Join Us On Social Media!

Caldercraft Northlight Clyde Puffer.

25 Posts · 29 Followers · 117 Photos · 381 Likes

Began 7 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 2 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Finally done

2 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 50 Views · 15 Likes · 2 Comments

Flag

💬 Add Comment

Hi yall. I finally got a chance to re-maiden the Puffer after the whole leak drama. She was in the water for several hours, ran a 5000 mah LiPo down to 40 percent. I'd say she was on the lake for 3 hours plus, full throttle, cruising speed, reverse, all over the place. The result? about a teaspoon of water from the stuffing box. All the reversing i was doing pushed a little water up the tube, you could see the big wad of grease that had been pushed out, and the grease was discolored by the water. Im happy, shes reliable, and shes now in the fleet under the "keeper" heading.

Cash

Cash

▲

⟩⟩

Fred

peter3l

flaxbybuck

Peejay

Trident73

Razor1955

stevedownunder

AlessandroSPQR

RodC

Len1

Wolle

jumpugly

Commodore-H

MouldBuilder

hermank

|

💬 Re: Finally done

2 months ago by 🇮🇹 AlessandroSPQR (

Rear Admiral) Rear Admiral)✧ 33 Views · 4 Likes

Flag

Hi Cash, I really like the system you used to control the rudder. Was this the case for the real ship too?

Do you consider this infiltration of water into the hull acceptable (considering the long navigation time) or do you want to remedy it and eliminate it completely? ▲

⟩⟩

Len1

Peejay

Wolle

Cashrc

|

|

💬 Re: Finally done

2 months ago by 🇺🇸 Len1 (

Lieutenant) Lieutenant)✧ 47 Views · 4 Likes

Flag

great news cash. Enjoy it the Puffer. Len

▲

⟩⟩

Peejay

Wolle

Cashrc

AlessandroSPQR

|

Login To

Remove Ads

Remove Ads

📝 Leak test passed, new railings with brass stanchions started

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 64 Views · 14 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. Made one more leak check this morning, with ballast. Set in the tub 20 minutes or so, nothing. Not a drop!! The tube was greased and nothing there either. I still have to do a minor refit on the shaft ends to slow any water coming in when reversing, but I feel she’s good. The rails aft, however, are another matter. Between multiple trips upstairs and all the handling trying to find the leak, I’ve bent the railings multiple times, and it didn’t take long for a couple of the stanchions to give way, so I pulled the railings off, redrilled the holes to clear the old railing bits that were left, and I’m making a new unit with brass stanchions. Don’t know if I’m going to paint them white again, or go for another color, but by all rights and measures this boat should be finished, including ships boat and a few other details, by the end of the week.

Cash

Cash

▲

⟩⟩

Fred

peter3l

Trident73

Razor1955

jumpugly

stevedownunder

Doogle

ToraDog

RNinMunich

Len1

hermank

SimpleSailor

Peejay

Wolle

|

💬 Re: Leak test passed, new railings with brass stanchions started

4 months ago by 🇺🇸 Chum444 (

Sub-Lieutenant) Sub-Lieutenant)✧ 62 Views · 8 Likes

Flag

Glad the leak(s) are resolved. If the railings develop some bends in the future I wouldn’t worry about it; would not be unusual on a 1:1. Adds to the realism.

▲

⟩⟩

peter3l

Peejay

Razor1955

Cashrc

stevedownunder

ToraDog

Len1

hermank

|

📝 I found the 🤬 leak!!!😁

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 89 Views · 21 Likes · 6 Comments

Flag

💬 Add Comment

Hi y’all. I took the Puffer back to the tub this morning, bound and determined to find the source of the leak. Within minutes I had a good teaspoon of water in the hull…but it didn’t come from the tube. I checked aft, dry as a bone, so I thought the bow had a leak and it was seeping past the bulkhead. After drying her off I took her to the bench, and added water thru a drilled hole in the bulkhead and sat her bow down. Nothing. As I was fiddling with her some of the water seeped back to mid hull, and I noticed one finger felt damp. There was a chip in the gel coat that was allowing water to seep into the hull!! I carefully set her up with the water in that spot, within a few seconds I had a drip, and if I pressed on the spot from inside the hull it got worse. I noticed a black spot inside too, I thought I had dropped a drop of paint in the hull, but I had painted the whole hull matte black before I painted her red below the water line, the paint had seeped thru.

I took some light fiberglass and epoxy/microballoons and patched over the spot from within, filled the outside with ca and painted over it to seal. I’m still going to set up my shaft ends as discussed, but I feel better now.

Also, I bent the railings again as I handled her, and some more of the white metal stanchions gave way. I pulled the assembly off best I could, and I will redrill and install brass stanchions that I have coming from Harbor Models. Then a few details and she’s done.

Cash

I took some light fiberglass and epoxy/microballoons and patched over the spot from within, filled the outside with ca and painted over it to seal. I’m still going to set up my shaft ends as discussed, but I feel better now.

Also, I bent the railings again as I handled her, and some more of the white metal stanchions gave way. I pulled the assembly off best I could, and I will redrill and install brass stanchions that I have coming from Harbor Models. Then a few details and she’s done.

Cash

▲

⟩⟩

Fred

peter3l

Razor1955

MouldBuilder

ToraDog

BarryS

Len1

Doogle

boatmam

EdW

RodC

RNinMunich

stevedownunder

Mike Stoney

jumpugly

hermank

Colin H

BOATSHED

Wolle

Peejay

Ronald

|

💬 Re: I found the 🤬 leak!!!😁

2 months ago by 🇬🇧 peter3l (

Able Seaman) Able Seaman)✧ 13 Views · 1 Like

Flag

If at first you dont sukseed try and try again an old saying but very true well done another puffer back on the water 👍👍👍👍 peter l 3

▲

⟩⟩

Len1

|

|

Login To

Remove Ads 💬 Re: I found the 🤬 leak!!!😁

4 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 77 Views · 4 Likes

Flag

Well done on finding the leak👍, can be a bugger to trace sometimes

▲

⟩⟩

Peejay

Cashrc

Len1

AlessandroSPQR

|

|

💬 Re: I found the 🤬 leak!!!😁

4 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 87 Views · 4 Likes

Flag

EULEAKA!!😀

Well done Cash👍 But I'm still wondering why you found that the underside of the shaft tube was wet!?🤔 Cheers, Doug😎 ▲

⟩⟩

Peejay

Len1

hermank

Cashrc

|

|

💬 Re: I found the 🤬 leak!!!😁

4 months ago by 🇺🇸 Chum444 (

Sub-Lieutenant) Sub-Lieutenant)✧ 85 Views · 4 Likes

Flag

Well on you!

▲

⟩⟩

Peejay

Len1

Cashrc

jumpugly

|

|

💬 Re: I found the 🤬 leak!!!😁

4 months ago by 🇬🇧 BOATSHED (

Lieutenant Commander) Lieutenant Commander)✧ 90 Views · 5 Likes

Flag

Lucky you found the leak👍, Remember the TITANIC👎👎.

▲

⟩⟩

Peejay

Cashrc

jumpugly

Len1

hermank

|

|

💬 Re: I found the 🤬 leak!!!😁

4 months ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 102 Views · 8 Likes

Flag

Glad you spotted the problem and were able to come through with a solution. It kinda reminds me of the little boy and his finger in the dyke.👉🏻

▲

⟩⟩

peter3l

RNinMunich

Cashrc

jumpugly

Len1

hermank

Wolle

Peejay

|

📝 Video

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 94 Views · 10 Likes

Flag

💬 Add Comment

Ronald, she was wet, but only about 1/4 to 1/3 cup after almost 2 hours in the pond. Even after everything I try, if that’s as good as I can get, I can live with it. However, like we say in Texas, “I ain’t done yet!!”😁

▲

⟩⟩

Fred

RodC

stevedownunder

Wolle

Peejay

Len1

jumpugly

hermank

Colin H

RNinMunich

📝 Leaking the leak

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 93 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

Doug, I have a mini grease gun tha is put out by Proboat. It has a pointed nozzle that will fit into the greasing tube of my stuffing tube. If I hold down tight while operating the plunger, it will pressurize the grease enough that I get grease coming out of the fore and aft bushings while the shaft is still installed. As y’all would say, it’s a nice bit of kit.

I was thinking about doing something similar to what you told me, but using a washer and oring at the prop end with the prop nut just, I mean just ever so slightly compressing the oring, washer backing that up to tube end, lubing the hades out of it. Am I overthinking this?

I’m doing another tub test this weekend. Will stay with the boat for the duration instead of leaving it be for an hour, maybe I can catch the leak in the act…will report.

Cash

I was thinking about doing something similar to what you told me, but using a washer and oring at the prop end with the prop nut just, I mean just ever so slightly compressing the oring, washer backing that up to tube end, lubing the hades out of it. Am I overthinking this?

I’m doing another tub test this weekend. Will stay with the boat for the duration instead of leaving it be for an hour, maybe I can catch the leak in the act…will report.

Cash

▲

⟩⟩

Fred

peter3l

stevedownunder

Mike Stoney

Wolle

Peejay

Len1

hermank

Colin H

RNinMunich

|

💬 Re: Leaking the leak

4 months ago by 🇺🇸 Chum444 (

Sub-Lieutenant) Sub-Lieutenant)✧ 87 Views · 2 Likes

Flag

Looks good on the water Cash. I would load up the shaft log with grease to see if that cures the issue. I’ve also had to find pinhole hull leaks in the ‘glass particularly where the hull halves are joined if it’s a two piece hull. If single piece I would look closely in the bow. Splash it & press down on the hull so as to increase the water pressure. But then you’ve probably done all of that.

▲

⟩⟩

Wolle

Cashrc

|

|

💬 Re: Leaking the leak

4 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 94 Views · 8 Likes

Flag

Hi Cash,

I'd put 'em on the other way round! I.e. washer against the prop hub and O ring against the tube end, and I wouldn't compress the O ring at all. Can only create drag. With a 5 to 10 thou gap to allow for some forward thrust absorption when you put the 'pedal to metal' without creating excessive pressure on the O ring and hence friction drag😉 Prime objective of a thrust washer is to reduce friction between moving parts; i.e. the prop hub, and fixed parts, i.e. the end of the shaft tube. In our case, mini scale drive trains, it also helps to reduce/eliminate water ingress up the shaft tube😀 I'd use a nylon washer rather than an O ring; less drag and better fit against the tube so better sealing against water ingress. Just my thunks😁 Cheers, Doug😎 PS I bet my giant syringe was much cheaper than a ProBoat grease gun😁 Less than €5. ▲

⟩⟩

roycv

Cashrc

RodC

Wolle

Peejay

Len1

hermank

Colin H

|

📝 A little video

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 94 Views · 13 Likes · 3 Comments

Flag

💬 Add Comment

I made a vid of our run last Sunday and posted it in the club lakes section. Here's the bit with the Puffer...

Cash

Cash

▲

⟩⟩

Fred

peter3l

Trident73

Razor1955

MouldBuilder

BarryS

RodC

Len1

EdW

stevedownunder

RNinMunich

Wolle

hermank

|

💬 Re: A little video

4 months ago by 🇺🇸 Cashrc (

Vice Admiral) Vice Admiral)✧ 81 Views · 1 Like

Flag

Yes Peejay, she’s a little quick…most Puffers were steam, then diesel…THIS Puffer is a scale model of a little known prototype worked up in Galveston, Texas. The builders weed a little more power, so they installed a big block Dodge with a cross ram intake….I tried to be faithful, but I just couldn’t do the zoomie headers coming thru the deck…that would have been tacky….😁

Cash ▲

⟩⟩

peter3l

|

|

Login To

Remove Ads 💬 Re: A little video

4 months ago by 🇺🇸 Peejay (

Sub-Lieutenant) Sub-Lieutenant)✧ 90 Views · 3 Likes

Flag

Fastest puffer I have seen! Para Handy would be very jealous! 😉😊

▲

⟩⟩

AlessandroSPQR

Len1

Cashrc

|

|

💬 Re: A little video

4 months ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 105 Views · 3 Likes

Flag

I would have brought it in to check water seeping after a few times around the circuit, much sooner than you did. Hope it was dry.

▲

⟩⟩

Len1

Cashrc

RNinMunich

|

📝 Looks good, runs good, leaks a bit

4 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 103 Views · 12 Likes · 5 Comments

Flag

💬 Add Comment

Hi y’all. The Puffer maidened this past weekend. Everything works like it should, she looks good in the water, but….I have a leak. Not huge, but annoying. I took on a bit of water in the tub test, double checked her and added more epoxy at the aft end of the boat where the tube exits, and ran ca thru a hole in the forward bulkhead and let it settle in the forward part of the bow. Ran her, still took on about a 1/4-1/2 cup down in the bilges after a 1.5 to 2 hour run. Didn’t phase the boat one bit, so it is a minor issue. I’m thinking it’s coming up the tube, tried a static test today in the tub with a cut down mixing cup under the tube end in the boat, a few drops of water were in the cup, but about a couple of tablespoons in the hull after 45 minutes or so. Tube felt a little wet on its bottom, so my theory might be correct, but at this stage I think I’ll do what I can just to slow the water ingress down a bit and live with it.

The other thing I plan to do in the not so distant future is to replace the railings with another unit made with brass stanchions versus the kits white metal units. Other than that, she’s a keeper, and looked good on the water.

Cash

The other thing I plan to do in the not so distant future is to replace the railings with another unit made with brass stanchions versus the kits white metal units. Other than that, she’s a keeper, and looked good on the water.

Cash

▲

⟩⟩

Fred

Razor1955

peter3l

Len1

Wolle

Colin H

boatmam

jumpugly

peterd

Peejay

hermank

RNinMunich

|

💬 Re: Looks good, runs good, leaks a bit

4 months ago by 🇬🇧 peter3l (

Able Seaman) Able Seaman)✧ 95 Views · 2 Likes

Flag

More grease in the shaft best bet try a blue marine grade as used on drive shafts may help peter l 3 👍👍

▲

⟩⟩

Len1

Cashrc

|

|

Login To

Remove Ads 💬 Re: Looks good, runs good, leaks a bit

4 months ago by 🇬🇧 PhilH (

Warrant Officer) Warrant Officer)✧ 103 Views · 3 Likes

Flag

Hi I thought you were describing my missus with that title 🤣🤣👍

Philuk ▲

⟩⟩

Len1

Wolle

Cashrc

|

|

💬 Re: Looks good, runs good, leaks a bit

4 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 104 Views · 10 Likes

Flag

Hi Cash,

Reckon you might be right about the toob😐 Designs like the puffer, and most naval ships, generally have the prop shaft running almost flat, i.e. horizontal so the motor end is below the water level. The water then creeps along the shaft tube. One way to stop it- Remove the shaft and inject some Teflon based grease into the tube. I use a giant syringe. Put a thrust washer (dished) onto the shaft against the prop hub. Followed by a nylon washer to fit against the tube end. Refit the shaft with a turning motion, to 'screw' it into and through the grease. At the motor end fit a nylon washer followed by a thrust washer. Adjust the shaft in the tube so that there is no more than 5 thou longitudinal play. Takes longer to type than to do😉 Worked on the twin shafts of my 1/72 scale destroyer😊 Re-grease before each new season start and you shouldn't have any more trouble.🤞 Cheers, Doug😎 ▲

⟩⟩

Fred

Cashrc

Len1

Wolle

Ronald

Colin H

jumpugly

River Rat

Peejay

hermank

|

|

💬 Re: Looks good, runs good, leaks a bit

4 months ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 112 Views · 5 Likes

Flag

Could you apply several coats of polyurethane on the outside of hull? Try four, let them dry between coats. Then do another tub test.

▲

⟩⟩

Len1

Wolle

Cashrc

jumpugly

hermank

|

|

💬 Re: Looks good, runs good, leaks a bit

4 months ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 104 Views · 4 Likes

Flag

Well, you could say it is a made scale like full size ships,

they had bilge pumps ya' know! Barry ▲

⟩⟩

Len1

Wolle

Cashrc

jumpugly

|

📝 Rigging. I hate rigging…

5 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 115 Views · 19 Likes · 1 Comment

Flag

💬 Add Comment

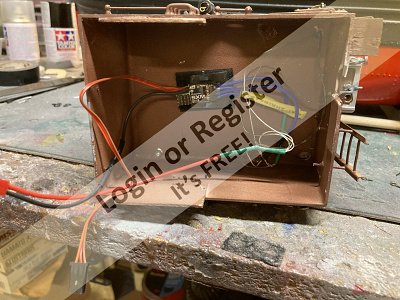

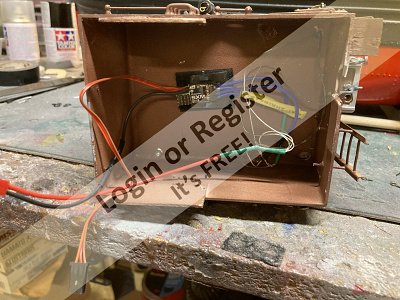

Hi y’all. Didn’t get a lot done last weekend, but this past week and today saw the mast installed, boom installed and rigging done. Well, mostly. First thing you might notice is the lack of rigging for the lamp on the side of the mast. I decided to modify the fittings as I noticed some later Puffers didn’t have that as they have electric lamps, so no need to have a pulley system to raise and lower the lamp to light, douse or refill it. There’s a couple of things I didn’t do, as the plans and instructions were kind of vague, but I got the majority done. It looks okay, I think I MIGHT have done better, but it looks good from a few feet away.

I also got the Control Hobbies (Graupner) SXM installed. This is a electronic latching switch that will run 4 banks of lights on one 3 position switch. I’ve used them before, they work great!! I decided instead of having a second connector coming of my battery lead to power the switch, I’ll use a small 1500-2200 mah 2 cell lipo to power it. I’ll ballast the boat with the main battery installed, but not the smaller battery. Most runs are in the morning, so I’ll not have need of the lights, but I can install the smaller pack when I want to do a dusk run, and it’s small and light enough the effect on the boats waterline will be negligible.

Cash

I also got the Control Hobbies (Graupner) SXM installed. This is a electronic latching switch that will run 4 banks of lights on one 3 position switch. I’ve used them before, they work great!! I decided instead of having a second connector coming of my battery lead to power the switch, I’ll use a small 1500-2200 mah 2 cell lipo to power it. I’ll ballast the boat with the main battery installed, but not the smaller battery. Most runs are in the morning, so I’ll not have need of the lights, but I can install the smaller pack when I want to do a dusk run, and it’s small and light enough the effect on the boats waterline will be negligible.

Cash

▲

⟩⟩

Fred

Razor1955

Mike Stoney

Peejay

hermank

Wolle

Trident73

River Rat

boatmam

Weebill

RNinMunich

BarryS

flaxbybuck

stevedownunder

Graham93

Len1

jumpugly

Colin H

EdW

|

💬 Re: Rigging. I hate rigging…

5 months ago by 🇺🇸 BarryS (

Warrant Officer) Warrant Officer)✧ 109 Views · 2 Likes

Flag

Good looking job Cash.

When will we see it on the pond? Barry ▲

⟩⟩

Len1

Cashrc

|

📝 The hatch

5 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 124 Views · 18 Likes · 2 Comments

Flag

💬 Add Comment

Hi y’all. I was able to fabricate a decent looking hatch for the Puffer over the past few days. I’ve put a lot of detail into this boat, but the hatch/hold is where I skimped a bit, at least for now. The kit is supposed to come with a molded plastic hatch that the builder adds details to, but this kit, although never started, was used, and the only thing missing was the hatch. Sooo……I built it up out of plastic sheet, then added the kit wood pieces to make it look like a simple hold. This is the one part of the boat that will be removed and reinstalled on a regular basis, so I kept it simple. Now, the radio gear IS under the deckhouse, but once everything is wired in and hooked up, there should be no reason whatsoever to access that except in the case of a malfunction, so once that checks out I’ll use small “L” brackets to mount the deckhouse to the deck…if something does go tango uniform I’ll be able to take out 2-3 screws and access the radio components. So, my next step is the mast and boom. Don’t know if I’m going to mount the boom in the stock location or raise it up a bit. I just need to get it built to the point to where I can install and remove a battery and make sure I have enough clearance to remove the hatch without breaking anything.

Cash

Cash

▲

⟩⟩

Fred

peter3l

Razor1955

Weebill

stevedownunder

Peejay

PeterL3

Len1

GaryLC

Ronald

Graham93

EdW

hermank

Mike Stoney

Colin H

Wolle

jumpugly

RNinMunich

|

💬 Re: The hatch

5 months ago by 🇬🇧 PeterL3 (

Petty Officer 2nd Class) Petty Officer 2nd Class)✧ 121 Views · 3 Likes

Flag

Like your hatch nice and neat plus workman like are you going to cover with tarpaulin don't forget the wedge blocks round the edge great build so far you cannot beat a puffer peter l👍👍👍

▲

⟩⟩

Wolle

Len1

RNinMunich

|

|

💬 Re: The hatch

5 months ago by 🇩🇪 Wolle (

Commander) Commander)✧ 126 Views · 4 Likes

Flag

Really well done, I really like it.

▲

⟩⟩

PeterL3

Len1

Cashrc

AlessandroSPQR

|

📝 Chains and rails yall, chains and rails

5 months ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 129 Views · 21 Likes · 3 Comments

Flag

💬 Add Comment

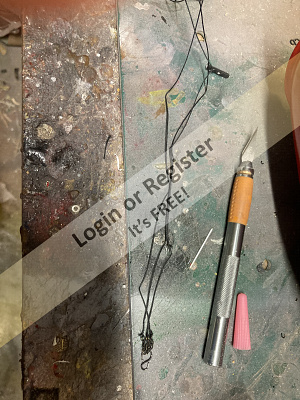

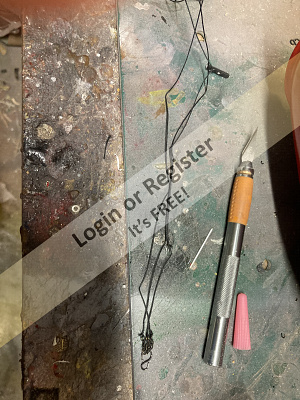

Hi y’all. Did the rudder chains and associated parts and the railings for the back deck today.

The rudder chains were first. I didn’t have enough chain to complete the job, but I looked in my stash and had a short piece of the same size, so I used fine wire to attach the 2 pieces and we were in business. There a faux rudder horn that slips over the rudder post and is glued to the deck. Once I measured the chain into 2 halves and all the paint was dry, I assembled my chain system. I checked fit, realized my port chain was too long, and glued everything together, and realized my port chain was now a quarter inch too short, and the final pulley was already glued to the chain. I went ahead and used it. I know it’s there, but it’s not that noticeable, unlike my port drifting winch, which was obvious. So, I finished up the rudder chains as it sits. In the future I might get a wild hair and break the pulley loose, lengthen the chain by 2 links and redo it, but not right now.

I made up the aft railing. I wanted to use brass wire vs the kit supplied mild steel, but I only had enough brass to do the top railing. So once my holes were drilled, I set up the stanchions and glued the top rail in place once I was satisfied with the fit. I pre bent a slight bend into the mild steel, fed it thru the holes and once it looked okay I glued it in place. I then removed the assembly for painting and installed on the boat. The rudder servo is mounted too.

So, I have a few more minor details to do aft, but those will wait till im almost done. Next up is the main hatch, then the mast and associated rigging.

Cash

The rudder chains were first. I didn’t have enough chain to complete the job, but I looked in my stash and had a short piece of the same size, so I used fine wire to attach the 2 pieces and we were in business. There a faux rudder horn that slips over the rudder post and is glued to the deck. Once I measured the chain into 2 halves and all the paint was dry, I assembled my chain system. I checked fit, realized my port chain was too long, and glued everything together, and realized my port chain was now a quarter inch too short, and the final pulley was already glued to the chain. I went ahead and used it. I know it’s there, but it’s not that noticeable, unlike my port drifting winch, which was obvious. So, I finished up the rudder chains as it sits. In the future I might get a wild hair and break the pulley loose, lengthen the chain by 2 links and redo it, but not right now.

I made up the aft railing. I wanted to use brass wire vs the kit supplied mild steel, but I only had enough brass to do the top railing. So once my holes were drilled, I set up the stanchions and glued the top rail in place once I was satisfied with the fit. I pre bent a slight bend into the mild steel, fed it thru the holes and once it looked okay I glued it in place. I then removed the assembly for painting and installed on the boat. The rudder servo is mounted too.

So, I have a few more minor details to do aft, but those will wait till im almost done. Next up is the main hatch, then the mast and associated rigging.

Cash

▲

⟩⟩

peter3l

Mike Stoney

Peejay

Ronald

Graham93

Len1

GaryLC

stevedownunder

RNinMunich

Commodore-H

PeterL3

BarryS

luckyduck

River Rat

jumpugly

hermank

EdW

MouldBuilder

Colin H

Fred

Wolle

|

💬 Re: Chains and rails yall, chains and rails

5 months ago by 🇬🇧 PeterL3 (

Petty Officer 2nd Class) Petty Officer 2nd Class)✧ 125 Views · 4 Likes

Flag

Like the way you have done the steering chains very nice build peter l

▲

⟩⟩

Cashrc

Len1

Wolle

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Chains and rails yall, chains and rails

5 months ago by 🇬🇧 PhilH (

Warrant Officer) Warrant Officer)✧ 133 Views · 5 Likes

Flag

Hi great looking model some top class work👍

Philuk ▲

⟩⟩

Cashrc

PeterL3

Len1

Commodore-H

Wolle

|

|

💬 Re: Chains and rails yall, chains and rails

5 months ago by 🇧🇪 hermank (

Captain) Captain)✧ 130 Views · 6 Likes

Flag

Cash rc a good sunday morning

very nice built. congratulations👍👍👍 ▲

⟩⟩

Cashrc

Peejay

AlessandroSPQR

Len1

jumpugly

Wolle

|

United States

United States