Join Us On Social Media!

Rescue Launch

12 Posts · 17 Followers · 80 Photos · 151 Likes

Began 3 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 3 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Maiden Voyage

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 134 Views · 17 Likes · 15 Comments

Flag

💬 Add Comment

A cold, frosty morning with little wind provided ideal conditions for the maiden voyage.

As soon as the boat was in the water, Finley took control. He remembered the control functions from the 'bathtub' test and had little difficulty in sailing the model. It is fast and responsive.

Grandad was more stressed than he was, trying to ensure that there were no collisions with the other boats on the lake, or with the ducks!!

All in all, a nice kit to build with only a few small issues. A convenient size, easy to transport and store. It sails well and looks good on the water.

What's next I wonder?

As soon as the boat was in the water, Finley took control. He remembered the control functions from the 'bathtub' test and had little difficulty in sailing the model. It is fast and responsive.

Grandad was more stressed than he was, trying to ensure that there were no collisions with the other boats on the lake, or with the ducks!!

All in all, a nice kit to build with only a few small issues. A convenient size, easy to transport and store. It sails well and looks good on the water.

What's next I wonder?

▲

⟩⟩

Len1

Scratchbuilder

firefighter

RNinMunich

dave976

DWBrinkman

Martin555

stevedownunder

Seanympth

Muskrat

Madwelshman

RC Sailing

Colin H

GaryLC

robbob

jbkiwi

Newby7

|

💬 Re: Maiden Voyage

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 27 Views · 1 Like

Flag

Graham what a lucky granddad you are! You must be over the moon! Sailing with your grandson. I. Shure your heart beat Will be over 160. But thé joy Will be immense.

▲

⟩⟩

Graham93

|

|

Login To

Remove Ads 💬 Re: Maiden Voyage

1 year ago by 🇬🇧 firefighter (

Lieutenant) Lieutenant)✧ 38 Views · 1 Like

Flag

Lovely boat. Looks great!

I'm now convinced I want one. But which one! 😁 Greg 👍 ▲

⟩⟩

Graham93

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 NigelTailyour (

Master Seaman) Master Seaman)✧ 106 Views · 1 Like

Flag

Well done Finlay. Excellent sailing.

▲

⟩⟩

Martin555

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 HAKits (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 138 Views · 4 Likes

Flag

Great to see the younger generation getting involved. This was exactly my idea when i started to produce the small simple kits. Well done.

▲

⟩⟩

Colin H

jbkiwi

Rookysailor

Graham93

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 115 Views · 4 Likes

Flag

Thanks Everyone for the comments and the 'likes' 👍

Here is a video of the Maiden voyage:

▲

⟩⟩

Colin H

RNinMunich

Martin555

dave976

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 124 Views · 4 Likes

Flag

What a great finale, both of you must be really pleased with the result.

▲

⟩⟩

Griss

Graham93

stevedownunder

Martin555

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 124 Views · 7 Likes

Flag

Martin, Colin,

He had a great time this morning. Now he’s asking if he can come sailing every Sunday morning 😏 Graham93 ▲

⟩⟩

Griss

dave976

jbkiwi

GaryLC

Madwelshman

Martin555

stevedownunder

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 124 Views · 5 Likes

Flag

Hi JB,

It was more than fast enough for me while trying to ensure that the novice pilot didn’t ram it into the bank, a duck, or another boat. He did see an airboat on the lake which seemed to catch his attention. May have had something to do with the speed it was travelling 🙄. Graham93 ▲

⟩⟩

jbkiwi

GaryLC

Madwelshman

Martin555

stevedownunder

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 124 Views · 5 Likes

Flag

Graham you've just scored major points for best grandad awards.

Any chance you could adopt me. Wonderful to see another youngster enjoying this wonderful hobby. Cheers Colin. ▲

⟩⟩

RNinMunich

jbkiwi

Martin555

stevedownunder

Graham93

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Muskrat (

Warrant Officer) Warrant Officer)✧ 123 Views · 3 Likes

Flag

Hi Graham it doesn't take them long does it, i watched a young lady about the same age on my local pond in charge of a RNLI life boat this morning even though it was quite windy down here today, a lot better than her Dad with his Yacht.

Cheers Jon ▲

⟩⟩

stevedownunder

Seanympth

Graham93

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Madwelshman (

Midshipman) Midshipman)✧ 131 Views · 4 Likes

Flag

The Police launch looks great on the water.

Smiles all round I bet. Yes, so what is next Graham? Will ▲

⟩⟩

Martin555

stevedownunder

Seanympth

Graham93

|

|

Login To

Remove Ads 💬 Re: Maiden Voyage

3 years ago by 🇬🇧 RC Sailing (

Recruit) Recruit)✧ 130 Views · 3 Likes

Flag

Well done Finley ! - (and well done Gramps !)👍🚤

▲

⟩⟩

Martin555

stevedownunder

Graham93

|

|

💬 Re: Maiden Voyage

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 149 Views · 4 Likes

Flag

Hi Graham,

I bet young Finley was extremely happy when his boat went on the water for the first time. And with a smile from ear to ear. Martin555. ▲

⟩⟩

stevedownunder

Graham93

Madwelshman

GaryLC

|

|

💬 Re: Maiden Voyage

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 134 Views · 6 Likes

Flag

Looks good and seems to be going well Graham, was it fast enough for the skipper, or is it "a deep v racing boat next please Grandad" ?😁

JB ▲

⟩⟩

RNinMunich

stevedownunder

Graham93

Madwelshman

GaryLC

Martin555

|

|

💬 Re: Maiden Voyage

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 133 Views · 4 Likes

Flag

Well done skipper and crew chief.

Rick ▲

⟩⟩

stevedownunder

Graham93

GaryLC

Martin555

|

Login To

Remove Ads

Remove Ads

📝 Finishing touches

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 143 Views · 13 Likes · 5 Comments

Flag

💬 Add Comment

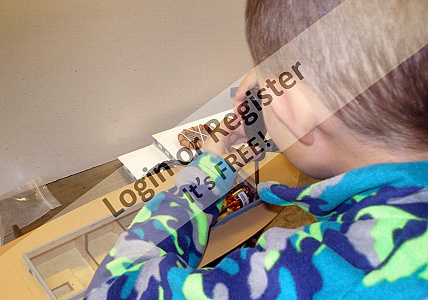

A ship's wheel was marked out on plastic sheeting using a compass. The pieces were glued together and then carved to shape. The completed wheel we trial fitted before painting.

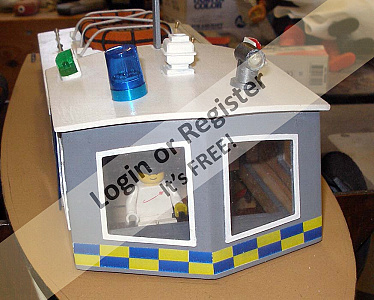

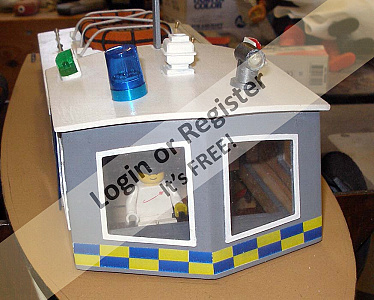

Finley found a 'Skipper' among his large box of Lego. The scale doesn't look too bad.

Lifebelts were also made from plastic sheet, turned on the lathe, painted and with ropes added. Handrails made from brass wire and small woodscrews were added to the main cabin roof.

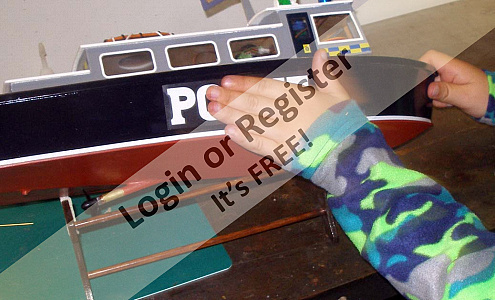

Finally a quick test float in the 'domestic test tank' in preparation for the maiden voyage on the lake.

Finley found a 'Skipper' among his large box of Lego. The scale doesn't look too bad.

Lifebelts were also made from plastic sheet, turned on the lathe, painted and with ropes added. Handrails made from brass wire and small woodscrews were added to the main cabin roof.

Finally a quick test float in the 'domestic test tank' in preparation for the maiden voyage on the lake.

▲

⟩⟩

Seanympth

robbob

dave976

philcaretaker

jbkiwi

RNinMunich

Rookysailor

mturpin013

stevedownunder

redpmg

Colin H

Martin555

Newby7

|

💬 Re: Finishing touches

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 141 Views · 1 Like

Flag

Some really nice finishing touches Finley and Graham

▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Finishing touches

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 140 Views · 4 Likes

Flag

Hi Martin,

Thought you would like the plastic 😉 Lots of switches for Finley to play with so it took him a little while to work them all out. Graham93 ▲

⟩⟩

Seanympth

Martin555

Colin H

dave976

|

|

💬 Re: Finishing touches

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 141 Views · 4 Likes

Flag

"Skipper we seem to be stuck in this pond I don't see a way out."

Another victim of 'The Philadelphia Experiment' Rick 😮 😎 ▲

⟩⟩

Seanympth

dave976

Graham93

Newby7

|

|

💬 Re: Finishing touches

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 156 Views · 4 Likes

Flag

Great work,

I like the plastic manipulation.(helm, lifebelts) I see young Finley has the controls, how many times did he hit the horn.LOL!! Martin555. ▲

⟩⟩

Colin H

dave976

Graham93

stevedownunder

|

|

💬 Re: Finishing touches

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 141 Views · 6 Likes

Flag

Skipper we seem to be stuck in this pond I don't see a way out.

Nice work Graham on the wheel and lifebelts. Rick ▲

⟩⟩

Seanympth

dave976

Graham93

RNinMunich

stevedownunder

Martin555

|

📝 Blues and Twos

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 164 Views · 12 Likes · 2 Comments

Flag

💬 Add Comment

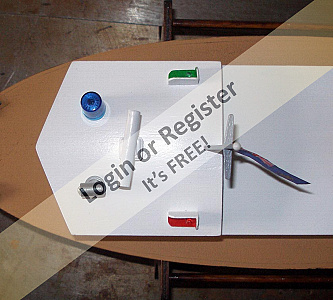

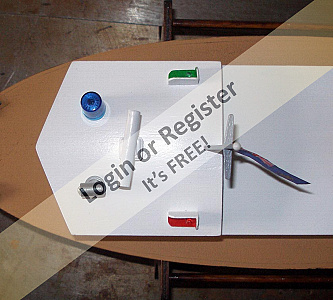

As Michael noticed in the last post, there is a blue Police light on the cabin roof. This is one half of the 'blues and twos' installation on the boat.

The light was bought on-line and simply plugs into a spare channel on the Rx. Using the corresponding switch channel on the Tx allows four different flashing patterns to be selected in sequence.

The two tone horn is provided by a small waterproof speaker mounted on the underside of the main cabin roof. This is driven by a two tone oscillator (yes, another PIC!) plugged into another Rx channel. To disguise the hole for the speaker in the cabin roof, a lifeboat is mounted on spacers above the hole. The lifeboat was bought as a 3D printed item and painted appropriately.

With all the bits and pieces fitted, time for a short video:

The light was bought on-line and simply plugs into a spare channel on the Rx. Using the corresponding switch channel on the Tx allows four different flashing patterns to be selected in sequence.

The two tone horn is provided by a small waterproof speaker mounted on the underside of the main cabin roof. This is driven by a two tone oscillator (yes, another PIC!) plugged into another Rx channel. To disguise the hole for the speaker in the cabin roof, a lifeboat is mounted on spacers above the hole. The lifeboat was bought as a 3D printed item and painted appropriately.

With all the bits and pieces fitted, time for a short video:

▲

⟩⟩

Seanympth

robbob

Colin H

mturpin013

philcaretaker

Rock

jbkiwi

dave976

redpmg

DWBrinkman

stevedownunder

Martin555

|

💬 Re: Blues and Twos

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 153 Views · 2 Likes

Flag

That's pretty cool Graham, I'm sure he's going to have a lot of fun with that, (as long as he's not horn happy 😁)

JB ▲

⟩⟩

Graham93

Martin555

|

|

💬 Re: Blues and Twos

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 166 Views · 3 Likes

Flag

Hi Graham,

I think Finley is really going to love it. Martin555. ▲

⟩⟩

Graham93

dave976

stevedownunder

|

📝 Lights

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 173 Views · 12 Likes · 3 Comments

Flag

💬 Add Comment

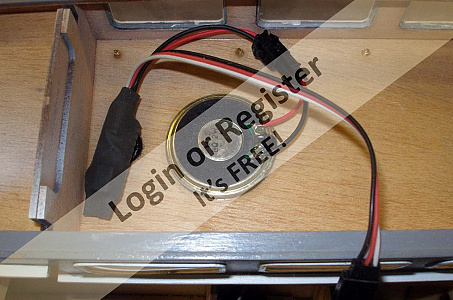

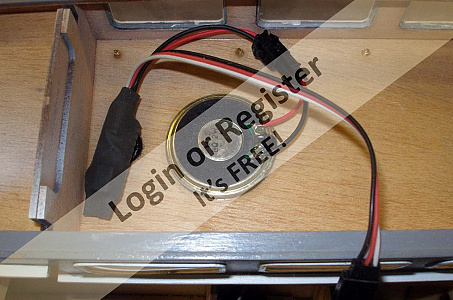

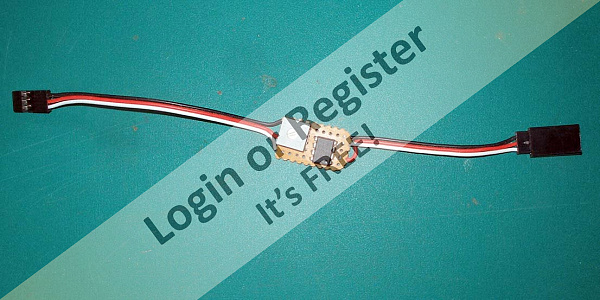

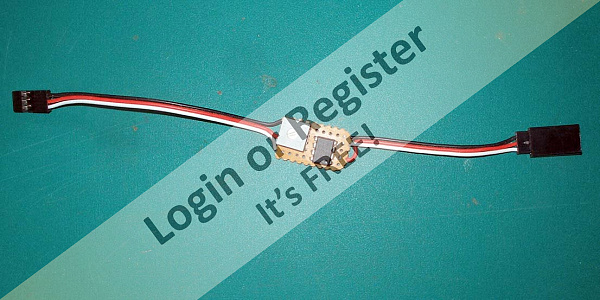

The navigation lights are simply red and green leds fitted through holes in the cabin roof. The leds are wired in series and connected to one port of a two port RCswitch.

A simple searchlight was built from bits of plastic tube and fitted with a 5mm white led. This is connected to the second port of the two port RCswitch.

The RCswitch is homemade based on a PIC microchip programmed to allow control of the two outputs from the Ch4 joystick on the Tx. From centre position, pushing the joystick to one side turns on the nav lights. Pushing it to the other side turns on the spotlight. Repeating these movements turns off the lights. The RCswitch, protected with green heatshrink, is attached to the underside of the cabin roof with velcro.

A simple searchlight was built from bits of plastic tube and fitted with a 5mm white led. This is connected to the second port of the two port RCswitch.

The RCswitch is homemade based on a PIC microchip programmed to allow control of the two outputs from the Ch4 joystick on the Tx. From centre position, pushing the joystick to one side turns on the nav lights. Pushing it to the other side turns on the spotlight. Repeating these movements turns off the lights. The RCswitch, protected with green heatshrink, is attached to the underside of the cabin roof with velcro.

▲

⟩⟩

Seanympth

robbob

RNinMunich

Colin H

mturpin013

philcaretaker

redpmg

dave976

jbkiwi

Martin555

Mike Stoney

stevedownunder

|

💬 Re: Lights

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 164 Views · 2 Likes

Flag

JB,

I'm not sure who is getting the most fun out of this build, me or Finley 🤔 He hasn't been here to help with the electronics, but I'm sure he will be here for the maiden voyage 😀 Graham93 ▲

⟩⟩

RNinMunich

Martin555

|

|

Login To

Remove Ads 💬 Re: Lights

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 167 Views · 3 Likes

Flag

Hi Graham, young Finley's done a great job of building the model and fitting all the electronics 😁, I'm sure he'll be wanting to do another one soon😉🙄

JB ▲

⟩⟩

Seanympth

Graham93

Martin555

|

|

💬 Re: Lights

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 174 Views · 3 Likes

Flag

Hi Graham I'm sorry I've not commented on this build since a month ago but for some reason a whole load of updates have just come through not just yours but some others as well.

Anyway its looking great and ready for a "wetting"? The blue police light looks good I think its the same as one I picked up at Blackpool show last month, it has different settings? so keep up the good work and lets see what Finley decides to build next 🤔. ▲

⟩⟩

Seanympth

Graham93

Martin555

|

📝 Radar

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 185 Views · 13 Likes · 8 Comments

Flag

💬 Add Comment

I want to add as many 'bells and whistles' to the boat as I reasonably can to give my grandson plenty of controls to operate. That should make it more interesting (and challenging) for him to operate.

First up is the radar. Martin recently posted in his blog an excellent write-up of how to build and motorise a radar:

First up is the radar. Martin recently posted in his blog an excellent write-up of how to build and motorise a radar:

▲

⟩⟩

Seanympth

robbob

mturpin013

philcaretaker

redpmg

stevedownunder

Scratchbuilder

dave976

Mike Stoney

GaryLC

Rowen

Colin H

jbkiwi

|

💬 Re: Radar

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 175 Views · 0 Likes

Flag

Thank's Graham.

I will take a look. Martin555. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Radar

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 180 Views · 5 Likes

Flag

Martin,

Microchip ( ▲

⟩⟩

Seanympth

philcaretaker

Mike Stoney

stevedownunder

Martin555

|

|

💬 Re: Radar

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 179 Views · 1 Like

Flag

Thank you Graham.

Not quite as simple as i had expected. What software do you use to program the PIC ? Martin555. ▲

⟩⟩

stevedownunder

|

|

💬 Re: Radar

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 183 Views · 5 Likes

Flag

Hi Martin,

As you have probably seen in my previous blogs I like to build my own RC mixers, switches, smokers etc. The pulse generator/RCswitch is built from just 3 components, a potentiometer to adjust the pulse width (motor speed), a PIC microchip, and a decoupling capacitor ( mounted on the back of the board). I wrote some software which is programmed into the PIC to monitor the incoming signal from the Rx channel. If the incoming pulse width is greater than 1.5mS then the RCswitch is ‘on’. While the switch is ‘on’, the PIC generates a repeating string of pulses for the radar servo. The width of these pulses is set by the potentiometer. Hope that’s clear and understandable 🤔 Graham93 ▲

⟩⟩

philcaretaker

mturpin013

stevedownunder

dave976

Martin555

|

|

💬 Re: Radar

3 years ago by 🇨🇭 Mike Stoney (

Commander) Commander)✧ 180 Views · 3 Likes

Flag

Hello Graham!

Graham, you saved me! Soon wanted to buy an expensive motor with gearbox for my radar! I have so many old servos that I can easily convert! **** What I learned from you in a short time is amazing! Handicraft greetings from Heidiland. .😁😁😁 Michel-Claude ▲

⟩⟩

stevedownunder

dave976

Graham93

|

|

💬 Re: Radar

3 years ago by 🇨🇦 Rowen (

Captain) Captain)✧ 188 Views · 2 Likes

Flag

Have done something similar on previous radars. Found a cheap, geared 6V motor available from our usual Far Eastern sources though.

Found the servo approach bulky, noisy and heavy. ▲

⟩⟩

dave976

Graham93

|

|

💬 Re: Radar

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 185 Views · 2 Likes

Flag

Good idea with the 'fiddle limiter' Graham 👍

JB ▲

⟩⟩

Graham93

Martin555

|

|

💬 Re: Radar

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 182 Views · 2 Likes

Flag

Hi Graham,

Thank you for the comments and posting the links. The transfers really add that extra professional Finnish to what is already a Professional job. Great work. I would be very interested in knowing more about the adjustable pulse generator that you have made (photo five). Martin555. ▲

⟩⟩

dave976

Graham93

|

📝 Fitting the motor and rudder

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 185 Views · 13 Likes · 6 Comments

Flag

💬 Add Comment

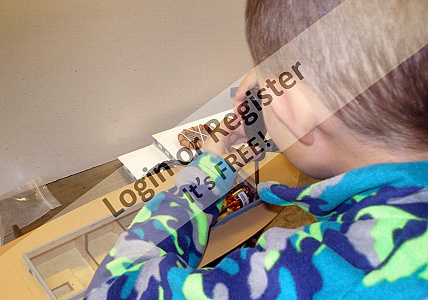

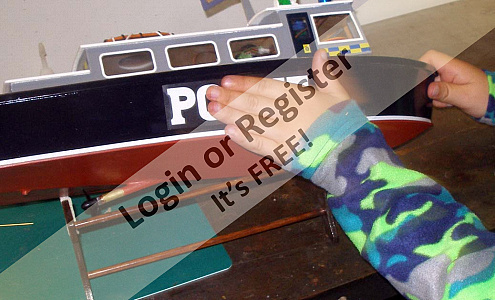

Before fitting the motor, Finley added vinyl decals to each side of the hull. I'd sourced these from ebay and it was a simple task to position them and rub them down onto the hull before peeling off the protective film. The hull will be lacquered later to seal and protect the decals.

The motor was screwed into position on the previously installed mounting block. Small fingers are definitely an advantage when placing the screws into position 😉. The propshaft was coupled to the motor with a metal flexible joint. Connecting the ESC, battery and a servo tester allowed for a quick test of the installation. The noise was terrible !🙉 Despite the care taken earlier in the build to align the motor and propshaft, something was not right. Loosening the motor mount screws and wiggling the motor mount resulted in better alignment and slightly less noise 🤔.

Moving on to the rudder, the 9g servo was fitted to the mounting plate and a wire link connected between the rudder horn and servo. Again small fingers made this easier. A quick test showed the rudder works smoothly - and without any significant noise! 👍

Once Finley had gone home I decided to revisit the motor coupling issue. JBkiwi uses rubber tubing to link his motors to propshafts so a length of 3mm bore silicone vacuum hose was ordered to replace the metal coupling. This turned out to be a bargain. A 500mm length of silicone tube, 3mm bore with 2mm thick walls sent by First Class post for a total cost of 99p. There is enough tube for at least 10 couplings for less than 10p each 👍👍

Fitting the new coupling was straightforward. The motor shaft and propshaft are both 4mm dia so the silicone is a tight fit. I did have to shorten the propshaft tube by 5mm to give enough exposed shaft to slide the coupling onto as well as having enough room to fit a brass collar between the coupling and the propshaft. This collar is held in place with a grubscrew and ensures that the propshaft cannot slide out of the tube should there be any slippage of the coupling on the shaft.

I'm pleased to be able to report that there is now an acceptable level of noise when the motor is running. All of the noise is now the usual high pitched whine from the motor, with no sound from the coupling.😁

The motor was screwed into position on the previously installed mounting block. Small fingers are definitely an advantage when placing the screws into position 😉. The propshaft was coupled to the motor with a metal flexible joint. Connecting the ESC, battery and a servo tester allowed for a quick test of the installation. The noise was terrible !🙉 Despite the care taken earlier in the build to align the motor and propshaft, something was not right. Loosening the motor mount screws and wiggling the motor mount resulted in better alignment and slightly less noise 🤔.

Moving on to the rudder, the 9g servo was fitted to the mounting plate and a wire link connected between the rudder horn and servo. Again small fingers made this easier. A quick test showed the rudder works smoothly - and without any significant noise! 👍

Once Finley had gone home I decided to revisit the motor coupling issue. JBkiwi uses rubber tubing to link his motors to propshafts so a length of 3mm bore silicone vacuum hose was ordered to replace the metal coupling. This turned out to be a bargain. A 500mm length of silicone tube, 3mm bore with 2mm thick walls sent by First Class post for a total cost of 99p. There is enough tube for at least 10 couplings for less than 10p each 👍👍

Fitting the new coupling was straightforward. The motor shaft and propshaft are both 4mm dia so the silicone is a tight fit. I did have to shorten the propshaft tube by 5mm to give enough exposed shaft to slide the coupling onto as well as having enough room to fit a brass collar between the coupling and the propshaft. This collar is held in place with a grubscrew and ensures that the propshaft cannot slide out of the tube should there be any slippage of the coupling on the shaft.

I'm pleased to be able to report that there is now an acceptable level of noise when the motor is running. All of the noise is now the usual high pitched whine from the motor, with no sound from the coupling.😁

▲

⟩⟩

Seanympth

robbob

mturpin013

RNinMunich

Rowen

Scratchbuilder

redpmg

dave976

jbkiwi

stevedownunder

GaryLC

Colin H

philcaretaker

|

💬 Re: Fitting the motor and rudder

3 years ago by 🇨🇦 Rowen (

Captain) Captain)✧ 188 Views · 1 Like

Flag

Have had similar experiences of excess noise using that style of coupling. If you push a length of plastic type tubing over the whole assembly it stiffens and damps the noise

▲

⟩⟩

Graham93

|

|

Login To

Remove Ads 💬 Re: Fitting the motor and rudder

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 188 Views · 3 Likes

Flag

Graham.

Trust me.I know.😤😂😂😂😂 Your right,but it’s great fun. Trouble is,when it comes to computing and various modern skills there way above me 🤔😅. Great to see the youngsters taking on the older skills we love. Regards Bill. ▲

⟩⟩

Seanympth

Martin555

Colin H

|

|

💬 Re: Fitting the motor and rudder

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 185 Views · 4 Likes

Flag

Bill,

🤣😂 That’s exactly what it’s like 🙄 Graham93 ▲

⟩⟩

Seanympth

mturpin013

Martin555

Scratchbuilder

|

|

💬 Re: Fitting the motor and rudder

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 187 Views · 3 Likes

Flag

Now then Grandad !

This is the way we do it. I know you have done it before,but….times have moved on,so….just watch and learn. Great,so nice to see. Regards Bill. ▲

⟩⟩

Colin H

Graham93

Martin555

|

|

💬 Re: Fitting the motor and rudder

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 3 Likes

Flag

Hi Graham,

I hope you are picking up a few tips from young Finley. He looks as though he knows what he is doing. Martin555. ▲

⟩⟩

RNinMunich

Colin H

Graham93

|

|

💬 Re: Fitting the motor and rudder

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 7 Likes

Flag

Hi Graham, boat's coming along well, and small more flexible fingers must be a big help with small screws.😁 Glad you found the tube coupling idea useful,- I've given up on any Chinese couplings, they are all rubbish for anything high speed and the type you tried are especially bad, as the center crosses have too much side play, and get thrown off center at speed. The shaft holes usually have too much clearance as well, making it worse. The tube by itself is perfect for smaller motors or as I've found, with a firm plastic tube covering for more powerful motors.

Once the lathe is sorted, I'm going to try out an idea for stepped shaft adaptors with silicone in between, (similar to the moulded ones or rubber type from CMB) but with the tubing being able to be replaced if it starts slipping due to oil getting in, or whatever. The best thing about the tubing is that if you get something tangling the prop, it will usually just let go and squeal, but grip again when you stop. As long as you have a collet or similar against each end of it, it shouldn't migrate up the shaft towards the motor (hence the idea of the stepped adaptors) won't matter with outrunners, more inrunners/brushed motors. Interested to see how it runs with that set-up. I'm going to try and find some thicker walled tube for my adaptor idea, as I'm only using 2m wall fuel tubing at the moment. JB ▲

⟩⟩

Seanympth

Colin H

Scratchbuilder

redpmg

dave976

Graham93

Martin555

|

📝 Painting the hull

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 195 Views · 13 Likes · 8 Comments

Flag

💬 Add Comment

With the hull assembly complete, its time to get painting!

The hull was first coated with epoxy resin and fibreglass cloth.

Once set, the rubbing strips were shaped and fitted to the gunwales. A former to bend these strips was cut from some scrap MDF using the top deck outline left in the laser cut ply as a template. The rubbing strips were soaked in hot water, clamped in the former until dry and then glued in place.

Grey primer and knifing putty were used to prepare the hull for the finish coats of paint. The deck was been painted with a textured paint to give a non-slip appearance. The hull sides are dark blue (left over from the Gaff Cutter). Below the waterline is red primer.

A white pinstripe was added to separate the two colours.

The kit comes with 3D printed window frames. These were primed with an etch primer and then painted white. Windows are glazed with clear plastic sheet which was also supplied with the kit. The superstructure was painted grey and the completed windows glued in place.

Finally a few decals complete the overall effect.

Finley has been back at school so he hasn't seen the recent progress but it is half term this week. He's going to be a bit surprised when he sees it!

Now it's time to start adding the electronics..

The hull was first coated with epoxy resin and fibreglass cloth.

Once set, the rubbing strips were shaped and fitted to the gunwales. A former to bend these strips was cut from some scrap MDF using the top deck outline left in the laser cut ply as a template. The rubbing strips were soaked in hot water, clamped in the former until dry and then glued in place.

Grey primer and knifing putty were used to prepare the hull for the finish coats of paint. The deck was been painted with a textured paint to give a non-slip appearance. The hull sides are dark blue (left over from the Gaff Cutter). Below the waterline is red primer.

A white pinstripe was added to separate the two colours.

The kit comes with 3D printed window frames. These were primed with an etch primer and then painted white. Windows are glazed with clear plastic sheet which was also supplied with the kit. The superstructure was painted grey and the completed windows glued in place.

Finally a few decals complete the overall effect.

Finley has been back at school so he hasn't seen the recent progress but it is half term this week. He's going to be a bit surprised when he sees it!

Now it's time to start adding the electronics..

▲

⟩⟩

Seanympth

robbob

mturpin013

Scratchbuilder

RNinMunich

philcaretaker

dave976

jbkiwi

stevedownunder

Newby7

Martin555

Madwelshman

Colin H

|

💬 Re: Painting the hull

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 194 Views · 2 Likes

Flag

Looking good Graham.

The electronics will be an interesting read. Keep it coming. Regards Bill ▲

⟩⟩

Martin555

Graham93

|

|

Login To

Remove Ads 💬 Re: Painting the hull

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 191 Views · 4 Likes

Flag

MODEL BOAT TREK:

COMMODORE'S LOG: YARD DATE 2021 POINT 10 POINT 27: MY CONTINUING MISSION: TO EXPLORE THE MODEL BOAT UNIVERSE; DISCOVER NEW BOATS AND TAKE YOUNG ENSIGN FINLEY WHERE HE HAS NEVER BEEN BEFORE: Absorbing stuff Graham. With some good tips n tricks along the way. Can hardly wait for Ensign Finley's next furlough from Model Boat Fleet Academy and his response to developments on board! 👍 Cheers, Doug 😎 Possible registration number: MPB1701F (Metropolitan Police Boat) Name: HMPB FINLEY (Her Majesty's Police Boat) 😉 ▲

⟩⟩

Seanympth

Martin555

Graham93

Rookysailor

|

|

💬 Re: Painting the hull

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 193 Views · 6 Likes

Flag

JB,

I’m sure he will find plenty of opportunities to create unintentional smoke in the future. I know I did ( and still do )🤗😠 Graham93 ▲

⟩⟩

mturpin013

Scratchbuilder

dave976

RNinMunich

jbkiwi

Martin555

|

|

💬 Re: Painting the hull

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 191 Views · 4 Likes

Flag

You'll have to let him blow something up Graham,- how's he going to learn otherwise. ⚡⚡⚡🔥😮🙈 That's how most of us did it, (at least I did)😂

JB ▲

⟩⟩

Scratchbuilder

dave976

Graham93

Martin555

|

|

💬 Re: Painting the hull

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 193 Views · 5 Likes

Flag

Hi JB,

I don't think he'll be able to help with the wiring, but there are lights and other bits and pieces to be fitted which he can help with. I'll wire them up once he has gone home 😂🤣 Graham93 ▲

⟩⟩

mturpin013

Scratchbuilder

dave976

Martin555

jbkiwi

|

|

💬 Re: Painting the hull

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 193 Views · 3 Likes

Flag

Looking good Graham, (couldn't help yourself I see)😁😉 The young fella should be happy! Are you going to get him involved in the electrical side,?

JB ▲

⟩⟩

dave976

Graham93

Martin555

|

|

💬 Re: Painting the hull

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 194 Views · 3 Likes

Flag

So right Graham. Finley will be surprised by the build. Nicely done.

Rick ▲

⟩⟩

dave976

Martin555

stevedownunder

|

|

💬 Re: Painting the hull

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 195 Views · 2 Likes

Flag

Great work Graham.

I bet young Finley will be over the moon with his boat. It won't be long and Finley will be asking grandad "when can we put the Police boat in the water." Martin555. ▲

⟩⟩

dave976

stevedownunder

|

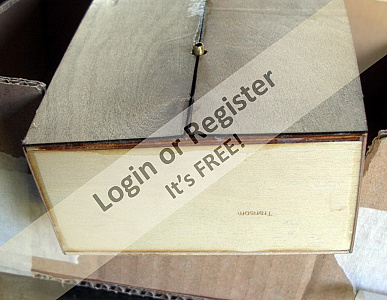

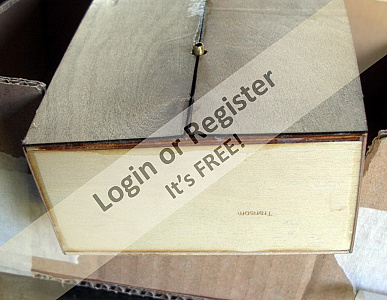

📝 Skinning the hull

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 204 Views · 13 Likes · 7 Comments

Flag

💬 Add Comment

The hull sides and bottom are skinned with 1mm ply. This is supplied laser cut to size.

I held the first side in place while Finley applied the superglue. I'd bought some superglue from the local pound store which came with a long flexible nozzle which was ideal as it allowed me to keep my fingers away from the liberal application of glue by Finley 😉. I'm amused by the wording on the package and haven't yet worked out how to 'reuse' the glue that didn't go in the right place! 😂🤣

Finley's younger sister decided she would like to be involved 🙄 Unfortunately her idea of helping was to grab anything she could in the workshop that was within reach, so we had to cut the session short.

I used my trusty block plane to trim the side to size, and then fitted the other side. Before fitting the bottom panels holes were drilled in the framework so that it would be possible to seal all the internal ply once the hull was complete. The bottom sheets were glued in place and held with masking tape while the glue set. These sheets were barely long enough or wide enough at the transom. A few more mm in length and width would have helped. The gaps were filled with epoxy and smoothed to shape.

I also made a simple stand for the completed model which Finley helped to paint with 'quick drying woodstain'. This is ideal for this application as it is water based and washes off little sticky fingers quite easily 👍

I held the first side in place while Finley applied the superglue. I'd bought some superglue from the local pound store which came with a long flexible nozzle which was ideal as it allowed me to keep my fingers away from the liberal application of glue by Finley 😉. I'm amused by the wording on the package and haven't yet worked out how to 'reuse' the glue that didn't go in the right place! 😂🤣

Finley's younger sister decided she would like to be involved 🙄 Unfortunately her idea of helping was to grab anything she could in the workshop that was within reach, so we had to cut the session short.

I used my trusty block plane to trim the side to size, and then fitted the other side. Before fitting the bottom panels holes were drilled in the framework so that it would be possible to seal all the internal ply once the hull was complete. The bottom sheets were glued in place and held with masking tape while the glue set. These sheets were barely long enough or wide enough at the transom. A few more mm in length and width would have helped. The gaps were filled with epoxy and smoothed to shape.

I also made a simple stand for the completed model which Finley helped to paint with 'quick drying woodstain'. This is ideal for this application as it is water based and washes off little sticky fingers quite easily 👍

▲

⟩⟩

Seanympth

mturpin013

dave976

dads boat

RNinMunich

philcaretaker

redpmg

GaryLC

stevedownunder

jbkiwi

Colin H

Scratchbuilder

Martin555

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 200 Views · 1 Like

Flag

Thanks Red,

Yes, it is a combined water based stain/varnish. Comes in several colours, touch dry in 30 minutes, and the brush ( and little fingers) clean in water 👍 ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Skinning the hull

3 years ago by 🇿🇦 redpmg (

Commodore) Commodore)✧ 201 Views · 2 Likes

Flag

Coming along nicely Graham - sure Finley is enjoying it - sister sounds like our cat - except he tries to sit on whatever it is you are working on..............

Is that a combined Stain/Varnish you gave Finley to use ? Hopefully you will later have a convert to our hobby.......... Definitely good to share with them. ▲

⟩⟩

Martin555

Graham93

|

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 203 Views · 2 Likes

Flag

Thanks everyone for the comments. It’s fun working with the grandson, although progress is slow.

No Mike, the plane isn’t for sale😀 it is far too useful . ▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 205 Views · 4 Likes

Flag

Some really good progress, its great to work with children who are not afraid of anything including sharp knives and super glue😜

I notice that your still using that trusty block plane, are you sure its not for sale.😁 ▲

⟩⟩

RNinMunich

Martin555

stevedownunder

Graham93

|

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 203 Views · 3 Likes

Flag

Well done sir, looks like the youngster is enjoying the build with you. Tell the lad well done from me.

Cheers Colin. ▲

⟩⟩

Graham93

stevedownunder

Martin555

|

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 207 Views · 3 Likes

Flag

Graham.

Looking good,congratulations. Good to see you have the workshop Forman there to help you and make sure Grandad gets it right. Let’s hope that he carries on the good work. Regards Bill. ▲

⟩⟩

Graham93

stevedownunder

Martin555

|

|

💬 Re: Skinning the hull

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 203 Views · 2 Likes

Flag

Hi Finley and Graham,

Finley you are doing a really good job on your boat. It is good that you have your grandad there to help you and i am looking forward to seeing more of your build. Keep up the good work Finley. Graham, I have some of that reusable glue and like you i don't know how to reuse it ether. LOL!! Martin555. ▲

⟩⟩

Graham93

stevedownunder

|

📝 Rudder and servo

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 215 Views · 11 Likes · 6 Comments

Flag

💬 Add Comment

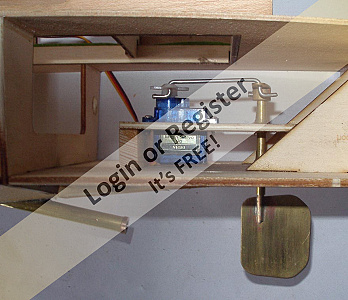

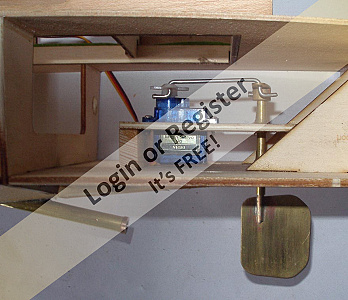

Another part of the RC installation best completed before the skins are applied to the hull is the rudder and associated servo.

A simple rudder was first made from some thin brass sheet and a length of 3mm brass rod. I think it may be a bit on the large size, but better that than too small. I can always trim it down if it proves to be overly effective.

There is no information with the kit about locating the rudder. A laser etched marking for the recommended position would be helpful for a novice building the kit. I chose a position to give plenty of clearance behind the prop on the basis that 'if it looks right, it probably is'... time will tell.

A brass tube was installed through the bottom of the hull. A servo mount was cut from spare ply that came with the kit. The top of the rudder tube passes through this ply panel and is epoxied in place to provide plenty of support.

Now that the motor and rudder installation are complete, it is time to fit the side and bottom skins. I just need to wait for Finley's return....

A simple rudder was first made from some thin brass sheet and a length of 3mm brass rod. I think it may be a bit on the large size, but better that than too small. I can always trim it down if it proves to be overly effective.

There is no information with the kit about locating the rudder. A laser etched marking for the recommended position would be helpful for a novice building the kit. I chose a position to give plenty of clearance behind the prop on the basis that 'if it looks right, it probably is'... time will tell.

A brass tube was installed through the bottom of the hull. A servo mount was cut from spare ply that came with the kit. The top of the rudder tube passes through this ply panel and is epoxied in place to provide plenty of support.

Now that the motor and rudder installation are complete, it is time to fit the side and bottom skins. I just need to wait for Finley's return....

▲

⟩⟩

Seanympth

philcaretaker

dave976

RNinMunich

Colin H

mturpin013

stevedownunder

redpmg

Martin555

jbkiwi

Scratchbuilder

|

💬 Re: Rudder and servo

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 211 Views · 3 Likes

Flag

Hi Martin, Red,

I have a rule that I will only have one build on the go at a time. Trying to build more than one at a time just makes it stressful.There are plenty of other (non modelling) tasks to keep me busy during pauses in the build. I do have a few ideas about what to build next, but I have to help Finley finish this build first 😉 ▲

⟩⟩

Seanympth

Martin555

redpmg

|

|

Login To

Remove Ads 💬 Re: Rudder and servo

3 years ago by 🇿🇦 redpmg (

Commodore) Commodore)✧ 213 Views · 2 Likes

Flag

Hi Graham - difficult not to do too much - the urge to take over is strong - but you have to remember how we all started - lots of blunders - some of them irreparable until some kind expert helped - that's the sort of role we have to adopt if we are to interest them in what we do.

Perhaps you should start another smaller kit for yourself apart from any other new build - only work on that when you are together - that way some of the temptation will be avoided - seem to be plenty of other kits on offer from SLEC - Cornwall MB online shop also has a few listed - similar sort of prices to HA . Perkins have a couple listed on their website too if memory serves. ▲

⟩⟩

Seanympth

Martin555

|

|

💬 Re: Rudder and servo

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 210 Views · 1 Like

Flag

Graham.

Great i am glad you are managing to leave plenty for Finley to do. I do hope you are giving it some thought as to what your next project will be as we all really look forward to your build logs. Martin555. ▲

⟩⟩

Graham93

|

|

💬 Re: Rudder and servo

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 212 Views · 3 Likes

Flag

Hi Martin,

I don’t think so, at least I hope not! He is keen to help, which is great as I want him to feel like he’s built it, rather than it being something that Granddad made and gave him. So far it’s working out OK although progress is slow. I’ve been trying not to do too much without him, which is difficult, so I have been making all sorts of bits and pieces which will be added as the build progresses. ▲

⟩⟩

Martin555

jbkiwi

Colin H

|

|

💬 Re: Rudder and servo

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 212 Views · 4 Likes

Flag

Nice work Graham.

I think Finley has wised up. He knows that you will not be able to just sit there without doing something to his boat.LOL!! He is also probably thinking to him self ' if i keep away for a month or two most of the boat will be done' LOL!! Martin555. ▲

⟩⟩

Colin H

jbkiwi

Graham93

stevedownunder

|

|

💬 Re: Rudder and servo

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 212 Views · 4 Likes

Flag

Hi Graham, agree with you about fitting internals (or at least setting them up for later) without the sheeting, - makes life a lot easier when you are not having to work blind at times, or having to use mirrors.

JB ▲

⟩⟩

Colin H

Graham93

stevedownunder

Martin555

|

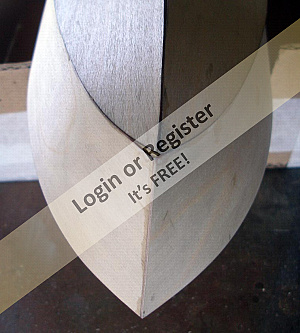

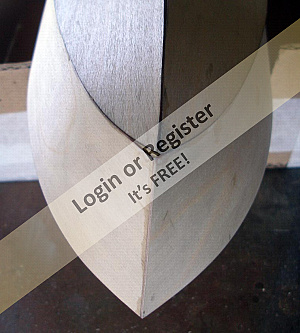

📝 Motor and Propshaft

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 238 Views · 11 Likes · 11 Comments

Flag

💬 Add Comment

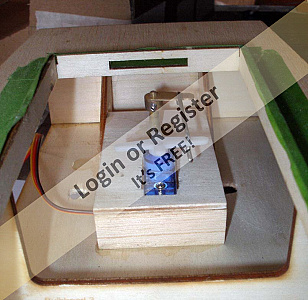

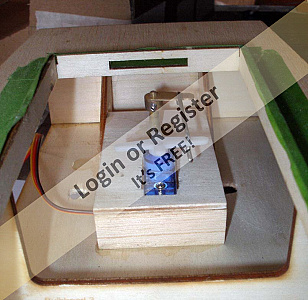

Before Finley returns to continue with the construction. I need to install and align the motor and propshaft.

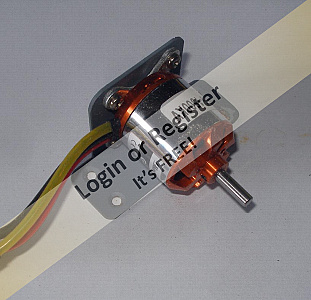

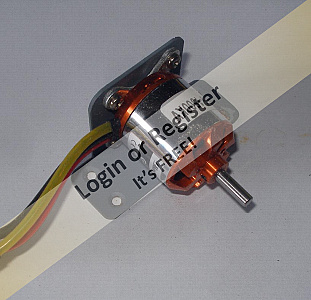

The instruction booklet suggests fitting a 1500kV brushless motor which surprised me as I was expecting it to call for a brushed motor, but I thought 'why not?' so a suitable motor and ESC were ordered.

First job once the motor arrived was to make a mounting bracket. I found an old domestic radiator mounting bracket in the scrap box. A short length cut from this gave a strong, lightweight right angled bracket. Four holes were drilled and tapped for the motor mount, and another four holes drilled and countersunk for screwing the bracket into the hull.

The motor has a 4mm dia. shaft and I'd already found a 30mm propeller, left over from Crash Tender commissioning, which had an M4 thread. Based on these part dimensions, I decided to use a 4mm propshaft and a 7mm dia. outer tube. With the tube in situ, but not glued, a hardwood wedge was made to match the angle of the tube. To align the motor shaft with the tube, an alignment tool was made. This is simply a length of steel which was turned to be a sliding fit in the propshaft tube, and with a 4mm hole to slip over the motor shaft. With this tool, it was a simple matter to adjust the heights of the wooden wedge to align the motor shaft with the propshaft tube. The wedge was then glued into position.

While the glue was drying, two phosphor bronze bushes were turned for the propshaft. With these fitted, and the alignment tool used to ensure everything was in line, the propshaft tube was epoxied into position.

Finally, the alignment tool was replaced with a universal coupling, and the other end of the shaft was threaded M4 so that the propeller could be attached. A quick check was carried out with the ESC attached and powered up. All seems to be OK so far. 🤞

The instruction booklet suggests fitting a 1500kV brushless motor which surprised me as I was expecting it to call for a brushed motor, but I thought 'why not?' so a suitable motor and ESC were ordered.

First job once the motor arrived was to make a mounting bracket. I found an old domestic radiator mounting bracket in the scrap box. A short length cut from this gave a strong, lightweight right angled bracket. Four holes were drilled and tapped for the motor mount, and another four holes drilled and countersunk for screwing the bracket into the hull.

The motor has a 4mm dia. shaft and I'd already found a 30mm propeller, left over from Crash Tender commissioning, which had an M4 thread. Based on these part dimensions, I decided to use a 4mm propshaft and a 7mm dia. outer tube. With the tube in situ, but not glued, a hardwood wedge was made to match the angle of the tube. To align the motor shaft with the tube, an alignment tool was made. This is simply a length of steel which was turned to be a sliding fit in the propshaft tube, and with a 4mm hole to slip over the motor shaft. With this tool, it was a simple matter to adjust the heights of the wooden wedge to align the motor shaft with the propshaft tube. The wedge was then glued into position.

While the glue was drying, two phosphor bronze bushes were turned for the propshaft. With these fitted, and the alignment tool used to ensure everything was in line, the propshaft tube was epoxied into position.

Finally, the alignment tool was replaced with a universal coupling, and the other end of the shaft was threaded M4 so that the propeller could be attached. A quick check was carried out with the ESC attached and powered up. All seems to be OK so far. 🤞

▲

⟩⟩

Seanympth

dave976

Colin H

philcaretaker

redpmg

Martin555

Newby7

mturpin013

stevedownunder

jbkiwi

RNinMunich

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 214 Views · 1 Like

Flag

Thank's Graham.

I am looking forward to seeing your next project. Your build logs are really interesting so i really hope you do another log soon. Martin555. ▲

⟩⟩

Graham93

|

|

Login To

Remove Ads 💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 218 Views · 4 Likes

Flag

Hi Red,

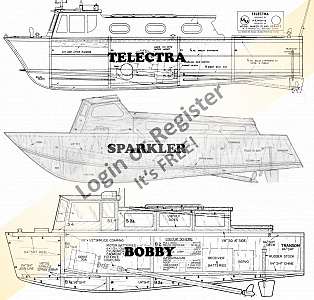

It has worked out well for the grandson to build, or at least to help with the build. I think it would be something of a challenge for a novice without any experience as there is missing guidance on fitting the RC gear, and the best stages during construction to carry out some of the equipment installation. Looking at the Bobby plan, it does look very similar. Graham93 ▲

⟩⟩

Seanympth

Colin H

jbkiwi

Martin555

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 218 Views · 2 Likes

Flag

Thanks Martin,

Unfortunately, now he is back at school, I'm not seeing as much of Finley, so progress is very slow. (Really pleased you are back on the site with us!) Graham93 ▲

⟩⟩

Seanympth

Martin555

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇿🇦 redpmg (

Commodore) Commodore)✧ 218 Views · 4 Likes

Flag

Great build blog Graham - wish my grandson lived a bit closer (1000 odd miles) so we could finish his boat.

Good choice of kit for a child as its designed on the EeZeBilt method - simple lock together construction . Looks like it was based on the Bobby which was a free plan in MB many years ago. One good thing about brushless motors is the aircraft ESC's are cheap - and with your knowledge of electrics you should be able to sort out a reverse switch easily............ Will be following your blog with interest

▲

⟩⟩

Colin H

jbkiwi

Martin555

Graham93

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 216 Views · 3 Likes

Flag

Hi Graham,

I nearly missed this log. Please tell young Finley that i am following his build, and to keep up the good work. Young Finley cannot ask for a more excellent teacher. Martin555. ▲

⟩⟩

Seanympth

jbkiwi

Graham93

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 223 Views · 2 Likes

Flag

Rick,

Yes he will. Trouble is that he is now back at school so not sure when he will have time. His diary is busier than mine 🙄 ▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 223 Views · 2 Likes

Flag

Nice job Graham.With power in Finley will be able to proceed to all the good parts of the build.

Rick ▲

⟩⟩

Martin555

Graham93

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 228 Views · 3 Likes

Flag

Exactly right Michael. Wood moves with changes in temperature/humidity. I thinks some sort of flexible joint is essential.

Graham93 ▲

⟩⟩

Seanympth

Martin555

RNinMunich

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 227 Views · 2 Likes

Flag

Removed as its Duplicated below

▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 227 Views · 5 Likes

Flag

Hi Graham that looks a nice assembly, in particular the modified Phosphor bronze bushes, I see a joint in the drive chain, a lot of modelers go for a solid connector taking great care to align the motor and prop shaft, I personally think this isn't the best option, the reason being having done this myself and gone to the trouble of using a dial indicator to align the shafts in the workshop (workshop heated) I later went to the test tank (in the garage cold) and found the alignment was no longer ! this was due to temperature change when wood has a habit of moving around at different temperatures.

I'm sure that some sort of universal joint is the way to go, It may be with some types they are a little noisier but still probably not as noisy as a brushless motor anyway. I still go to the trouble of aligning the shaft and motor with a solid joint first and then replace it with an appropriate flexible joint. As demonstrated in Grahams description😊 ▲

⟩⟩

Seanympth

Martin555

RNinMunich

Graham93

stevedownunder

|

|

💬 Re: Motor and Propshaft

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 230 Views · 3 Likes

Flag

Hi Graham,

I bet Finley will be eager to get cracking on this boat, can't start them too young. Cheers, Stephen. ▲

⟩⟩

jbkiwi

Martin555

Graham93

|

United Kingdom

United Kingdom