Like

Flag

Nicely done Graham. Have you any tips on un-gluing double sided tape? I have a sail that over the years has developed a slight ruckle in the glue joint. I also used mylar and double sided tape. I am loathe to unpeal it without knowing exactly what I am doing.

regards Roy ▲

⟩⟩

stevedownunder

|

|

💬 Re: Sail making

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 119 Views · 2 Likes

Flag

Hi Graham,

Looking forward to the maiden voyage. Cheers, Stephen. ▲

⟩⟩

Graham93

roycv

|

📝 Radio installation

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 137 Views · 7 Likes · 5 Comments

Flag

💬 Add Comment

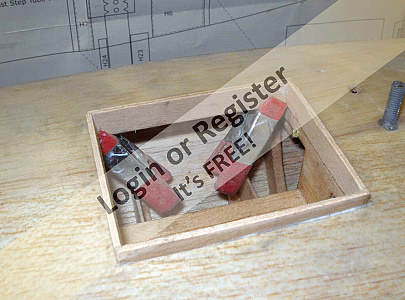

The radio installation is quite simple comprising the battery, receiver, a sail winch and the rudder servo. Unlike my other models there are no custom electronic mixers, lighting, sound effects, pumps etc so it should be reliable 😉

The rudder was built from three layers of 1.5mm balsa. The middle layer was made from offcuts. It had a hole to accommodate the rudder shaft with a piece of brass sheet soldered to it to prevent rotation of the rudder on the shaft. The completed rudder was sanded to shape, coated with epoxy and glass cloth and then painted.

I've included a photo from earlier in the build to show the arrangement of the rudder servo and the link to the brass horn which is held on the rudder shaft with a grubscrew. Fitting the horn onto the rudder shaft in the completed model was a bit of a challenge as it is located under the rear deck. I hope I don't have to remove it ever again 🤞

I've also included a photo from earlier in the build showing the sail winch arrangement as it is difficult to photograph in the completed model. This proved relatively easy to install through the small central hatch. Threading the sheets through the two fairleads and below deck to the winch was achieved using a long pair of tweezers to grab the cords below deck.

The battery sits on the other side of the keel box, and the receiver is velcroed to the bulkhead.

With everything in place, the next step was to attach the sheets to the winch drum and adjust them to the correct length. This is when it all went wrong! The winch servo would not respond to commands from the TX. I know I should have tested it before installing it, but modern electronics are so reliable I missed out this basic step. Eventually, I removed the winch from the model and bench tested it, but it still wouldn't work.

A phone call to the supplier on Tuesday afternoon to explain the problem resulted in an immediate promise to send a replacement which duly arrived on Wednesday morning. The replacement worked just fine. So, a big THANK YOU from me to Components Shop for their excellent customer service.

All it needs now is the sails......

The rudder was built from three layers of 1.5mm balsa. The middle layer was made from offcuts. It had a hole to accommodate the rudder shaft with a piece of brass sheet soldered to it to prevent rotation of the rudder on the shaft. The completed rudder was sanded to shape, coated with epoxy and glass cloth and then painted.

I've included a photo from earlier in the build to show the arrangement of the rudder servo and the link to the brass horn which is held on the rudder shaft with a grubscrew. Fitting the horn onto the rudder shaft in the completed model was a bit of a challenge as it is located under the rear deck. I hope I don't have to remove it ever again 🤞

I've also included a photo from earlier in the build showing the sail winch arrangement as it is difficult to photograph in the completed model. This proved relatively easy to install through the small central hatch. Threading the sheets through the two fairleads and below deck to the winch was achieved using a long pair of tweezers to grab the cords below deck.

The battery sits on the other side of the keel box, and the receiver is velcroed to the bulkhead.

With everything in place, the next step was to attach the sheets to the winch drum and adjust them to the correct length. This is when it all went wrong! The winch servo would not respond to commands from the TX. I know I should have tested it before installing it, but modern electronics are so reliable I missed out this basic step. Eventually, I removed the winch from the model and bench tested it, but it still wouldn't work.

A phone call to the supplier on Tuesday afternoon to explain the problem resulted in an immediate promise to send a replacement which duly arrived on Wednesday morning. The replacement worked just fine. So, a big THANK YOU from me to Components Shop for their excellent customer service.

All it needs now is the sails......

▲

⟩⟩

philcaretaker

Colin H

robbob

AndyB

stevedownunder

Ronald

mturpin013

|

💬 Re: Radio installation

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 135 Views · 1 Like

Flag

Hi Ron,

As a contributor to the upkeep of the site (i.e. I make a nominal contribution each year) I never see any advertisements on the site 👍 Graham93 ▲

⟩⟩

robbob

|

|

Login To

Remove Ads 💬 Re: Radio installation

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 135 Views · 2 Likes

Flag

Hi Michael,

The winch is a Kingmax 55g metal gear 4 turn model. Having just installed it and attached it to the rigging, the 2 turn version might just have enough range. The rigging stays are plastic coated 120lb 7strand sea fishing braided leader wire. The sheets are Dynema braided cord. Graham93 ▲

⟩⟩

AndyB

stevedownunder

|

|

💬 Re: Radio installation

2 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 129 Views · 2 Likes

Flag

Yes sailboats are so much less expensive than the powered vessels. No esc, no motor, stuffing box and shaft, no prop, no power supply for the motor just 4 AA batteries.

▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Radio installation

2 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 129 Views · 0 Likes

Flag

Are any of the rest of you getting advertisements in your posts? i was reading down through Grahams post and advertising appeared twice which really disrupts the posting.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Radio installation

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 139 Views · 2 Likes

Flag

Hi Graham, what type of rigging are you using and also what type is the sail winch.

I like the rudder assembly nice and sturdy ▲

⟩⟩

robbob

stevedownunder

|

📝 Rigging

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 145 Views · 9 Likes · 3 Comments

Flag

💬 Add Comment

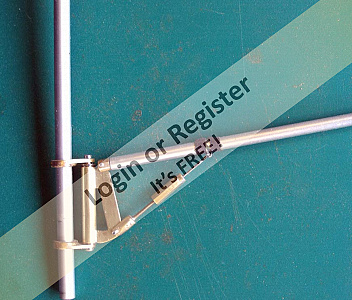

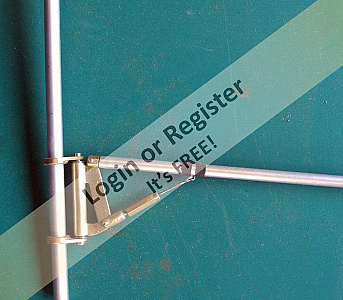

To fit the chainplate 'screws' to the deck, holes were drilled to match the core diameter of the screw. The chainplates were then simply screwed into position.

The mast is an 8mm diameter aluminium tube. These are readily available in the UK from the DIY warehouses in 1 metre lengths. Unfortunately the model mast is 1.045m long. Tubes longer than 1m are available from on-line retailers, but at a much higher cost. Accordingly the mast was made up from a 1m length plus a short offcut from the scrap box. The two pieces were joined using a 6mm tube, also from the scrap box, which was a good fit in the 8mm tubes.

A few small holes were drilled in the mast to attach the stays, which are plastic coated wire fishing trace.

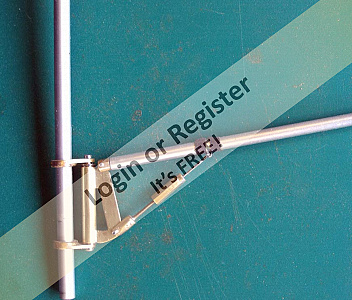

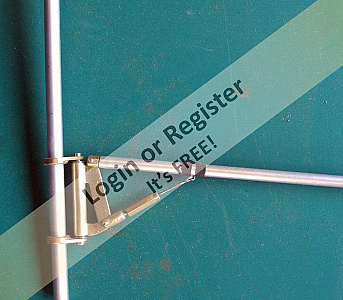

The mast fits over the 6mm threaded stud mounted in the deck and sits on a brass knurled nut which can be used to jack the mast up to tension the stays. (The screws on the gooseneck still need to be trimmed to length - there is always more to do!)

The main and jib booms are 6mm diameter aluminium tube. Split pins, fixed through holes in the booms provide fixing points for the sails and sheets. The jib boom is attached to the forward chainplate with a fishing swivel. I have a small concern that this swivel may not be strong enough.

(The black rubber boot over the on/off switch will be replaced with a white version when it arrives in the post!)

The mast is an 8mm diameter aluminium tube. These are readily available in the UK from the DIY warehouses in 1 metre lengths. Unfortunately the model mast is 1.045m long. Tubes longer than 1m are available from on-line retailers, but at a much higher cost. Accordingly the mast was made up from a 1m length plus a short offcut from the scrap box. The two pieces were joined using a 6mm tube, also from the scrap box, which was a good fit in the 8mm tubes.

A few small holes were drilled in the mast to attach the stays, which are plastic coated wire fishing trace.

The mast fits over the 6mm threaded stud mounted in the deck and sits on a brass knurled nut which can be used to jack the mast up to tension the stays. (The screws on the gooseneck still need to be trimmed to length - there is always more to do!)

The main and jib booms are 6mm diameter aluminium tube. Split pins, fixed through holes in the booms provide fixing points for the sails and sheets. The jib boom is attached to the forward chainplate with a fishing swivel. I have a small concern that this swivel may not be strong enough.

(The black rubber boot over the on/off switch will be replaced with a white version when it arrives in the post!)

▲

⟩⟩

Mike Stoney

robbob

mturpin013

ChrisG

dave976

philcaretaker

AndyB

Colin H

stevedownunder

|

💬 Re: Rigging

2 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 134 Views · 0 Likes

Flag

" I am so excited for you Graham - cant wait to see the finished product ! "⛵😎

Phil ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Rigging

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 144 Views · 0 Likes

Flag

That's looking the part now, the water awaits. What rigging wire are you using?

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Rigging

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 132 Views · 0 Likes

Flag

Hi Graham,

Looks like she is nearly ready for the water. Lovely work on the fittings. Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

📝 Fittings

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 142 Views · 10 Likes · 7 Comments

Flag

💬 Add Comment

While waiting for the paint to dry, I found time to make some of the fittings needed for the rigging.

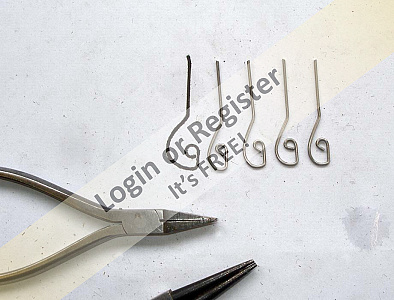

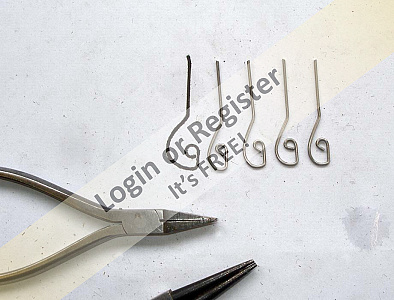

First up, the chainplates to attach the rigging to the hull. The plans suggest simply glueing split pins into holes in the deck but I have reservations about how secure that would be. I made mine from brass rod, turned on the mini lathe. The photo shows the stages from left to right. The last stage was to solder some 0.5mm copper wire round the shaft to form a screw thread. To test how secure these will be when fixed into the balsa deck, a test rig was assembled. One of the chainplates was screwed into a scrap block of balsa and then clamped in the vice. A spring scale was then used to measure the force applied while trying to pull the chainplate out of the balsa block. I wasn't able to pull it out with a force of 25kgs, so I think it will be secure enough.

Next I bent up some pelican clips from 1mm dia stainless steel welding rod. These are to attach the stays to the chainplates.

Finally I made the gooseneck to attach the mainsail boom to the mast. This was cut from several bits of brass sheet and tube and then silver soldered together. An adjustable vang was also put together from bits of brass and threaded rod.

First up, the chainplates to attach the rigging to the hull. The plans suggest simply glueing split pins into holes in the deck but I have reservations about how secure that would be. I made mine from brass rod, turned on the mini lathe. The photo shows the stages from left to right. The last stage was to solder some 0.5mm copper wire round the shaft to form a screw thread. To test how secure these will be when fixed into the balsa deck, a test rig was assembled. One of the chainplates was screwed into a scrap block of balsa and then clamped in the vice. A spring scale was then used to measure the force applied while trying to pull the chainplate out of the balsa block. I wasn't able to pull it out with a force of 25kgs, so I think it will be secure enough.

Next I bent up some pelican clips from 1mm dia stainless steel welding rod. These are to attach the stays to the chainplates.

Finally I made the gooseneck to attach the mainsail boom to the mast. This was cut from several bits of brass sheet and tube and then silver soldered together. An adjustable vang was also put together from bits of brass and threaded rod.

▲

⟩⟩

Mike Stoney

pressonreguardless

dave976

stevedownunder

robbob

AndyB

philcaretaker

Colin H

jbkiwi

GaryLC

|

💬 Re: Fittings

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 136 Views · 1 Like

Flag

Soldered Screw Threads, Capital Idea 👍👍👍

Trev ▲

⟩⟩

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Fittings

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 144 Views · 1 Like

Flag

Hi Michael,

I wanted a coarse screw thread that would 'bite' into the balsa. I could have tried screwcutting on the lathe, but soldering a thread on was an easier and quicker option. Just need to try and keep the threads evenly spaced, although it doesn't seem to be too critical with balsa. Graham93 ▲

⟩⟩

stevedownunder

|

|

💬 Re: Fittings

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 144 Views · 1 Like

Flag

Hi Phil,

I don't think it will be frozen, but perhaps you could arrange for (another) fire in the middle of the lake just in case! 😮 ▲

⟩⟩

stevedownunder

|

|

💬 Re: Fittings

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 138 Views · 2 Likes

Flag

I agree with the others, that these are very designed and made. The deck eyes/chain plates are especially well thought out and I'm sure a 25kg load is plenty for a test and far exceeds what will happen in real life.

▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Fittings

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 136 Views · 1 Like

Flag

Lovely work Graham,

Can't really add to what Mike and Phil have said. Cheers, Stephen. ▲

⟩⟩

Graham93

|

|

💬 Re: Fittings

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 148 Views · 3 Likes

Flag

Hi Graham, never stuck for a solution, I really like the screw thread, very inventive and one I had never thought of, it will get used in the future. The rest of the design and manufacture is of course up to the usual standard, very nice

▲

⟩⟩

AndyB

stevedownunder

robbob

|

|

💬 Re: Fittings

2 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 139 Views · 2 Likes

Flag

How will she cut though ice Graham ? - ie. forecast not good for Thursday !.

Love the home brew screws by the way !!. ⛵ Phil😎 ▲

⟩⟩

stevedownunder

Graham93

|

📝 More painting

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 148 Views · 7 Likes · 4 Comments

Flag

💬 Add Comment

The hull has been painted with several coats of 'Appliance white' from a rattle can, rubbing down carefully between coats with 1200 grit wet and dry, used wet.

There is a 'Racing Sparrow' logo available to download from the website:

There is a 'Racing Sparrow' logo available to download from the website:

▲

⟩⟩

robbob

Colin H

jbkiwi

AndyB

Peejay

stevedownunder

philcaretaker

|

💬 Re: More painting

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 149 Views · 3 Likes

Flag

Thanks Phil, Stephen,

I’m looking forward to finishing it and getting it on the water. Andy, Once your design is printed onto the decal paper the paper is soaked in water for 30 seconds to release the backing just like traditional decals. The ink used in inkjet printers is not waterproof, so, before the decal is soaked, the artwork is lacquered to protect the ink from the soaking. First time I’ve made decals, but it worked a treat 👍 Graham93 ▲

⟩⟩

robbob

stevedownunder

AndyB

|

|

Login To

Remove Ads 💬 Re: More painting

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 145 Views · 1 Like

Flag

Very impressive

Interesting to learn about the decal paper and that you used some lacquer before applying the decals. ▲

⟩⟩

Graham93

|

|

💬 Re: More painting

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 142 Views · 0 Likes

Flag

Looks great Graham, 👍

Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: More painting

2 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 144 Views · 2 Likes

Flag

Can`t wait to get it on video Graham ! - as usual it looks - AMAZING !👍😎⛵⛵⛵⛵⛵⛵

▲

⟩⟩

Graham93

stevedownunder

|

📝 Painting, Stand and Hatches

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 151 Views · 5 Likes · 3 Comments

Flag

💬 Add Comment

With the keel in place, time to start painting.

The underside of the hull and the keel have been given several coats of grey etch primer from a rattle can. Each coat was sanded and any irregularities filled with knifing putty. After three coats, its looking nice and smooth.

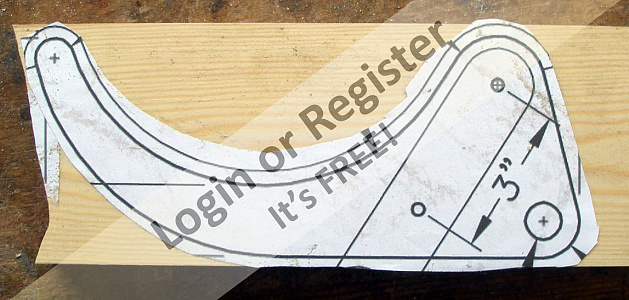

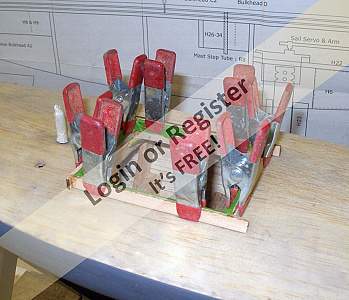

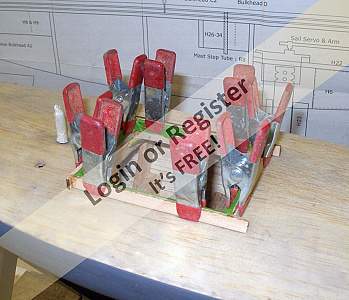

With the keel fitted, the hull no linger fits in the temporary stand so attention turned to making a proper stand. An internet search came up with drawings for a stand for the IOM yacht

The underside of the hull and the keel have been given several coats of grey etch primer from a rattle can. Each coat was sanded and any irregularities filled with knifing putty. After three coats, its looking nice and smooth.

With the keel fitted, the hull no linger fits in the temporary stand so attention turned to making a proper stand. An internet search came up with drawings for a stand for the IOM yacht

▲

⟩⟩

jbkiwi

Colin H

mturpin013

philcaretaker

AndyB

|

💬 Re: Painting, Stand and Hatches

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 147 Views · 1 Like

Flag

Stand set-up is great Graham, good idea to stop the boat swinging with that side pad and velcro. Hull's looking very sleek now.

JB ▲

⟩⟩

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Painting, Stand and Hatches

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 152 Views · 1 Like

Flag

The stand is a great design Ill be using that on my next build. I like your masking tape idea, I use as slice of cornflake box as spacers.

I'm looking forward to the colour scheme it will be immaculate with all that preparation, great work. ▲

⟩⟩

stevedownunder

|

|

💬 Re: Painting, Stand and Hatches

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 148 Views · 1 Like

Flag

Looking very impressive. The hull shape seems quite “classic” with the angled transom. There must be a correct term for this but I don’t know it.

The stand is an interesting and useful design, thanks. Just need a suitable boat! ▲

⟩⟩

stevedownunder

|

📝 Keel

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 156 Views · 7 Likes · 2 Comments

Flag

💬 Add Comment

The keel comprises an aluminium strip clad with balsa and a lead bulb weighing 1.3kgs.

The 3/4" x 1/8" aluminium strip was prepared by cutting to length and then adding holes/notches at each end to help with gluing in place. The balsa cladding was made up as a tube from 4 pieces of balsa glued together. Once the glue was dry, the cladding was sanded to an aerodynamic shape.

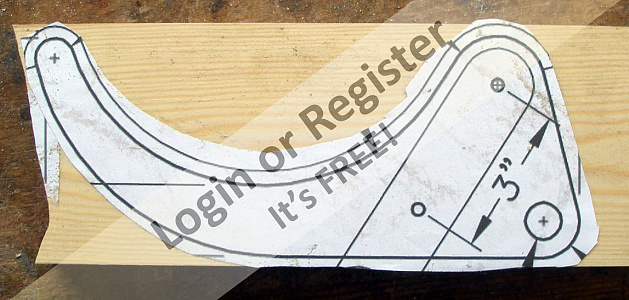

The plans suggest making a plaster mould from a wooden master to cast the lead bulb. The master was constructed from three pieces of wood glued together and shaped to the required profile. The central piece had a slot cut in it for the aluminium keel. I was not convinced about being able to produce a plaster mould which would include a negative of this slot. I didn't have any plaster of paris available, but I do have a large bag of builder's finishing plaster left over from some house renovation so decided to use that instead. The wooden master plug was suspended in a cardboard box and plaster was poured in to halfway up the plug. After a week, the plaster had still not set! It had simply dried to a mud like consistency.🤔 On to plan B I decided to use the technique previously used on the Gaff Rigged Cutter.

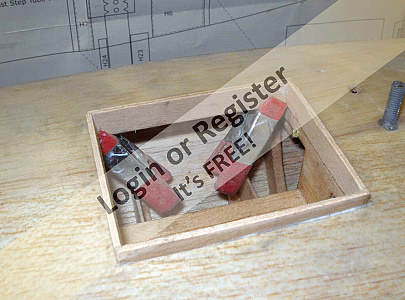

A series of graduated holes were cut into pieces of plywood which were then glued/screwed together to form a mould. The aluminium keel was clamped in place and 1.6kgs of molten lead poured in. After a couple of hours, the rough casting was released from the mould and carved to shape using a craft knife and surform tool.

Finally a jig was constructed to hold the keel over the inverted hull with the end inserted into the keel box. It was then glued in place with a mix of epoxy resin and chopped fibreglass and left for several days to set hard.

The 3/4" x 1/8" aluminium strip was prepared by cutting to length and then adding holes/notches at each end to help with gluing in place. The balsa cladding was made up as a tube from 4 pieces of balsa glued together. Once the glue was dry, the cladding was sanded to an aerodynamic shape.

The plans suggest making a plaster mould from a wooden master to cast the lead bulb. The master was constructed from three pieces of wood glued together and shaped to the required profile. The central piece had a slot cut in it for the aluminium keel. I was not convinced about being able to produce a plaster mould which would include a negative of this slot. I didn't have any plaster of paris available, but I do have a large bag of builder's finishing plaster left over from some house renovation so decided to use that instead. The wooden master plug was suspended in a cardboard box and plaster was poured in to halfway up the plug. After a week, the plaster had still not set! It had simply dried to a mud like consistency.🤔 On to plan B I decided to use the technique previously used on the Gaff Rigged Cutter.

A series of graduated holes were cut into pieces of plywood which were then glued/screwed together to form a mould. The aluminium keel was clamped in place and 1.6kgs of molten lead poured in. After a couple of hours, the rough casting was released from the mould and carved to shape using a craft knife and surform tool.

Finally a jig was constructed to hold the keel over the inverted hull with the end inserted into the keel box. It was then glued in place with a mix of epoxy resin and chopped fibreglass and left for several days to set hard.

▲

⟩⟩

jbkiwi

pressonreguardless

Colin H

stevedownunder

Mike Stoney

philcaretaker

AndyB

|

💬 Re: Keel

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 148 Views · 0 Likes

Flag

Like the frame to ensure the keel is square to the hull. Good idea.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Keel

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 150 Views · 0 Likes

Flag

Hi Graham,

Good that you had a plan B, nice resalt. Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

📝 Adding the deck

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 162 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

Before fitting the deck, the inside of the hull was given a coat of epoxy resin. This was warmed in a waterbath before application to make it easier to apply in the restricted spaces within the hull.

The deck is made up from two sheets of 1.6mm balsa. These were simply cut to size and glued in place with plenty of pins. The balsa was thin and flexible enough to follow the shape of the deck supports without the need for any contouring.

Once the glue had set, the deck was given a layer of fibreglass and two coats of epoxy resin.

The deck is made up from two sheets of 1.6mm balsa. These were simply cut to size and glued in place with plenty of pins. The balsa was thin and flexible enough to follow the shape of the deck supports without the need for any contouring.

Once the glue had set, the deck was given a layer of fibreglass and two coats of epoxy resin.

▲

⟩⟩

Colin H

Mike Stoney

stevedownunder

AndyB

jbkiwi

philcaretaker

|

💬 Re: Adding the deck

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 162 Views · 3 Likes

Flag

The exciting part, putting the roof on 😊 Looks good Graham.

JB ▲

⟩⟩

Mike Stoney

stevedownunder

Graham93

|

📝 Fitting out

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 170 Views · 7 Likes · 14 Comments

Flag

💬 Add Comment

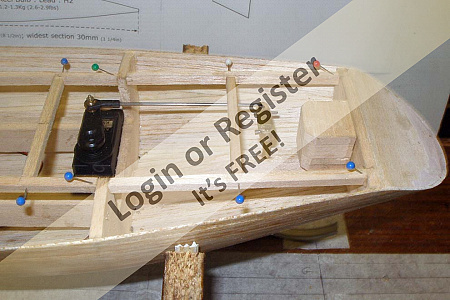

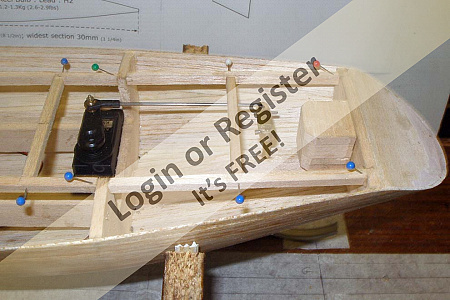

The stern has an angled transom which was cut/sanded to shape and then glued in place.

When fitting out the test of the hull, great care was taken to ensure that all the parts to be added were the correct length so that no stress was put on the hull which might cause it to twist out of shape.

A length of M6 threaded rod has been used for the maststep. This is glued and screwed into the supporting balsa block. A thin sheet of aluminium was threaded M6 and added to the maststep (photo 3) to spread the load. Just forward of the maststep a fairlead is fitted to carry the sheet which will control the jib sail. The fairlead is made from copper tube with both ends faired out.

The receiver was tried in position and two lengths of sleeving fitted for the aerial leads to thread into.

The rudder servo is fitted as shown in the plan. This connects to a brass horn on the rudder post using a length of bicycle spoke.

The plan suggests using a long arm servo for sail control but I have had bad experience with long arms and prefer to use a sail winch. A suitable winch was sourced and mounted into position. A mounting box for the battery was also put together so that it isn't left to rattle about in the bottom of the hull.

The plan also suggests that both the main sheet and the jib sheet should run through a single fairlead in the deck, the jib sheet then being routed forward across the deck before attaching to the jib boom. This routing has to be either round, or over the hatch neither of which options seem like a good idea. I opted to run the jib sheet below the deck, bringing it up through a second fairlead to just below the jib boom. To help with this below deck routing, a ceramic ring was fitted to one of the bulkheads. These rings are readily available from fishing tackle suppliers as replacement parts for fishing rods. With everything in place, a check was made that the sheets can be routed without any snags.

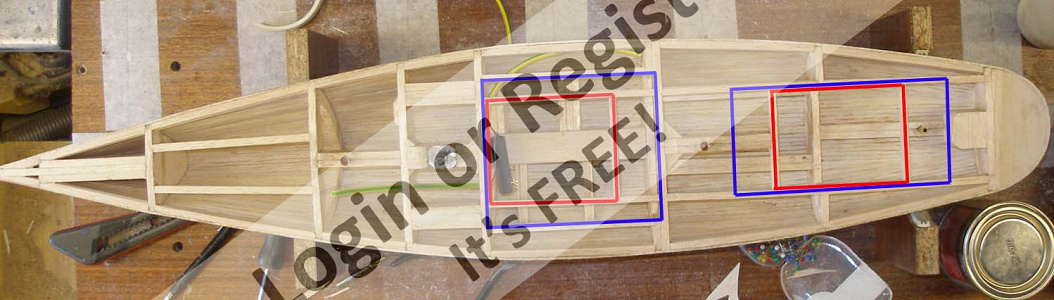

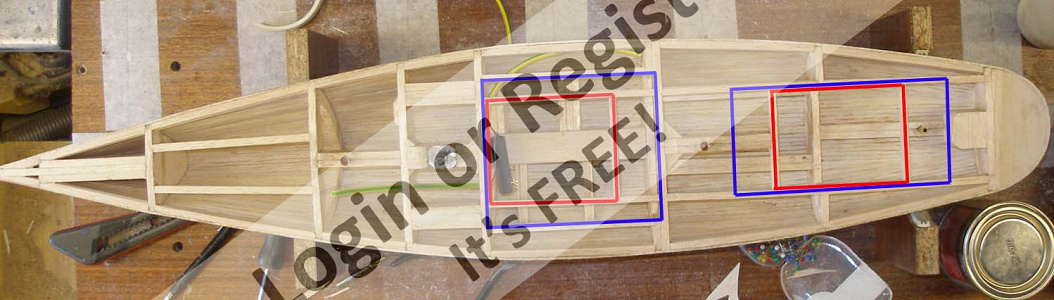

Finally, the support members for the two hatches were fitted. I've opted to make the hatches as small as possible, consistent with being able to fit and remove all the radio gear. This to help keep the inside of the hull dry. The picture shows the hatch size on the plans in blue and the size I have opted for in red. Hope I haven't made them too small 🤞

When fitting out the test of the hull, great care was taken to ensure that all the parts to be added were the correct length so that no stress was put on the hull which might cause it to twist out of shape.

A length of M6 threaded rod has been used for the maststep. This is glued and screwed into the supporting balsa block. A thin sheet of aluminium was threaded M6 and added to the maststep (photo 3) to spread the load. Just forward of the maststep a fairlead is fitted to carry the sheet which will control the jib sail. The fairlead is made from copper tube with both ends faired out.

The receiver was tried in position and two lengths of sleeving fitted for the aerial leads to thread into.

The rudder servo is fitted as shown in the plan. This connects to a brass horn on the rudder post using a length of bicycle spoke.

The plan suggests using a long arm servo for sail control but I have had bad experience with long arms and prefer to use a sail winch. A suitable winch was sourced and mounted into position. A mounting box for the battery was also put together so that it isn't left to rattle about in the bottom of the hull.

The plan also suggests that both the main sheet and the jib sheet should run through a single fairlead in the deck, the jib sheet then being routed forward across the deck before attaching to the jib boom. This routing has to be either round, or over the hatch neither of which options seem like a good idea. I opted to run the jib sheet below the deck, bringing it up through a second fairlead to just below the jib boom. To help with this below deck routing, a ceramic ring was fitted to one of the bulkheads. These rings are readily available from fishing tackle suppliers as replacement parts for fishing rods. With everything in place, a check was made that the sheets can be routed without any snags.

Finally, the support members for the two hatches were fitted. I've opted to make the hatches as small as possible, consistent with being able to fit and remove all the radio gear. This to help keep the inside of the hull dry. The picture shows the hatch size on the plans in blue and the size I have opted for in red. Hope I haven't made them too small 🤞

▲

⟩⟩

RNinMunich

Mike Stoney

jbkiwi

philcaretaker

stevedownunder

AndyB

Colin H

|

💬 Re: Fitting out

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 162 Views · 0 Likes

Flag

Hi Andy,

I'm not planning to have an elastic cord on deck to keep the sheet tight on the drum. I haven't found it necessary on the WeeNip which I sail frequently and which hasn't given any trouble with the winch. The winch does have an enclosed drum which helps prevent tangles. Graham93

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Fitting out

2 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 166 Views · 4 Likes

Flag

Ref Mike's last post -

"Damit kein der Segelschnüre sich nicht verhederten, habe ich eine Führung mit einem Rohr an der kritischen Stelle gesichert." For members not so familiar with German as Mike and I here a translation😉 'To stop the sail lines getting tangled up I secured the lead-throughs at critical positions with a tube.' 😎 (A free service of the MB Website Central Europe Intelligence Centre, CEIC! 😁🤣) PS Attached a recent contribution / comment to CEIC ref current European events🤔

▲

⟩⟩

robbob

Mike Stoney

Rookysailor

Colin H

|

|

💬 Re: Fitting out

2 years ago by 🇨🇭 Mike Stoney (

Commander) Commander)✧ 166 Views · 0 Likes

Flag

Hi AndyB,

Missed your comment. I adopted your version from back then because I kept getting tangled sail lines! Luckily I installed a water pump so I can use hydro power to retrieve my ship!! Regards Michel-Claude ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Fitting out

2 years ago by 🇨🇭 Mike Stoney (

Commander) Commander)✧ 166 Views · 2 Likes

Flag

Hi Graham . .

Regarding the sail servo, I have my own experience collected. First I attached a yo-yo to the opposite side. but this did not satisfy me at all, since the sail servo was always under "tension". (photo 1) Then I removed the whole thing again and designed the structure in such a way that the sail winch was never under tension. (photo 2) Damit kein der Segelschnüre sich nicht verhederten, habe ich eine Führung mit einem Rohr an der kritischen Stelle gesichert.(Last photo is with all units) It's not perfect, but useful. Had no more problems. Greets Michel-Claude

▲

⟩⟩

Graham93

Colin H

|

|

💬 Re: Fitting out

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 164 Views · 1 Like

Flag

Thanks Graham

I assume you will have some form of elastic/shock cord on the deck that pulls the sheets "against" the winch, so they stay tight on the drum. I've only ever used a continuous loop system on a winch. ▲

⟩⟩

Mike Stoney

|

|

💬 Re: Fitting out

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 167 Views · 3 Likes

Flag

Hi Graham, tilting it fore and aft can have a similar result for fine tuning . 100% OK racing dinghies (for eg) actually have a a set of wedges with a sliding mast bearing in an oblong deck slot so the mast can be moved to correct the balance, depending on the sailors preferred sailing position and weight. An inch at the top of the mast moves quite a bit of sail. The OKs also have an adjustable sliding mast step (Lasers, Optimists and other keel stepped un-stayed dinghies have them as well). I made a similar adjustable foot for my 12ft Cherokee, (had to make a complete rotating mast system) just in case, and was lucky enough to set it in the right hole first time, and it balances perfectly, (mast is un-stayed and turns with the boom)

▲

⟩⟩

Colin H

Mike Stoney

stevedownunder

|

|

💬 Re: Fitting out

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 167 Views · 1 Like

Flag

Hi JB,

Yes, too late now to have an adjustable mast step. I'm just following the plans (sort of!). As a novice sailor I don't fully understand the subtleties of the mast adjustments for helm. While the mast foot is in a fixed position, I will be able to tilt the mast fore and aft a little using the stays. Would that help achieve the same result? ▲

⟩⟩

stevedownunder

|

|

💬 Re: Fitting out

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 166 Views · 1 Like

Flag

Hi Steve,

I wanted to move the sides of the hatch away from the gunwhales as much as possible to keep the hatches above water when she heels and to help keep the insides dry. I'm good at 'keyhole' surgery 🤣😆 ▲

⟩⟩

stevedownunder

|

|

💬 Re: Fitting out

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 167 Views · 3 Likes

Flag

Hi Michael, Andy,

With regard to sail winch selection, no complex calculations I'm afraid. I based the selection on my 'extensive' experience of building two sailboats 🤣😆 For my Gaff Rigged Cutter I used two HiTec HS-785HB sail winches. These are large, heavy and relatively expensive but they work really well. The Cutter is heavy with 1180 sq. in of sail. The servos are as recommended by the designer. For the WeeNip, I originally used a long arm servo but found it stalled and ran the battery flat quickly. I replaced it with a KingMax 45g sail winch which works fine. This winch is rated 6kg/cm with a 6v supply. I haven't been able to find a reference for the Wee Nip sail area but I guess around 200 sq. in. The Racing Sparrow is bigger than the WeeNip, and smaller than the Cutter with a sail area of 387sq. in. The Kingmax 45g servo might be adequate but I opted for a slightly larger Kingmax SW5513 55g winch. This is rated at 9.24kg/cm with a 4.8v supply. I expect (hope!) it will be suitable.🤞 It doesn't matter if the servo has too much torque The number of turns needed on a sail winch is easily calculated by measuring on the plan the length of sheet needed for the full range of sail control. Knowing the diameter of the winch drum (25mm in the case of the KingMax) the number of turns can be calculated. End point adjustment on the Transmitter allows reduction of the number of turns actually used. ▲

⟩⟩

Colin H

stevedownunder

dave976

|

|

💬 Re: Fitting out

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 171 Views · 2 Likes

Flag

Hi Graham, you're really making quick work of this ! Is that another Hitec sail winch you've used? Liked the idea of over building the hull and trimming it back to the transom. I would have suggested an adjustable mast step, to allow for fore and aft adjustment, (for correcting any possible slight lee or weather helm ) but it's a bit late now😀

JB ▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Fitting out

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 168 Views · 1 Like

Flag

If I can butt in here,

I have a Wee Nip that was given to me. I went and bought a low cost servo probably $5, that according to it's specs should have been fine though in reality it only lasted 2 sailing sessions before letting out the smoke, I then went and bought a Hitec heavy duty sail arm which cost $50 the good thing is it works as advertised. Cheers, Stephen. ▲

⟩⟩

Graham93

|

|

Login To

Remove Ads 💬 Re: Fitting out

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 168 Views · 0 Likes

Flag

Very nice work Graham,

I have always thought the bigger the hatch the better, gaining access to change the line pops to mind, just my thoughts. Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Fitting out

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 171 Views · 1 Like

Flag

Come on Graham give us the detail😀

I'm planning on using a servo winch but all the information I have talks about Kgs, but how this relates to sail size has yet to be researched. Did you do such calculations. I'm confused about the price, I have seen them for as much as £40 and as little £6 With not enough specification detail to see why the price variation and which is best ▲

⟩⟩

stevedownunder

|

|

💬 Re: Fitting out

2 years ago by 🇬🇧 AndyB (

Warrant Officer) Warrant Officer)✧ 170 Views · 1 Like

Flag

Impressed

Interested in what type of winch and drum you are using, as I’ve only experienced a loop system. Thanks ▲

⟩⟩

stevedownunder

|

United Kingdom

United Kingdom