Join Us On Social Media!

Gaff Rigged Pilot Cutter

44 Posts · 36 Followers · 434 Photos · 545 Likes

Began 4 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 3 years ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Maiden voyage

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 207 Views · 32 Likes · 28 Comments

Flag

💬 Add Comment

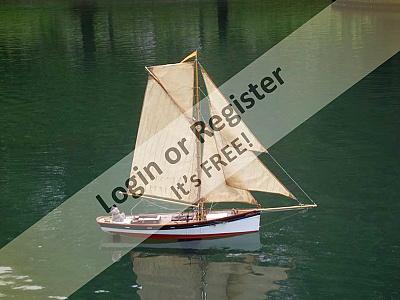

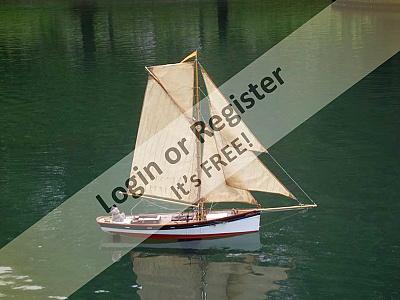

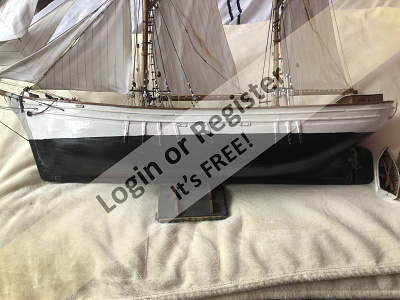

At last, the day arrived! The weather this morning for the Buxton area looked to be ideal with 10mph winds forecast.

I don't have access to a Transit van or similar 😊 so the boat has to be transported in bits and assembled at the lake side. It is a bit of a squeeze to fit it all into the car.

The large, yellow sided case keeps the mast and sails safe during transit. It is a simple pair of wooden frames hinged together and covered with twinwall plastic sheeting which I just happened to have in the shed. Also in the car is a folding stand for use at the side of the lake, and a launch cradle made from copper pipe.

At he lakeside, assembly involves fitting the keel, rudder, mast and sails. It takes around 15 minutes to complete - possibly less in future with a bit of practice.

Once launched, she was away ⛵👍. The wind was a lot less than forecast, maybe 5mph with some gusts. She did struggle a bit on such a gentle breeze. When it did blow, she was fast and responsive, outrunning the video chase boat on occasions.

She is named 'Ellen' after my grandmother. Oh, and the helmsman? The designer, Gary Webb (bearospaceindustries.com) has started a bit of tradition of having a bear as helmsman 😀

I don't have access to a Transit van or similar 😊 so the boat has to be transported in bits and assembled at the lake side. It is a bit of a squeeze to fit it all into the car.

The large, yellow sided case keeps the mast and sails safe during transit. It is a simple pair of wooden frames hinged together and covered with twinwall plastic sheeting which I just happened to have in the shed. Also in the car is a folding stand for use at the side of the lake, and a launch cradle made from copper pipe.

At he lakeside, assembly involves fitting the keel, rudder, mast and sails. It takes around 15 minutes to complete - possibly less in future with a bit of practice.

Once launched, she was away ⛵👍. The wind was a lot less than forecast, maybe 5mph with some gusts. She did struggle a bit on such a gentle breeze. When it did blow, she was fast and responsive, outrunning the video chase boat on occasions.

She is named 'Ellen' after my grandmother. Oh, and the helmsman? The designer, Gary Webb (bearospaceindustries.com) has started a bit of tradition of having a bear as helmsman 😀

▲

⟩⟩

Kev1

Peejay

PeterL3

Scratchbuilder

EdW

Len1

PeteJev

Alain Pascal

Alwanl

BillB1

peterd

GaryLC

Madwelshman

JBRCfloats

pressonreguardless

Muskrat

figtree7nts

Mike Stoney

Nonsuch

AndyB

redpmg

jbkiwi

Martin555

philcaretaker

Nerys

Rookysailor

AustinG

stevedownunder

Ronald

RNinMunich

robbob

Colin H

|

💬 Re: Maiden voyage

5 months ago by 🇬🇧 PeterL3 (

Petty Officer 2nd Class) Petty Officer 2nd Class)✧ 42 Views · 2 Likes

Flag

What a great set of photos you must be very proud of your work like the sail box looks like it all fits well in your motor regards peter l⛵⛵⛵

▲

⟩⟩

Graham93

fireboat

|

|

Login To

Remove Ads 💬 Re: Maiden voyage

5 months ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 53 Views · 1 Like

Flag

Thanks Alain,

I’m glad you have enjoyed reading through the blog and hope you found it useful Regards Graham ▲

⟩⟩

Len1

|

|

💬 Re: Maiden voyage

5 months ago by 🇨🇦 Alain Pascal (

Recruit) Recruit)✧ 50 Views · 2 Likes

Flag

s/v Hellen is just absolutely lovely.

Spectacular build. Fantastic build Blog. And from the videos she sails beautifully. Kind regards, a. ▲

⟩⟩

Graham93

Len1

|

|

💬 Re: Maiden voyage

2 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 112 Views · 0 Likes

Flag

Gary, Shows how the bear is done on the YouTube video. Search for SailTails and the Bear. You can also email Gary @

gringogary8@aol.com ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Maiden voyage

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 134 Views · 1 Like

Flag

Hi Bob,

I didn’t think it was worth the effort to animate the bear but In case you haven’t seen it, I have animated other figures:

▲

⟩⟩

Madwelshman

|

|

💬 Re: Maiden voyage

2 years ago by 🇬🇧 bobonthelough (

Leading Seaman) Leading Seaman)✧ 133 Views · 0 Likes

Flag

You can also fit a micro servo into the shoulders with a split servo cable to the rudder to control the head movement from the rudder channel. With regard to the flexible arm all that is needed is to attach the hand to the tiller with an

empty sleeve. No one will notice. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Maiden voyage

2 years ago by 🇦🇺 peterd (

Midshipman) Midshipman)✧ 161 Views · 0 Likes

Flag

Looks like a great job. He certainly gives good follow up via video and clear plans.

When I received the plans I checked the draft and compared it to my IOM. A fraction longer which at the moment would be an issue where I live. People have dumped weed or grass into the waterway which grew to the extent that we cannot sail or put any watercraft in. Had to move to another location with shallower water. Wee Nip size. Regardless, am really looking forward to the build. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 stevejf (

Recruit) Recruit)✧ 169 Views · 0 Likes

Flag

Thanks for the advise and the link Graham the photos of Tallulah will certainly help.

Steve ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 172 Views · 4 Likes

Flag

Hi Steve,

Glad you like the blog.👍 I also spent some time searching for photos of gaff rigged cutters on the internet. The ones I found most useful are of Tallulah by Luke Powell. ▲

⟩⟩

stevedownunder

stevejf

jbkiwi

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 stevejf (

Recruit) Recruit)✧ 171 Views · 2 Likes

Flag

Hi Graham, fantastic boat. I was looking on the internet for some photos showing details of gaff rigged boats so I could incorporate some of the features into the boat that I'm building. I was very pleasantly surprised to find your build blog, not only because the details on your boat are exactly what I was looking for but but also because your boat is exactly the same as the one I'm building, Gary Webb's "Flyer". I hope you don't mind if I use some of your ideas. If mine turns out half as good as yours I'll be very pleased.

Steve ▲

⟩⟩

Graham93

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 195 Views · 1 Like

Flag

Graham, I've read somewhere of how he 'doctors' the bears to give them a flexible arm that is attached to the tiller and gives the impression that the bear is steering. I'm sure you could produce a flexible joint of some sort. I have a recollection that the bear moved with the tiller.

Cheers, Nerys ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Maiden voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 199 Views · 5 Likes

Flag

Nerys,

It’s not clear from the photos, but the bear does ‘steer’ the boat using the tiller - at least that’s how it looks from a distance.😉 😂😆 Graham93 ▲

⟩⟩

NigelTailyour

Nerys

RNinMunich

stevedownunder

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 199 Views · 3 Likes

Flag

Thanks everyone for the positive feedback. I’m glad you enjoyed the blog, I certainly enjoyed the build, even if it did take a lot longer than I expected. I am pleased with the end result, although whatever I build, there are always things I think could be better. I expect I’ll tweak a few bits here and there and possibly make a smaller lighter keel for light winds.

JB, it will be my favourite on windy days. The rowing boat is the favourite for windless days 😆. Graham93 ▲

⟩⟩

jbkiwi

stevedownunder

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 196 Views · 5 Likes

Flag

The Bearospace man who designed your boat has, I believe had considerable experience in training his bears to sail his boats, particularly the schooners. They do a grand job of it. With your ability to build this boat, I see no reason why you could not train a bear to sail it. As a matter of interest, there used to be an organisation called, 'The Boating Bears Club', it was mainly canal based. Many of the bears had their own boats, usually purpose built dinghies. The lady who ran it was married to a gentleman who was chairman of the 'Odd Boat Society'. I am afraid I have not heard anything of either organisation for some years so I do not think they are still in existence.

Cheers, Nerys ▲

⟩⟩

RNinMunich

stevedownunder

Graham93

Martin555

Colin H

|

|

💬 Re: Maiden voyage

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 196 Views · 3 Likes

Flag

And you had doubts Graham😁, she looks absolutely perfect👍👍 love the sail 'bag' as well! New favourite model I'll bet,- ⛵⛵⛵⛵⛵ out of⛵⛵⛵⛵⛵

JB ▲

⟩⟩

stevedownunder

Graham93

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 202 Views · 2 Likes

Flag

"He would have to duck every time the boom swung past"

I have every faith in your ability to make him do that Graham 👍 AND smoke a pipe at the same time 😉 😎 ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 201 Views · 2 Likes

Flag

Graham,

I like many other members have followed your build log from the very start. And i have to say i have thoroughly enjoyed it. Normally i would just glance at a sail boat but now i find myself looking more in-depth at them with more of an understanding about them thanks to your log. I am just amazed at how you have turned bits of wood into such a fantastic sailboat. And to see her on the water is a real pleasure. I really wish i could actually see her in real life instead of in digital format. You are a very talented and skilful man. I bet you had the biggest buzz of your life when the wind started to fill the sails and she started to move. Also you have chose a beautiful name for a really beautiful boat. Well done you deserve to be extremely proud of this wonderful Boat. Martin555. ▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 201 Views · 3 Likes

Flag

Doug,

Thanks for the offer of a Pilot bear for the Cutter, but a little too big I'm afraid. He would have to duck everytime the boom swung past 😂🤣 Graham93 ▲

⟩⟩

stevedownunder

RNinMunich

Martin555

|

|

💬 Re: Maiden voyage

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 201 Views · 3 Likes

Flag

Graham well done the boat looks great on the water.

Rick ▲

⟩⟩

stevedownunder

Martin555

Graham93

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 203 Views · 4 Likes

Flag

She really does look good on the water Graham, sailing beautifully. No need to ask how she responds to controls, one can see her pedigree from the pictures.

Cheers, Nerys ▲

⟩⟩

RNinMunich

stevedownunder

Martin555

Graham93

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Rookysailor (

Commodore) Commodore)✧ 209 Views · 3 Likes

Flag

Quality ,quality, quality what more can one say, a beautiful boat, just wish I could build one the same.🤤

Cheers, Pete ▲

⟩⟩

stevedownunder

Martin555

Graham93

|

|

Login To

Remove Ads 💬 Re: Maiden voyage

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 205 Views · 4 Likes

Flag

Hi Graham,

She looks stunning on and off the water, also well thought out transport, assembly and launching gear. 👍 Cheers, Stephen. ▲

⟩⟩

RNinMunich

jbkiwi

Martin555

Graham93

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 alan44 (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 211 Views · 4 Likes

Flag

Absolutely beautiful, a fantastic build, top quality everything!!!

▲

⟩⟩

Martin555

Graham93

stevedownunder

Ronald

|

|

💬 Re: Maiden voyage

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 207 Views · 3 Likes

Flag

Gob smackin' good Graham! 😋👍☀️☀️☀️

BTW If you want a 'real' Pilot Bear for your Pilot Cutter 😁 I have one about the right size you can have if you wish. Complete with leather jacket, helmet, goggles and scarf. In a sitting position about 11cm from bum to helmet. See pic. Cheers, Doug 😎

▲

⟩⟩

Martin555

Graham93

stevedownunder

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 robbob (

Admiral) Admiral)✧ 226 Views · 3 Likes

Flag

Congratulations on completing such a wonderful model Graham 😀👍

She certainly looks beautiful on the water. It looks like you had a 'camera boat' following her so I'm looking forward to seeing some interesting video soon 📽 😉. Rob. ▲

⟩⟩

Martin555

Graham93

stevedownunder

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 212 Views · 3 Likes

Flag

What a momentous day, she looks really wonderful on the water.

Another great addition to the fleet. ▲

⟩⟩

Martin555

Graham93

stevedownunder

|

|

💬 Re: Maiden voyage

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 206 Views · 4 Likes

Flag

Now she looks at home, a stunning little model with great presence on the water.

You must be really chuffed with your efforts, be proud shipmate she's a fine model. Cheers Colin. ▲

⟩⟩

RNinMunich

Martin555

Graham93

stevedownunder

|

|

💬 Re: Maiden voyage

3 years ago by 🇺🇸 Black Shoe (

Sub-Lieutenant) Sub-Lieutenant)✧ 216 Views · 3 Likes

Flag

Congratulations!

Beautiful build and "Ellen" looks wonderful afloat! Well done! ▲

⟩⟩

Martin555

Graham93

stevedownunder

|

Login To

Remove Ads

Remove Ads

📝 Fin and Keel

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 213 Views · 10 Likes · 12 Comments

Flag

💬 Add Comment

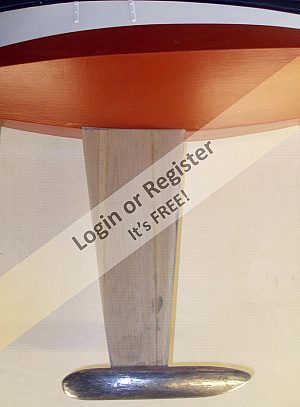

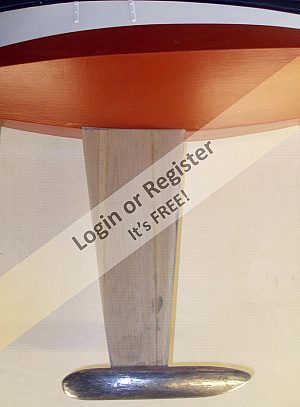

Unlike traditional Pilot Cutters, this plan calls for the model to be fitted with a fin and weighted lead keel.

I left this part of the build to the end for two reasons. I needed to know the weight of the model before the keel could be cast, and I didn't like the idea of messing about with 4+kgs of molten lead😮.

The plans give a target weight for the completed model of 8.2kgs (18lbs) including a keel weighing 4.5kgs. With all the extra details I've added to the hull it has turned out heavier than the design weight (No surprise there then 😉) so to keep the total weight of the model on target, the keel weight needed to be reduced to 4kgs. To compensate for the lighter keel, I decided to extend the fin length by 50mm.

The fin is made from 3mm aluminium sheet. This was cut out using a jigsaw fitted with a metal cutting blade. The large hole at the top of the fin reduces the weight a little, and provides a convenient hand hold. The three holes at the bottom are to provide a key for the lead keel.

A wooden mold was made from scrap timber and the fin clamped in place. 4.5kgs of lead was melted and poured in - very carefully! Once cooled, the mold was removed and the keel was then shaped using a 'surform' tool bringing the completed weight of the keel down to 4ks.

Thin balsa sheet was glued to both sides of the fin with contact adhesive and then sanded to give a streamlined cross section to the fin. The completed fin slides into the keel box below the hull and is held in place with two steel cross pins fitted through one of the deck hatches.

The completed assembly was finished with two part epoxy, glass cloth, and several coats of navy blue paint from a rattle can.

I left this part of the build to the end for two reasons. I needed to know the weight of the model before the keel could be cast, and I didn't like the idea of messing about with 4+kgs of molten lead😮.

The plans give a target weight for the completed model of 8.2kgs (18lbs) including a keel weighing 4.5kgs. With all the extra details I've added to the hull it has turned out heavier than the design weight (No surprise there then 😉) so to keep the total weight of the model on target, the keel weight needed to be reduced to 4kgs. To compensate for the lighter keel, I decided to extend the fin length by 50mm.

The fin is made from 3mm aluminium sheet. This was cut out using a jigsaw fitted with a metal cutting blade. The large hole at the top of the fin reduces the weight a little, and provides a convenient hand hold. The three holes at the bottom are to provide a key for the lead keel.

A wooden mold was made from scrap timber and the fin clamped in place. 4.5kgs of lead was melted and poured in - very carefully! Once cooled, the mold was removed and the keel was then shaped using a 'surform' tool bringing the completed weight of the keel down to 4ks.

Thin balsa sheet was glued to both sides of the fin with contact adhesive and then sanded to give a streamlined cross section to the fin. The completed fin slides into the keel box below the hull and is held in place with two steel cross pins fitted through one of the deck hatches.

The completed assembly was finished with two part epoxy, glass cloth, and several coats of navy blue paint from a rattle can.

▲

⟩⟩

RNinMunich

Alain Pascal

alan44

Martin555

Nerys

robbob

jbkiwi

stevedownunder

philcaretaker

Colin H

|

💬 Re: Fin and Keel

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 205 Views · 0 Likes

Flag

Hi Graham, I was guessing around 12", 12lbs should be cyclone proof😁

JB ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Fin and Keel

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 217 Views · 3 Likes

Flag

Well if the plan shows a fin & weight. That’s that I always draw my own plans so I do what I want😀. I have found the biggest problem, for good sailing is the size of the rudder. I cheat with my schooners. Photo tells all. In first photo the square is the hatch to stop model rolling upright.

▲

⟩⟩

Colin H

Martin555

Ronald

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 208 Views · 3 Likes

Flag

Very impressed by the way you have made the bulb and fin keel, just like the rest of the build, excellent. Wish I could even approach your standards of build.

Nerys ▲

⟩⟩

Martin555

Graham93

stevedownunder

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 208 Views · 3 Likes

Flag

Hi JB,

I've just measured the fin length. It's effectively 16" so the torque will be closer to 12 ft lbs. Graham93 ▲

⟩⟩

jbkiwi

Martin555

stevedownunder

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 212 Views · 2 Likes

Flag

Its getting closer!

▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Fin and Keel

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 207 Views · 2 Likes

Flag

Turned out well Graham, good that it's removable for any adjustment. Does that equate roughly to 9 ft lbs of torque?😁

JB ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 210 Views · 6 Likes

Flag

Martin,

It is a shame it needs a keel but it should make it stable. It would need a lot more weight in the hull to achieve the same stability, but then it would be too low in the water. The keel is easily removable, so I will be able to experiment with alternative shorter fins/lighter keels if the initial trials show that could be a viable option. I painted the fin dark blue so that it wouldn’t be obvious under water - and I had plenty left over after painting the gunwales 😀 Weight training today 😂🤣 Graham93 ▲

⟩⟩

RNinMunich

Alain Pascal

stevedownunder

robbob

jbkiwi

Martin555

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 210 Views · 2 Likes

Flag

Phil,

You should have just enough time to get your camera batteries charged 🤞. I have to work out how to load it into the car🙄 Graham93 ▲

⟩⟩

stevedownunder

Martin555

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 210 Views · 2 Likes

Flag

Hi Graham,

It is a shame a fin keel had to be made for this fantastic boat. Still when she is in the water we won't see it. So the next job to do before her Maiden Voyage is a bit of Body Building and Weight Training LOL!! Like the rest of the members I too am looking foreword to seeing her in the water. Martin555. ▲

⟩⟩

Graham93

stevedownunder

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 218 Views · 3 Likes

Flag

I am getting very excited Graham in anticipation of the "Maiden Voyage" !!!!😁😁😁

▲

⟩⟩

Graham93

stevedownunder

Martin555

|

|

💬 Re: Fin and Keel

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 221 Views · 4 Likes

Flag

Oh dear very sad. None of my sailing models have false fins. They sail very well with internal ballast. Just reduce sail to fit weather. I will admit to needing a false keel one of my paddle steamers. 5” long sailing on 1.5 draft with a 5lb steam plant. Sorry 😆

▲

⟩⟩

Peejay

stevedownunder

Martin555

Colin H

|

|

💬 Re: Fin and Keel

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 213 Views · 2 Likes

Flag

That looks great Graham. Nice bit of engineering .

Rick ▲

⟩⟩

stevedownunder

Martin555

|

📝 RC installation

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 221 Views · 10 Likes · 4 Comments

Flag

💬 Add Comment

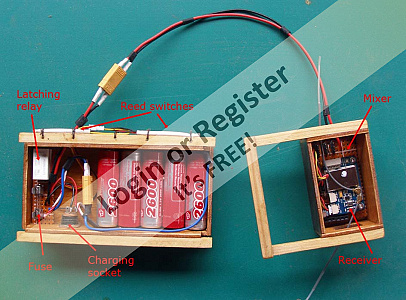

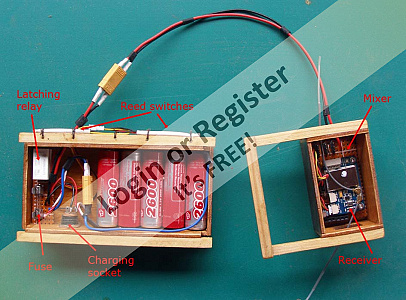

There is a rudder servo and two winches to control the sails.

The sheet to control the main sail is routed from one of the winches through a fairlead in the deck just behind the mast. It then passes through two blocks attached to the boom and terminates on a traveller just abaft the main cabin.

The three fore sails each have two sheets attached. One sheet from each sail runs down the port side of the deck, through a fairlead in the deck and is then tied off on a loop driven by the second winch. The three remaining sheets from these sails are routed in the same way, but along the starboard side of the deck. These are tied off on the other side of the loop below deck. Running this winch from one end to the other tacks the foresails by pulling the sheets in on one side and letting them out on the other.

The plans suggest that the fore sail winch is controlled from a rotary knob on the transmitter so that the sails can be tacked. I have put together a custom electronic mixer that has two operating states. In one state, it allows direct control of the winch from a rotary knob on the transmitter as suggested in the plans. In the other operating state, the fore sheet winch is controlled in tandem with the main sheet winch from the same stick on the transmitter. A switched channel on the Tx reverses and offsets the signal to the winch thus tacking the fore sails at the flick of a switch! It will be interesting to see if this works as intended.

The electronics is installed in two wooden boxes which slide into runners below the deck. The construction and mounting of these was shown earlier in this blog. I've used magnetic reed switches to turn the power on/off as in my other models. This allows the power to be turned on and off using a magnet above the deck and avoids the need to find somewhere to hide a toggle switch.

The sheet to control the main sail is routed from one of the winches through a fairlead in the deck just behind the mast. It then passes through two blocks attached to the boom and terminates on a traveller just abaft the main cabin.

The three fore sails each have two sheets attached. One sheet from each sail runs down the port side of the deck, through a fairlead in the deck and is then tied off on a loop driven by the second winch. The three remaining sheets from these sails are routed in the same way, but along the starboard side of the deck. These are tied off on the other side of the loop below deck. Running this winch from one end to the other tacks the foresails by pulling the sheets in on one side and letting them out on the other.

The plans suggest that the fore sail winch is controlled from a rotary knob on the transmitter so that the sails can be tacked. I have put together a custom electronic mixer that has two operating states. In one state, it allows direct control of the winch from a rotary knob on the transmitter as suggested in the plans. In the other operating state, the fore sheet winch is controlled in tandem with the main sheet winch from the same stick on the transmitter. A switched channel on the Tx reverses and offsets the signal to the winch thus tacking the fore sails at the flick of a switch! It will be interesting to see if this works as intended.

The electronics is installed in two wooden boxes which slide into runners below the deck. The construction and mounting of these was shown earlier in this blog. I've used magnetic reed switches to turn the power on/off as in my other models. This allows the power to be turned on and off using a magnet above the deck and avoids the need to find somewhere to hide a toggle switch.

▲

⟩⟩

RNinMunich

Peejay

robbob

philcaretaker

jbkiwi

stevedownunder

Martin555

MouldBuilder

mturpin013

Colin H

|

💬 Re: RC installation

3 years ago by 🇿🇦 redpmg (

Commodore) Commodore)✧ 214 Views · 4 Likes

Flag

Great build Graham - the detail is tremendous and puts most of us to shame.

Envy your electronics capability - mine usually ends with the smell of burning plastic from the wiring........... ▲

⟩⟩

Peejay

Graham93

Martin555

jbkiwi

|

|

Login To

Remove Ads 💬 Re: RC installation

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 215 Views · 2 Likes

Flag

Nice tidy set-up Graham, should work nicely.

JB ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: RC installation

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 221 Views · 4 Likes

Flag

The mainsheet seems very practical for a boomed mainsail and should work well, the sheeting for the foresails is clever and I'll be very interested to see how it pans out. Hopefully they will all work off the one control. The electrical installation is very neat, like everything else you do.

Cheers, Nerys ▲

⟩⟩

Peejay

Graham93

stevedownunder

Martin555

|

|

💬 Re: RC installation

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 220 Views · 3 Likes

Flag

That's a very neat layout, I'm impressed with the simplicity of your system.

I'm looking forward to seeing it on the water. Cheers Colin. ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

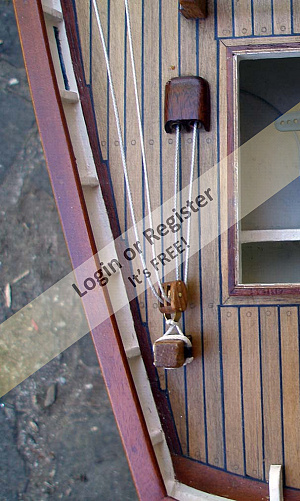

📝 Rigging the Sails

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 223 Views · 13 Likes · 12 Comments

Flag

💬 Add Comment

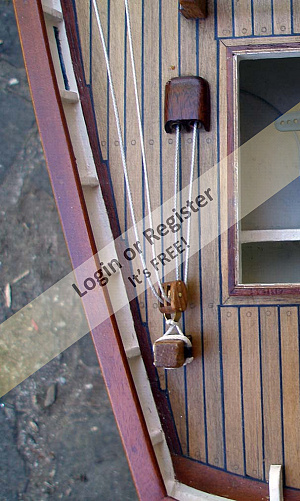

After a week of threading, knotting, whipping and a bit of cursing I've managed to rig all the sails.

The rigging cord is 1mm diameter, 12 strand braided 'Dynema'. This is very strong, and doesn't stretch. The loops at the ends of the lines are glued with CA and then whipped with cotton thread which is also secured with CA. I hope this will be sufficiently secure. The pins in the shackles and blocks are screwed in and then seized with a fine stainless wire so that they will not come apart on the lake.

Instead of tying off the downhauls on the belaying pins on the Fife rail I have chosen to loop them round the belaying pins and use a bowsie to tension the lines. This is to speed up rigging of the sails at the lake side. The last photo shows one of the bowsies, disguised as a block. Thanks to 'hammer' for this suggestion.

The rigging cord is 1mm diameter, 12 strand braided 'Dynema'. This is very strong, and doesn't stretch. The loops at the ends of the lines are glued with CA and then whipped with cotton thread which is also secured with CA. I hope this will be sufficiently secure. The pins in the shackles and blocks are screwed in and then seized with a fine stainless wire so that they will not come apart on the lake.

Instead of tying off the downhauls on the belaying pins on the Fife rail I have chosen to loop them round the belaying pins and use a bowsie to tension the lines. This is to speed up rigging of the sails at the lake side. The last photo shows one of the bowsies, disguised as a block. Thanks to 'hammer' for this suggestion.

▲

⟩⟩

RNinMunich

Peejay

Alain Pascal

Psyi

MouldBuilder

jbkiwi

Martin555

philcaretaker

Nerys

stevedownunder

Ronald

Colin H

robbob

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 225 Views · 2 Likes

Flag

A slight delay on comments due to holidays, but that's a fine piece of modelling and one to be proud of, we look forward to launch day.

▲

⟩⟩

Peejay

Martin555

|

|

Login To

Remove Ads 💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 221 Views · 2 Likes

Flag

JB,

Still have to make the fin/keel so that it will stay upright, but shouldn't be long now to the maiden voyage. Bill and Ben don't go out when it's windy as they find rowing hard work in a wind. So they won't be missing out too much. It is going to be one or the other depending on the forecast. In any case I won't be able to take both models to the lake at the same time as they won't fit in the car together. In fact, I'm a bit concerned about fitting this one in the car by itself🤔. Time will tell. Graham93 ▲

⟩⟩

Ronald

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 221 Views · 2 Likes

Flag

Thanks Colin, I hope you are right!

Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 221 Views · 5 Likes

Flag

That looks absolutely brilliant Graham. The sails look spot on for colour and the sewing, sheet and rigging work looks immaculate. Can't be too long till launching now ? Bill and Ben are going to be jealous😁

JB ▲

⟩⟩

Peejay

Ronald

Graham93

bobonthelough

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 222 Views · 4 Likes

Flag

That's a very realistic outlook the youngster has. But he was only stating facts without any prejudice.

I agree it is a beautiful boat and I'm sure you'll be a fine master, so shouldn't sink. Happy sailing, cheers Colin. ▲

⟩⟩

Peejay

Ronald

Graham93

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 223 Views · 2 Likes

Flag

That's for sure on the sinking.

Rick ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 223 Views · 4 Likes

Flag

Thanks everyone for the kind comments and the ‘likes’.

My 9 year old grandson visited this week, first time we have seen him in over a year. He made two comments: “It looks very realistic” which was nice 👍, and “It might sink” 😭☹️. I hope he’s wrong with that one 😆 Graham93 ▲

⟩⟩

Peejay

robbob

Colin H

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 232 Views · 3 Likes

Flag

Brilliant that’s all👍

▲

⟩⟩

Peejay

Martin555

Graham93

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 221 Views · 3 Likes

Flag

Wow What a beauty Graham.

That is the best sail boat i have ever had the privilege to cast my eyes on. All the time you have spent working on her has definitely paid off. I hope you plan on getting Phil to shoot some good video of her made voyage. I can't wait to see her on the water. Martin555. ▲

⟩⟩

Ronald

Graham93

stevedownunder

|

|

💬 Re: Rigging the Sails

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 224 Views · 3 Likes

Flag

Very impressive Graham, I wish my poor old arthritic and feelingless fingers could do things like that.

Nerys ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 222 Views · 2 Likes

Flag

Splendid work Graham,

Good to hear there was no lashing going on... Cheers, Stephen. ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Rigging the Sails

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 223 Views · 4 Likes

Flag

Well done with the rigging and only a little cursing to get it done.

Rick ▲

⟩⟩

Peejay

Martin555

stevedownunder

Ronald

|

📝 Standing Rigging

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 229 Views · 13 Likes · 14 Comments

Flag

💬 Add Comment

Having made all the bits and pieces needed for the rigging, it's time to replace the temporary blue string with something more appropriate.

I read somewhere that plastic coated fishing trace line can be used for the shrouds that support the mast. Photos 1 and 2 show the shrouds and bowsprit stays I made using this trace line. It just didn't look right, so I replaced these with twisted nylon cord which I think looks much better.

The lower end of each shroud is formed into a loop which fits round a deadeye. The lanyards which connect the pairs of deadeyes together are elastic cord which ensures that the shrouds are kept taught. Each lower deadeye is attached to the chainplate using an 'R' clip which makes it relatively easy to de-rig the shrouds and remove the mast.

A forestay runs from the mast to the stem where it is also attached using an 'R' clip.

The bowsprit rigging comprises a chain bobstay fitted between the stem and the cranse iron at the end of the bowsprit together with two stays, one fitted on either side. The chain was made in the same way as described for the anchor chain in an earlier post. A pair of blocks form a tackle which allows the chain to be tensioned.

The lateral stays are made from the same nylon cord as used for the mast shrouds. Each stay has a tackle to tension it.

I read somewhere that plastic coated fishing trace line can be used for the shrouds that support the mast. Photos 1 and 2 show the shrouds and bowsprit stays I made using this trace line. It just didn't look right, so I replaced these with twisted nylon cord which I think looks much better.

The lower end of each shroud is formed into a loop which fits round a deadeye. The lanyards which connect the pairs of deadeyes together are elastic cord which ensures that the shrouds are kept taught. Each lower deadeye is attached to the chainplate using an 'R' clip which makes it relatively easy to de-rig the shrouds and remove the mast.

A forestay runs from the mast to the stem where it is also attached using an 'R' clip.

The bowsprit rigging comprises a chain bobstay fitted between the stem and the cranse iron at the end of the bowsprit together with two stays, one fitted on either side. The chain was made in the same way as described for the anchor chain in an earlier post. A pair of blocks form a tackle which allows the chain to be tensioned.

The lateral stays are made from the same nylon cord as used for the mast shrouds. Each stay has a tackle to tension it.

▲

⟩⟩

Peejay

Alain Pascal

Psyi

Ronald

T33CNO

jbkiwi

philcaretaker

stevedownunder

robbob

Colin H

mturpin013

Martin555

RNinMunich

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 227 Views · 4 Likes

Flag

Thanks everyone for the positive comments on the rigging so far 👍. There will have to be some compromises with the running rigging to speed up the task of assembling the model at the lakeside where it won't be a realistic option to be fiddling with shackles and pins. It is bad enough having to find dropped pins on the workshop floor 😠

Graham93 ▲

⟩⟩

Peejay

jbkiwi

T33CNO

Martin555

|

|

Login To

Remove Ads 💬 Re: Standing Rigging

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 227 Views · 2 Likes

Flag

Thanks for the suggestion Gary. That's certainly a valid alternative for attaching the shrouds to the mast. I chose to do it with the shrouds looped round the mast over wooden cheeks as that is how it is shown on the plan.

A bit of research in 'Gaff Rigging' by John Leather came up with " In traditional rigged craft, the shrouds are looped over the masthead and rest on wood bolsters set on wooded hounds cheeks... Alternatively, a mastband fitting can be made with eyes to which the shrouds are shackled." So both approaches are valid. Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 226 Views · 4 Likes

Flag

I think this is the most realistic and accurate rigging in every way I have ever seen in a model, everything is exactly what I would expect in the real thing. Well done Graham.

Cheers, Nerys ▲

⟩⟩

Peejay

jbkiwi

Graham93

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 226 Views · 5 Likes

Flag

Thought you'd been a bit quiet lately Graham😁, now we know why, -more fancy bits! Excellent realistic looking fittings, and the rigging looks the part with the black cord👍👍

JB ▲

⟩⟩

Peejay

Graham93

stevedownunder

Ronald

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 227 Views · 3 Likes

Flag

Hi Graham,

Stunning workmanship. Looking forward to some on the water shots when that happens. Cheers, Stephen. ▲

⟩⟩

Peejay

Martin555

GaryLC

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 231 Views · 4 Likes

Flag

I absolutely love this boat Graham, and the fine detail on the fittings and fitments is mind-blowing. Just one thing which I find a little strange as I am quite into the rigging on older boats, and that is the rigging for the main mast with the two sets of deadeyes at the bottom, at the top end of the same would look much better if instead of being looped around the mast, it was terminated at an eyelet on a brass ring, one eyelet each side. As I appreciate you are into brass fittings and gaff jaws not forgetting the hardwood blocks and tackle. Regards, Gary.

▲

⟩⟩

Peejay

Ronald

Martin555

stevedownunder

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 229 Views · 4 Likes

Flag

Hammer,

“When the great day comes I hope she sails as good as she looks” So do I, so do I. It’s been a long build. I’ve enjoyed it, but it will be really disappointing if it doesn’t perform on the lake. I don’t need a static model cluttering up the workshop. I keep thinking there’s not much more to do, but I keep finding things I haven’t done yet.😔 Graham93 ▲

⟩⟩

Peejay

stevedownunder

robbob

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 229 Views · 3 Likes

Flag

Great job .Looks to be full speed ahead. Hope you get fair winds for your first sail.

Rick ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 229 Views · 2 Likes

Flag

Thank's Graham,

I really like this boat. You have done a fantastic job so far keep it up. Martin555. ▲

⟩⟩

Peejay

stevedownunder

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 231 Views · 3 Likes

Flag

fine work as usual, I bet you can't wait for the maiden voyage.

We can't ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 229 Views · 5 Likes

Flag

Hi Martin,

The mast is quite substantial. I don’t think it will bend. If there is a strong gust it will heel the boat and spill the wind from the sails. At least that’s how I hope it will work. All this is new to me as well 🙄. The elastic works well to self tension the shrouds when rigging/ derigging the mast. If it proves to be a problem, I can replace it with regular cord, but then it will be more difficult to maintain tension. Graham93 ▲

⟩⟩

Peejay

Ronald

stevedownunder

robbob

Martin555

|

|

Login To

Remove Ads 💬 Re: Standing Rigging

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 239 Views · 3 Likes

Flag

The stress on a scale model are nowhere near those on original. The scale effect working for us for a change

▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 237 Views · 4 Likes

Flag

When the great day comes I hope she sails as good as she looks. Well done Graham 👍

▲

⟩⟩

Peejay

stevedownunder

Graham93

Martin555

|

|

💬 Re: Standing Rigging

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 229 Views · 3 Likes

Flag

Excellent work Graham.

As you know i know very little about sail boats. However i have a question. You have elastic cord in-between the two deadeyes. What keeps the tension to stop the mast from bending ? Martin555. ▲

⟩⟩

Peejay

stevedownunder

Graham93

|

📝 Sail making

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 234 Views · 14 Likes · 25 Comments

Flag

💬 Add Comment

Time to make the sails! This is my first attempt at making cotton sails.

Full sized paper templates were made using the sail dimensions provided on the plan. These were used to mark out the outline of each sail on an old polycotton sheet by drawing round the templates onto the sheet with a pencil. For each sail, care was taken to ensure that the warp of the cloth was aligned with the leech of the sail. A 12mm wide strip of hardboard was then used as a guide to draw an additional line around each sail providing a 12mm hem allowance. The sails were cut from the sheet, together with triangular reinforcing pieces for each corner on each sail.

My wife was volunteered to machine sew the hems and reinforcing pieces 😉❤️. The sails were then returned to me for the rest of the sewing🙄. A bolt rope was hand sewn around each sail. The rope is sewn along each edge of the sail, except the leech. It is sewn onto the Port side of the sail. I don't know why it should be on the Port side, but I understand is the convention. Can anyone enlighten me as to why?

Grommets were formed at the corners of each sail by sewing in a copper ring.

The hand sewing for each sail took 4-5 hours 😮

Once completed, each sail was fitted to the Cutter using temporary rigging. This was to ensure that the sails were the right size and shape. At this point, the main sail had to be remade as, despite it being cut out to the right size and shape using the paper template, it had somehow 'grown' to a size which meant it just didn't fit once finished 😭 The second attempt fits OK.

Finally lines were drawn onto the sails to represent the seams that would be present on full sized sails and the sails were stained using tea and waterproofed using a mix of beeswax and linseed oil. The last photo shows the 'before and after' effect of the staining and waterproofing.

Full sized paper templates were made using the sail dimensions provided on the plan. These were used to mark out the outline of each sail on an old polycotton sheet by drawing round the templates onto the sheet with a pencil. For each sail, care was taken to ensure that the warp of the cloth was aligned with the leech of the sail. A 12mm wide strip of hardboard was then used as a guide to draw an additional line around each sail providing a 12mm hem allowance. The sails were cut from the sheet, together with triangular reinforcing pieces for each corner on each sail.

My wife was volunteered to machine sew the hems and reinforcing pieces 😉❤️. The sails were then returned to me for the rest of the sewing🙄. A bolt rope was hand sewn around each sail. The rope is sewn along each edge of the sail, except the leech. It is sewn onto the Port side of the sail. I don't know why it should be on the Port side, but I understand is the convention. Can anyone enlighten me as to why?

Grommets were formed at the corners of each sail by sewing in a copper ring.

The hand sewing for each sail took 4-5 hours 😮

Once completed, each sail was fitted to the Cutter using temporary rigging. This was to ensure that the sails were the right size and shape. At this point, the main sail had to be remade as, despite it being cut out to the right size and shape using the paper template, it had somehow 'grown' to a size which meant it just didn't fit once finished 😭 The second attempt fits OK.

Finally lines were drawn onto the sails to represent the seams that would be present on full sized sails and the sails were stained using tea and waterproofed using a mix of beeswax and linseed oil. The last photo shows the 'before and after' effect of the staining and waterproofing.

▲

⟩⟩

Peejay

Alain Pascal

Psyi

sirscapa

robbob

stevedownunder

Ronald

Martin555

RNinMunich

philcaretaker

jimdogge

jbkiwi

Colin H

jacko

|

💬 Re: Sail making

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 228 Views · 2 Likes

Flag

Ecky thump! Typical Yorkshire man! (Even if he's emigrated to Cheshire!)

50% FREE! 🤑 'Well I'll go t' foot a my stairs!' 😁😂 😎 ▲

⟩⟩

Peejay

Martin555

|

|

Login To

Remove Ads |

|

💬 Re: Sail making

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 228 Views · 2 Likes

Flag

"The sails look to be done to a tee."

Do you play golf with tea bags in your neck o the woods Rick? 😮😆 Must be difficult to judge the flight path; slice or 'in the botanic! 😁 😎 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 228 Views · 3 Likes

Flag

Since when has tea been grown in Yorkshire Graham?

Eee baih gumm, musta bin Tetleys! 😋😉 Coz 'Tetleys make tea bags make tea!' Good brew! 😎 ▲

⟩⟩

Peejay

dads boat

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 230 Views · 2 Likes

Flag

😂🤣

▲

⟩⟩

Martin555

RNinMunich

|

|

💬 Re: Sail making

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 229 Views · 4 Likes

Flag

The sails look to be done to a tee.

Rick ▲

⟩⟩

Peejay

RNinMunich

Graham93

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 231 Views · 3 Likes

Flag

Michael, Doug,

You are both wrong! It was Yorkshire tea😆 Graham93 ▲

⟩⟩

Peejay

RNinMunich

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 229 Views · 2 Likes

Flag

Deffo Twining Darjeeling by the look of it Mike 😋😁

Earl Grey would have been exactly that! 😎 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 234 Views · 3 Likes

Flag

A great job Graham, your making me feel as if I should be doing something with sails.

By the way was it PG or Typhoo ! ▲

⟩⟩

Peejay

Martin555

RNinMunich

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 239 Views · 3 Likes

Flag

In practice when sailing I found it very rare to have full rig set. Most sailing done with main & stay only. I also have a storm stay used with main reffed.

▲

⟩⟩

RNinMunich

Peejay

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 231 Views · 3 Likes

Flag

Hi Nerys,

Thank you for the 'criticism' which I don't take as a criticism, your input is most valuable and welcome. I can see what you mean when I look at it again. The jib stay is attached to the bowsprit traveller so can easily be brought inboard to reduce the overhang of the jib topsail. The rigging of the jib topsail is also a bit loose in the photo causing it to sag a little increasing the overhang. I'll see how it looks once I have it rigged properly. If all else fails, I can always make a smaller replacement jib topsail (more sore fingers!). The sails are made to the dimensions shown on the plan, but the overhang is bigger than it looks on the plan which I don't understand. Please don't hold back with your helpful comments. Graham93

▲

⟩⟩

Peejay

Nerys

Martin555

|

|

Login To

Remove Ads 💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 231 Views · 2 Likes

Flag

Thanks Hammer,

I knew there had to be a reason for the rope being on the Port side, Now I know 👍 Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 231 Views · 3 Likes

Flag

Jacko, On your picture of a Thames Barge, there is no overlap of jib topsail over jib. The aperture between the stays for the jib topsail and the jib is filled but there is no overlap. A jib topsail as big as that would be one specially intended for a racing barge and not used in normal working conditions. There is a little overlap of the foot of the topsail over the mainsail which was normal in a barge, but as these sails worked in unison that did not matter. Too much overlap on sails before the mast, let's call them headsails would prevent them being able to be brought round onto the leeward side when tacking. A little overlap on headsails is a good thing, but too much makes for very difficult handling, especially with a small crew which working vessels tended to have, "a man and a boy", how often have we heard that quoted. In Thames Barges a jib topsail would rarely be carried unless she was racing.

Nerys ▲

⟩⟩

Peejay

Martin555

RNinMunich

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Nerys (

Fleet Admiral) Fleet Admiral)✧ 231 Views · 3 Likes

Flag

Graham, What a superb job you and your wife have made of the sails. The way you have put the eyes in the corners and the strengthening pieces looks most professional and could easily be sails for a full size boat. I do have one criticism though, hope you don't mind me telling you, but there is far too much overhang of the jib topsail to the jib, The sail as it is would not fill and would be very difficult to bring over when tacking. The tack needs to go further out along the bowsprit and perhaps the jib stay could come inboard a bit. I hate criticising what all round is a wonderful model, but I think she would sail better if you could alter the jib topsail.

Cheers, Nerys ▲

⟩⟩

Peejay

Graham93

RNinMunich

|

|

💬 Re: Sail making

3 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 235 Views · 3 Likes

Flag

Super work your wife has done for you, the stitching around the grommets and all around. Hats off!

▲

⟩⟩

Peejay

Graham93

stevedownunder

|

|

💬 Re: Sail making

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 234 Views · 4 Likes

Flag

Don't encourage him Doug, it'll never get launched😁

JB ▲

⟩⟩

Peejay

stevedownunder

Martin555

RNinMunich

|

|

💬 Re: Sail making

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 232 Views · 3 Likes

Flag

Brilliant stuff Graham👍

Most educational. 'Never mind the quality - Feel the width!' 😁 The Grommets look great, but where are the Wallaces?😂 Not so sure about the leeches though! Orrible things. Ugh!😝 Like the "'before and after' effect of the staining". What's next I wonder? Stained glass in the portholes? 😉 😎 ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 234 Views · 4 Likes

Flag

Hi Martin,

Haven’t had her assembled with the stained sails yet. That will have to wait until I have all the proper rigging in place. The mast is 48” if that helps you gauge the scale better Graham93 ▲

⟩⟩

Peejay

robbob

stevedownunder

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 234 Views · 5 Likes

Flag

Hi JB,

The eyes (grommets) were hand sewn and I have the scars in my fingertips to prove it 😆. As for making suits, that’s definitely not one for me. ( I did however get married in a suit made by my fiancé ! 👍) Graham93 ▲

⟩⟩

Peejay

stevedownunder

jbkiwi

Martin555

RNinMunich

|

|

Login To

Remove Ads 💬 Re: Sail making

3 years ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 235 Views · 4 Likes

Flag

She`s looking great Graham, I wait with baited breath and fully charged Gopro on the camera boat ! 👍😋🙄⛵

Phil ▲

⟩⟩

Peejay

stevedownunder

Martin555

Graham93

|

|

💬 Re: Sail making

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 238 Views · 3 Likes

Flag

Hi Graham,

Looking at the photo of her with the white sails she looks very nice and i bet she looks even better with the stained sails. As for the needle work your wife has done a great job. And your needle work is not to shabby ether. It is still difficult to gauge the scale of this beauty. Awesome work. Martin555. ▲

⟩⟩

Peejay

stevedownunder

Graham93

|

|

💬 Re: Sail making

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 235 Views · 5 Likes

Flag

Nice bit of sewing there Graham, you'll be making your own suits next😁 Looking really smart in its' new clothes. Were the eyes hand done or machine ? very tidy !

JB ▲

⟩⟩

Peejay

stevedownunder

RNinMunich

Graham93

Martin555

|

|

💬 Re: Sail making

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 233 Views · 3 Likes

Flag

I know for a fact it would not of been me doing the sails. Well done Graham, great job.

Rick ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

📝 Mast hoops

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 239 Views · 10 Likes · 10 Comments

Flag

💬 Add Comment

On full sized Cutters, the luff of the mainsail is often held to the mast with wooden hoops (Photo 1). These hoops are made from steamed elm, ash or oak. I had some ash veneer available so decided to use this to laminate the hoops.

A wooden mandrel was turned to the required inner diameter of the hoops - approximately 20mm for the 16mm diameter mast. A strip of ash veneer was then dampened and wound round the mandrel and left to dry. Once dry, it was removed, coated with glue, rewound onto the mandrel, taped into position and left to dry again.

Removing the completed wooden tube from the mandrel was difficult despite having wound the glued veneer over a layer of paper to prevent it sticking to the mandrel. In the end, I had to drill out the centre of the mandrel to get the tube off.

The wooden tube was then cut to form 6 hoops. Brass pins were added primarily for visual effect, but also to ensure that the laminations will not come apart.

A wooden mandrel was turned to the required inner diameter of the hoops - approximately 20mm for the 16mm diameter mast. A strip of ash veneer was then dampened and wound round the mandrel and left to dry. Once dry, it was removed, coated with glue, rewound onto the mandrel, taped into position and left to dry again.

Removing the completed wooden tube from the mandrel was difficult despite having wound the glued veneer over a layer of paper to prevent it sticking to the mandrel. In the end, I had to drill out the centre of the mandrel to get the tube off.

The wooden tube was then cut to form 6 hoops. Brass pins were added primarily for visual effect, but also to ensure that the laminations will not come apart.

▲

⟩⟩

Peejay

Alain Pascal

robbob

stevedownunder

jbkiwi

philcaretaker

GaryLC

Martin555

Colin H

RNinMunich

|

💬 Re: Mast hoops

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 238 Views · 3 Likes

Flag

Martin, JB,

Sorry to disappoint but there won’t be any automated hoisting or dropping of sails. I have plenty to keep me busy, there are lots of jobs to do round the house and garden which seem to have been neglected in recent months. 🤔 As for Bill and Ben’s relatives, still looking for one of them to volunteer 😂🤣 Graham93 ▲

⟩⟩

stevedownunder

Martin555

jbkiwi

|

|

Login To

Remove Ads 💬 Re: Mast hoops

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 240 Views · 3 Likes

Flag

We have to keep him busy Martin😂 now you've probably given him another idea😁

JB ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

💬 Re: Mast hoops

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 239 Views · 4 Likes

Flag

Be careful with the ideas JB as knowing Graham he is likely to have Bill and Ben's relatives setting the sails LOL!!

Martin555. ▲

⟩⟩

Peejay

stevedownunder

jbkiwi

Graham93

|

|

💬 Re: Mast hoops

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 240 Views · 4 Likes

Flag

Can't help yourself, can you Graham,?😁 lovely job, will certainly make dropping the sail easy, -might even be able to r/c it if its smooth enough! (sorry can't help myself😁)

JB ▲

⟩⟩

Peejay

stevedownunder

Graham93

Martin555

|

|

💬 Re: Mast hoops

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 238 Views · 5 Likes

Flag

Thanks everyone for the kind comments and feedback.

Michael, I’ll have to investigate my wife’s baking cupboard 😁 Black shoe, I did make a spare hoop but I haven’t fitted it. I have taken care to ensure I can dismantle the fittings on the mast, so if/when I next do that I’ll fit the spare. That way it won’t get lost in the workshop. Martin/Rick, glad you’re enjoying the build. Doug, it’s a long time since I last had a game of chess, and even longer since I tried rug making. However, I am going to take up sailmaking next 😉 Graham93 ▲

⟩⟩

Peejay

robbob

RNinMunich

stevedownunder

Martin555

|

|

💬 Re: Mast hoops

3 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 240 Views · 4 Likes

Flag

Hi Graham, you've been busy again and with a great result. I can help with the sticking tube on the mandrel, instead of using paper you should use the silicon baking sheets (available from Lakeland), I use it all the time to ensure glue doesn't stick where I don't want it. I haven't come across a glue that sticks to it yet epoxy wood glue just doesn't stick,

It comes in a large sheet and I just cut it up as required ▲

⟩⟩

Peejay

stevedownunder

Martin555

RNinMunich

|

|

💬 Re: Mast hoops

3 years ago by 🇺🇸 Black Shoe (

Sub-Lieutenant) Sub-Lieutenant)✧ 248 Views · 4 Likes

Flag

Another method I've used is to plane down an ash board to the thickness of the height of the proposed mast hoop then using a hand plane cutting (shaving) strips off of the edge. These strips come off with a natural curl and can be installed on the mast then glued.

The prototype would add one extra hoop as a spare in the event one gets broken. I'm thoroughly enjoying this build Graham! ▲

⟩⟩

Peejay

stevedownunder

Martin555

RNinMunich

|

|

💬 Re: Mast hoops

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 240 Views · 3 Likes

Flag

Great work I really love this build Graham.

I am learning more and more about this sailing boat. So whoever said "you can't teach an old dog new tricks" Needs to look at your build and then maybe he will re-word his quote.LOL!! RE :- over a layer of paper to prevent it sticking to the mandrel You could of used cling film or a bit of a polythene bag around the mandrel. Martin555. ▲

⟩⟩

Peejay

stevedownunder

RNinMunich

|

|

💬 Re: Mast hoops

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 239 Views · 4 Likes

Flag

😮

I think I'd better take up rug making, or maybe return to chess 🤔 Too old for cricket now I'm afraid 😭 😎 ▲

⟩⟩

Peejay

stevedownunder

Rookysailor

Martin555

|

|

💬 Re: Mast hoops

3 years ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 240 Views · 3 Likes

Flag

Graham looks like it was a long process but a great result.

Rick ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

📝 Shackles

3 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 249 Views · 12 Likes · 29 Comments

Flag

💬 Add Comment

Attaching the blocks and other rigging to the hull requires a number of shackles. These were made from 3mm dia brass rod. Lengths of rod were turned on the lathe to reduce the center section to 1.7 mm. These pieces were then annealed and forged to flatten the ends. This annealing and forging process was repeated until the ends were the same 1.7mm thickness as the center section.

The forged pieces were then annealed again and then bent around a steel rod to form a 'U' shape. Once the forming was complete the shackles were cleaned up with files and emery paper. The two flattened ends were then drilled for the cross pin. One end was drilled with a 1.6mm clearance hole and the other end was drilled and tapped 12BA.

The cross pins were turned from the same 3mm dia brass bar. One end is threaded 12BA and the other end is filed flat and cross drilled for a securing wire to prevent the pin becoming loose.

I needed to make quite a few of these, so have been making them in my 'spare time' over recent weeks. 😀

(The blue cord in some of the photos is temporary and not what will be used for the rigging)

The forged pieces were then annealed again and then bent around a steel rod to form a 'U' shape. Once the forming was complete the shackles were cleaned up with files and emery paper. The two flattened ends were then drilled for the cross pin. One end was drilled with a 1.6mm clearance hole and the other end was drilled and tapped 12BA.

The cross pins were turned from the same 3mm dia brass bar. One end is threaded 12BA and the other end is filed flat and cross drilled for a securing wire to prevent the pin becoming loose.

I needed to make quite a few of these, so have been making them in my 'spare time' over recent weeks. 😀

(The blue cord in some of the photos is temporary and not what will be used for the rigging)

▲

⟩⟩

Peejay

Alain Pascal

philcaretaker

RNinMunich

jbkiwi

stevedownunder

Ronald

Rookysailor

hammer

robbob

Martin555

Colin H

|

💬 Re: Shackles

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 250 Views · 2 Likes

Flag

Happy you like that Graham. Sails next yes. Not teaching you to suck eggs but this is my way. I use ticking cotton made for pillows tightly woven. Turning the edge on small models is tricky. Scale about 1/8” I brush P.V.A on that wide, turn over & iron. I do have my own must not upset Boss. Then stitch on bolt rope. To represent the join in cloth mark with pencil. Tape to window can see to mark other side. On my cutters scale I cut 1/4” strips sowing them on buy machine. My own again. The eye is brass tube super glued. Should be stitched but I am lazy.

▲

⟩⟩

Peejay

Martin555

|

|

Login To

Remove Ads 💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 241 Views · 2 Likes

Flag

Thanks Hammer,

I like that idea. I’m thinking about how to rig the Cutter quickly at the lakeside and your ‘block bowsie’ might come in very useful 👍 Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 hammer (

Lieutenant) Lieutenant)✧ 250 Views · 4 Likes

Flag

Blocks. You are sticking how it should be. Brilliantly engineered & wood working. I have been imposing on your blog sorry but I am doing it again.

I used to sail my cutters in all weathers so compromise has been made. This is one in the photo a bowsie or adjuster or tensioner whatever it’s called. Pretending to be a block , found in strange places on my models. Makes sail trimming & changes a lot easier. Someone may find it of use.

▲

⟩⟩

RNinMunich

Peejay

Martin555

Graham93

|

|

💬 Re: Shackles

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 245 Views · 2 Likes

Flag

Re shackle key-

Hi Graham, was going to suggest the flattened tube idea, but thought it might be too easy for you😁. I actually made a larger long version from heavy brass tube years ago, to remove the jet from my old Swedish Sievert kero blow torch. JB ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 246 Views · 3 Likes

Flag

"I had a play with the knurling attachment I recently bought for the mini lathe and made a brass knob 😉"

Really Graham? Didn't realise you kept brass monkeys! 😮 A toolmaker extraordinaire Colin! 😁 Oh dear, slapped wrists again 😭 😎 ▲

⟩⟩

Peejay

Martin555

Rookysailor

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 252 Views · 4 Likes

Flag

Not only a great modeller but also a toolmaker. That's engineering to be proud of.

Cheers Colin. ▲

⟩⟩

Peejay

Martin555

RNinMunich

Graham93

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 247 Views · 7 Likes

Flag

Hi JB,

"you are going to have to make a scale shackle key to go with all these" I don't think a scale shackle key would help with fitting the pins, It would probably make it even more fiddly. However, your suggestion did get me thinking about a suitable tool to make screwing the pins into the shackles easier. It is simply a piece of brass tube with the end squashed to an oval shape so that it will slide over the flattened end of the pin. While I was at it, I had a play with the knurling attachment I recently bought for the mini lathe and made a brass knob 😉 Graham93

▲

⟩⟩

Peejay

Alain Pascal

jacko

jbkiwi

Martin555

RNinMunich

Colin H

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 248 Views · 3 Likes

Flag

JB,

RE :- We'll have you sailing yet. I think i have been sailing before as i have been told on many occasion that i am sailing close to the wind LOL!!! Martin555. ▲

⟩⟩

Peejay

jbkiwi

RNinMunich

|

|

💬 Re: Shackles

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 247 Views · 3 Likes

Flag

"wind powered submarine 😂😂"

Ooh er! Are you going to feed the crew exclusively on baked beans Graham? 😮🙊 😁😎 ▲

⟩⟩

Peejay

jbkiwi

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 247 Views · 4 Likes

Flag

Hi JB,

“This thing better float Graham, remember the ballast is supposed to go in the bottom” If it turns out too heavy, perhaps I’ll try converting it to a wind powered submarine 😂😂 Graham93 ▲

⟩⟩

Peejay

jbkiwi

Martin555

RNinMunich

|

|

💬 Re: Shackles

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 246 Views · 3 Likes

Flag

Re A twist shackle___

Hi Martin, they also help stop your halyard twisting, and if you want to orientate a block in a particular direction where 2 fittings (eg mast and deck) might be at 90Deg to each other. There are many different types of blocks with attachment points 1. in line with the sheaves, 2. 90 Deg, (where these might be used) or 3. swivelling. Also to do with swivelling is a foresail drum furler, which has a swivel on the upper mast fitting and attaches under the drum to the foredeck fitting. Sail is pulled out with the sheet and furled with a cord wound on the drum. - Just in case you asked later😁 We'll have you sailing yet😁 (lol) Pic- furler set-up on my small yacht. (could easily be done on a model, but haven't seen one yet) JB

▲

⟩⟩

Peejay

Martin555

RNinMunich

|

|

Login To

Remove Ads 💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 248 Views · 4 Likes

Flag

Thanks Martin,

Glad you found that reference. The shackle is for the jib halyard block. Nice to know that “ if it looks right it probably is right” is good advice 😆 Graham93 ▲

⟩⟩

Peejay

jbkiwi

jacko

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 249 Views · 3 Likes

Flag

Hi Graham,

Sorry I should of looked it up on the net before asking the question. I found this, now it makes sense. A twist shackle is usually somewhat longer than the average, and features a 90° twist so the top of the loop is perpendicular to the pin. One of the uses for this shackle include attaching the jib halyard block to the mast, or the jib halyard to the sail, to reduce twist on the luff and allow the sail to set better. Martin555.

▲

⟩⟩

Peejay

RNinMunich

jbkiwi

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 248 Views · 2 Likes

Flag

Thanks Colin, glad you are enjoying the build.

Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 248 Views · 2 Likes

Flag

Hi Martin,

“why use a twisted shackle when a swivel block could be used” Simple answer is it just seemed the right thing to do! You have to realise I’m making this up as I go along. 😂🤣 The plans I have don’t go into this level of detail, and I don’t have any experience of the full sized craft so I’m following the “if it looks right it probably is right” rule. I’d be happy to receive any guidance from anyone with some experience of these boats, and I’ll try to rework parts that are wrong, although I can’t promise I’ll always be able to do that. Graham93 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 248 Views · 2 Likes

Flag

"why use a twisted shackle when a swivel block could be used."

Simple Martin, So you don't get your swivels in a twist! Ooh naaasty! 😮🤔😭 😎 ▲

⟩⟩

Peejay

Martin555

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 253 Views · 4 Likes

Flag

Nice looking bottle opener JB.

Cheers Colin. ▲

⟩⟩

Peejay

Martin555

stevedownunder

RNinMunich

|

|

💬 Re: Shackles

3 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 248 Views · 3 Likes

Flag

"... this time with a twist "

Hope that's all you got in a twist while fiddlin' about with that lot Graham!😮 Suspect that The Management shackled you to the table 'til you got 'em all finished and stopped cussin' and chuntering! A real labour of love (or hate)! Remarkable 👍 😎 ▲

⟩⟩

Peejay

Martin555

stevedownunder

|

|

💬 Re: Shackles

3 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 248 Views · 3 Likes

Flag

Hi Commodore Graham,

Just showing my ignorance, why use a twisted shackle when a swivel block could be used. Martin555. ▲

⟩⟩

Peejay

stevedownunder

jbkiwi

|

|

💬 Re: Shackles

3 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 247 Views · 3 Likes

Flag

Showing off again Graham?😁 very clever👍

JB ▲

⟩⟩

Peejay

stevedownunder

Martin555

|

|

Login To

Remove Ads 💬 Re: Shackles

3 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 253 Views · 3 Likes