Join Us On Social Media!

Amati Riva Aquarama

23 Posts · 25 Followers · 71 Photos · 165 Likes

Began 3 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 1 year ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Thought I had finished!!

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 70 Views · 18 Likes · 5 Comments

Flag

💬 Add Comment

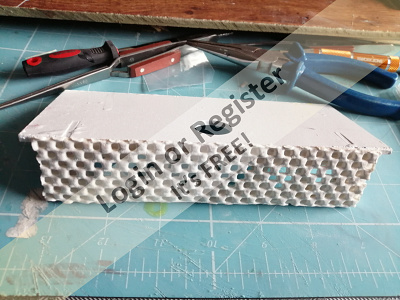

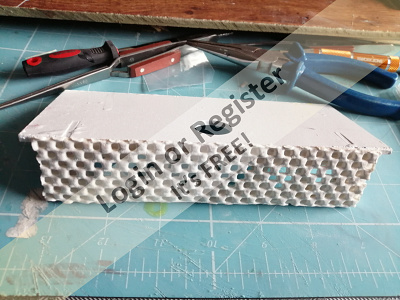

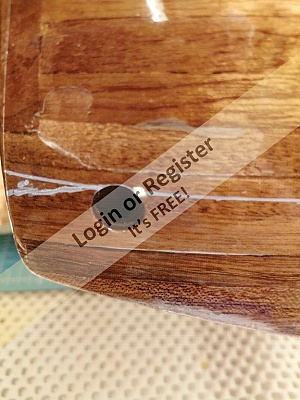

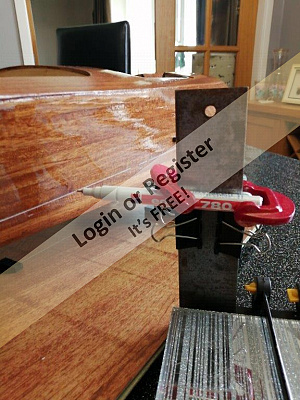

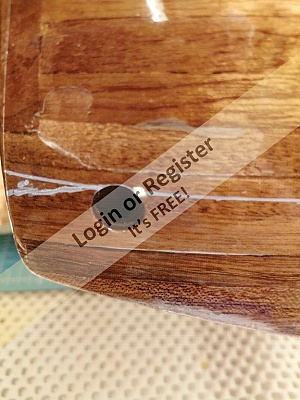

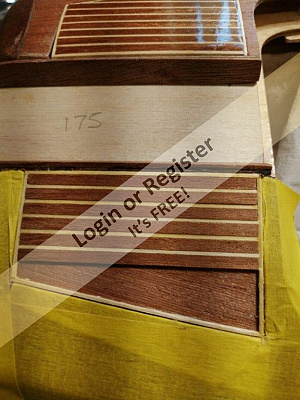

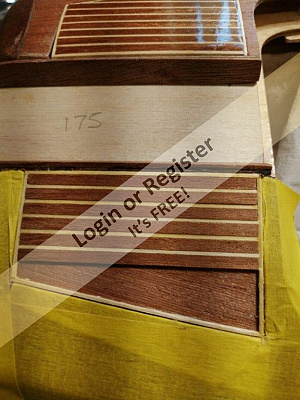

Having seen another Aquarama built by Damian on Model Boat Mayhem I decided to follow his lead and replace the vinyl cockpit floor( as supplied in the kit) with a walnut planked floor. The planks are 6mm x 0.5mm walnut from Cornwall Model boats. I ordered 4 metres of them and I thought there would be plenty but I ran out before even starting the foot rests! I ended up having patch under the magnetic catches for the seats. I couldn't believe it - 4metres! I've separated the planking with 0.75 black rigging string. I eventually decided to order another 1 metre of walnut to do the foot rests so as to finish off the job properly! Needless to say the postage was 4x more than the plank!! I think it looks a lot better than white vinyl. Thanks to Damian Curzon-Price's great idea.😊

▲

⟩⟩

AlessandroSPQR

GaryLC

flaxbybuck

River Rat

Kevin-56

boatmam

Len1

pressonreguardless

jbkiwi

luckyduck

Doogle

stevedownunder

RNinMunich

chugalone100

tiggy_cat

hermank

Colin H

ChrisG

|

💬 Re: Thought I had finished!!

10 months ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 31 Views · 1 Like

Flag

Yes I quite agree that the planking looks better than the plain vinyl.

You have made a lovely job of her and I am quite envious !😉 ▲

⟩⟩

DuncanP

|

|

Login To

Remove Ads 💬 Re: Thought I had finished!!

1 year ago by 🇺🇸 Len1 (

Lieutenant) Lieutenant)✧ 65 Views · 2 Likes

Flag

been there, done that

▲

⟩⟩

DuncanP

stevedownunder

|

|

💬 Re: Thought I had finished!!

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 65 Views · 3 Likes

Flag

Much nicer👍

JB ▲

⟩⟩

DuncanP

stevedownunder

pressonreguardless

|

|

💬 Re: Thought I had finished!!

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 64 Views · 8 Likes

Flag

Don’t worry, we all do that. We finish our models, take pictures of it and THEN….we find something to improve to what we already did and approved.

There is ALWAYS something to add…it never stops until we say….enough.😎 ▲

⟩⟩

RamseyA

pressonreguardless

jbkiwi

ChrisG

DuncanP

stevedownunder

RNinMunich

Scratchbuilder

|

|

💬 Re: Thought I had finished!!

1 year ago by 🇬🇧 ChrisG (

Commander) Commander)✧ 72 Views · 5 Likes

Flag

Duncan what a beautiful finish for the floor such a damn good idea. It’s often the incidental little finishes which just make the model.

Certainly well worth the cost, beautiful model you no doubt are very proud of her. Regards ChrisG ▲

⟩⟩

chugalone100

luckyduck

stevedownunder

DuncanP

Colin H

|

Login To

Remove Ads

Remove Ads

📝 Riva Aquarama Maiden Voyage

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 76 Views · 11 Likes · 2 Comments

Flag

💬 Add Comment

After a test in a paddling pool at home it was off to the local model boat club in Bury for the maiden voyage - along with a bottle of fizz! It was such a beautiful day it was so perfect for a launch. After christening the boat it was time for the moment of truth - will she run OK! I'm pleased to say that she handled very well although I thought she might run a little faster. The bonus was she was perfectly dry inside - great! Perhaps a direct drive rather than going through the supplied gearbox that arrived with the motorising kit. Since I'm going to have it as a display model I'm not that bothered about the speed. Perhaps it is about the correct scale speed of the original boats than weren't fitted with dual V12 Lamborghini engines! Please see this video of the V12:-

▲

⟩⟩

Colin H

ChrisG

stevedownunder

hermank

River Rat

pressonreguardless

jbkiwi

chugalone100

RNinMunich

Scratchbuilder

Len1

|

💬 Re: Riva Aquarama Maiden Voyage

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 76 Views · 6 Likes

Flag

Re Lamborghini, a little known fact, was that Bob Wallace from NZ was their development engineer in the early days (I didn't know myself till a few years ago, after I watched a video on Lamborghini history (they started making tractors) and picked up on the Kiwi accent.

▲

⟩⟩

DuncanP

Kevin-56

Colin H

stevedownunder

River Rat

RNinMunich

|

|

💬 Re: Riva Aquarama Maiden Voyage

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 73 Views · 1 Like

Flag

It is not only a pleasure to built but also to see her sailing.With such a boat you enjoy the Beaty of the boat, theview and the sun

▲

⟩⟩

DuncanP

|

📝 FINISHED AT LAST!!

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 87 Views · 17 Likes · 11 Comments

Flag

💬 Add Comment

Hi Everyone,

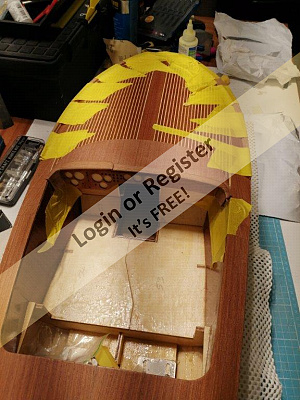

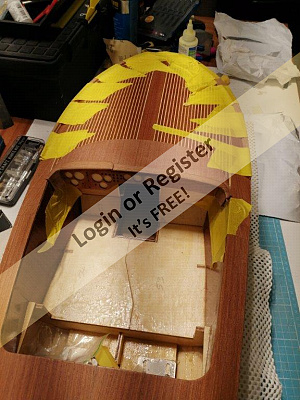

Finally after 2 years and 2 months I have finally finished my Riva. Even though I say it myself I think she looks beautiful! I must admit I haven't put all the cleats on because the base of the cleats are flat and so small that I think they could easily get caught and broken off when I get round to sailing her. This could end up damaging the mahogany veneer.

To fit the forward chromed metal fittings I put a layer of masking tape on the bow then drew round the bases and cut out the shape with a modelling knife before roughing up the varnish and then gluing the fittings with 5 minute Araldite. The 4 engine air vents on the sides were a bit daunting to fit with the very fine 'Aquarama' lettering and also having to drill through the hull for each vent. I used cockpit glue as it is relatively ease to wipe away any excess. I had to nail the back strip on first so I drilled tiny holes so that I didn't have to use the hammer too much! I then chromed over the strip and the nail with the chrome pen I mentioned earlier in the blog. Unfortunately on one side strip there was a nail hole missing and 'try as I must' I could get my hand drill to create this tiny hole 0.3mm. Once in place The holes in the metal strip for the air vents show where to drill. I was surprised that I had to go through completely to hold the peg on the back of the air vents. I tried to epoxy the inside of the holes in order to seal the wood around the holes. I've fitted the seats to the floor with magnetic door catches so that I can easily remove the seats for cleaning. Eventually I will replace the floor with a planked floor but this wasn't part of the kit. I found using digital callipers useful to measure the size of the pegs on the fittings and then chose the appropriate drill bit. Because this has been my first build since my early twenties I have had to buying quite a lot of stuff and tools to complete the build. I would like to do another build but I don't think my hands are not up to that any more unfortunately.

I think the next stage is a bath tub test and then sit and admire it before I pluck up courage for the maiden voyage! I hope you have all found my blog interesting and helpful especially if you attempt this kit. I've learnt a lot along the way and had some sleepless nights wondering how to tackle certain things! Hopefully my blog will help you to avoid some of these deep searching thoughts!😊

Cheers Duncan 🚤

Finally after 2 years and 2 months I have finally finished my Riva. Even though I say it myself I think she looks beautiful! I must admit I haven't put all the cleats on because the base of the cleats are flat and so small that I think they could easily get caught and broken off when I get round to sailing her. This could end up damaging the mahogany veneer.

To fit the forward chromed metal fittings I put a layer of masking tape on the bow then drew round the bases and cut out the shape with a modelling knife before roughing up the varnish and then gluing the fittings with 5 minute Araldite. The 4 engine air vents on the sides were a bit daunting to fit with the very fine 'Aquarama' lettering and also having to drill through the hull for each vent. I used cockpit glue as it is relatively ease to wipe away any excess. I had to nail the back strip on first so I drilled tiny holes so that I didn't have to use the hammer too much! I then chromed over the strip and the nail with the chrome pen I mentioned earlier in the blog. Unfortunately on one side strip there was a nail hole missing and 'try as I must' I could get my hand drill to create this tiny hole 0.3mm. Once in place The holes in the metal strip for the air vents show where to drill. I was surprised that I had to go through completely to hold the peg on the back of the air vents. I tried to epoxy the inside of the holes in order to seal the wood around the holes. I've fitted the seats to the floor with magnetic door catches so that I can easily remove the seats for cleaning. Eventually I will replace the floor with a planked floor but this wasn't part of the kit. I found using digital callipers useful to measure the size of the pegs on the fittings and then chose the appropriate drill bit. Because this has been my first build since my early twenties I have had to buying quite a lot of stuff and tools to complete the build. I would like to do another build but I don't think my hands are not up to that any more unfortunately.

I think the next stage is a bath tub test and then sit and admire it before I pluck up courage for the maiden voyage! I hope you have all found my blog interesting and helpful especially if you attempt this kit. I've learnt a lot along the way and had some sleepless nights wondering how to tackle certain things! Hopefully my blog will help you to avoid some of these deep searching thoughts!😊

Cheers Duncan 🚤

▲

⟩⟩

RNinMunich

Wolle

Doogle

Kevin-56

hermank

Len1

flaxbybuck

ChrisG

jbkiwi

chugalone100

River Rat

Colin H

pressonreguardless

stevedownunder

Scratchbuilder

neilw

DWBrinkman

|

💬 Re: FINISHED AT LAST!!

11 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 40 Views · 2 Likes

Flag

A great looking build, well done 👏

▲

⟩⟩

DuncanP

Scratchbuilder

|

|

Login To

Remove Ads 💬 Re: FINISHED AT LAST!!

11 months ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 45 Views · 1 Like

Flag

Hi Duncan.

Great build I see there is a similar build described in the October Model Boats Magazine. Regards Bill ▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 CHRISTOPHERH1 (

Able Seaman) Able Seaman)✧ 82 Views · 0 Likes

Flag

Usually when i build the keel i christen it with a drop of refreshing liquid for good luck! the two boats i forgot to do it are the ones i`ve had the most trouble with !!

daft but true ! ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 CHRISTOPHERH1 (

Able Seaman) Able Seaman)✧ 82 Views · 1 Like

Flag

What motors,esc`s and battery are you using for reference sake please?

▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 CHRISTOPHERH1 (

Able Seaman) Able Seaman)✧ 82 Views · 1 Like

Flag

Cracking job mate.I HAVE JUST GOT THE KIT AND WILL BE MY SUMMER PROJECT.I`VE JUST FINISHED MY THAMES SLIPPER,SO AM RARING TO GET STARTED!

▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 88 Views · 1 Like

Flag

Duncan

You created a beautiful master piece. Your model has impecable interiors, overall is a remarkable piece.😍 ▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 82 Views · 1 Like

Flag

Duncan.

A cracking build to be proud off 👍👍 Regards Bill. ▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 83 Views · 1 Like

Flag

A build to be proud of Duncan.

Hope you enjoy sailing it on water.😉 ▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇬🇧 ChrisG (

Commander) Commander)✧ 91 Views · 1 Like

Flag

Hello Duncan

Love your build and why rush anyway, for me at certainly, the building is the important part of the exercise. Love your attention to detail and perseverance when things were not going according to plan. I will contact you regarding the booklet when I get my act together having been away, sorry. Best regards ChrisG What is the next build ????? ▲

⟩⟩

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 83 Views · 3 Likes

Flag

Duncan a good evening

Madre madonna, sancta Maria What a beauty!! I can understand, evenwicht all the layers ofvarnish you don’t want to put her into the water. I have a hard cased book about the start of the Riva boats and his owner and I must say the artwork,design everything is magnifico I hope you enjoy sailing the model ▲

⟩⟩

stevedownunder

Colin H

DuncanP

|

|

💬 Re: FINISHED AT LAST!!

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 98 Views · 2 Likes

Flag

Hi Duncan,

Your boat looks fantastic, well worth the effort. Looking forward to some on the water shots at some point. Cheers, Stephen. ▲

⟩⟩

AlessandroSPQR

DuncanP

|

📝 Getting towards the end of the build

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 93 Views · 6 Likes · 3 Comments

Flag

💬 Add Comment

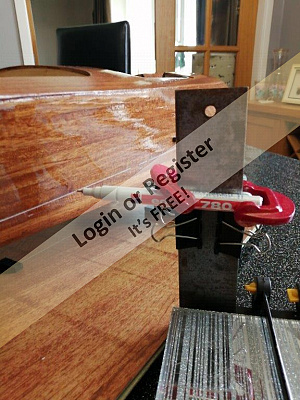

Getting towards the final fitting out. Just fitted the R/C. The receiver is in the blue box and the ESC is in the removeable white platform I've constructed from scraps. I've secured this and the battery using elastic bands. Fitted the switch to a piece of scrap ply. On the recommendation of another modeller I got some self adhesive 2mm x 2mm 'D' shaped chrome moulding off Amazon for covering the joint between the deck and the hull. I would personally recommend this rather than having to paint the white strip provided in the kit and then gluing this on without spoiling the beautiful varnish finish! It would have been better without the very thin black foam backing but the backing is hardy noticeable. I attached this strip after polishing with G10 polishing compound. Only done one side so far. So flooring, side upholstery , steering wheel, windscreen, air vents, exhausts and various other chrome fittings need to be attached. Some of these require drilling into the side of the hull. I hope this won't affect the water tightness!! I've also drilled out the back of the rear seat mount in order for some air to get through to the motors. I then covered this with a strip of non slip rubber matting. You can see my model standing on this matting in earlier photos. I sprayed it with some white primer in order for it to match. Not long now hopefully before I can send some finished photos! So far I've spent over 2 years working on it on and off. During the winter not much got done because it was too cold out in the garage workshop!

▲

⟩⟩

jbkiwi

Colin H

hermank

stevedownunder

flaxbybuck

RNinMunich

|

💬 Re: Getting towards the end of the build

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 81 Views · 1 Like

Flag

One of my boats has been over two years in the making, and my workshop is heated ! But it doesn't matter if it takes a long time because we do it for pleasure, as and when we can. 😉

▲

⟩⟩

DuncanP

|

|

Login To

Remove Ads 💬 Re: Getting towards the end of the build

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 87 Views · 2 Likes

Flag

Beautifully finished Duncan. Well done. There are too few of us building model boats, but it is always encouraging to see the really high standard of modelling that a few achieve. I reckon you are in the top notch Duncan !😉

▲

⟩⟩

DuncanP

stevedownunder

|

|

💬 Re: Getting towards the end of the build

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 90 Views · 2 Likes

Flag

What à Beauty. You can be very proud of your model

▲

⟩⟩

DuncanP

stevedownunder

|

📝 Please see above for post!

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 93 Views · 2 Likes

Flag

💬 Add Comment

This was a duplicate - sorry

▲

⟩⟩

ChrisG

River Rat

📝 Painting complete - I hope!

1 year ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 102 Views · 12 Likes · 6 Comments

Flag

💬 Add Comment

My build of the Riva has been on hold because of the cold weather making it too cold in my work room but I have now put two coats of undercoat and one coat of Humbrol gloss white onto the bottom. This is on top of the 6 coats of varnish. Once it is thoroughly hardened I will then start to put the blue waterline stripe on and the chrome accessories on the decks etc. I made a rod for my own back though with painted the blue sides on the seats. I've lost count on the number of times I had to redo the paint of white and blue because of seepage through the masking tape! I think it now looks good but a lot of frustration getting there!

▲

⟩⟩

mturpin013

RNinMunich

flaxbybuck

jbkiwi

pressonreguardless

stevedownunder

Graham93

neilw

hermank

ChrisG

luckyduck

Colin H

|

💬 Re: Painting complete - I hope!

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 91 Views · 1 Like

Flag

I particularly like the upholstery on your seats. Really good !😉

▲

⟩⟩

DuncanP

|

|

Login To

Remove Ads 💬 Re: Painting complete - I hope!

1 year ago by 🇬🇧 DuncanP (

Lieutenant) Lieutenant)✧ 100 Views · 1 Like

Flag

Hi Stephen. Thank you for your comments. I used yellow premium masking tape. I also bought some 'Tamiya masking tape for curves' but that was no better on the seats!! Cheers D

▲

⟩⟩

stevedownunder

|

|

💬 Re: Painting complete - I hope!

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 112 Views · 2 Likes

Flag

Great resalt Duncan,

Worth the effort I would say. What sort of masking tape did you use? Cheers, Stephen. ▲

⟩⟩

pressonreguardless

DuncanP

|

|

💬 Re: Painting complete - I hope!

1 year ago by 🇬🇧 neilw (

Lieutenant) Lieutenant)✧ 104 Views · 2 Likes

Flag

Looks amazing, I feel your pain when it doesn’t go to plan. Just waiting for some consistent warm and most importantly dry weather to put the final few coats of varnish on my bigger project.

▲

⟩⟩

stevedownunder

DuncanP

|

|

💬 Re: Painting complete - I hope!

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 103 Views · 3 Likes

Flag

Duncan Forget thé frustration and look at the fantastic résult!!

Rome is also not built in one day!! Be proud if thé result you achieved And the jalous êyes at the lake ▲

⟩⟩

DuncanP

stevedownunder

neilw

|

|

💬 Re: Painting complete - I hope!

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 97 Views · 4 Likes

Flag

I congratulate you on persisting with the job whilst keeping the highest standards - this can be really frustrating. Many of us I'm sure experience these set backs, two steps forward, three steps back ! Sheer doggedness sometimes wins out.

Good luck with completion. You will keep us informed ?😉 ▲

⟩⟩

stevedownunder

hermank

neilw

DuncanP

|

📝 DISASTER has struck!!

2 years ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 156 Views · 6 Likes · 8 Comments

Flag

💬 Add Comment

DISASTER! I left my yacht varnish to go hard for nearly 3 weeks. I put standard masking tape on in order to form a line of where to sand the bottom up to the waterline. It was difficult when applying this masking tape to cope with the curves leading up to the bow so I decided to order some 12mm Tamiya Masking Tape for Curves. I also ordered an Edding 0.8mm white marker pen because it was difficult trying to mark and see a pencil maker on the varnish.

I made up my own waterline marker with clamps and set square and a box with felt feet which made it easy to slide along the side of the hull. It worked OK.

I then applied the Tamiya Masking tape for curves tape.

It did the job I wanted but then I noticed a slight kink in it on the transom. I therefore lifted the tape off to reposition it and to my horror this tape pulled the varnish off! The other standard masking tape was fine. I therefore decided to take the tape off the rest of the hull and again in one place it has pulled the yacht varnish off! It would not have been so bad if it had just been the transom that I would have to sand and repaint but now it will be the whole hull again!! One step forward and 4 backwards. Depressing.

Any suggestions for masking up again after revarnishing without having the other problem of bleeding!

I made up my own waterline marker with clamps and set square and a box with felt feet which made it easy to slide along the side of the hull. It worked OK.

I then applied the Tamiya Masking tape for curves tape.

It did the job I wanted but then I noticed a slight kink in it on the transom. I therefore lifted the tape off to reposition it and to my horror this tape pulled the varnish off! The other standard masking tape was fine. I therefore decided to take the tape off the rest of the hull and again in one place it has pulled the yacht varnish off! It would not have been so bad if it had just been the transom that I would have to sand and repaint but now it will be the whole hull again!! One step forward and 4 backwards. Depressing.

Any suggestions for masking up again after revarnishing without having the other problem of bleeding!

▲

⟩⟩

hermank

jbkiwi

RonBMK2

stevedownunder

Colin H

pressonreguardless

|

💬 Re: DISASTER has struck!!

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 103 Views · 1 Like

Flag

For any work where you need a perfect Line between 2 colours i m using a rubber based latex which you can bring on with a brush. If necessary you can bring on more coatings. When thé rubber is dry you pull of the part where you don’t need thé spray, When thé painting is done you pull of thé film withouten any damage

It works extremely well and is much better as the masking tape. I agrée it is more work but thé result is muuuuuuuch better And that’s what counts ▲

⟩⟩

DuncanP

|

|

Login To

Remove Ads 💬 Re: DISASTER has struck!!

2 years ago by 🇬🇧 DuncanP (

Lieutenant) Lieutenant)✧ 125 Views · 1 Like

Flag

For the final coat of varnish I used to 2000 grade sandpaper. Perhaps it was too fine. I've now sanded it down with 1200 grade paper and recoated the varnish. I've had my electric radiator on as well so the temperature was 20degrees C before starting to varnish - but I will switch off soon otherwise I won't be able to afford the electric bill! How long do you suggest leaving the varnish to harden before applying masking tape? My man cave is normally about 14degrees during the day during these mild days that we are unexpectedly experiencing at the moment. I have a dehumidifier in there keeping it between 60 and 70 humidity. Thanks Duncan. 😝

▲

⟩⟩

hermank

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇺🇸 Len1 (

Lieutenant) Lieutenant)✧ 123 Views · 1 Like

Flag

for what its worth it seams that the varnish has not adhered well to the substrate and/or has not entirely cured. I would be concerned with the varnish lifting on its own over a period of time

▲

⟩⟩

DuncanP

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇺🇸 LewZ (

Commodore) Commodore)✧ 149 Views · 4 Likes

Flag

Masking for my models: I use blue masking tape which gives me a good edge. As for those curved surfaces, I lay down a section of masking tape, maybe 12 - 18 inches long keeping it straight. Using a sharp cutting tool and a steel straight edge I cut a strip (or multiple), maybe 1/8 inch wide (depending on the curve) and use that on the model burnish it down good to get a sealed edge. Then you can add wider tape to that.

Lew ▲

⟩⟩

DuncanP

Len1

stevedownunder

jbkiwi

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 157 Views · 4 Likes

Flag

Hi Duncan,

What a shame, but such is the nature of model building. If you are only having to take four steps backwards, you are not doing too badly. I also like Frog tape. Readily available at the diy sheds in the UK Graham93 ▲

⟩⟩

DuncanP

stevedownunder

pressonreguardless

Rookysailor

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇬🇧 ChrisG (

Commander) Commander)✧ 157 Views · 2 Likes

Flag

Oh! such a shame, devastating but recoverable. Masking tape can be a nightmare for many reasons I have been using Tamiya for a while, it seems the stickier they are the more trouble they cause.

Everything will be great in the end she is still a model to be proud of and in time it will be funny story to tell. Regards ChrisG ▲

⟩⟩

DuncanP

stevedownunder

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 159 Views · 4 Likes

Flag

Duncan, sorry to hear of your problems, but for the tape to pull Varnish off sounds like your Varnish hadn't bonded with the wood.

I only ever had that happen once on a boat I was restoring and it turned out that the wood still had moisture in it. I had to put it in the airing cupboard for a week before it was fully dry. After it was fully dry I re-sanded and fresh Varnish, masked and repainted below the waterline without any problems. I use Frog tape for complex shapes as it's easy to work round the shape. Cheers Colin. ▲

⟩⟩

DuncanP

stevedownunder

jbkiwi

pressonreguardless

|

|

💬 Re: DISASTER has struck!!

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 157 Views · 3 Likes

Flag

I have used Frog Tape for delicate surfaces. I apply the tape; paint immediately and immediately remove the tape before the paint dries.

Good Luck! Trev ▲

⟩⟩

DuncanP

stevedownunder

Colin H

|

📝 Gluing fittings

2 years ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 172 Views · 1 Like

Flag

💬 Add Comment

Thank you for all your suggestions for gluing the fittings onto the decks. I will experiment with your ideas and then choose. Cheers Duncan

▲

⟩⟩

stevedownunder

📝 Varnishing complete!

2 years ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 181 Views · 10 Likes · 6 Comments

Flag

💬 Add Comment

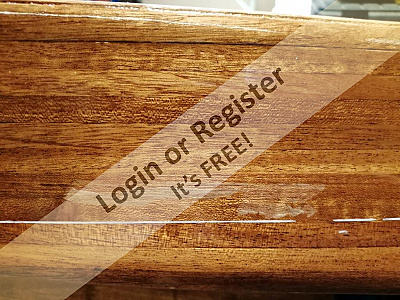

Hi Everyone. Managed to get 4 coats of varnish onto first of all the decks and then onto the hull sides. The bottom had 4 coats earlier in the build. I will need to polish out the dust specks eventually. I tried really hard to avoid any dust by sanding and wiping down outside but still got dust specks! I've started to build the dashboard which I found very fiddly and inevitably got some CA glue on my figures even though I was using reverse tweezers. Unfortunately, the simulated light switches seem to have the glass domes missing from the kit so I've raided my wife's bead box and managed to find some small coloured beads to make the domed fronts of the light switches! I still need to fit the key sockets and keys, plus the gear levers and steering wheel to the dashboard. After a lot of messing about with paints for the seats I have found the Tamiya TS10 French Blue spray paint to be the best match. Having sprayed them I have then sprayed them with a Matt lacquer finish over the top of these seats. I decided to separate the seat sides from the main part of the seat to make the painting job easier as after my first attempt I found some leakage under the masking tape. I've just ordered an Edding white 0.8mm permanent marker to create my waterline mark prior to painting the bottom of the hull white. I couldn't see the pencil maker clearly on the varnish and this marker writes on glass and metal and is waterproof - so it should be OK. Pity in a way I'm going to be covering up the lovely mahogany bottom with white paint but in the end I think it will look better. I bought a 13mm wood drill from the Blackpool Model boat show to create the two holes for the cabin skylights. I drilled these holes with great trepidation! Added a touch of varnish around the inside of the holes afterwards. Just a warning to anyone else building this model - I measured the distance from the dashboard to the centre of the skylight on the full size plan. Unfortunately, this turned out to be right over one of the bulkheads which then involved cutting away a small portion on each side for the skylights. Once the bottom has been painted white, I will be able to get on with the deck fittings. Any suggestions for best glue for chromed brass fittings to be attached to the varnished decks. I wondered about using my Deluxe Cockpit canopy glue - any thoughts?

▲

⟩⟩

PeterJ

RonBMK2

stevedownunder

boatmam

jbkiwi

pressonreguardless

AndyB

DWBrinkman

Colin H

ChrisG

|

💬 Re: Varnishing complete!

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 171 Views · 3 Likes

Flag

Beautiful work Duncan,

I would agree with JBs recommendation. Cheers, Stephen. ▲

⟩⟩

jbkiwi

RonBMK2

pressonreguardless

|

|

Login To

Remove Ads 💬 Re: Varnishing complete!

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 176 Views · 1 Like

Flag

Great resolution, JB👍👍

Trev ▲

⟩⟩

jbkiwi

|

|

💬 Re: Varnishing complete!

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 175 Views · 3 Likes

Flag

Terrific job, dash is looking great. For the fittings, if at all possible, drill a 1mm hole for a pin in the bottoms, making the pins a tight fit and cyanoing (tiny dab of gel not liquid) them in, then drill holes in the deck for the pins and glue them in with a slower setting glue. If you glue the fittings onto the varnish and you knock them, you are liable to rip a patch or layer of varnish off with them, as the joint is only as strong as the top coat of varnish. Don't use cyano on the varnish as it might bloom and ruin the surface.

JB ▲

⟩⟩

Colin H

stevedownunder

pressonreguardless

|

|

💬 Re: Varnishing complete!

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 176 Views · 1 Like

Flag

Dash looks great Duncan.

for mounting hardware to the deck you could try double sided mounting tape available on amazon. Do a trial run first on scrap to test. Trev ▲

⟩⟩

stevedownunder

|

|

💬 Re: Varnishing complete!

2 years ago by 🇺🇸 DWBrinkman (

Commander) Commander)✧ 181 Views · 1 Like

Flag

What a gorgeous boat! Superb workmanship, the varnish finish is superb.

▲

⟩⟩

stevedownunder

|

|

💬 Re: Varnishing complete!

2 years ago by 🇬🇧 ChrisG (

Commander) Commander)✧ 182 Views · 1 Like

Flag

Absolutely amazing varnish work, difficult to find better and I think the white bottom will enhance the varnish work and not detract from it, my opinion only I hasten to add.

The detail you are building into the dash is quite something, an all round beautiful model to be very proud of. Regards ChrisG ▲

⟩⟩

stevedownunder

|

📝 Deck Planking

2 years ago by 🇬🇧 DuncanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 205 Views · 13 Likes · 5 Comments

Flag

💬 Add Comment

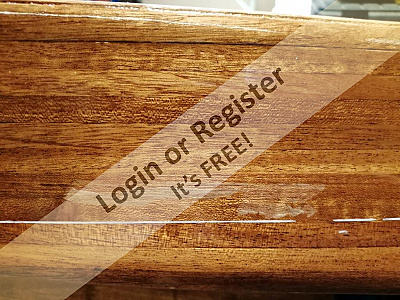

Just a bit of an update. Finished the deck planking which took quite a long time to complete! I've applied a couple of coats of sanding sealer onto the deck and also applied some sealer to the saxboards before gluing to avoid any glue staining. I found fitting these saxboards quite difficult as they need to bend in two directions. I heated them in boiling water and then applied them to the deck with masking tape and left them to dry for a couple of days to take on the shape of the deck. It was only semi successful. I then glued them on the deck and held them in place using strong car masking tape. I've had to do some filling using aliphatic glue and mahogany dust mix in places as I couldn't get it to follow the contours exactly. Fitting the rear removal hatches was also a bit of a challenge but got there in the end! Will soon be ready to apply the first coat of varnish - followed by several more coats. Weather is turning colder so my 'man cave' at the back of my garage is not very warm to work in. I'm worried about putting the heater on with the cost of electricity these days because it takes a lot of heating up. 'Catch 22'!!

▲

⟩⟩

Colin H

DaveWhittaker

GaryLC

RonBMK2

stevedownunder

Len1

Peejay

River Rat

Graham93

ChrisG

Norway

Rowen

pressonreguardless

|

💬 Re: Deck Planking

2 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 1 Like

Flag

That's a fantastic finish, do you really need to paint the bottom?

I've seen a few real ones that were not painted, and they looked fantastic. As for the fittings, I prefer to pin or screw if possible, if you must glue Varnish a scrap of wood and check it doesn't react with the glue before using on your model. Cheers Colin. ▲

⟩⟩

RonBMK2

|

|

Login To

Remove Ads 💬 Re: Deck Planking

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 192 Views · 0 Likes

Flag

Great job, looks really smart👍👍

JB ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Deck Planking

2 years ago by 🇬🇧 ChrisG (

Commander) Commander)✧ 205 Views · 3 Likes

Flag

Lovely decking and yes to get it looking as good as you have does take lots of time, this is ok if you have other parts of the build to be carrying on with but frustrating if you have to keep walking away.

My goodness me though very much worth it in the end. Regards ChrisG ▲

⟩⟩

Colin H

RonBMK2

Peejay

|

|

💬 Re: Deck Planking

2 years ago by 🇬🇧 Norway (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 207 Views · 0 Likes

Flag

It's looking good. All your hard work is paying off.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Deck Planking

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 205 Views · 0 Likes

Flag

Looks Great, Duncan

Trev ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

United Kingdom

United Kingdom