Join Us On Social Media!

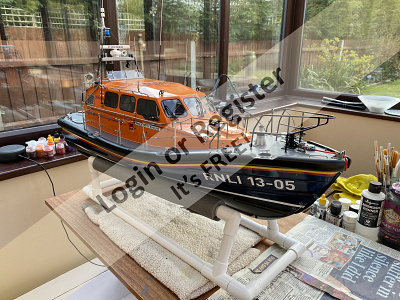

Speedline Models RNLI Shannon Class Lifeboat 1:16 scale

31 Posts · 18 Followers · 226 Photos · 238 Likes

Began 5 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 5 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Test run......

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 117 Views · 14 Likes · 17 Comments

Flag

💬 Add Comment

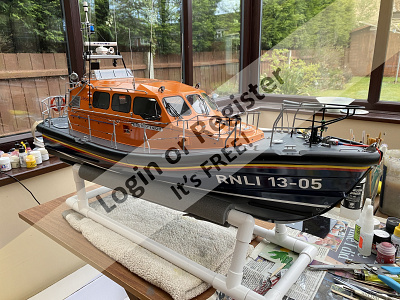

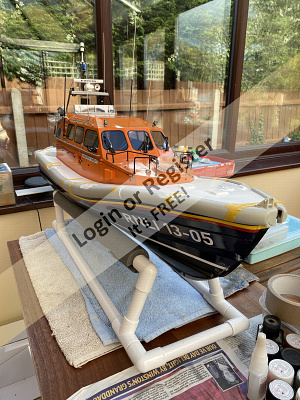

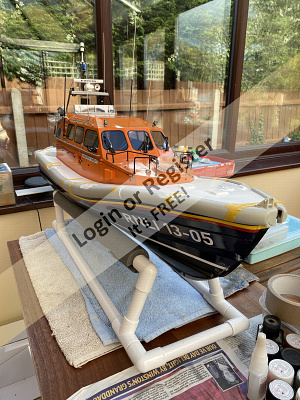

So, on a chilly Southwold boating lake, my completed “Shannon” got her first run on a choppy water. Overall she went great, top speed was as scale as you like, any faster it would look silly. Also very pleased with the sound of the jet drives and brushless motors, so much so I might remove the speaker and sound system at some point as I think the boat needs to be a little lighter, sitting a little low in the water?

After 15 minutes run time, still plenty of battery left, didngt get low enough for the lipo alarms to kick in and everything inside was still cool, so no over heating issues. There was a little water inside after sailing, I’m putting this down to the reverse buckets as they through up a lot of spray in reverse?

It’s been a long five months build, but well worth it, she’s deffo a keeper.

There will be a little break before I start the next build as I’ve got decorating tasks ahead, but I’ll be back soon with the build of the Dumas USCG Motor Lifeboat 36500 next .......

After 15 minutes run time, still plenty of battery left, didngt get low enough for the lipo alarms to kick in and everything inside was still cool, so no over heating issues. There was a little water inside after sailing, I’m putting this down to the reverse buckets as they through up a lot of spray in reverse?

It’s been a long five months build, but well worth it, she’s deffo a keeper.

There will be a little break before I start the next build as I’ve got decorating tasks ahead, but I’ll be back soon with the build of the Dumas USCG Motor Lifeboat 36500 next .......

▲

⟩⟩

RossJ

alan44

Seanympth

mistyoptic

GaryLC

robbob

Colin H

T33CNO

Martin555

MouldBuilder

stevedownunder

Rookysailor

Ronald

jbkiwi

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 108 Views · 3 Likes

Flag

Hi Geoff, many thanks for your kind comments and yes, thrilled with her. Just a couple of tweaks and she will be my new favourite!

I shall let my wife’s dad know that the Alfred Corey can remain in her resting place at the museum. Once the museum re-opens next week, Jim will be giving his very informative talks about her, he is the font of all knowledge and his great grandfather was the coxswain on her. As for “Annie”, I think she needs to remain on station for the time being😂 Kind regards. Simon ▲

⟩⟩

Seanympth

stevedownunder

Martin555

|

|

Login To

Remove Ads 💬 Re: Test run......

5 years ago by 🇬🇧 mistyoptic (

Midshipman) Midshipman)✧ 112 Views · 4 Likes

Flag

You must be absolutely thrilled with how she looks on the water, what a marvellous achievement.

No doubt, both the Alfred Corry and the Annie Tranmer can stand down now! Super model Regards Geoff ▲

⟩⟩

Seanympth

stevedownunder

Skydive130

Martin555

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 111 Views · 3 Likes

Flag

Hi JB, many thanks for the tips! I reckon the bucket position in the down position maybe the issue, I’ll have a go at adjusting the trim settings to see if I can reduce the back flow. Failing that I will keep down buckets to a minimum, although the dramatic effect of dropping the buckets at full forward speed is a delight to watch as the boat stops dead!

Kind regards. Sy ▲

⟩⟩

stevedownunder

jbkiwi

Martin555

|

|

💬 Re: Test run......

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 113 Views · 3 Likes

Flag

Hi Sy, don't know if you have room for something like this as a deflector ? Try playing with the bucket down positions. If they are too far down, they tend to fire water back at the transom,- might just need a bit of adjustment. Ideally you want them to fire almost horizontally below the hull in reverse. It can take a bit of mucking around to get them right, - also if the steering nozzles are a bit small (as was the new one I made) you can get pack pressure water blowing back through the gap around the fixed nozzle .

The real jets have a close fitting ball and socket style nozzle set up which prevents this. I thought I was being clever making a close fitting steering nozzle, but the jet was putting out more on mine than the smaller nozzle could handle, so I had to revert to the original larger one, which stopped most of the blow-back. JB

▲

⟩⟩

stevedownunder

Martin555

Skydive130

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 136 Views · 2 Likes

Flag

Hi Sy.

"Any new builds from your good self planned?" Yes, there's a new one lined up from a kit but it's still in final stages of production and adjustments to the CAD files. Hopefully won't be too long now 🤞. In the meantime I'm still catching up with DIY (house painting) and gardening (landscaping and then some new turf) so I've got plenty to keep me busy at the moment. There's a good chance of my club doing a show in September and I'm also hoping to show my boats at the IMBS at Warwick in November too if all goes ahead as planned. Rob. ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 111 Views · 2 Likes

Flag

Hi Martin, I’m going to take out the sound system and half kilo of lead to try and get her higher in the water. She doesn’t need the sound, the motors sound awesome.

Many thanks for following as always and the next build will start soon, watch this space.... Kind regards simon ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 111 Views · 3 Likes

Flag

Cheers Rob, on it like a car bonnet, decorating as we speak. AnyW builds from your good self planned?

Kind regards simon ▲

⟩⟩

stevedownunder

Martin555

robbob

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 111 Views · 2 Likes

Flag

I was glad of my big fleece that’s for sure Steve, but was so nice to see a bit of sunshine!

▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 136 Views · 3 Likes

Flag

Congratulations on another spectacular model and a successful maiden voyage Sy😀👍.

The video of her performing looks great and she's very confident even in choppy water. The water ingress may indeed just be splashback from the drives as mentioned. Now take a break and get that DIY and decorating sorted 😉 Rob. ▲

⟩⟩

stevedownunder

Martin555

Skydive130

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 117 Views · 2 Likes

Flag

Hi Sy,

Fantastic. I really like your work. Your attention to detail is amazing. As you say she dose look a little low in the water but her speed looks just right. And to build her in only five months to that standard is outstanding. I am now looking forward to your next masterpiece. Martin555. ▲

⟩⟩

stevedownunder

Skydive130

|

|

💬 Re: Test run......

5 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 124 Views · 2 Likes

Flag

You really have done an outstanding job Sy. Looks perfect. The detail, as ever, is so good. I can only hope to get to 50% of this skill level.

Peter.😀 ▲

⟩⟩

stevedownunder

Martin555

|

|

Login To

Remove Ads 💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 117 Views · 2 Likes

Flag

I was glad of my big fleece that’s for sure Steve, but was so nice to see a bit of sunshine!

▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Test run......

5 years ago by 🇦🇺 stevedownunder (

Commodore) Commodore)✧ 121 Views · 3 Likes

Flag

Hi Sy,

She looks just as fantastic on the water as she does off, and a lovely little video as well. I guess the RNLI guys would have been worm in their survival suits on the cold Southwold boating lake. 😉 Cheers, Stephen. ▲

⟩⟩

GaryLC

Martin555

Skydive130

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 117 Views · 3 Likes

Flag

Cheers JB, like the sound of the deflectors if I can fashion something that doesn’t show too much?

The lake isn’t my normal lake. My family on my wife’s side are all keen model “yachters”, the type that don’t require RC. The lake has been used for model yachts since the late 1890’s and still drawers plenty of sailors. They have no issue with me tearing up and down after the days comp..... Sy ▲

⟩⟩

jbkiwi

Martin555

stevedownunder

|

|

💬 Re: Test run......

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 117 Views · 2 Likes

Flag

A pleasure Ron, glad you enjoyed it 👍

▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Test run......

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 119 Views · 3 Likes

Flag

Looks great Sy, speed looks pretty scale, (nice wash behind as well) and the boat looks spot on !👍👍 You have to be a happy chap after all that work. . It's normal for jets to be a bit frothy in reverse, - a bit like shooting a fire hose at a wall. I ended up putting a deflector above mine, as I had a similar problem. Nice job all round👍.

Good looking pond you have there a well. JB ▲

⟩⟩

Martin555

stevedownunder

Skydive130

|

|

💬 Re: Test run......

5 years ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 120 Views · 3 Likes

Flag

Looks great on the water. Thanks for sharing your build with us along the way.👍

▲

⟩⟩

Martin555

stevedownunder

Skydive130

|

Login To

Remove Ads

Remove Ads

📝 Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 145 Views · 12 Likes · 29 Comments

Flag

💬 Add Comment

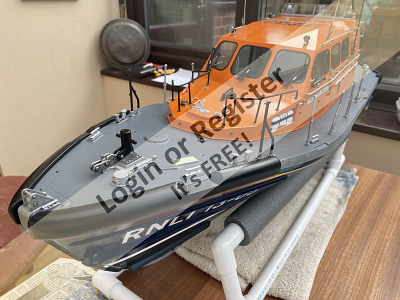

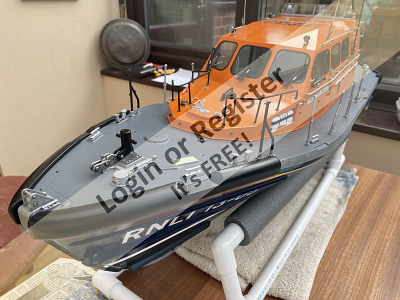

So, at long last I’ve added the finishing touches to the boat itself. This included finishing the railings, sorting the electronics, glueing the main cabin to the deck and a little bit of paint touch up here and there. As Doug rightly says, is a model ever finished? Apart from an RNLI flag to add and the crew, I don’t anticipate adding anymore to it apart from ballast if needed!

Today I set about painting the first of 4 crew figures. I did have 5 figures but I’ve “squirrelled” one away for my next build as these figures are no longer available and he will be ideal for the model, to be revealed! This one figure took about 4 hours of painting post primer, hopefully the other 3 will be quicker!

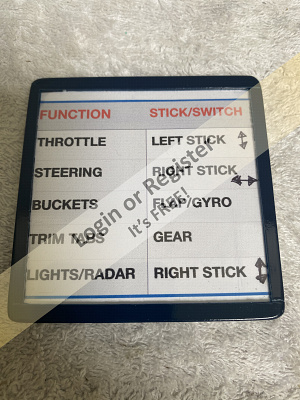

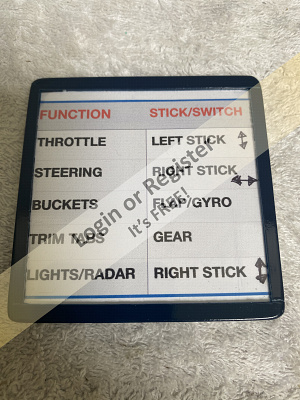

AS this model requires several transmitter inputs, I decided not to put sticky reminder labels on my transmitter. Instead I opted to make a board from plasticard then printed the control inputs, mashed it and painted it. It now slips over the transmitter antenna as a reminder, but once I’ve learnt the controls, I can easily discard.

So, the next update should included the completed figures in position on the boat and then hopefully some shots on the water......

Today I set about painting the first of 4 crew figures. I did have 5 figures but I’ve “squirrelled” one away for my next build as these figures are no longer available and he will be ideal for the model, to be revealed! This one figure took about 4 hours of painting post primer, hopefully the other 3 will be quicker!

AS this model requires several transmitter inputs, I decided not to put sticky reminder labels on my transmitter. Instead I opted to make a board from plasticard then printed the control inputs, mashed it and painted it. It now slips over the transmitter antenna as a reminder, but once I’ve learnt the controls, I can easily discard.

So, the next update should included the completed figures in position on the boat and then hopefully some shots on the water......

▲

⟩⟩

MouldBuilder

stevedownunder

robbob

jbkiwi

Seanympth

Scratchbuilder

RNinMunich

Rookysailor

Julio

T33CNO

Martin555

Colin H

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 T33CNO (

Sub-Lieutenant) Sub-Lieutenant)✧ 130 Views · 1 Like

Flag

He will still make them for friends I’m sure but yes exactly right.

Great job 🤗 ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 126 Views · 2 Likes

Flag

Hi JB, sadly the guy who made these figures has stopped making them. He was doing it for fun, people who bought them were over critical on features, so he decided it wasn’t worth the hassle. Very sad 😢

▲

⟩⟩

Martin555

jbkiwi

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 131 Views · 2 Likes

Flag

Figures look great Sy, - hard to find decent figures for certain scales, we're not exactly spoilt for choice unless you want to pay silly prices.😐

JB ▲

⟩⟩

Skydive130

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 136 Views · 1 Like

Flag

Excellent Sy,

Looking forward to it. Martin555. ▲

⟩⟩

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 132 Views · 1 Like

Flag

I like her simple lines Martin and it’s a little different from my norm. There’s plenty of scope to super detail the cabin area and add the canvas roof and sides that she sports in real life. Also the kit detail parts have plenty of scope for improvement or replace with scratch built.

As for a “what’s in the box”, no problem, once I start the post that will be the first entry 👍 ▲

⟩⟩

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 137 Views · 1 Like

Flag

Hi Sy,

I knew it was USCG but unsure as to what model. Was expecting something with a lot of detail on the deck. This boat however looks very nice and i am looking forward to seeing you work your magic on her. How about a 'Whats in the box review' before you start. Martin555. ▲

⟩⟩

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 136 Views · 1 Like

Flag

Wasn't so hard Sy, the clues were pretty broad 😉

The kit seems a bit spartan, so plenty of scope for your 'detailing'. Looking forward to that 👍 Go Sy Go! 😁 😎 ▲

⟩⟩

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 133 Views · 2 Likes

Flag

Boom! Nailed it Doug, that’s 2 cents of 1€ I owe you 😂😂😂.

It’s a pretty little thing with an interesting history and a well documented rescue. Happy to report it’s a better quality kit by Dumas after a previous experience with one of theirs. The original 36500 is still about in the states, so plenty of reference available. I shall hopefully be starting her in June after the finale on the Shannon and a few essential tasks about the house 👍 ▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 136 Views · 2 Likes

Flag

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 134 Views · 1 Like

Flag

Cheers Rob, let the guessing game begin, if the clues are anything to go by, it should be reasonably easy to work out 😂😂😂

▲

⟩⟩

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 151 Views · 3 Likes

Flag

Hi Sy.

Congratulations on completing another masterpiece 👏 😀. Supreme workmanship and finish as always. So onto the next project then......and just like everyone else I'm intrigued as to what it will be after considering the 'clues' that you have given us. Looking forward to seeing some video of this one and the RHIB too. Rob. ▲

⟩⟩

hmsnostalgia

Martin555

Skydive130

|

|

Login To

Remove Ads 💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 137 Views · 2 Likes

Flag

Hi Stephen, many thanks for joking the party and thank you for your kind comets.

Kind regards Sy ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇦🇺 stevedownunder (

Commodore) Commodore)✧ 142 Views · 2 Likes

Flag

Absolutely stunning Sy,

Fantastic boat and crew member, looks like 4 hours well spent in my opinion. Cheers, Stephen. ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 141 Views · 1 Like

Flag

In Chile and Brazil as well Sy 👍

😎 ▲

⟩⟩

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 138 Views · 2 Likes

Flag

Cheers Mike, sea trials soon! As for getting back to wood, indeed poetic licence and the chance to make those little things👍

Kind regards Sy ▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 138 Views · 4 Likes

Flag

JB, that business of the water going down the plug the other way in the Southern Hemisphere is myth, when I was in Australia in went the same way 😂😂😂

▲

⟩⟩

Martin555

jbkiwi

stevedownunder

RNinMunich

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 141 Views · 3 Likes

Flag

Hi Sy what a great finish, it is surly one of the smartest models on the site, we are all looking forward to sea trials.

Your next project is to be wood - welcome back to real creative modelling and a bit of poetic licence.😁 ▲

⟩⟩

Martin555

stevedownunder

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 139 Views · 3 Likes

Flag

I think it's mainly the Northern hemisphere which likes mode 2 Sy, cos you guys are upside down to us, 😂 water runs a different way down the plug hole down here😁

JB ▲

⟩⟩

stevedownunder

Skydive130

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 138 Views · 4 Likes

Flag

Indeed JB, train on one mode, try and switch to another mode, thinking throttle is elevator and vice versa, result, model re-kitted! I think mode 2 is the norm in Uk?

Hopefully not too long before I can get done video of this Shannon and the 21 Kind regards Sy ▲

⟩⟩

stevedownunder

robbob

jbkiwi

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 141 Views · 4 Likes

Flag

Extra nice job Sy, will be looking forward to the vid now you're allowed out. Interested to see how the RIB goes as well. I see you're a cack hander (mode 2)😂lol. We're mostly mode 1 down here,- hard to train someone on planes when they've started on mode 2 ( probably the same in reverse) can get hairy😮

JB ▲

⟩⟩

stevedownunder

Scratchbuilder

Skydive130

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 140 Views · 3 Likes

Flag

Cheers Bill, must admit, very pleased with it, it’s taken goodness only knows how many hours!

As for the next model, happy to say back to wood and plenty of scope for added detailing, thing USCG? ▲

⟩⟩

stevedownunder

Scratchbuilder

Martin555

|

|

Login To

Remove Ads 💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 146 Views · 3 Likes

Flag

Morning Sy.

Yet another model to exhibition and display standards. First class work in all areas. Regards Bill. PS.....And the next project will be??? ▲

⟩⟩

stevedownunder

Skydive130

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 141 Views · 4 Likes

Flag

Hi Doug, my lady crew member had been out on the “lash” the night before and hadn’t removed her eye shadow before a shout! 😂

As for throttle left stick and steering right, don’t forget I come from a RC Aircraft background, so it would have been throttle left, aileron/elevator right in mode 2, just going with what I’m used too. As for a biergarten next to your lake, you lucky sod, all we’ve got is a ice cream van on a nice day and he doesn’t even do whippy ice cream, it’s that horrible scoop stuff 😂😂😂 Kind regards. Sy ▲

⟩⟩

RNinMunich

stevedownunder

robbob

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 145 Views · 4 Likes

Flag

Exquisite work Sy 👍

But we don't expect anything less from you now 😉 Ref your Controls; I still wonder why folks waste an RC channel to switch the radar!? No self respecting skipper would leave harbour without ensuring that his radar is fully operational before he orders 'Let go forrard, let go aft'. And no way would he switch it off before he is safely tied up back in harbour again. I 'switch' on the radar in my destroyer simply by inserting the 1.5V alkaline cell before launching.😉 Rudder and throttle: Why on two sticks? I set up all my ships for throttle and rudder both on the right stick. Then I only need one thumb for navigating. Leaving the left hand free for special function switches etc, or the Bierkrug or wine glass😋 - I sail on the lake right next to the Biergarten in the Ostpark here in Munich 😉😋 For 'hands free' cruising I use the Trim switches to set cruising speed and rudder for a circular patrol. Looking forward to your sea trials. Cheers, Doug 😎 PS I think your lady crew member needs a finer eyeshadow pencil. Or did she try to apply her eyeshadow whilst underway? 😮 ▲

⟩⟩

Colin H

stevedownunder

Martin555

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 146 Views · 1 Like

Flag

"That way your crew could be put on ether boat."

That'll be one sleepy crew Martin 😮🙊😴💤💤💤 "I see this member of the crew is female (Blue eyeshadow)." Not to mention the 'bumps' in the rescue suit Martin! 😁😁😎 ▲

⟩⟩

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 143 Views · 3 Likes

Flag

The fact that they are RNLI and not US Coast Guard should be clue enough Martin 😂😂😂

▲

⟩⟩

stevedownunder

Martin555

RNinMunich

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 146 Views · 2 Likes

Flag

SY,

Sooo ! you won't be able to interchange this crew as they have RNLI on their clothing. Martin555. ▲

⟩⟩

stevedownunder

Skydive130

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 144 Views · 3 Likes

Flag

Hi Martin, I don’t want to say too much bout my next build yet as I would rather finish this, have a Few days off to do stuff around the house before I start the next build. Suffice to say, the next build is a lifeboat, but not one of ours?

However your idea of fitting magnets may well be a good idea! I’ve got some rare earth neodymium magnets somewhere, I’ll see what I can do! Kind regards Sy ▲

⟩⟩

stevedownunder

robbob

Martin555

|

|

💬 Re: Model complete, figures started.....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 146 Views · 2 Likes

Flag

Sy,

Firstly i must say you workmanship and skills always amazes me. I see this member of the crew is female (Blue eyeshadow). You say these figures are no longer available. So the crew member you squirrelled away could have the rest of the crew join him/her. Have you thought about drilling the crews feet and fitting small magnets or steel cut off from nail's, and placing magnets under the deck were you want the crew to stand/sit. That way your crew could be put on ether boat. Martin555. ▲

⟩⟩

stevedownunder

Skydive130

|

📝 Almost there....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 150 Views · 10 Likes · 9 Comments

Flag

💬 Add Comment

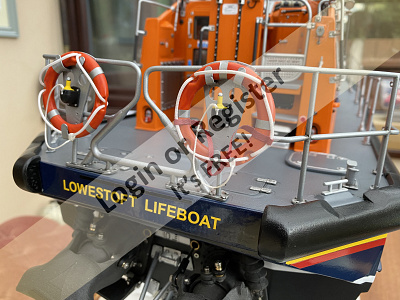

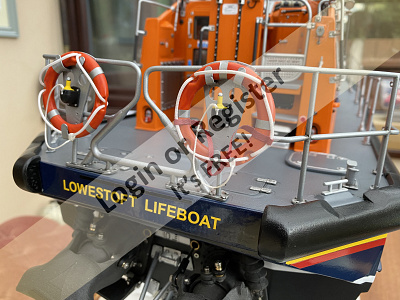

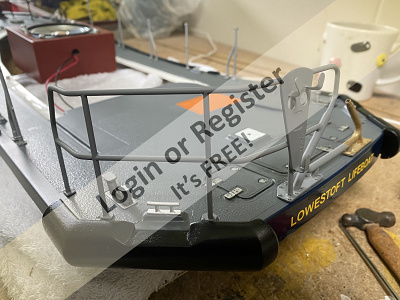

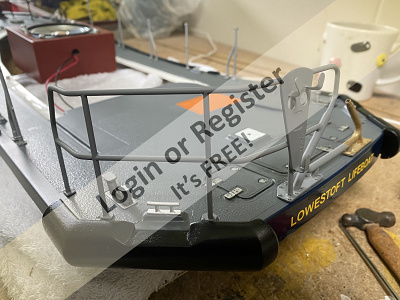

All that remains now is to complete the railings on the stanchions and the crew. Completed the stern railings, a job I didn’t enjoy and hope never to repeat! It’s not perfect, but acceptable. Also finished are the lifebuoys and beacons, along with finishing the anchor weathering and straps.

Final jobs include the crew, finish the lighting wiring, finish radio setup and ballast as required....

Oh, and promoted to “Rear Admiral “ too, is that a high rank? I’m ex army and made SSgt, so thinking it’s better than that ha ha

Final jobs include the crew, finish the lighting wiring, finish radio setup and ballast as required....

Oh, and promoted to “Rear Admiral “ too, is that a high rank? I’m ex army and made SSgt, so thinking it’s better than that ha ha

▲

⟩⟩

MouldBuilder

RNinMunich

T33CNO

alan44

jbkiwi

stevedownunder

Rookysailor

Martin555

Scratchbuilder

Colin H

|

💬 Re: Almost there....

5 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 150 Views · 2 Likes

Flag

No build is ever perfect Sy, but you have made an exceptional boat you should be proud of, we need builders who can inspire new-comer's to the hobby and as Rear Admiral you fall into that category, great job👍

▲

⟩⟩

Martin555

Scratchbuilder

|

|

Login To

Remove Ads 💬 Re: Almost there....

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 148 Views · 2 Likes

Flag

Congrats Admiral .

Rick ▲

⟩⟩

Scratchbuilder

Martin555

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 148 Views · 2 Likes

Flag

Ha ha, cheers Martyn, sadly I don’t think it comes with pay, pension or @ny other benefits 😂😂😂

▲

⟩⟩

Scratchbuilder

Martin555

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 151 Views · 2 Likes

Flag

Congratulations on your promotion Rear Admiral Sy.

Extremely well deserved. Martin555. ▲

⟩⟩

Scratchbuilder

Skydive130

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 149 Views · 2 Likes

Flag

Thank you all very much for your kind comments, I just wish my long suffering wife felt the same!

▲

⟩⟩

Scratchbuilder

Martin555

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 150 Views · 1 Like

Flag

Sy,

I can only agree with the other guys. Awesome work. Martin555. ▲

⟩⟩

Skydive130

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 152 Views · 2 Likes

Flag

Sy.

Words fail. First class workmanship and top quality work. You should be very proud of all you do. Regards Bill. ▲

⟩⟩

Skydive130

Martin555

|

|

💬 Re: Almost there....

5 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 155 Views · 3 Likes

Flag

Sy, your amazing models are some of the very best quality and finish.

Your idea of acceptable is better than most of us normal people can achieve. Keep it it up shipmate, I may get there one day before I die. Cheers Colin. ▲

⟩⟩

Skydive130

Martin555

Scratchbuilder

|

|

💬 Re: Almost there....

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 150 Views · 2 Likes

Flag

Hi Sy your acceptable would make me feel good.Another great looking boat.

Rick ▲

⟩⟩

Skydive130

Martin555

|

📝 The end is in sight.....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 151 Views · 9 Likes · 10 Comments

Flag

💬 Add Comment

Quite a bit done over the last few days, and my wife’s summer house is also finished, so happy wife, happy life 😂

I spent a whole day shaping, bending, soldering, and filing the stern rail and only got it half finished, I shall finish that off Tuesday I promise!

The life rings were somewhat easier, just requiring the resin parts cleaning, priming then a couple of light coats of brilliant orange before giving them a acrylic wash of orange/red to darken them as per the real thing. Finished off with some strips of silver trim tape and paracord they are ready to go on when the railing is finished.

Other jobs have included seeing the fendering competed. Also made was the mounting bracket for the anchor made from plasticard as not supplied in the kit. The strap with made from a sliver of ultrathin plasticard and crimped with pliers before painting and giving it a brown wash.

I’ve now made a start on adding the railing wire and turnbuckles. The turnbuckles were supplied as cast brass parts and really would be very difficult to model from scratch. However the supplied turnbuckles are short in qty and I’ve contacted the seller for extras as need another 10 pieces to complete!

As far as the model is concerned, all that’s left to do is finish the railings, bond the cabin to the deck, a couple of odd small items to paint and add, add ballast as required and finish sorting the electrics. Oh, and there is the matter of painting 5 crew figures...........!

I spent a whole day shaping, bending, soldering, and filing the stern rail and only got it half finished, I shall finish that off Tuesday I promise!

The life rings were somewhat easier, just requiring the resin parts cleaning, priming then a couple of light coats of brilliant orange before giving them a acrylic wash of orange/red to darken them as per the real thing. Finished off with some strips of silver trim tape and paracord they are ready to go on when the railing is finished.

Other jobs have included seeing the fendering competed. Also made was the mounting bracket for the anchor made from plasticard as not supplied in the kit. The strap with made from a sliver of ultrathin plasticard and crimped with pliers before painting and giving it a brown wash.

I’ve now made a start on adding the railing wire and turnbuckles. The turnbuckles were supplied as cast brass parts and really would be very difficult to model from scratch. However the supplied turnbuckles are short in qty and I’ve contacted the seller for extras as need another 10 pieces to complete!

As far as the model is concerned, all that’s left to do is finish the railings, bond the cabin to the deck, a couple of odd small items to paint and add, add ballast as required and finish sorting the electrics. Oh, and there is the matter of painting 5 crew figures...........!

▲

⟩⟩

Colin H

Ronald

Seanympth

jbkiwi

stevedownunder

Rookysailor

RNinMunich

robbob

Martin555

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 150 Views · 1 Like

Flag

Hi Rob, by the time I post my next update, possibly today, at latest tomorrow, the boat will be finished less one side of the railings. I was short changed in the prototype kit, but the seller has sent some more cast brass turnbuckles, hopefully here the next couple of days. Then it’s onwards with the figures!

As for a next project? RC wise I’ve nothing lined up. I’m still awaiting delivery of the MS Loyal Fleet tender kit from France, no idea when that will arrive. I’ve also got a couple of Occre display ships in the cupboard, one of those could be next, alternatively I’ve been eyeing up the Dumas Motor Lifeboat USCG 36500 kit for quite a while, may push the buy now button on that? What about you, anything planed? Kind regards Sy ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: The end is in sight.....

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 165 Views · 3 Likes

Flag

Hi Sy.

Just loving your work 👍😀👍 The detail is quite amazing and Im looking forward to seeing the finished crew figures. Congratulations on another marvellous build...so what's next I wonder? Rob. ▲

⟩⟩

hmsnostalgia

Skydive130

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 151 Views · 2 Likes

Flag

Shouldn’t be too long JB, all down to detailing now and the figures, electrics and final touch ups!

Kind regards Sy ▲

⟩⟩

jbkiwi

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 151 Views · 2 Likes

Flag

Top stuff Sy, your detailing is brilliant👍 Hope we'll get to see a vid of the sea trials soon, now you are all allowed out to play😁.

JB ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 151 Views · 1 Like

Flag

Thank you for your kind comments Gary, glad your enjoying it.

Thankfully (or not!😂) I’ve got a few Shannon crew members on another forum following my build who keep sending me pictures of other things I can add. This is we’re I get to add a few scratch built details not in the kit and really bring this model to life. Kind regards Simon ▲

⟩⟩

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 159 Views · 2 Likes

Flag

Absolutely love it, it is all the fine and intricate detail that makes all the difference in the world.

A great-looking boat, well done. Regards,Gary. ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 151 Views · 1 Like

Flag

Indeed Martyn, all the wiring will duct along the underside of the roof and down the back wall out of sight, out of mind. Still got to wire in the switching unit for lights and radar.

Cheers for now, Sy ▲

⟩⟩

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 151 Views · 1 Like

Flag

Many thanks Rick 👌

▲

⟩⟩

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 151 Views · 1 Like

Flag

Love the work you do. Adds so much to the builds .

Rick ▲

⟩⟩

Martin555

|

|

💬 Re: The end is in sight.....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 153 Views · 1 Like

Flag

Fantastic work again Sy,

Your attention to detail is excellent. I assume when you said finishing the electrics you are going to hide the small white cables to the two searchlights on top of the bridge. Martin555. ▲

⟩⟩

Skydive130

|

📝 Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 163 Views · 9 Likes · 11 Comments

Flag

💬 Add Comment

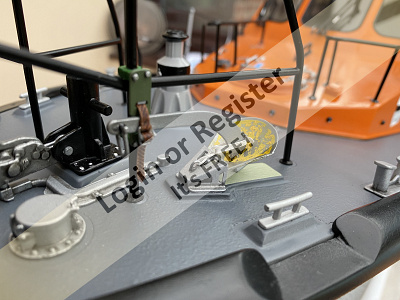

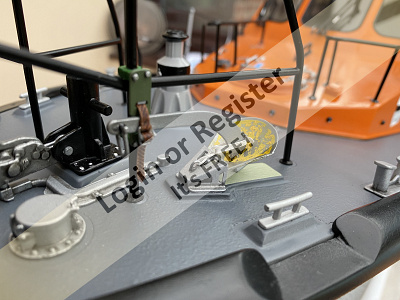

So, it may not look like a lot has been done, but trust me, what you see is another 25 hours of progress!

I decided to leave the crew figures alone until the bank holiday break and concentrate on getting the deck progressed.

After many hours of masking all the areas not getting a coat of texture paint, the textured paint was applied with 2 light coats. once fully hardened overnight, the masking tape was removed before giving the whole deck another coat of primer to seal the texture and then hit with Tamiya German tank grey for the final deck colour. once that was dry i gave the whole deck a couple of coats of matt lacquer. On some full size Shannons, there seems to be a lighter grey on the deck on all the areas not treated with grip paint, but i decided against this keeping things simple and not trusting my masking to give me a reas of bleed that would require hours of swearing and cursing!

Onwards with starting to fit the deck fittings, most of which had been prepared and painted weeks ago. There are still quite a few details to add to the deck which include the remaining bumper strips, fore and aft railings (looking forward to making them from 2.5mm brass rod-Not!), grab lines, towing bits, anchor ect, hopefully crack the back of them at the next session before finally glueing the cabin to the deck. Not seen in the pictures is the rudder sealing strip I have applied to the top lip of the hull to hopefully give me a water tight seal when the deck is bolted down, we shall see!

I decided to leave the crew figures alone until the bank holiday break and concentrate on getting the deck progressed.

After many hours of masking all the areas not getting a coat of texture paint, the textured paint was applied with 2 light coats. once fully hardened overnight, the masking tape was removed before giving the whole deck another coat of primer to seal the texture and then hit with Tamiya German tank grey for the final deck colour. once that was dry i gave the whole deck a couple of coats of matt lacquer. On some full size Shannons, there seems to be a lighter grey on the deck on all the areas not treated with grip paint, but i decided against this keeping things simple and not trusting my masking to give me a reas of bleed that would require hours of swearing and cursing!

Onwards with starting to fit the deck fittings, most of which had been prepared and painted weeks ago. There are still quite a few details to add to the deck which include the remaining bumper strips, fore and aft railings (looking forward to making them from 2.5mm brass rod-Not!), grab lines, towing bits, anchor ect, hopefully crack the back of them at the next session before finally glueing the cabin to the deck. Not seen in the pictures is the rudder sealing strip I have applied to the top lip of the hull to hopefully give me a water tight seal when the deck is bolted down, we shall see!

▲

⟩⟩

Julio

stevedownunder

mturpin013

robbob

jbkiwi

RNinMunich

Rookysailor

Colin H

Martin555

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 153 Views · 1 Like

Flag

Indeed Mike, the detail looks great after all the masking, but not something I wish to repeat soon 😂😂

▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 159 Views · 3 Likes

Flag

All that time spent masking and then its all over, as the spraying takes such a short time compared with the masking, but its worth it for that finishing detail

▲

⟩⟩

Skydive130

Martin555

RNinMunich

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 163 Views · 2 Likes

Flag

I get one once in a while Sy. 😉

If I try really really hard!🤕😁 😎 ▲

⟩⟩

Skydive130

Martin555

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 161 Views · 2 Likes

Flag

Now there’s a thought Doug 😂😂👌

▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 164 Views · 2 Likes

Flag

I'm sure you can find room for a Barnacle or two Sy 😉

A shark tooth stuck in the transom perhaps 😁 😎 ▲

⟩⟩

Skydive130

Martin555

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 163 Views · 2 Likes

Flag

Cheers Doug, the “Orca” is special I must admit. I was watching Jaws the other day to see if I could add anything else!

▲

⟩⟩

RNinMunich

Martin555

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 163 Views · 1 Like

Flag

Cheers Rick 👍

▲

⟩⟩

Martin555

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 165 Views · 2 Likes

Flag

"and not trusting my masking to give me a areas of bleed that would require hours of swearing and cursing!"

Hi Simon, I used to have that problem when I still used 'normal' crepe masking tape. Since I switched to the (admittedly more expensive, but wodja get for sixpence these days?🙄) Tamiya masking tape no more creep. No more agro 😀 Of course a textured surface does complicate the issue! Nevertheless, great result Si, as expected 👍 (Still prefer your Orca though 😁) Cheers, Doug 😎 ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 163 Views · 2 Likes

Flag

Sy 👍👍👍Can only say WOW. you do great work.

Rick ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 163 Views · 2 Likes

Flag

Cheers Martin, certainly likely to be a keeper!

▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Once again the devils in the detail...

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 167 Views · 1 Like

Flag

Hi Sy,

Well worth all the time spent masking up. She is looking great. Martin555. ▲

⟩⟩

Skydive130

|

📝 Let figure painting commence.....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 171 Views · 8 Likes · 3 Comments

Flag

💬 Add Comment

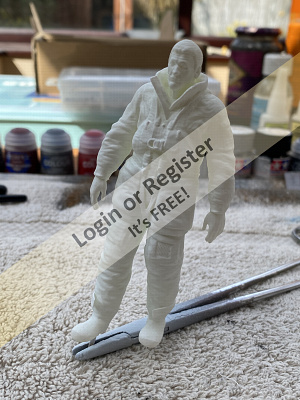

In between doing the work on the deck shown in my previous post, I’ve made a start on the first of the figures.

Made of resin, they are quite superb and deserve the best painting I can muster! First thing was to clean any flash, wash and then prime in white.

I tend to use citadel paints for figures from Games Workshop, simply because I used to paint gaming figures, am used to working with them and they have strong colour properties. The choice of colours available is vast like most model paint companies, but if you stick to a fairly basic pallet of about 30 colours, most other shades can be mixed from them. Another great investment was a wet pallet, something I’ve never had until recently, but put paint on it, they last for days and can be mixed on it instead of a plate which drys too quickly. Also worth having are contrast washes for shadows ect.

Once the primer was dry, the hole figure got a wash with an orange/yellow pigment then dry brushed in yellow adding a cream white for highlights.

I made a start on picking out the black detail and started the skin tones, a long way to go before the figure is finished......

Made of resin, they are quite superb and deserve the best painting I can muster! First thing was to clean any flash, wash and then prime in white.

I tend to use citadel paints for figures from Games Workshop, simply because I used to paint gaming figures, am used to working with them and they have strong colour properties. The choice of colours available is vast like most model paint companies, but if you stick to a fairly basic pallet of about 30 colours, most other shades can be mixed from them. Another great investment was a wet pallet, something I’ve never had until recently, but put paint on it, they last for days and can be mixed on it instead of a plate which drys too quickly. Also worth having are contrast washes for shadows ect.

Once the primer was dry, the hole figure got a wash with an orange/yellow pigment then dry brushed in yellow adding a cream white for highlights.

I made a start on picking out the black detail and started the skin tones, a long way to go before the figure is finished......

▲

⟩⟩

MouldBuilder

robbob

Ronald

Rookysailor

RNinMunich

Colin H

Scratchbuilder

Martin555

|

💬 Re: Let figure painting commence.....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 171 Views · 2 Likes

Flag

I think the figures will bring the Shannon to life Bill, that’s the plan anyway!

▲

⟩⟩

robbob

Martin555

|

|

Login To

Remove Ads 💬 Re: Let figure painting commence.....

5 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 180 Views · 2 Likes

Flag

Sy.

As always your attention to detail is beyond reproach. Keep up the good work. Bill ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Let figure painting commence.....

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 172 Views · 3 Likes

Flag

Sy steady hand and a good eyes. Excellent work.

Rick ▲

⟩⟩

Martin555

Skydive130

Scratchbuilder

|

📝 Deck painting commences....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 171 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

Today has seen the start of preparing the deck for primer and paint........

First thing was to ensure a good fit on the hull, followed by a gentle sanding with 600 grit to act as a key for the paint then the whole thing was washed in warm soapy water to remove any grease ect and left to dry in the sun.

This was followed by 2 coats of Halfords grey primer and later in the day a couple of coats of humbrol light grey. All areas that are to have the anti slip texture paint applied will eventually be a darker grey, but this will be after a horrendous amount of masking on the areas to be left light grey.

I shall move onto that stage Tuesday and Wednesday, meanwhile, I’ve been working on the first crew figure!

First thing was to ensure a good fit on the hull, followed by a gentle sanding with 600 grit to act as a key for the paint then the whole thing was washed in warm soapy water to remove any grease ect and left to dry in the sun.

This was followed by 2 coats of Halfords grey primer and later in the day a couple of coats of humbrol light grey. All areas that are to have the anti slip texture paint applied will eventually be a darker grey, but this will be after a horrendous amount of masking on the areas to be left light grey.

I shall move onto that stage Tuesday and Wednesday, meanwhile, I’ve been working on the first crew figure!

▲

⟩⟩

MouldBuilder

robbob

RNinMunich

Colin H

Martin555

|

💬 Re: Deck painting commences....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 171 Views · 2 Likes

Flag

There in lies my surprise Martin! The cabin will be bonded to the deck, then the deck will clamp fore and aft to the hull with a seal in between. All will be revealed 👍

Kind regards Sy ▲

⟩⟩

robbob

Martin555

|

|

💬 Re: Deck painting commences....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 171 Views · 2 Likes

Flag

Sy,

I was surprised to see the deck was not glued to the hull. Martin555. ▲

⟩⟩

Skydive130

Scratchbuilder

|

📝 Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 183 Views · 13 Likes · 17 Comments

Flag

💬 Add Comment

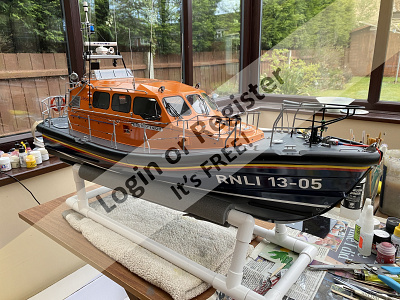

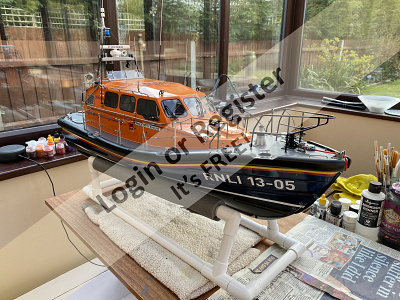

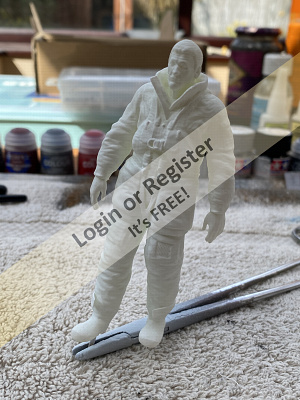

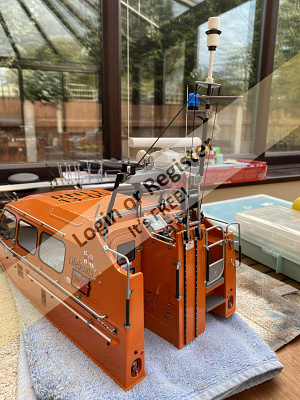

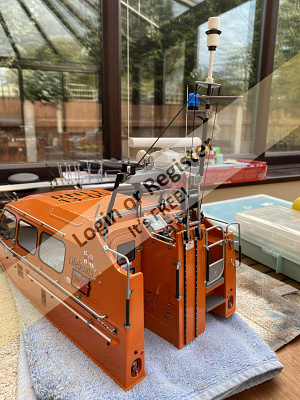

So.....

In-between painting my good lady’s summer house whilst dodging showers and watching my beloved West Ham United give me close to another heart attack after being 3-0 up for the third time in the bounce and neatly throwing it away, I’ve managed to get the remaining parts painted and added to the cabin.

The only thing left to do is add a 1mm carbon rod upper section to one of the longer antennas as I’ve run out, but more on the way. There was no mounting bracket for the search light in the kit (although looking at various Shannon’s, they aren’t always fitted?) so I made one from bits of plasticard and tube, you’d never know!

Also not supplied are the locking levers for the upper gantry which allows the gantry to be lowered when in a boathouse (slipway launched), again made from plasticard and painted red before fitting. Try as I might, I cannot find anything else to add to the wheelhouse/cabin having looked at the official RNLI plans and photos hundreds of times, so that’s it, wheelhouse done less the antenna and finishing the light wiring...

Next, onwards with the deck and all the associated parts for that.

In-between painting my good lady’s summer house whilst dodging showers and watching my beloved West Ham United give me close to another heart attack after being 3-0 up for the third time in the bounce and neatly throwing it away, I’ve managed to get the remaining parts painted and added to the cabin.

The only thing left to do is add a 1mm carbon rod upper section to one of the longer antennas as I’ve run out, but more on the way. There was no mounting bracket for the search light in the kit (although looking at various Shannon’s, they aren’t always fitted?) so I made one from bits of plasticard and tube, you’d never know!

Also not supplied are the locking levers for the upper gantry which allows the gantry to be lowered when in a boathouse (slipway launched), again made from plasticard and painted red before fitting. Try as I might, I cannot find anything else to add to the wheelhouse/cabin having looked at the official RNLI plans and photos hundreds of times, so that’s it, wheelhouse done less the antenna and finishing the light wiring...

Next, onwards with the deck and all the associated parts for that.

▲

⟩⟩

Scratchbuilder

Inkoust

Seanympth

RNinMunich

mturpin013

Ronald

Rowen

Rookysailor

MouldBuilder

jbkiwi

Martin555

Colin H

robbob

|

💬 Re: Cabin completed as promised....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 161 Views · 0 Likes

Flag

Please yourself Sy! 🙄

😁😎 ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 159 Views · 2 Likes

Flag

Thank you very much for the compliment, I aim to please 👌

▲

⟩⟩

RNinMunich

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Lordgord (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 166 Views · 3 Likes

Flag

Looking at these photos I wonder at the talent and patience of the builder.

Wonderful model. 👍 ▲

⟩⟩

RNinMunich

Skydive130

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇨🇦 AustinG (

Warrant Officer) Warrant Officer)✧ 181 Views · 1 Like

Flag

Hi Doug,

Many thanks started it a few min ago. Austin ▲

⟩⟩

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 181 Views · 1 Like

Flag

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇨🇦 AustinG (

Warrant Officer) Warrant Officer)✧ 184 Views · 3 Likes

Flag

hi Sy,

I'm fairly new to building and this is first time have considered installing lights. Beside the normal nav lights red and green mounted on cabin top this boat has the following 1 anchor light, 2 amber towing lights, 1 stern light located on mast plus 1 blue light 2 spot lights 1 searchlight, 2 deck lights on base of mast which mounted on gantry above cabin. Sorry to be long winded but unable to find any real information on web re where to start. This is the one used by USA and Canadian Coast Guard, my model is based on Thunder Cape located in Ontario. All suggestions welcomed. Austin ▲

⟩⟩

Scratchbuilder

Seanympth

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 179 Views · 2 Likes

Flag

Hi Austin, ask away on lighting advise, if I don’t have the answer there are certainly friends of mine on here who will.

Kind regards Sy ▲

⟩⟩

Seanympth

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 179 Views · 2 Likes

Flag

I agree Doug, Orca is still my fave too, especially as she was virtually scratch built. Defo a keeper!

Kind regards Sy ▲

⟩⟩

Scratchbuilder

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 179 Views · 2 Likes

Flag

Cheers JB, shouldn’t be too long now before she gets her feet wet!

Kind regards Sy ▲

⟩⟩

jbkiwi

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 180 Views · 2 Likes

Flag

Excellent job Sy, looking forward to the sea trials (first rescue job) You certainly have a way with the fiddly bits😁

JB ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 2 Likes

Flag

Yet another Gobsmacker Sy 😮 😀👍

My favourite is still 'Orca' though! She was (still is I hope) SUPERCALIFRAGILISTICEXPIALIDOCIOUS 😉 😎 ▲

⟩⟩

Martin555

Skydive130

|

|

Login To

Remove Ads 💬 Re: Cabin completed as promised....

5 years ago by 🇨🇦 AustinG (

Warrant Officer) Warrant Officer)✧ 184 Views · 2 Likes

Flag

Fantastic work, real professional. I,m building a MLB 47 life boat and would appreciate information regarding installation of lights.

Austing ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 2 Likes

Flag

I try mouldbuilder, if I can inspire others, that’ll do 😂

▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 1 Like

Flag

Cheers for the compliment Rick 😂

▲

⟩⟩

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 2 Likes

Flag

Great job Sy .Are you sure your not working for a boat museum.

Rick ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 186 Views · 3 Likes

Flag

Stunning. You have once again done a fabulous job Sy. 👍👍

▲

⟩⟩

Ronald

Skydive130

Martin555

|

|

💬 Re: Cabin completed as promised....

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 184 Views · 1 Like

Flag

Very nice indeed Sy,

Martin555. ▲

⟩⟩

Skydive130

|

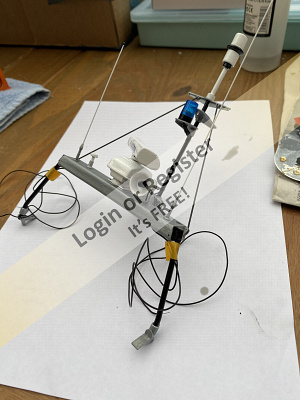

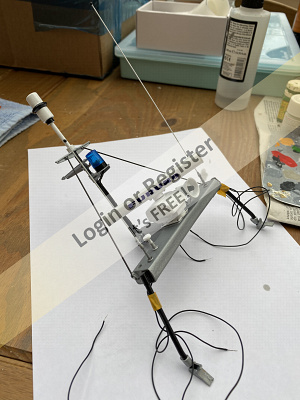

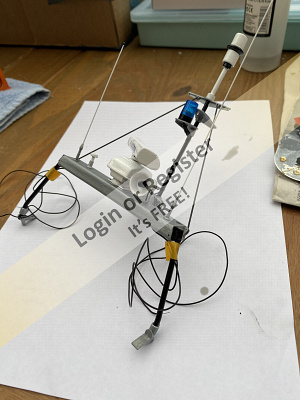

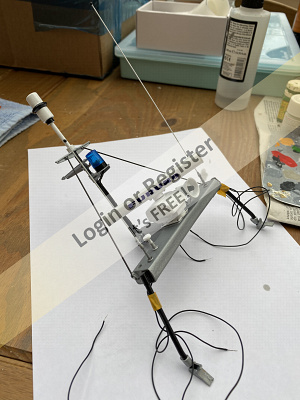

📝 Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 183 Views · 7 Likes · 9 Comments

Flag

💬 Add Comment

Just so that you didn’t think I’d disappeared off the face of the earth, I thought I’d better do a little update. Last Easter weekend was mostly spent in the garden building the wife’s summer house, this weekend I’ve been excused garden chores!

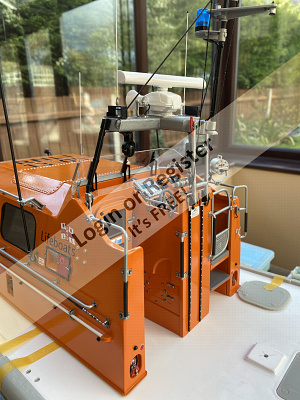

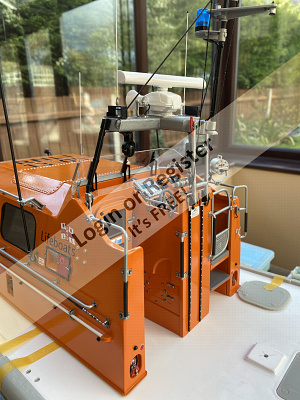

I’ve now just about finished the radar gantry and all the wiring now disappears into the cabin for sorting onto the switch later. I’ve decided that all lights and radar will be operated on a single switch just so that I could hide all the wiring connections inside the gantry head and then having a single wire coming down each arm into the cabin. In an ideal world I would have control over each component individually but that would have resulted in a mess of wires tracking down the arms and at this scale that would have wound me up!

The remaining jobs to see the cabin complete is adding the remaining 4 antenna, a few dummy mast lights and the search light, followed by any corrections and paint touch ups. Following that I can then get on with the deck painting and components and rapidly heading to a completed model, a month or so of work to do I reckon?

The crew figures arrived today. They are an accurate set of modern RNLI crew cast in resin, but very light considering. The detail is superb and I plan to employ techniques painting them similar to how I used to paint military and war gaming figures. They were not cheap, but I feel money well spent and will set the finished boat of nicely. The only modification I plan on carrying out is the alter the arm position on the coxswain so that he will have control of the helm on the flying bridge.....

I’ve now just about finished the radar gantry and all the wiring now disappears into the cabin for sorting onto the switch later. I’ve decided that all lights and radar will be operated on a single switch just so that I could hide all the wiring connections inside the gantry head and then having a single wire coming down each arm into the cabin. In an ideal world I would have control over each component individually but that would have resulted in a mess of wires tracking down the arms and at this scale that would have wound me up!

The remaining jobs to see the cabin complete is adding the remaining 4 antenna, a few dummy mast lights and the search light, followed by any corrections and paint touch ups. Following that I can then get on with the deck painting and components and rapidly heading to a completed model, a month or so of work to do I reckon?

The crew figures arrived today. They are an accurate set of modern RNLI crew cast in resin, but very light considering. The detail is superb and I plan to employ techniques painting them similar to how I used to paint military and war gaming figures. They were not cheap, but I feel money well spent and will set the finished boat of nicely. The only modification I plan on carrying out is the alter the arm position on the coxswain so that he will have control of the helm on the flying bridge.....

▲

⟩⟩

Rookysailor

MouldBuilder

jbkiwi

RNinMunich

Martin555

Colin H

robbob

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Rookysailor (

Rear Admiral) Rear Admiral)✧ 190 Views · 2 Likes

Flag

I'm also looking forward to you starting the build on the Fleet Tender sy, as I have had one for some time now, and still in the box, bought it from Adrian Clutterbuck, who used to run 'Adrians Figures' now owned my 'Mountfleet', 😊

btw, your attention to detail is amazing, just wish I could see it in the flesh, so to speak. Cheers, Pete ▲

⟩⟩

Martin555

Skydive130

|

|

Login To

Remove Ads 💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 1 Like

Flag

That would certainly be my first choice too Martin, hopefully it will arrive soon!

▲

⟩⟩

Martin555

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 184 Views · 1 Like

Flag

Sy,

I must admit i personally would like to see you make the Fleet Tender. I think you will also like to make it as i think you will do a lot of weathering and make it look like the real thing and going by your previous builds it will be museum quality. Martin555. ▲

⟩⟩

Skydive130

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 1 Like

Flag

Hi Rob, I’ve 2 options after this. Whenever it arrives, I’ve managed to source an unstarted Model Slipway Loyal Class fleet tender which is currently in France awaiting the owner jumping on a ferry and heading back to the U.K. when COVID allows. Otherwise, I’ve got a Aerokits Sea Commander cabin cruiser which I got off fleabay for £60, although it’s not here yet. Hard to tell from the pictures when I bought it, but it’s very old and I’m hoping the ply hasn’t delaminated ect, time will tell.

Or, I’ve a couple of Ocree display only ships I could start, but might not be too much interest on here. Time will tell what’s next..... Kind regards Sy ▲

⟩⟩

Martin555

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 187 Views · 4 Likes

Flag

Hi Sy.

"What about you, have you a next project lined up?" I'd love to tell you all but until the prototype is in my hands I'll have to keep it a secret. Besides my own 'SWMBO' is taking advantage of the lull in my model making to catch up with mundane DIY and stuff 😋 Rob. ▲

⟩⟩

hmsnostalgia

MouldBuilder

Martin555

Skydive130

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 1 Like

Flag

Hi Martin, yes your right, I do miss making bits although I’ve had to make a few bits on this as I’ve gone along. But she still been an enjoyable build and the most scale like boat I’ve built to date, albeit it at a cost in wonga!

Cheers for now, Sy ▲

⟩⟩

Martin555

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 183 Views · 1 Like

Flag

Hi Sy,

Awesome. I know it is a kit but when you work your magic on it it starts to look like the real thing. Your model making skills put mine to shame. I bet you still miss making all the fittings yourself instead of cleaning and fitting kit parts. Keep working your Magic. Martin555. ▲

⟩⟩

Skydive130

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 183 Views · 3 Likes

Flag

Trouble is Rob, “she who must be obeyed” wants man things done in the garden, so it’s finding that fine line! Plus, I’ve nothing else lined up for after this build as the MS kit I’ve got promised is still in France waiting to come across the channel when people are allowed to travel again.

What about you, have you a next project lined up? Kind regards Sy ▲

⟩⟩

Martin555

robbob

Colin H

|

|

💬 Re: Radar gantry nears completion and crew arrive!

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 187 Views · 3 Likes

Flag

More excellent progress Sy 😀👍.

"a month or so of work to do I reckon?" I reckon that at your work rate you'll have it finished much quicker than that 😉!. Rob. ▲

⟩⟩

hmsnostalgia

Skydive130

Martin555

|

📝 Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 192 Views · 8 Likes · 15 Comments

Flag

💬 Add Comment

Thought I’d better do an update just in case you were thinking I’d given up 😂.

In between shifts at work and being dispatched into the garden, I’ve found the time to hook up most of the control surfaces to their respective servos. No issues with the steering nozzles and the reverse thruster buckets, they hooked up and were easily set up for travel, direction, exponential (steering only) in my Spektrum DX8 transmitter. I’ve set the buckets up onto a 2 way switch meaning that they are either up or down.

The issue I’ve come up against and it’s quite a biggie is the trim tabs? I hooked them up via a Y-lead to go into Aux 3 on rx/tx to be on a rotary switch giving me good control over their position. However, the trim tabs only need about 15% of the servos travel to give full deflection up and down which I set up in the transmitter using end point adjustment. The issue though is when you switch the transmitter on followed by the receiver, the trim tab servo arm goes through a quick full travel movement in both directions whist it is binding. If I was to leave it like this, something will break as the trim tabs have limited deflection, either they will break, or the servo pushrod will bend, servo horn break or worst still, the servo will give! If anyone has any solutions to this drama, I’m all ears!

Onto easier things, I’ve spent the last 3 days on and off in between chores building the radar gantry which was mostly kit supplied resin parts with a bit of brass tube and carbon rod.

I eventually used a radar motor the same as Rob used on his Pilot boat, it just meant hollowing out the radars motor box to contain it and the base of the motor is hidden in the gantry.

The blue flashing light is the best I could find and works well on 4-6v. The blue lens is a little tall for scale as on the Shannon it’s quite a stumpy one, but mine will do.

I’ve still to make the Nav light boxes and the red and green grain of wheat bulbs I’ve got aren’t very bright on 6v, again if anyone knows of brighter ones for 6v, please let me know before I fit them.

The photo showing the gantry on top of the wheelhouse isn’t the final result as you can see i5 looks a little wonky. Once I’ve finished installing all the lights and figure a way of getting the wiring down the arms neatly and inside the wheel house, then I will final fit the gantry.

That’s it now until the Easter weekend, gotta work for the next 4 days 🤬🤬🤬

In between shifts at work and being dispatched into the garden, I’ve found the time to hook up most of the control surfaces to their respective servos. No issues with the steering nozzles and the reverse thruster buckets, they hooked up and were easily set up for travel, direction, exponential (steering only) in my Spektrum DX8 transmitter. I’ve set the buckets up onto a 2 way switch meaning that they are either up or down.

The issue I’ve come up against and it’s quite a biggie is the trim tabs? I hooked them up via a Y-lead to go into Aux 3 on rx/tx to be on a rotary switch giving me good control over their position. However, the trim tabs only need about 15% of the servos travel to give full deflection up and down which I set up in the transmitter using end point adjustment. The issue though is when you switch the transmitter on followed by the receiver, the trim tab servo arm goes through a quick full travel movement in both directions whist it is binding. If I was to leave it like this, something will break as the trim tabs have limited deflection, either they will break, or the servo pushrod will bend, servo horn break or worst still, the servo will give! If anyone has any solutions to this drama, I’m all ears!

Onto easier things, I’ve spent the last 3 days on and off in between chores building the radar gantry which was mostly kit supplied resin parts with a bit of brass tube and carbon rod.

I eventually used a radar motor the same as Rob used on his Pilot boat, it just meant hollowing out the radars motor box to contain it and the base of the motor is hidden in the gantry.

The blue flashing light is the best I could find and works well on 4-6v. The blue lens is a little tall for scale as on the Shannon it’s quite a stumpy one, but mine will do.

I’ve still to make the Nav light boxes and the red and green grain of wheat bulbs I’ve got aren’t very bright on 6v, again if anyone knows of brighter ones for 6v, please let me know before I fit them.

The photo showing the gantry on top of the wheelhouse isn’t the final result as you can see i5 looks a little wonky. Once I’ve finished installing all the lights and figure a way of getting the wiring down the arms neatly and inside the wheel house, then I will final fit the gantry.

That’s it now until the Easter weekend, gotta work for the next 4 days 🤬🤬🤬

▲

⟩⟩

Martin555

mturpin013

bednall

robbob

Colin H

stevedownunder

jbkiwi

MouldBuilder

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Rookysailor (

Rear Admiral) Rear Admiral)✧ 194 Views · 2 Likes

Flag

Glad to hear you have ordered a servomorph Sy, if I had though better, I could have sent you one to try first, as I always have a couple in stock, but I am sure it will fix your problem with the trim tabs.😊

Cheers, Pete ▲

⟩⟩

Martin555

Skydive130

|

|

Login To

Remove Ads 💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 192 Views · 3 Likes

Flag

Hi Sy.

I did find that as the internal gearing is only a push fit on the shaft you can move it to some degree to lengthen the shaft by pushing the shaft upwards through the gearbox housing. That might give you a bit more shaft to fix the scanner onto. Do that with caution though ! I fixed my scanner with a grub screw fixing but I did incorporate that when scratchbuilding it. Rob. ▲

⟩⟩

hmsnostalgia

Martin555

Skydive130

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 188 Views · 3 Likes

Flag

Hi Pete, I have ordered a servomorph today hoping this will cure my problem with over servo travel on boot up. I’ve tried the servos on other switches and it’s still happening, we shall see after it arrives 👍

▲

⟩⟩

Martin555

Rookysailor

robbob

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 188 Views · 2 Likes

Flag

Hi Rob, it was a squeeze, but carefully hollowing with the dremel was sufficient to get 3/4 of the gearbox inside the housing and the remaining 1/4 sits inside the gantry, so all hidden nicely. My only concern is the output spindle is very short with only about 3mm going into the radar. I put a piece of slightly pressed brass tube inside the radar and this is a reasonably tight fit onto the spindle, but still at risk of coming off and falling into the deep blue yonder!

Wee shall see ha ha. Kind regards Sy ▲

⟩⟩

Martin555

robbob

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 robbob (

Fleet Admiral) Fleet Admiral)✧ 192 Views · 3 Likes

Flag

Hi Sy.

Looking very good 👍👍 Was the radar motor and gearbox a bit of a squeeze to get into the radar housing? Rob. ▲

⟩⟩

hmsnostalgia

Martin555

Skydive130

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 190 Views · 2 Likes

Flag

Hi Pete, that servo morph maybe the solution? I’m going to try another switch first before I splash out on the gadget, but I’ll get one if I can’t solve it in the tx.

Kind regards simon ▲

⟩⟩

Martin555

Rookysailor

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 190 Views · 2 Likes

Flag

Cheers pete, must admit she is starting to look the part now, it was certainly daunting at the beginning!

Kind regards. Sy ▲

⟩⟩

Martin555

Rookysailor

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 190 Views · 1 Like

Flag

Hi Rowan, many thanks for your suggestion, I’ll have to look into the spring idea.

Kind regards Sy ▲

⟩⟩

Martin555

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Rookysailor (

Rear Admiral) Rear Admiral)✧ 197 Views · 2 Likes

Flag

Have had a similar problem myself Sy, had a servo on a warship turret, that used to swing past the stop on power up, I tried a servomorph from Action Electronics, which narrows the servo movement on power up, works fine, have left a link for you.

btw, loving the build👍👍👍 Cheers, Pete ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇨🇦 Rowen (

Captain) Captain)✧ 192 Views · 2 Likes

Flag

Note there are some suggestions to fix this electronically. Am sure they will work.

As a simple Mechanical Engineer, could you use a couple of small springs in the linkage to protect the tabs? Very interesting build and enjoying reading about it. Rowen ▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇭🇺 MouldBuilder (

Admiral) Admiral)✧ 203 Views · 2 Likes

Flag

Good Grief Sy. I thought I had only been away for a couple of weeks. You have been making stunning progress on this model. It is looking fantastic. Great workmanship as usual.

Peter.👍👍 ▲

⟩⟩

Martin555

Skydive130

|

|

Login To

Remove Ads 💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 192 Views · 1 Like

Flag

Still a way to go mike, all the deck details ect, I reckon late April to early may before finished. Must admit though, the remaining kit parts are a lot less than when I started!

Kind regards. Sy ▲

⟩⟩

Martin555

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 195 Views · 2 Likes

Flag

Its getting near to launch time, I hope we'll see some video's

▲

⟩⟩

Martin555

Skydive130

|

|

💬 Re: Radar gantry and engine components....

5 years ago by 🇬🇧 Skydive130 (

Rear Admiral) Rear Admiral)✧ 192 Views · 1 Like

Flag