Join Us On Social Media!

Highlander Clyde Puffer.

8 Posts · 25 Followers · 44 Photos · 125 Likes

Began 3 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 1 year ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Tyre's and bow fender completed.

1 year ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 95 Views · 18 Likes · 10 Comments

Flag

💬 Add Comment

Just a minor improvement on the progress front, I have fitted ten rubber tyre's five along each side, and a bow fender on the front as the boating lake has concrete sides. I am afraid the quality of the photo leaves a lot to be desired. Regards, Gary.

▲

⟩⟩

PeterH6

boatmam

EdW

Fred

hermank

Mike Stoney

AlessandroSPQR

Wolle

Julio

RNinMunich

stevedownunder

Len1

Doogle

pressonreguardless

Scratchbuilder

jbkiwi

Colin H

chugalone100

|

💬 Re: Tyre's and bow fender completed.

7 months ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 45 Views · 3 Likes

Flag

Hi Lew, and yes, I agree entirely with your comment, the Bow Fender is a little on the pristine white side and needs a bit of toning down somewhat. This build of mine seems to be taking forever to complete, as I am having a few problems despite the fact it is almost complete. I have a problem with a serious list to one side, due to the fact I have installed a very heavy condenser well-off the center line, due to the lack of space around the steam plant. Plus for good measure, I have a leak around the prop shaft and very limited access to seal it with epoxy. Mind I am sure I will get around to it in time. Very much like yourself, I am also suffering a few medical problems at this moment in time which hopefully will be sorted in the not-too-distant future. I dare say it's all part of the getting on a bit syndrome, and lifes great plan. Regards, Gary.

▲

⟩⟩

Mike Stoney

stevedownunder

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Tyre's and bow fender completed.

7 months ago by 🇺🇸 LewZ (

Commodore) Commodore)✧ 41 Views · 4 Likes

Flag

Gary, again, another model that is very well done. I zoomed in on various portions of the photo and checked out your fantastic details. Even the shackles on the ends of the rigging look great!

The only criticism I have is the bow fender. By itself the fender looks great but on this model I think is distracts from the distinctive bold look of the "Puffer" and your excellent workmanship. I also looked online and did not see any Puffers with bow fenders. I understand about the issues with concrete possibly damaging your boat. Perhaps by dark staining the fender it would reduce the distraction by blending in with the black hull. Just a thought. Lew Florida ⛵, USA ▲

⟩⟩

stevedownunder

GaryLC

Wolle

hermank

|

|

💬 Re: Tyre's and bow fender completed.

7 months ago by 🇮🇹 AlessandroSPQR (

Rear Admiral) Rear Admiral)✧ 43 Views · 1 Like

Flag

Hi Gary.

Fantastic creation. I missed it. ▲

⟩⟩

GaryLC

|

|

💬 Re: Tyre's and bow fender completed.

10 months ago by 🇩🇪 Wolle (

Commander) Commander)✧ 50 Views · 2 Likes

Flag

Great, perfect. I would be happy if I could do my Britannia even half as well. 👍

▲

⟩⟩

GaryLC

AlessandroSPQR

|

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 71 Views · 9 Likes

Flag

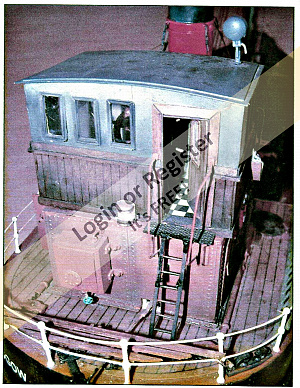

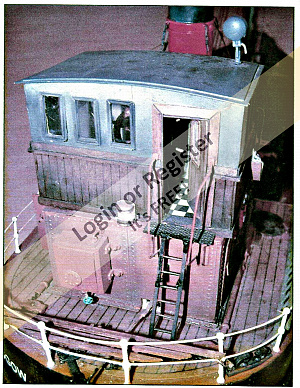

Hi Chug, as I am or have installed a steam engine, I tend to leave windows port holes and even the holes in the hatch cover boards open, along with working ventilators so as to circulate as much air as possible for the gas boiler burner, and this saves me fitting an electric fan. I also tend to cut holes into wheel-house floors on most boats, not pretty I admit but definitely functional and it works for me. I would have answered your query before but have just noticed it. Regards. Gary. (A photo of the real thing VIC 32 at Crinan, Scotland, Western Isles, and my inspiration to finally finish my Puffer.)

▲

⟩⟩

Mike Stoney

hermank

AlessandroSPQR

Wolle

Rogal118

RNinMunich

stevedownunder

chugalone100

pressonreguardless

|

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 85 Views · 0 Likes

Flag

Gary:

Did you detailed tinterior bridge? What material did you use for your windows? I looked through your posts but could see any with it. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 91 Views · 3 Likes

Flag

A lovely looking vessel, well done on your build 👍

▲

⟩⟩

AlessandroSPQR

GaryLC

stevedownunder

|

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 91 Views · 2 Likes

Flag

A superb build.

Many congratulations 👍 Regards Bill. ▲

⟩⟩

AlessandroSPQR

GaryLC

|

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 88 Views · 3 Likes

Flag

The 1mm black elastic together with the heat shrinking tubes is a BRILLIANT IDEA.

Thank you for sharing it with us. ▲

⟩⟩

pressonreguardless

GaryLC

Scratchbuilder

|

|

💬 Re: Tyre's and bow fender completed.

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 88 Views · 3 Likes

Flag

It’s a perfect build.

Have you tried it for buoyancy? How much counter weight did you have to add? ▲

⟩⟩

AlessandroSPQR

Scratchbuilder

GaryLC

|

Login To

Remove Ads

Remove Ads

📝 Highlander Clyde Puffer, (Episode 5.)

1 year ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 102 Views · 11 Likes · 3 Comments

Flag

💬 Add Comment

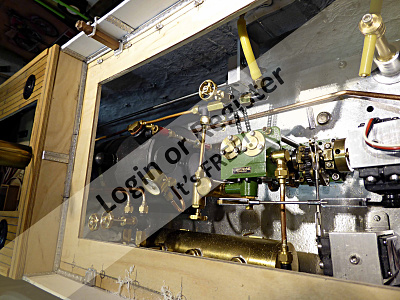

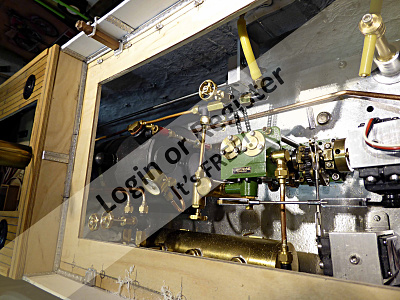

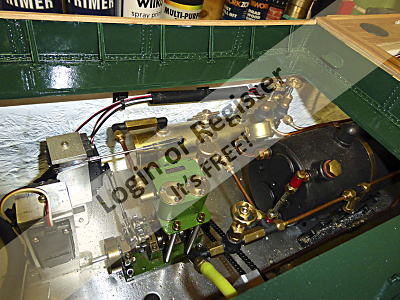

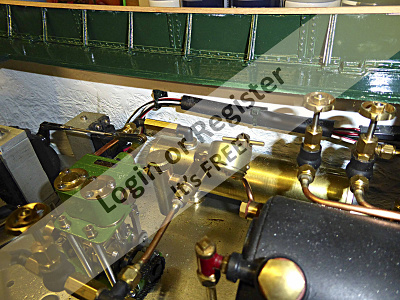

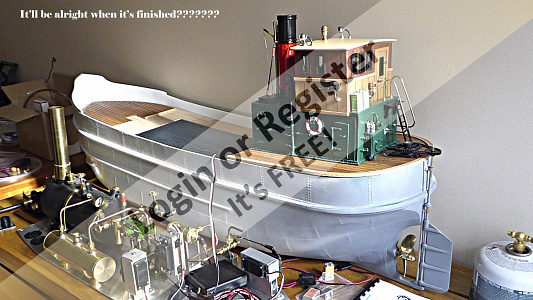

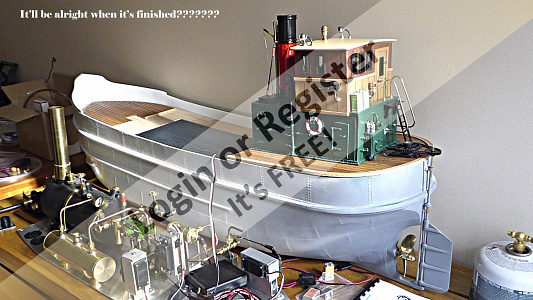

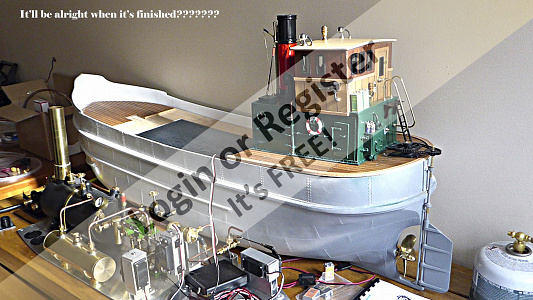

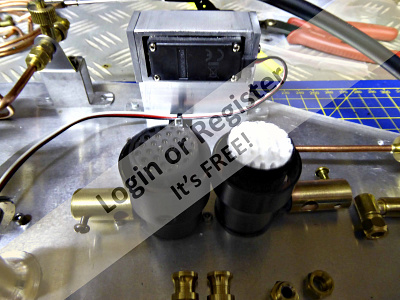

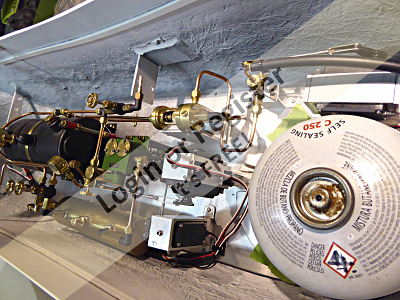

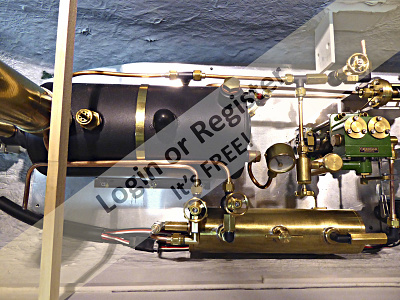

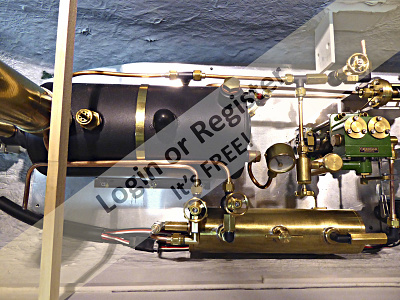

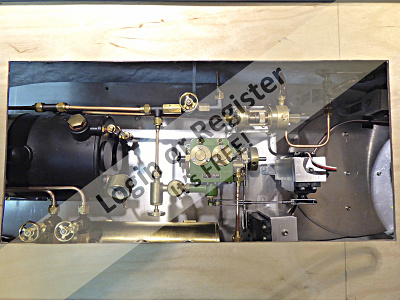

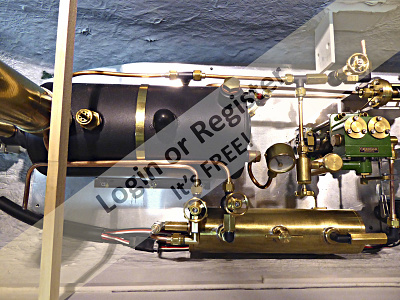

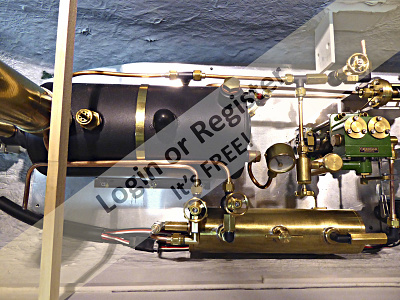

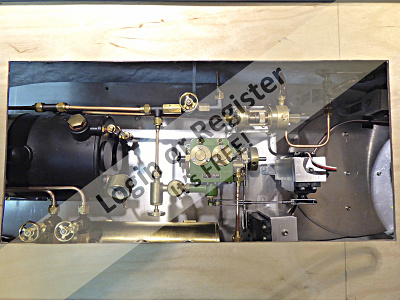

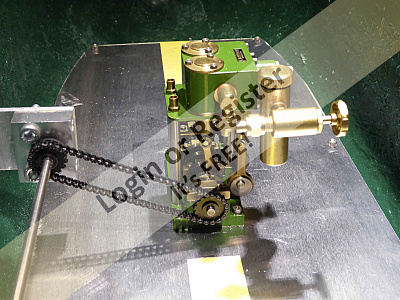

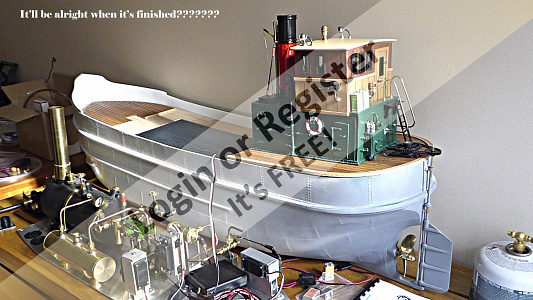

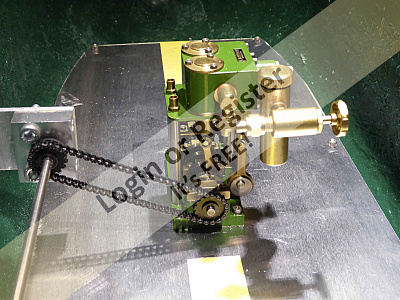

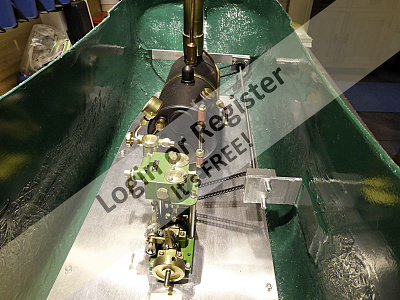

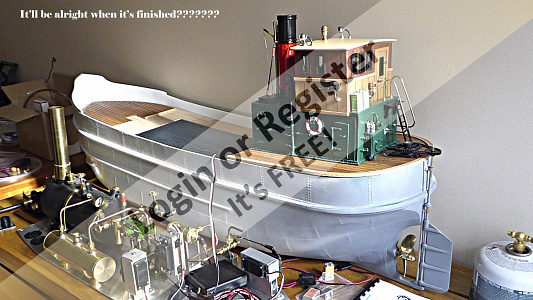

I posted a few interesting details earlier, to be found under Episode 4, with regard to the mast light and rigging fittings. I have to admit to the fact that now that I am once again involved with the building of this boat, I am very much enjoying every minute of the build, as there is just something special about Clyde Puffers, despite the fact it is definitely the most difficult boat to try and fit a steam plant into, as it is so unconventional as near enough everything is at the extreme back end. My solution to this problem is to use two drive chains and a drive shaft around the boiler, to connect the centrally-mounted steam engine to the short prop shaft. Mind I admit to a fair bit of chain testing to hopefully ensure it was robust enough and up to what I had in mind, and I am reasonably happy with the results. I think the best description of a puffer is a boat with lots of character, which does not need a boat stand as it is flat-bottomed, and at home either on a canal or out at sea. A few more photographs which are in no particular order. Regards, Gary.

▲

⟩⟩

Doogle

hermank

Mike Stoney

jbkiwi

Wolle

stevedownunder

Len1

pressonreguardless

Colin H

RNinMunich

chugalone100

|

💬 Re: Highlander Clyde Puffer, (Episode 5.)

1 year ago by 🇨🇦 RodC (

Lieutenant) Lieutenant)✧ 76 Views · 2 Likes

Flag

|

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer, (Episode 5.)

1 year ago by 🇺🇸 martyvz (

Leading Seaman) Leading Seaman)✧ 85 Views · 1 Like

Flag

Beautiful model, I particularly like the steam set up and the workaround for the prop shaft.

▲

⟩⟩

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 5.)

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 95 Views · 1 Like

Flag

It’s magnificent. It’s a showcase piece no doubt about it. It’s all perfect.😮😮

▲

⟩⟩

GaryLC

|

📝 Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 112 Views · 18 Likes · 10 Comments

Flag

💬 Add Comment

This has been a long time coming and I am now in a position where I can say it is almost complete. It is not quite to scale as I had to extend the rear deck slightly to give access to the pressure relief valve as this is also my boiler filling point. Plus, I have slightly enlarged the hatch opening and cover, with regard to better access to the steam engine and control valves. I had a problem with the pressure-controlled gas valve, which did not work despite the fact I gave it a damn good looking at. I then forked out another £70 for a manual version of the same to find exactly the same problem, they were both bought from Microcosm care of Mr. Galgig. In the end, I decided to remove this valve and manage without it. The steam plant was tested both inside and outside of the boat before the deck was fitted and fastened in place. The boiler is extremely efficent and will hold a three bar pressure with the engine running at a normal speed which I find quite surprising everything considered. As the pressure valve is set at 4 bar to operate this does tend to leak a bit at 3 plus bar, and a pipe was fitted in front of the wheelhouse engine superstructure. This was an afterthought and does look a bit odd, but I didn't want to spoil the pipework around the smoke stack come chimney. The photos are in no particular order. Comments and queries are more than welcome. More soon, regards, Gary.

▲

⟩⟩

Mike Stoney

KenThompson

jbkiwi

hermank

ChrisG

Colin H

boatmam

Albert90

flaxbybuck

RNinMunich

River Rat

stevedownunder

Newby7

chugalone100

Scratchbuilder

pressonreguardless

Wolle

Fred

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 96 Views · 4 Likes

Flag

Gary, that's a work of art, love your rigging details, absolutely stunning.

Cheers Colin. ▲

⟩⟩

pressonreguardless

stevedownunder

Scratchbuilder

GaryLC

|

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 102 Views · 7 Likes

Flag

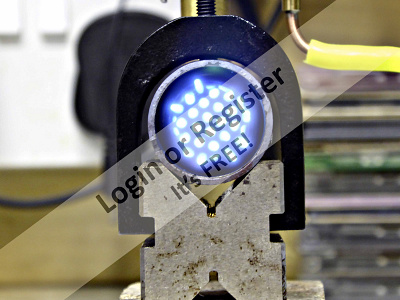

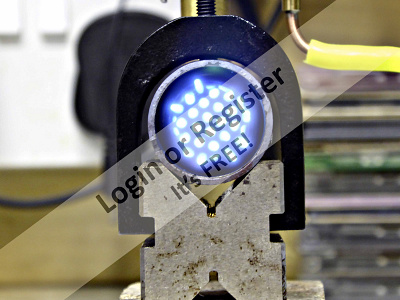

A little more progress today on the main mast with a 1940s vintage-type lantern probably of the paraffin variety, which slides up and down on two guy ropes. All of my rigging is 1mm black elastic with most of the ends doubled over and encased in heat shrink, hopefully, to give a spliced effect. I am quite happy with the way it turned out as it has a realistic effect and looks like the real thing. This is running off a 6-volt switched battery pack hidden under the deck. The lights on the wheelhouse structure run from another 6-volt switched battery pack fastened to the roof of the wheelhouse, so as not to have wires to disconnect when removing decks and superstructure. Regards, Gary.

▲

⟩⟩

Mike Stoney

Wolle

chugalone100

pressonreguardless

stevedownunder

Colin H

Scratchbuilder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 107 Views · 4 Likes

Flag

Hi Gary,

I am sorry to say there has been no real progress on LT100 this year, mainly due to my wife's ongoing ill health. I have shelved the Drifter just last week, for the time being, although I have started a small side project a Revell deep sea trawler, Ross Jackal kit to a scale of 1/142 so the box says, being a plastic kit I don't need all that much time in each sitting to make some progress. I am converting it to RC and will make changes to some details as well. I probably have enough stuff to do an update on the Drifter, but at the moment I would rather do some building with my very limited hobby time. Cheers, Stephen. ▲

⟩⟩

AlessandroSPQR

Scratchbuilder

GaryLC

hermank

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 108 Views · 11 Likes

Flag

This is for anyone who is wondering why the hatch cover is minus three planks, this was definitely for novelty value, and the fact I had a small bag of genuine coal which I picked up at Whitby before they turned the coal yard into a carpark. The answer is in the attached photograph. Regards, Gary.

▲

⟩⟩

Wolle

chugalone100

Scratchbuilder

jbkiwi

hermank

stevedownunder

ChrisG

Len1

Colin H

pressonreguardless

RNinMunich

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 105 Views · 2 Likes

Flag

Everything RNinMunich said, and more.

Just wonderful ! 😉 ▲

⟩⟩

stevedownunder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 105 Views · 3 Likes

Flag

What a magnificent labyrinthine, magical, mechanical masterpiece😮

Oh! And the ship's pretty damn good too👍 Can't wait to see her puffing round the pond! Well done shipmate. Cheers, Doug 😎 ▲

⟩⟩

hermank

stevedownunder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 108 Views · 6 Likes

Flag

Thanks, Stephen, and your comment is very much appreciated. Please let me know what is happening at your end with regard to Formidable LT 100 the last wooden North Sea Drifter. Very much like myself, it has been a long time since your last progress report. I hope all is well at your end. Regards, and best wishes Gary.

▲

⟩⟩

Wolle

chugalone100

Scratchbuilder

stevedownunder

ChrisG

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 117 Views · 4 Likes

Flag

Hi Gary,

She looks fantastic all freshly painted up. Pity about the attenuator valve. Cheers, Stephen. ▲

⟩⟩

AlessandroSPQR

hermank

pressonreguardless

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 106 Views · 3 Likes

Flag

Extravagant model with a very nice looking steam engine.

I’m selling a Caldercraft model like this one on EBay. 325695723267 ▲

⟩⟩

pressonreguardless

stevedownunder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 4 )

1 year ago by 🇧🇪 hermank (

Captain) Captain)✧ 113 Views · 3 Likes

Flag

Beautifull model, well Made and nice details.in ou club KMYCA quite à lot of members havé built a puffer with a steam engine. You need to come to Antwerp as from march onwards once à month we have à compétition with only steam driven boats.

▲

⟩⟩

pressonreguardless

stevedownunder

GaryLC

|

📝 Highlander Clyde Puffer, (Episode 3 and a bit more.)

3 years ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 199 Views · 19 Likes · 1 Comment

Flag

💬 Add Comment

Sorry folks a whole month has passed since my last epistle, this is due to a combination of the building of a lathe, and I think slowing down a bit with old age. However, the lathe is very nearly finished now, which is just as well as I need to make some fittings with it, and then it is back to the Puffer. Regards, and Episode 4 is coming, mind, so is Christmas. Take care, Gary.

▲

⟩⟩

chugalone100

cdnfurball

hermank

Wolle

Colin H

ColinT2

mturpin013

MouldBuilder

tomarack

Commodore-H

bednall

Madwelshman

pressonreguardless

Jimba

stevedownunder

Scratchbuilder

Martin555

Ronald

RNinMunich

|

💬 Re: Highlander Clyde Puffer, (Episode 3 and a bit more.)

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 114 Views · 7 Likes

Flag

Christmas came and went followed by another Christmas with no progress on the Puffer build. However, last year while visiting Bonny Scotland my friend and I managed to find VIC 32 at a place called Crinan, and this definitely rekindled my interest and the good news is the puffer is almost complete. As per the two photographs before and after. I will update my blog with lots of photographs of the build in the very near future. Regards, Gary.

▲

⟩⟩

chugalone100

cdnfurball

stevedownunder

hermank

Wolle

pressonreguardless

Colin H

|

📝 Highlander Clyde Puffer, (Episode 3 and a bit.)

3 years ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 209 Views · 10 Likes · 1 Comment

Flag

💬 Add Comment

Just a little add-on bit to go with the last write-up. Today was spent testing two gas burners made for a Cheddar Boiler, the original burner was ceramic and worked quite well or at least I thought so until I tested the second one which was definitely better, and improved when I lifted the jet and holder slightly to let in more air. By placing a 6mm drill which is a good fit through the two air holes in the tube which holds the holder, then fitting the jet and holder into this tube until in sat on top of the drill bit, this seemed to be the best position as no yellow in the flame only a nice shade of baby blue, and the flame was a good 6" long, perfect. The second burner has a round drilled meta disc with a very fine steel mesh behind it, this burner was also much quieter than the first one. Regards Gary

▲

⟩⟩

chugalone100

hermank

Wolle

mturpin013

Commodore-H

jbkiwi

dave976

Martin555

stevedownunder

Colin H

|

💬 Re: Highlander Clyde Puffer, (Episode 3 and a bit.)

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 206 Views · 4 Likes

Flag

Gas burners, Its science in its own right however you seen to be on top of the issue.

▲

⟩⟩

hermank

Martin555

stevedownunder

GaryLC

|

📝 Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 217 Views · 23 Likes · 19 Comments

Flag

💬 Add Comment

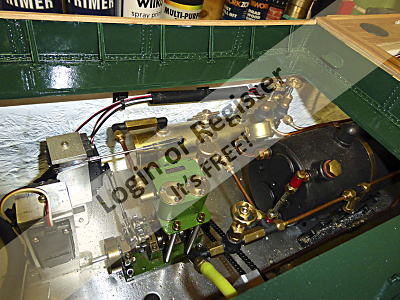

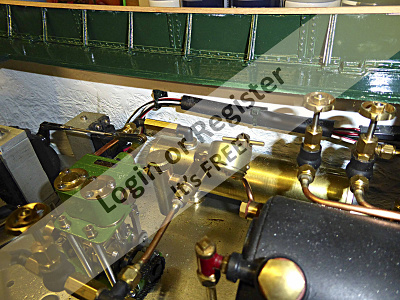

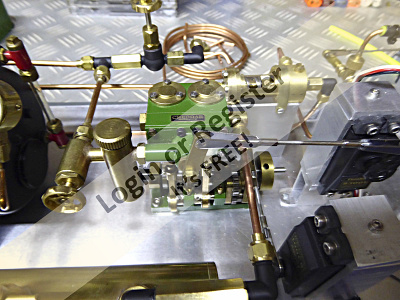

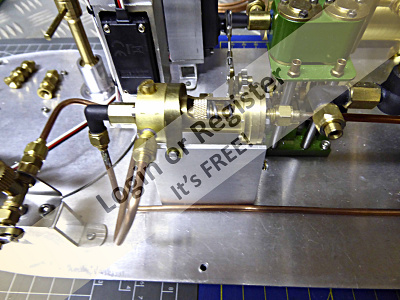

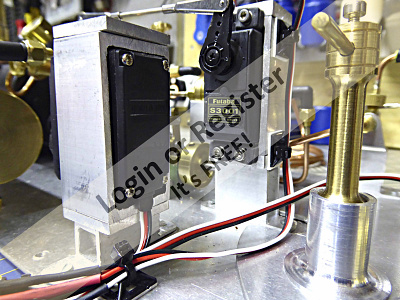

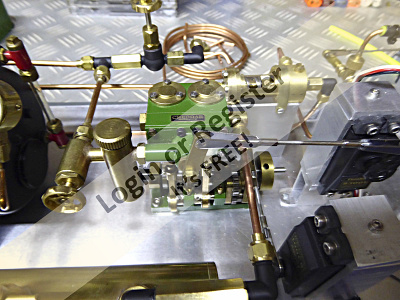

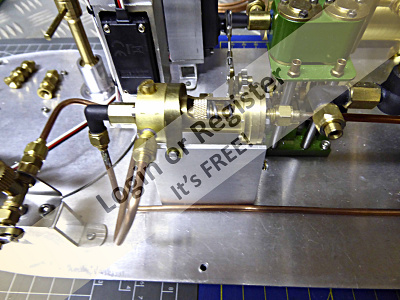

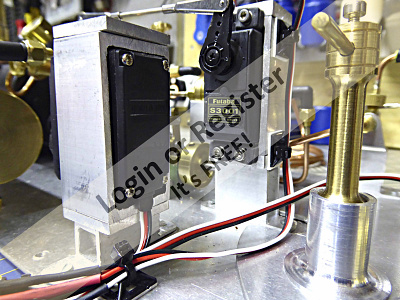

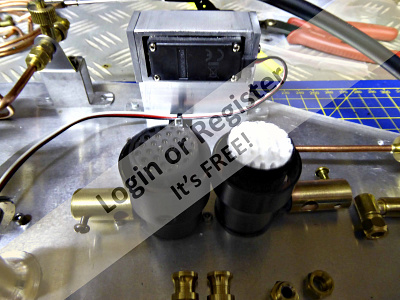

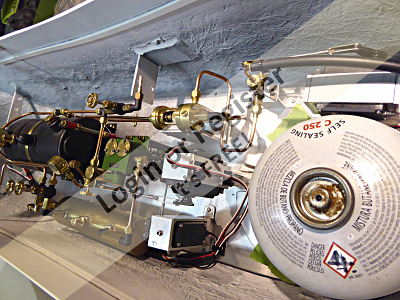

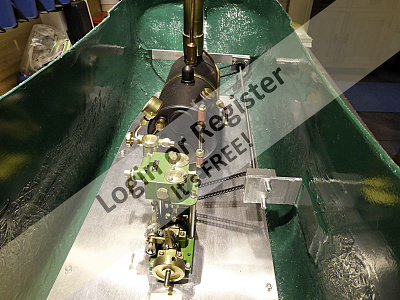

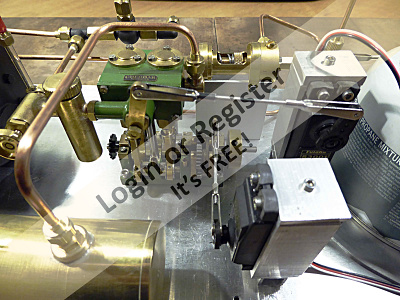

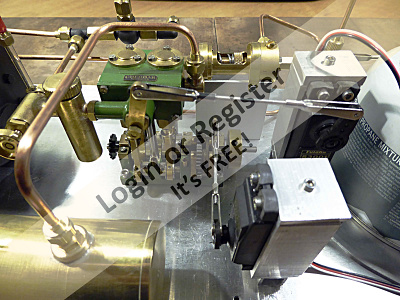

Continuing from where I left off in the last episode. I ordered aluminium sheet for the steam plant base at 1/8" thickness and cut too size, from Metals4U an extremely helpful company and reasonable prices. The base plate is mounted onto several pieces of 1/2" channel, having marked the hull bottom with the positions of the channel, the channels are filled to overflowing with epoxy car filler and fitted where required, then the base plate shaped to fit the hull, is positioned on to the channels and levelled with a spirit level, the excess filler is removed when still soft with a sharp knife. The support channels were then reinforced with milliput epoxy putty, then 2.5mm socket screws were used to secure the base to the support channels. Next up is the positioning of the four main components that make up the steam plant, the boiler first positioned so as the boiler chimney matches perfectly with the superstructure chimney, followed by the steam engine which is positioned reasonably central in the main hold, as this needs to be accessible in order to oil bearings and moving parts, as well as filling and emptying the lubricator. The condenser and automatic gas regulator were fitted on opposite sides of the main hold again very much with access in mind. Three servos are required to operate engine speed, forward and reverse, and the gas cut off valve which is definitely a must-have feature, as I am only too aware of what can happen and does happen if you do not fit this common-sense safety feature. Next up we have the servo linkages which I try to keep reasonably short and horizontal which means all of the servos are raised using alloy rectangular box section, the servos are fitted into rectangular box section as a method of securing the same, (servo full metal jacket.) Having arrived at this stage now you have the problem of fitting the copper piping, and I have never ever managed to get this completely right at my first attempt, as soon as a pipe is fitted realization dawns that if I had done it this way I would have a shorter pipe with fewer bends. I would strongly recommend don't silver solder any ferrules or fittings until the pipework is complete and cannot be improved. Brass hexagon bar measuring 8mm across the flats as per 2BA spanner is very useful for making couplings especially when you have 1/4"x 40 ME at one end and 1/4"x 32 ME at the other. ME (Model Engineer) Taps and Dies are a very good investment when involved with steam. Well I reckon that's about it for this one, so should you have any questions or require further information, then don't hesitate to get in touch. Regards, Gary.

▲

⟩⟩

chugalone100

hermank

Wolle

Peter D

MouldBuilder

Commodore-H

jbkiwi

Julio

Jimba

Ronald

pressonreguardless

dave976

Scratchbuilder

ARL58

Rock

Madwelshman

Newby7

mturpin013

Martin555

RNinMunich

Colin H

Graham93

stevedownunder

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇺🇸 ChrisR (

Master Seaman) Master Seaman)✧ 128 Views · 0 Likes

Flag

It looks amazing!!! Congratulations.

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 150 Views · 2 Likes

Flag

Yes, I quite like that shade of green also, but I am afraid the can has no colour code. It was from WILKINSON'S and is called Forest Green, and I hope this helps and I tend to buy all my paint there as it is very good quality at a reasonable price. Regards, Gary. (They sell a really good satin black which is ideal for painting a hull.)

▲

⟩⟩

hermank

stevedownunder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇧🇪 Peter D (

Recruit) Recruit)✧ 141 Views · 1 Like

Flag

Very beautiful work, the detail and finishing makes it.

Colours also very real. What is the code of the green Gary? ▲

⟩⟩

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 172 Views · 2 Likes

Flag

Fantastic work Gary, looking forward to the first sailing👍

JB ▲

⟩⟩

GaryLC

Peter D

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 xtramaths (

Master Seaman) Master Seaman)✧ 189 Views · 1 Like

Flag

First class installation, I admit to having three attempts every time!

▲

⟩⟩

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 197 Views · 3 Likes

Flag

The Steam Engine and Installation is Exceptional!!

Of course the vessel is outstanding. I have an affinity to Steam Power!! ▲

⟩⟩

GaryLC

Griss

Jimba

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 206 Views · 3 Likes

Flag

Gary.

Stunning work. Keep it up. Regards Bill. ▲

⟩⟩

Jimba

GaryLC

Martin555

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 203 Views · 4 Likes

Flag

Hi Gary,

She is looking really good. It is a shame that a lot of your work will only be seen when she is in display mode. Keep up the fantastic work. Congratulations on your promotion to Sub-Lieutenant. Extremely well deserved. Martin555. ▲

⟩⟩

Jimba

Scratchbuilder

GaryLC

stevedownunder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 205 Views · 2 Likes

Flag

Hi Gary,

That's quite a collection. Cheers, Stephen. ▲

⟩⟩

GaryLC

Martin555

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 212 Views · 6 Likes

Flag

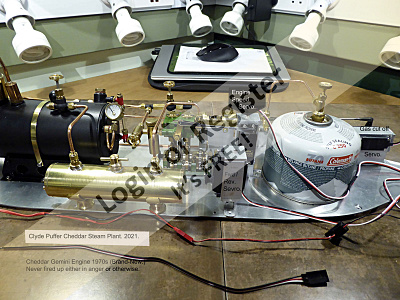

Hi Stephen, this is my current burner collection of spares, destroyed, and experimental burner plates mostly bought in although one is completely homemade, I was trying to find something that worked on my Maxwell Hemmings 4" x 4" boiler, an expensive exercise if ever there was and in the end opted for an adapted gas blowtorch. I shall keep you informed of my progress hopefully not too long before I light the blue touch paper. Regards, Gary.

▲

⟩⟩

Wolle

chugalone100

dave976

Martin555

stevedownunder

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 209 Views · 4 Likes

Flag

GLC Not only is your work on the boat great. The posts are easy to follow go into good detail.

Rick ▲

⟩⟩

Martin555

stevedownunder

GaryLC

Madwelshman

|

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 209 Views · 3 Likes

Flag

Hi Gary, yet another fantastic installation, really professional well done

▲

⟩⟩

Martin555

stevedownunder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 213 Views · 6 Likes

Flag

Hi Tug, and I also would like to know the exact use of the two water storage facilities, that is the round water tank on the roof of the engine housing, and the square tank on the rear bulkhead. I have tried to find answers to that question as it has been asked before and quite recently. I should imagine it is freshwater for the steam engine and maybe domestic use, as in making tea. The steam engine which would normally be a three-cylinder compound engine would use a lot of water, and would use a condenser on the steam exhaust to produce recycled water, as no oil was used inside the engine cylinders as the lubricant was steam. I will eventually find the answer to this question hopefully through the Crew of VIC 32, the last and only remaining steam operated Clyde Puffer. Regards, Gary.

▲

⟩⟩

Wolle

chugalone100

dave976

Martin555

stevedownunder

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 205 Views · 2 Likes

Flag

Hi Gary,

Looking forward to hearing about your tests.😀 Great work. Cheers, Stephen. ▲

⟩⟩

Martin555

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇨🇦 Tug Hercules (

Leading Seaman) Leading Seaman)✧ 209 Views · 3 Likes

Flag

Excellent build.

The green Tank, on the Starboard side of the Stack, what is it for? I believe there are different views on what water it may contain, but from Your perspective, what was the use of this Tank for? Thank You. Tug ▲

⟩⟩

Martin555

GaryLC

stevedownunder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 217 Views · 3 Likes

Flag

Hi Richard, I just wanted to say it really is not that complex at all. I started with steam back in the seventies and bought a steam plant from Maxwell Hemmings, as I was working in Saudi at the time and had joined the more money than sense syndrome. As I hadn't got a clue at that time I cut up the boat to make it fit as opposed to altering the pipework. Happy days, I think I have the hang of it now? Regards, Gary.

▲

⟩⟩

stevedownunder

Martin555

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 217 Views · 3 Likes

Flag

Hi Stephen, yes photo 5 the attenuator come boiler pressure gas control valve, the pipe from the right angle on the left-hand end is the gas supply to the burner, the boiler steam pressure is on the right-hand end, and the remaining tapping is to the gas cut-off valve to the left of the photo. That is the one problem which I was never very happy about the fact that the gas canister is at one end and the burner at the other.

The two burners, the ceramic one is the original, the other with the plate full of holes with a wire gauze behind it is the new and hopefully more efficient and quieter offering from Clevedon Steam. I shall do some testing on both and let you know the results. Yes, you are right that is a huge block of script and needs to be in paragraphs or something. Regards, Gary. ▲

⟩⟩

stevedownunder

Martin555

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇬🇧 Richard7 (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 213 Views · 3 Likes

Flag

Hello Gary, what a superb model, l am blown away with the steam power unit. I am happy to admit this engineering is way beyond my capabilities, but l will follow the progress and eventual first sailing.

Great photos by the way, Richard ▲

⟩⟩

stevedownunder

Martin555

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 3.)

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 210 Views · 3 Likes

Flag

Hi Gary,

Looks great, very neat instillation. In photo no5 there is a copper line running along touching the Aluminum plate, I am guessing this is the output from pressure regulating device or attenuator to the gas burners? Your 2 burners look different one looks like my old Cheddar steam ceramic burner while the other one doesn't have the ceramic bit. Great progress. 👍 Only one criticism, with such a large block of text it becomes difficult to read (for me) without some gaps in between. Cheers, Stephen. ▲

⟩⟩

Martin555

RNinMunich

GaryLC

|

📝 Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 222 Views · 13 Likes · 8 Comments

Flag

💬 Add Comment

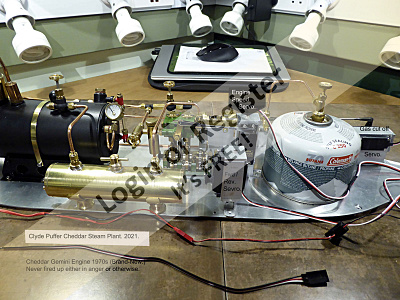

The steam engine and boiler for the Puffer have been borrowed from my Topaz (Edwardian) Steam Launch a static model with no radio gear installed. Consequently, despite the age of the steam plant, it has never been fired up as such either in anger or otherwise. Cheddar in their time made some really well-engineered engines and the Gemini is a shining example of that era. The boiler which measures 3" x 6" is none conventual as the chimney and burner are both at the same end, as opposed to the normal center flue with burner and chimney at opposite ends. So having positioned the boiler on its base plate to line up with the engine housing chimney, and with the burner at the back end. A short prop shaft was fitted and the rudder also. The problem is to get the propshaft to run around the boiler and connect to the engine. this was done using sprockets, chains, shafts and bearings from Micromold. To be perfectly honest this actually works rather well, and much better than I expected. I think the photos are hopefully self-explanatory, there are two chains one from the propshaft to the drive shaft which is fastened to the hull and runs the length of the boiler, this terminates at a second chain which is coupled to the engine. There is also a few photos of the steam plant and engine. I still have some modifications to make to the steam plant to make better access to control valves. I need to finish the steam plant work and fit it into the hull, then make sure everything works alright before I fasten the decks down, I have been thinking along the lines of a visit to the boating lake also before the decking and finishing. that is about it for this one, I will try and answer questions and comments. Regards, Gary.

▲

⟩⟩

Wolle

chugalone100

pressonreguardless

dave976

Madwelshman

mturpin013

Mike Stoney

MouldBuilder

Colin H

stevedownunder

Scratchbuilder

jbkiwi

Newby7

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 219 Views · 2 Likes

Flag

Awesome installation Gary.

I am enjoying this build log. Keep it coming. Martin555. ▲

⟩⟩

GaryLC

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 222 Views · 3 Likes

Flag

Colin, note the homemade steam spreader at the top of the chimney, for a more even output of condenser exhaust steam. Gary.

▲

⟩⟩

stevedownunder

Martin555

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 222 Views · 7 Likes

Flag

Hi Colin, and thanks for the positive comment, much appreciated. With regard to your steam plant and choice of the hull, I reckon the minimum size would be around 48" mark, as that is a heavy-weight steam plant. Tugs in general tend to be almost flat bottomed, good for a lower sense of gravity and wide in the beam. A fiberglass hull would make sense as no ribs, bulkheads, or keel to worry about. In an ideal world, a one-piece central superstructure that also carried the masts, as mine does is worth thinking about. I also have thought that converting to butane/propane gas using a purpose-made ceramic burner, which is available for the Babcock boiler would be safer and more efficient. The much easier solution would to go for the open launch and show off your nicely painted and polished steam plant. Please let me know which road WE are going down. Regards, Gary. (My tug by Mobile Marine, Marian Bell'e measures 39" x 10" and is quite heavy.)

▲

⟩⟩

Wolle

chugalone100

dave976

stevedownunder

Martin555

jbkiwi

Colin H

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 220 Views · 4 Likes

Flag

Gary, superb explanation and pictures.

I am currently trying to work out what size Hull I need for my Stuart Babcock 500 boiler and Sun motor. Do you think a 4 foot tug Hull would be okay. Cheers Colin. ▲

⟩⟩

stevedownunder

Martin555

Scratchbuilder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 218 Views · 3 Likes

Flag

Lovely explanation Gary,

I like the outside the box thinking for your drive system. Looking forward to seeing more. Cheers, Stephen. ▲

⟩⟩

Martin555

Scratchbuilder

GaryLC

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 220 Views · 3 Likes

Flag

Gary.

An excellent Episode 2. This is just like a good thriller on the TV. Your work is first class and in reality simplicity in itself in terms of what you have achieved in the restricted space. I know very little regarding steam power and find this really interesting. Very self explanatory photographs. Great work,keep it up. Regards Bill ▲

⟩⟩

Martin555

GaryLC

stevedownunder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 219 Views · 4 Likes

Flag

Great looking set-up Gary, nice drive solution👍👍 Engine's a beauty.

JB ▲

⟩⟩

Martin555

GaryLC

stevedownunder

Scratchbuilder

|

|

💬 Re: Highlander Clyde Puffer, (Episode 2.)

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 219 Views · 3 Likes

Flag

GLC You bring steam alive in finding a way to get power from the engine to the prop. Look foreword to watching this build.

Rick ▲

⟩⟩

Martin555

GaryLC

stevedownunder

|

📝 Highlander Clyde Puffer.

3 years ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 225 Views · 13 Likes · 5 Comments

Flag

💬 Add Comment

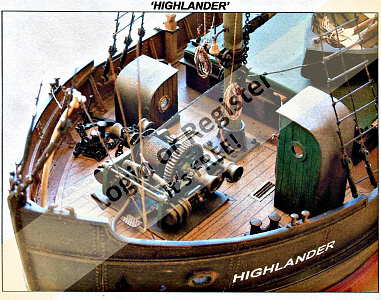

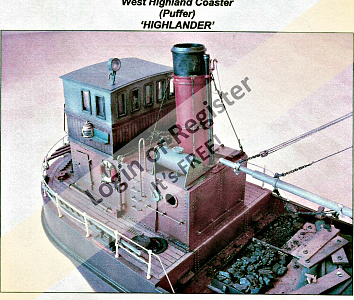

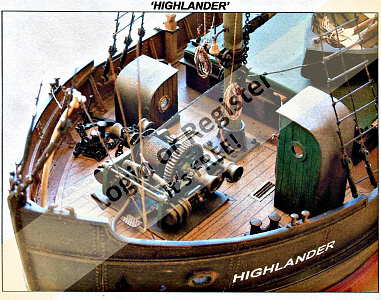

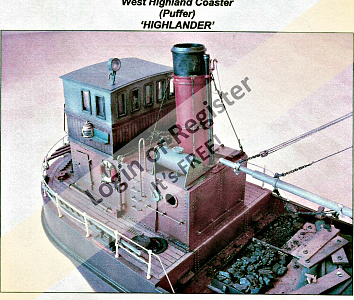

Having thought about doing a blog on this build for some time I have finally decided to give it a go and see how I get on. First and foremost this is a kit by Mountfleet, and it really does leave a little to be desired as in the quality of the fiberglass mouldings and the white metal fittings. It is not by any stretch of the imagination the company it used to be before the major fire they suffered some years ago. I have always liked the Clyde Puffers as great little working boats full of character and nostalgia, plus there is still one or two still working around the Islands on the west coast of Scotland. I think they are more involved these days with tourists and sightseers than carrying freight, although I dare say they still carry some occasionally. My personal preference is to build working boats from the 30s and 40s that were powered by steam engines. The reason I have left it this long is the very unconventional layout with the boiler and steam engine both at the back end of the boat. Then I had this idea with regard to using sprockets chains and shafts, not forgetting the bearings, to run the propshaft around the boiler and position the engine in front of the boiler. I think you will need to check the photos to see where I am coming from on that one. These first photos are from the kit brochure and I think the weathering has been somewhat over-done. It looks like it needs a good wash down. Any comments or suggestions I will gladly take on board, as I am making this up as I go and I am hoping this works out, time will tell. Regards, Gary.

▲

⟩⟩

Wolle

chugalone100

dave976

ARL58

Madwelshman

GARTH

Graham93

stevedownunder

Martin555

Colin H

Scratchbuilder

isabuncu

Newby7

|

💬 Re: Highlander Clyde Puffer.

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 221 Views · 2 Likes

Flag

It will be worth watching this blog GLC.

Rick ▲

⟩⟩

stevedownunder

Martin555

|

|

Login To

Remove Ads 💬 Re: Highlander Clyde Puffer.

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 223 Views · 2 Likes

Flag

Hi Gary,

Great to see you have started a build log, and I am looking forward to more updates. Cheers, Stephen. ▲

⟩⟩

Scratchbuilder

Martin555

|

|

💬 Re: Highlander Clyde Puffer.

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 222 Views · 2 Likes

Flag

Hi Gary,

I think you have made the right decision to be a build log. I will be following your progress. Martin555. ▲

⟩⟩

Scratchbuilder

stevedownunder

|

|

💬 Re: Highlander Clyde Puffer.

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 223 Views · 3 Likes

Flag

Gary, intrigued by your idea and will be following closely.

Cheers Colin. ▲

⟩⟩

Scratchbuilder

stevedownunder

Martin555

|

|

💬 Re: Highlander Clyde Puffer.

3 years ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 227 Views · 2 Likes

Flag

Gary.

Looking forward to this build. So far so good.Be interesting to see the engine position build as you describe. Regards Bill. ▲

⟩⟩

stevedownunder

Martin555

|

United Kingdom

United Kingdom