Join Us On Social Media!

Kayak

36 Posts · 29 Followers · 235 Photos · 483 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Updated mechanism

6 months ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 71 Views · 14 Likes · 3 Comments

Flag

💬 Add Comment

It's been a while since my last update!

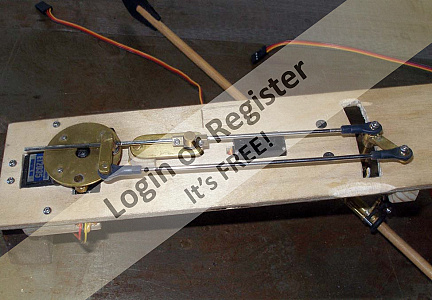

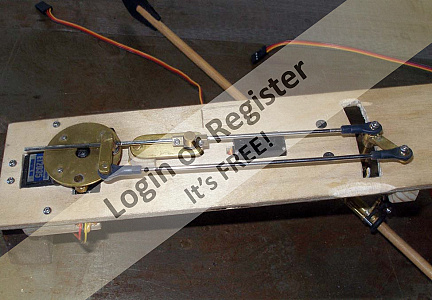

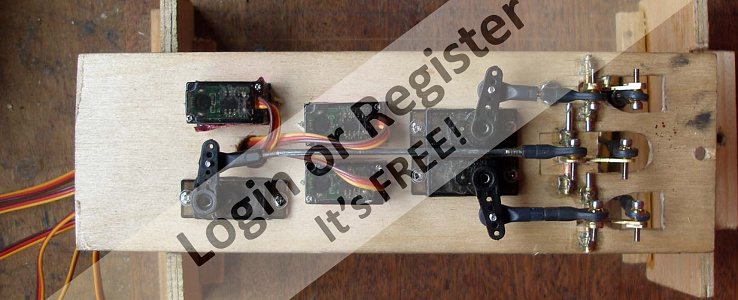

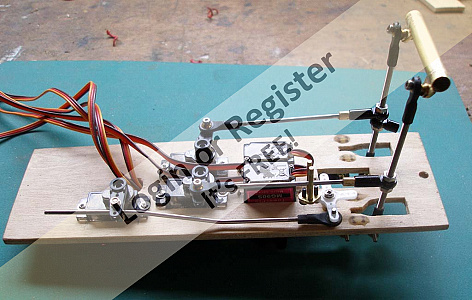

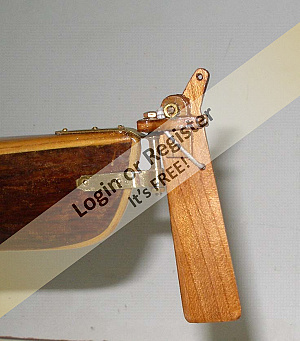

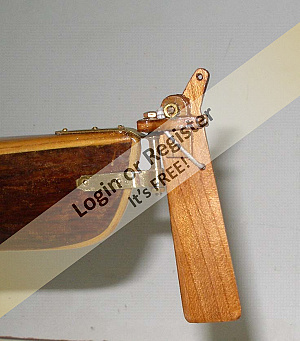

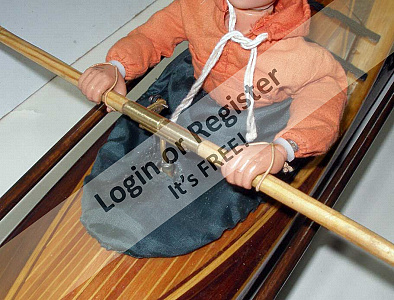

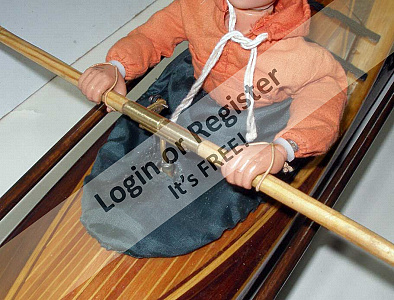

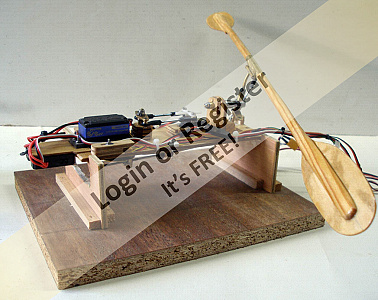

Up to this point, the kayak mechanism has been largely mechanical as shown in the first two photos. The trouble I find with such mechanical solutions is that to make adjustments to the action requires making new parts. This is often a trial and error process which takes a lot of time and leads to much frustration. I much prefer to use multiple servos with software in a microchip to coordinate the servo movements to achieve the desired effect. That way, changes to the action can be made quickly and easily by adjusting the software. Quicker changes and less frustration, at least for me.

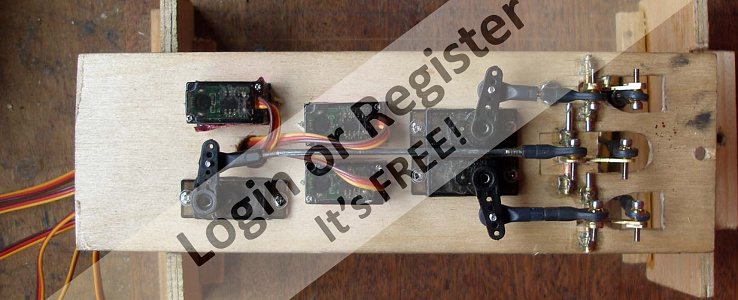

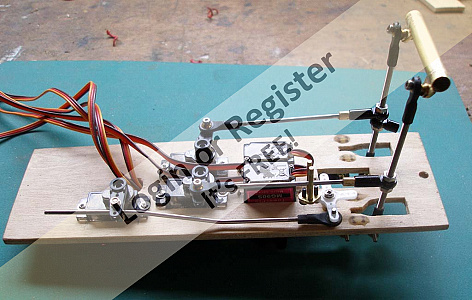

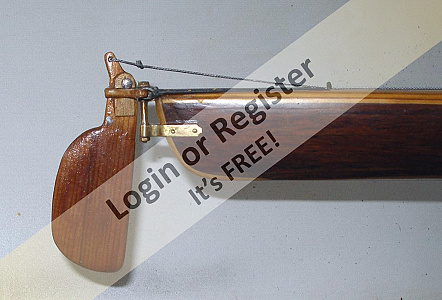

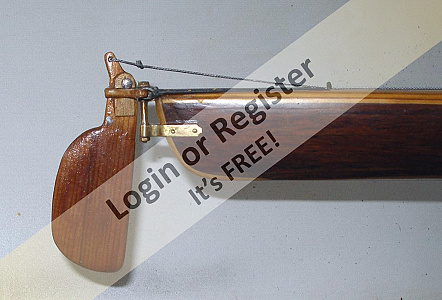

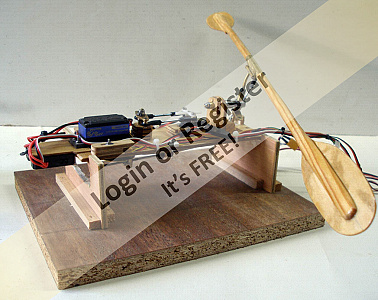

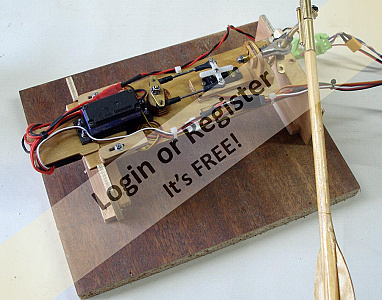

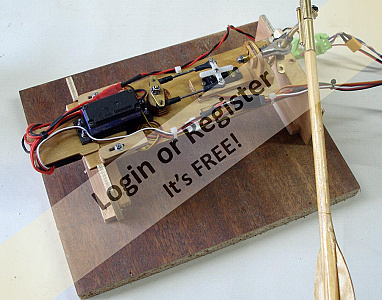

So, I've put together a new, servo based mechanism for the kayak as shown in photos 3 and 4. This uses 6 servos to produce the paddling motion.

A recent video from RCsailing includes clips of Katie paddling the kayak with this improved mechanism

Up to this point, the kayak mechanism has been largely mechanical as shown in the first two photos. The trouble I find with such mechanical solutions is that to make adjustments to the action requires making new parts. This is often a trial and error process which takes a lot of time and leads to much frustration. I much prefer to use multiple servos with software in a microchip to coordinate the servo movements to achieve the desired effect. That way, changes to the action can be made quickly and easily by adjusting the software. Quicker changes and less frustration, at least for me.

So, I've put together a new, servo based mechanism for the kayak as shown in photos 3 and 4. This uses 6 servos to produce the paddling motion.

A recent video from RCsailing includes clips of Katie paddling the kayak with this improved mechanism

▲

⟩⟩

philcaretaker

Colin H

Doogle

Peejay

Len1

ChrisG

stevedownunder

RNinMunich

hermank

mturpin013

EdW

robbob

Trident73

MotoPilot

|

💬 Re: Updated mechanism

6 months ago by 🇬🇧 Doogle (

Commodore) Commodore)✧ 51 Views · 2 Likes

Flag

Brilliant stuff Graham, as mentioned in earlier posts, my understanding of electronics is pretty basic. Well done 👏

▲

⟩⟩

philcaretaker

Graham93

|

|

Login To

Remove Ads 💬 Re: Updated mechanism

6 months ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 65 Views · 6 Likes

Flag

Thanks Michael,

I didn’t intend to be absent for so long. Life just got in the way. Can’t quite believe it’s been 8 months since my previous post on this blog! While I’ve been absent I’ve had in my mind that I needed to add one more post about the new ‘electronic ‘ mechanism. So now I’ve finally done it. We all have different skills and abilities, which is what makes this site so interesting. I always admire your problem solving and the use of jigs. Now when I have a mechanical problem I think “ is there a jig that would help me do this” ▲

⟩⟩

philcaretaker

Colin H

ChrisG

stevedownunder

RNinMunich

hermank

|

|

💬 Re: Updated mechanism

6 months ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 74 Views · 8 Likes

Flag

Great stuff Graham I'm glad to see you back. It seems a lot of the old crew have not been very active lately, I'm not sure if that's a permanent situation, I hope not.

Anyway back to your latest creation, as you will remember I'm more the mechanical solution type and I really admire your electronic ability, I'm afraid as soon as the wires enter the circuit board I'm lost. ▲

⟩⟩

philcaretaker

Colin H

Doogle

ChrisG

stevedownunder

RNinMunich

hermank

Graham93

|

Login To

Remove Ads

Remove Ads

📝 New Paddle

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 109 Views · 26 Likes · 10 Comments

Flag

💬 Add Comment

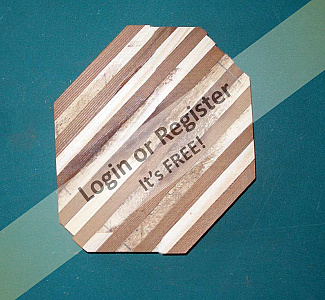

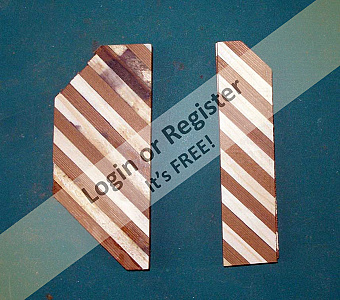

Having gained some experience with the test paddle, and having worked out the feathering angle needed between the two blades by trial and error, its time to make a fancy replacement.

Some cedar and pine were cut into strips and glued to produce a striped blank. This was then cleaned up and cut using a bandsaw to produce four blanks taking care to ensure that the stripe pattern lined up. A shaped sanding block was used to sand a curve into the blades which were then glued to a redwood shaft and cut to shape. Lots more sanding was needed to thin the blades and blend the joint between the blades and the shaft. Once the sanding was finished the blades were strengthened with a layer of lightweight glasscloth and epoxy on both sides, followed by 3 coats of yacht varnish.

The new paddle is slightly longer than the original, and the blades are also a little bigger.

A short video, courtesy of 'philcaretaker':

Some cedar and pine were cut into strips and glued to produce a striped blank. This was then cleaned up and cut using a bandsaw to produce four blanks taking care to ensure that the stripe pattern lined up. A shaped sanding block was used to sand a curve into the blades which were then glued to a redwood shaft and cut to shape. Lots more sanding was needed to thin the blades and blend the joint between the blades and the shaft. Once the sanding was finished the blades were strengthened with a layer of lightweight glasscloth and epoxy on both sides, followed by 3 coats of yacht varnish.

The new paddle is slightly longer than the original, and the blades are also a little bigger.

A short video, courtesy of 'philcaretaker':

▲

⟩⟩

Len1

Peejay

Trident73

robbob

dave976

luckyduck

DuncanP

mturpin013

bombero

AndyB

jacko

chugalone100

Scratchbuilder

pressonreguardless

Ronald

philcaretaker

hermank

stevedownunder

flaxbybuck

GaryLC

MouldBuilder

jbkiwi

RNinMunich

Colin H

River Rat

Julio

|

💬 Re: New Paddle

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 85 Views · 4 Likes

Flag

Thanks Michael, still fiddling with the kayak. May have another update soon.

▲

⟩⟩

philcaretaker

Peejay

robbob

stevedownunder

|

|

Login To

Remove Ads 💬 Re: New Paddle

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 85 Views · 5 Likes

Flag

Hi Graham, somehow missed this 27 days ago, however Its great to see a revisit to make improvements which seem small but have great results, I really like the stripe pattern, a lot of work but a great look

▲

⟩⟩

philcaretaker

Peejay

stevedownunder

Graham93

Scratchbuilder

|

|

💬 Re: New Paddle

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 102 Views · 5 Likes

Flag

Thanks everyone for the 'likes' and the comments. I expect I will continue to fiddle with it. Models never seem to be quite finished.....

▲

⟩⟩

philcaretaker

Peejay

stevedownunder

Colin H

jbkiwi

|

|

💬 Re: New Paddle

1 year ago by 🇺🇸 chugalone100 (

Sub-Lieutenant) Sub-Lieutenant)✧ 102 Views · 3 Likes

Flag

Great effort and precision went into creating your paddles, that’s what I call “Going the extra mile”.

‘And whosoever shall compel thee to go a mile, go with him twain’ (Matthew 5:41). ▲

⟩⟩

Peejay

Colin H

Graham93

|

|

💬 Re: New Paddle

1 year ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 97 Views · 3 Likes

Flag

Graham.

First class craftsmanship. Well done 👍 Regards Bill ▲

⟩⟩

jbkiwi

Graham93

chugalone100

|

|

💬 Re: New Paddle

1 year ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 100 Views · 4 Likes

Flag

Congratulations on figuring out how to make your dream come true. It has been an interesting marvel to see your progress since conception through to this current video and new paddle. No doubt you will continue to fiddle with it, fine tuning as you go.

Who knows, maybe the next one will be a white water kayak Sam! ▲

⟩⟩

Colin H

jbkiwi

Graham93

chugalone100

|

|

💬 Re: New Paddle

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 102 Views · 6 Likes

Flag

Graham - what a wonderful creation. From the electrical and mechanical design to the beautiful red head Katie - a work of art and fascinating to watch. No way I can compete with it !

Canoeists often paddle in groups - how about synchronised kayakers ?😉 ▲

⟩⟩

Colin H

jbkiwi

Graham93

chugalone100

hermank

stevedownunder

|

|

💬 Re: New Paddle

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 101 Views · 6 Likes

Flag

Perfect Graham. Wow, she can paddle at speed. Super job. 😃😃

▲

⟩⟩

jbkiwi

Graham93

chugalone100

hermank

stevedownunder

Colin H

|

|

💬 Re: New Paddle

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 102 Views · 5 Likes

Flag

All looks fantastic Graham, very realistic👍👍 New paddle looks great. Katie's getting the hang of it now😁

JB ▲

⟩⟩

Graham93

chugalone100

hermank

stevedownunder

Colin H

|

|

💬 Re: New Paddle

1 year ago by 🇺🇸 River Rat (

Captain) Captain)✧ 104 Views · 2 Likes

Flag

Beautiful work and even better results. Nice work, very fine. Love the video too! RR

▲

⟩⟩

Graham93

stevedownunder

|

📝 New Rudder

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 117 Views · 12 Likes · 2 Comments

Flag

💬 Add Comment

The original rudder was made to "scale size" (1/6th). It worked, but the turning circle wasn't great. I attached a piece of plastic to the rudder with double sided tape to try the effect of a bigger rudder, and as expected, the maneuverability of the kayak was much improved, even if the appearance wasn't 😆.

A replacement rudder made from western red cedar looks a lot better. The shape ensures that the increase in size is not visible when the kayak is out on the water.

A replacement rudder made from western red cedar looks a lot better. The shape ensures that the increase in size is not visible when the kayak is out on the water.

▲

⟩⟩

Peejay

Ronald

MouldBuilder

philcaretaker

GaryLC

jbkiwi

RNinMunich

stevedownunder

AndyB

mturpin013

Colin H

Scratchbuilder

|

💬 Re: New Rudder

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 110 Views · 2 Likes

Flag

Exquisite😀

But then I'd have been surprised and disappointed if it wasn't coming from Graham😉 He sets the bar so high ... then raises it again!👍 I need to buy a longer ladder!🤔 😎 ▲

⟩⟩

Ronald

Graham93

|

|

💬 Re: New Rudder

1 year ago by 🇬🇧 Scratchbuilder (

Vice Admiral) Vice Admiral)✧ 110 Views · 1 Like

Flag

Lovely carpentry work in miniature.

👍👍 ▲

⟩⟩

Graham93

|

📝 Update

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 129 Views · 16 Likes · 5 Comments

Flag

💬 Add Comment

I can't believe it's been two months since my last update to this blog. I haven't been idle though and have continued to tweak the paddling mechanism and the control electronics.

The latest tweak was to increase the size of the rudder as I had foolishly made it the correct 'scale' size, forgetting that water doesn't scale and a model rudder needs to be larger than scale. Anyway, I glued a bit of clear plastic on to the wooden rudder with double sided tape as a trial and it has greatly improved the turning circle. Now I just need to make a wooden replacement to replace the plastic and sticky tape version. I'm also part way through making a 'fancy' paddle to replace the test paddle, now that I have the blade feathering angle worked out.

Here's a short video clip of the latest outing yesterday:

The latest tweak was to increase the size of the rudder as I had foolishly made it the correct 'scale' size, forgetting that water doesn't scale and a model rudder needs to be larger than scale. Anyway, I glued a bit of clear plastic on to the wooden rudder with double sided tape as a trial and it has greatly improved the turning circle. Now I just need to make a wooden replacement to replace the plastic and sticky tape version. I'm also part way through making a 'fancy' paddle to replace the test paddle, now that I have the blade feathering angle worked out.

Here's a short video clip of the latest outing yesterday:

▲

⟩⟩

flaxbybuck

Julio

philcaretaker

mturpin013

ToraDog

MouldBuilder

AndyB

luckyduck

pressonreguardless

stevedownunder

River Rat

RNinMunich

Colin H

jbkiwi

neilw

Scratchbuilder

|

💬 Re: Update

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 115 Views · 3 Likes

Flag

What a difference Graham. If you can forget the concrete path it looks real. It is unbelievable that you have another trick up your sleeve to improve on perfect, the new paddle. Great video. Now looking forwards to Phil’s probably with the fully finished article.😃😃👍

▲

⟩⟩

Graham93

pressonreguardless

Scratchbuilder

|

|

Login To

Remove Ads 💬 Re: Update

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 117 Views · 2 Likes

Flag

Not only the low profile Graham, but probably the enclosed convex deck lets the wind zip right over without anything to 'grab hold of' and exert any force. Nicely done👍👍👍

Remotely adjustable tweaks! Brilliant. I'm gonna nominate you for the MBW 'Nobble Prize'😉 😎 ▲

⟩⟩

Ronald

Graham93

|

|

💬 Re: Update

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 127 Views · 3 Likes

Flag

Hi Doug,

She is quite quick on the water, and surprisingly unaffected by the wind. Bill and Ben in the dinghy just get blown around if there is any wind, but Katie is fine. Probably down to the low profile hull not catching the wind. The paddle blade penetration can be adjusted using a spare channel on the Tx so I can set it for best result. Once adjusted, I can then store the setting permanently with a command from the Tx. Several other parameters can be adjusted in a similar way, for example the port/stbd balance of the paddle and the rudder compensation to offset the alternating paddle thrust. ▲

⟩⟩

pressonreguardless

RNinMunich

stevedownunder

|

|

💬 Re: Update

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 129 Views · 2 Likes

Flag

Truly Amazing Graham!!

Maybe your Barbie and JB's Barbies can get together and compare notes? Trev ▲

⟩⟩

Graham93

jbkiwi

|

|

💬 Re: Update

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 118 Views · 5 Likes

Flag

Wow! Speedy Katie Kayak😮👍

I see you've got more water penetration now as well. That must give more thrust👍 Well tweaked Graham. Cheers, Doug 😎 ▲

⟩⟩

Graham93

Ronald

pressonreguardless

stevedownunder

Colin H

|

📝 Modifications - 1

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 149 Views · 13 Likes · 5 Comments

Flag

💬 Add Comment

I wanted to keep the paddle shaft in one piece for strength, but while undergoing 'sea trials' it has become clear that a means of adjusting the feather angle between the two paddle blades is essential. Accordingly, a brass coupling was made on the lathe. It comprises two pieces which screw together with a knurled locking nut. The paddle shaft was cut into two halves and epoxied into each end of the coupling. The two halves can now be adjusted to set the blade feather and locked in position.

The other problem during the first outing was Katie letting go of the paddle. Whilst this gave an impressive demonstration of one, or even no, handed paddling, it wasn't very realistic 😂🤣. Loops of elastic cord were added to keep her hands on the paddle.

The paddling action is produced with a combination of mechanics and software control. A few changes were made to the software to improve the ability to steer. There is still more to be done to improve this. If you watch carefully at 0:35 seconds in the video, you can see the rudder compensating for the paddle stroke to help keep Katie moving in a straight line.

Sorry the video is a bit jerky in parts with my camera mounted on the transmitter. I expect Phil may have something better to show, once he has had time to edit it.

The other problem during the first outing was Katie letting go of the paddle. Whilst this gave an impressive demonstration of one, or even no, handed paddling, it wasn't very realistic 😂🤣. Loops of elastic cord were added to keep her hands on the paddle.

The paddling action is produced with a combination of mechanics and software control. A few changes were made to the software to improve the ability to steer. There is still more to be done to improve this. If you watch carefully at 0:35 seconds in the video, you can see the rudder compensating for the paddle stroke to help keep Katie moving in a straight line.

Sorry the video is a bit jerky in parts with my camera mounted on the transmitter. I expect Phil may have something better to show, once he has had time to edit it.

▲

⟩⟩

dave976

mturpin013

GaryLC

Len1

RodC

pressonreguardless

jbkiwi

philcaretaker

MouldBuilder

neilw

ToraDog

stevedownunder

Colin H

|

💬 Re: Modifications - 1

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 144 Views · 6 Likes

Flag

Hi Peter,

A longer paddle might be necessary but I think a spacer might weaken the shaft too much. As it’s only a trial paddle, I’ll just make a longer one if I decide to go that way. Meanwhile I’m working on software changes to tilt the paddle more on each side when paddling in a straight line. The blades go into the water deeply enough when turning. Graham93 ▲

⟩⟩

pressonreguardless

jbkiwi

GaryLC

stevedownunder

Colin H

MouldBuilder

|

|

Login To

Remove Ads 💬 Re: Modifications - 1

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 144 Views · 2 Likes

Flag

Hi Neil,

Now that would be a challenge! One to add to the list of possible future projects perhaps🤔 ▲

⟩⟩

pressonreguardless

stevedownunder

|

|

💬 Re: Modifications - 1

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 137 Views · 4 Likes

Flag

That was quick Graham. The result of the improvements is clear to see. Would a slightly longer paddle make any difference. Could you try another brass spacer in the middle. It looks to me that as Katie’s arms do not lift at each stroke like we would, to dig the blade into the water, perhaps a slightly longer paddle might compensate.😃

▲

⟩⟩

jbkiwi

stevedownunder

Colin H

Graham93

|

|

💬 Re: Modifications - 1

1 year ago by 🇬🇧 neilw (

Lieutenant) Lieutenant)✧ 138 Views · 3 Likes

Flag

Excellent, will Katie be taking up Stand up paddle boarding for her next challenge?

▲

⟩⟩

jbkiwi

stevedownunder

Graham93

|

|

💬 Re: Modifications - 1

1 year ago by 🇺🇸 ToraDog (

Captain) Captain)✧ 138 Views · 2 Likes

Flag

Brilliant! Now... about all that red hair. With a following wind Katie won't be able to see a thing...😁

▲

⟩⟩

stevedownunder

Graham93

|

📝 Maiden voyage

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 168 Views · 18 Likes · 8 Comments

Flag

💬 Add Comment

Before the maiden (!) voyage, a quick head 'transplant' !! I'd like to introduce 'Katie the Kayaker' 😂🤣

It was with some trepidation that Katie was carefully launched onto the Buxton lake. An ideal day last weekend with very little wind. I knew she would float, but would she move, and be controllable? Well the answer is yes - sort of 🤔

Thanks to Philcaretaker for the video clip.

She managed to paddle out, turn and paddle back, which was a great start. At least she didn't need rescuing. Shame she wouldn't keep hold of the paddle!

The paddle blades are not feathered at the right angle. The starboard blade is at the wrong angle and is hitting the water causing the kayak to rock excessively from side to side.

Once back on dry land, the kayak was checked inside for water. There was just a drop but nothing to worry about, which was also a relief.

So, overall it was reasonably successful, but several teething problems to be resolved before the next outing.👍

It was with some trepidation that Katie was carefully launched onto the Buxton lake. An ideal day last weekend with very little wind. I knew she would float, but would she move, and be controllable? Well the answer is yes - sort of 🤔

Thanks to Philcaretaker for the video clip.

She managed to paddle out, turn and paddle back, which was a great start. At least she didn't need rescuing. Shame she wouldn't keep hold of the paddle!

The paddle blades are not feathered at the right angle. The starboard blade is at the wrong angle and is hitting the water causing the kayak to rock excessively from side to side.

Once back on dry land, the kayak was checked inside for water. There was just a drop but nothing to worry about, which was also a relief.

So, overall it was reasonably successful, but several teething problems to be resolved before the next outing.👍

▲

⟩⟩

jbkiwi

RodC

MouldBuilder

AndyB

stevedownunder

neilw

DWBrinkman

Black Shoe

mturpin013

GaryLC

River Rat

philcaretaker

pressonreguardless

cormorant

Ronald

Julio

hermank

Colin H

|

💬 Re: Maiden voyage

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 152 Views · 3 Likes

Flag

Stunning Graham. And the Kayak is extremely good too. 😬😬

▲

⟩⟩

jbkiwi

Graham93

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Maiden voyage

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 155 Views · 3 Likes

Flag

Hi Graham,

Great resalt, some tweaking required but you expected to need to make some adjustments. Looking forward to the next installment. Cheers, Stephen. ▲

⟩⟩

jbkiwi

MouldBuilder

Graham93

|

|

💬 Re: Maiden voyage

1 year ago by 🇺🇸 Black Shoe (

Sub-Lieutenant) Sub-Lieutenant)✧ 160 Views · 4 Likes

Flag

Katie gives "maiden" voyage a whole new perspective.😊

Well done! ▲

⟩⟩

jbkiwi

MouldBuilder

Graham93

stevedownunder

|

|

💬 Re: Maiden voyage

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 168 Views · 1 Like

Flag

Hi Trev,

I think she needs to get a grip...🤣😂 ▲

⟩⟩

stevedownunder

|

|

💬 Re: Maiden voyage

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 168 Views · 2 Likes

Flag

Thanks Colin,

I think once she has learnt how to paddle properly the boys will have trouble catching up with her 😂🤣 ▲

⟩⟩

jbkiwi

stevedownunder

|

|

💬 Re: Maiden voyage

1 year ago by 🇬🇧 MotoPilot (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 153 Views · 3 Likes

Flag

Fabulous. An imaginative model excellently executed. 😁👍

▲

⟩⟩

jbkiwi

stevedownunder

Graham93

|

|

💬 Re: Maiden voyage

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 155 Views · 3 Likes

Flag

Wow, Katie is so cool she can paddle with one hand.

Then thru telekinesis, she can paddle without Hands 😮😮 Love that red hair 😍 Trev ▲

⟩⟩

jbkiwi

stevedownunder

Graham93

|

|

💬 Re: Maiden voyage

1 year ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 159 Views · 5 Likes

Flag

Certainly looks like she will be a hit with the two boys, it could put them off stroke.

Cheers Colin. ▲

⟩⟩

jbkiwi

MouldBuilder

stevedownunder

Graham93

Ronald

|

📝 Installing the mechanism

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 171 Views · 17 Likes · 8 Comments

Flag

💬 Add Comment

With everything finished, it's just a matter of installing it all into the hull.😉

A temporary paddle was made for initial trials on the water. There are many variables to be settled for the paddle in terms of paddle length, blade size and the feathering angle between the blades. Once these are established, then a 'fancy' paddle will be made.

Pictures 3 & 4 are from an earlier post and show everything in situ, before the deck was added to the hull.

With the deck in place, it is difficult to see very much. It is also difficult to install all the bits, but with a little patience, it all fits.

Manufacture of a spray deck from rip stop nylon was subcontracted to my wife, who has much more patience than I do.😇 An elastic cord run inside a seam around the edge grips over the cockpit rim.

With everything in place, a short video to show the action:

A temporary paddle was made for initial trials on the water. There are many variables to be settled for the paddle in terms of paddle length, blade size and the feathering angle between the blades. Once these are established, then a 'fancy' paddle will be made.

Pictures 3 & 4 are from an earlier post and show everything in situ, before the deck was added to the hull.

With the deck in place, it is difficult to see very much. It is also difficult to install all the bits, but with a little patience, it all fits.

Manufacture of a spray deck from rip stop nylon was subcontracted to my wife, who has much more patience than I do.😇 An elastic cord run inside a seam around the edge grips over the cockpit rim.

With everything in place, a short video to show the action:

▲

⟩⟩

Scratchbuilder

flaxbybuck

jbkiwi

MouldBuilder

stevedownunder

hermank

Len1

philcaretaker

GaryLC

ToraDog

luckyduck

pressonreguardless

River Rat

cormorant

AndyB

dave976

Colin H

|

💬 Re: Installing the mechanism

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 114 Views · 1 Like

Flag

Simply amazing !😉

▲

⟩⟩

Graham93

|

|

Login To

Remove Ads 💬 Re: Installing the mechanism

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 157 Views · 1 Like

Flag

Hi Graham,

I cannot add to what others have said, however this is a wonderfully realistic build that has come to the testing phase. Cheers, Stephen. ▲

⟩⟩

Graham93

|

|

💬 Re: Installing the mechanism

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 168 Views · 2 Likes

Flag

Thanks to everyone for the comments and likes. It is finally coming together after what feels like a long journey. Not much more to do - I hope!

▲

⟩⟩

stevedownunder

GaryLC

|

|

💬 Re: Installing the mechanism

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 166 Views · 4 Likes

Flag

Hi Graham, an absolutely brilliant concept from day one, to see this all come together into one very realistic-looking working Kayak is quite incredible. A masterclass of engineering and electronic skills and an awful lot of patience to put it all together and give it the realism this project deserves. It really is quite something to behold. I think the words, "And Now for Something Completely Different", describes your latest project very nicely. Well done you, that is going to be a difficult act to follow, but I am sure you will think of something??????????????? Regards, Gary. (Can't wait to see the Kayak on the water.)

▲

⟩⟩

jbkiwi

stevedownunder

Graham93

johnf

|

|

💬 Re: Installing the mechanism

1 year ago by 🇺🇸 ToraDog (

Captain) Captain)✧ 159 Views · 2 Likes

Flag

Wicked nice!

"The speed of the paddler suggests he will be quite fast on the water."...no doubt the crewman's age is a factor here. Young pup.... ▲

⟩⟩

stevedownunder

Graham93

|

|

💬 Re: Installing the mechanism

1 year ago by 🇺🇸 River Rat (

Captain) Captain)✧ 166 Views · 4 Likes

Flag

Hi Graham, your mechanism works so smooth. Very fluid movements and quite real in appearance. You have done a wonderful job on this project. I also look forward to your trials. As they say...You are the man! Dave RR

▲

⟩⟩

stevedownunder

Graham93

ToraDog

Ronald

|

|

💬 Re: Installing the mechanism

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 159 Views · 3 Likes

Flag

Truly an amazing Creation, Graham!!

Trev ▲

⟩⟩

stevedownunder

Graham93

ToraDog

|

|

💬 Re: Installing the mechanism

1 year ago by 🇬🇧 dave976 (

Captain) Captain)✧ 164 Views · 5 Likes

Flag

Looking good Graham. The speed of the paddler suggests he will be quite fast on the water. Can't wait to see the video.

▲

⟩⟩

stevedownunder

ToraDog

pressonreguardless

Graham93

Colin H

|

📝 Fitting the Rudder

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 174 Views · 15 Likes · 6 Comments

Flag

💬 Add Comment

The rudder mounting pivot was attached to the stern of the kayak using brass pins and epoxy. The rudder itself was then fitted using a length of M2 threaded rod as a pivot. As with a full sized kayak, a length of bungee cord holds the blade vertical but allows the rudder blade to tilt backwards if it comes into contact with something underwater.

The rudder is linked to the servo using two cords which run from the servo, under the deck through the previously installed aluminium tubes and then exit through the deck adjacent to the rudder. The small springs provide some tension in the cords to remove any slack and backlash.

An additional line runs from just behind the cockpit, through small guides glued to the deck, and attaches to the top of the rudder blade. On a full sized craft, this allows the kayaker to raise the rudder blade to avoid obstructions.

The short video shows the rudder in operation:

The rudder is linked to the servo using two cords which run from the servo, under the deck through the previously installed aluminium tubes and then exit through the deck adjacent to the rudder. The small springs provide some tension in the cords to remove any slack and backlash.

An additional line runs from just behind the cockpit, through small guides glued to the deck, and attaches to the top of the rudder blade. On a full sized craft, this allows the kayaker to raise the rudder blade to avoid obstructions.

The short video shows the rudder in operation:

▲

⟩⟩

dave976

MouldBuilder

mturpin013

stevedownunder

AndyB

Colin H

philcaretaker

ToraDog

pressonreguardless

River Rat

Ronald

GaryLC

luckyduck

ChrisG

jbkiwi

|

💬 Re: Fitting the Rudder

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 171 Views · 4 Likes

Flag

Thanks Peter,

“Kevin the kayaker”. Now there’s a thought. Only a few days left to finish it off. At least it didn’t take 4 years 😉 Graham93 ▲

⟩⟩

Peejay

stevedownunder

pressonreguardless

dave976

|

|

Login To

Remove Ads 💬 Re: Fitting the Rudder

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 164 Views · 4 Likes

Flag

Super job Graham. It cannot be long before Kevin joins Bill and Ben on the lake. Looking forward to that day.

Peter. ▲

⟩⟩

stevedownunder

pressonreguardless

dave976

Graham93

|

|

💬 Re: Fitting the Rudder

1 year ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 162 Views · 3 Likes

Flag

Brilliant, Graham beautiful work.

Cheers, Stephen. ▲

⟩⟩

cormorant

Graham93

pressonreguardless

|

|

💬 Re: Fitting the Rudder

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 166 Views · 4 Likes

Flag

Beautiful finishing touch to a truly amazing intuitive and imaginative build

What's next? ▲

⟩⟩

cormorant

Graham93

pressonreguardless

stevedownunder

|

|

💬 Re: Fitting the Rudder

1 year ago by 🇬🇧 cormorant (

Lieutenant Commander) Lieutenant Commander)✧ 163 Views · 6 Likes

Flag

Superb!

I used to build Airfix kits in the '50s (two shillings each) and the advertising was "just like the real thing!" What more can I say. Steve ▲

⟩⟩

stevedownunder

Colin H

pressonreguardless

Ronald

GaryLC

Graham93

|

|

💬 Re: Fitting the Rudder

1 year ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 164 Views · 6 Likes

Flag

Excellent job Graham, and it works perfectly, (like the up-haul on the blade)

JB ▲

⟩⟩

stevedownunder

Colin H

pressonreguardless

River Rat

Ronald

Graham93

|

📝 Finishing the hatch

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 172 Views · 14 Likes · 9 Comments

Flag

💬 Add Comment

The hatch fittings that were made a few weeks ago screw into place either side of the hatch opening. Black 'knicker elastic' is threaded through the fittings to hold the hatch in place.

A neoprene gasket was made and glued to the underside of the hatch lid, together with a wire loop. A cord from this loop is attached inside the hull to ensure that the lid is never lost. Making a replacement to match the existing planking would be very difficult.

I was fortunate to find some miniature plastic buckle clips to fasten the elastic over the completed hatch.

A neoprene gasket was made and glued to the underside of the hatch lid, together with a wire loop. A cord from this loop is attached inside the hull to ensure that the lid is never lost. Making a replacement to match the existing planking would be very difficult.

I was fortunate to find some miniature plastic buckle clips to fasten the elastic over the completed hatch.

▲

⟩⟩

pressonreguardless

Ronald

jbkiwi

mturpin013

hermank

HappyHaggis

philcaretaker

MouldBuilder

stevedownunder

AndyB

GaryLC

MotoPilot

Colin H

River Rat

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 174 Views · 2 Likes

Flag

Won't be long now Michael 👍

▲

⟩⟩

stevedownunder

pressonreguardless

|

|

Login To

Remove Ads 💬 Re: Finishing the hatch

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 169 Views · 3 Likes

Flag

Lets go to the pond😀

▲

⟩⟩

pressonreguardless

GaryLC

stevedownunder

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 172 Views · 3 Likes

Flag

Sorry about that, how about rear view mirror or luggage rack, it was the shape of the cockpit opening that convinced me it was at the front. So we'll go rucksack holding down straps for his sandwiches.

▲

⟩⟩

Colin H

Graham93

stevedownunder

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 176 Views · 5 Likes

Flag

Thanks Colin,

That thought had crossed my mind, I think it’s a really nice idea. No promises though. Graham93 ▲

⟩⟩

pressonreguardless

stevedownunder

HappyHaggis

GaryLC

Colin H

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 176 Views · 4 Likes

Flag

Thanks Gary,

Nice suggestion. Trouble is he would need eyes in the back of his head as the hatch is behind the cockpit🤔 Graham93 ▲

⟩⟩

stevedownunder

HappyHaggis

GaryLC

Colin H

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 170 Views · 4 Likes

Flag

Good afternoon Graham, having watched your progress from day 1 I am in awe of your talent for overcoming the problems that this build has given you.

As for a name, I would like to suggest MARTIN the magnificent in memory of another fine modeller that is sadly missed by many of us. Cheers Colin. ▲

⟩⟩

pressonreguardless

MouldBuilder

stevedownunder

GaryLC

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 GaryLC (

Captain) Captain)✧ 172 Views · 4 Likes

Flag

Hi Graham, I have followed your very interesting build from day 1 with curiosity and apprehension, and love the "and now for something completely different approach," and all of the somewhat complex problems that you have solved in the process of this build. May I suggest that you provide your intrepid kayaker, with a waterproof map of the waterways slipped under the two straps on the hatch? So as he knows where he is going and doesn't row off into the wide blue yonder. Can't wait to see a video of the kayak in action on the water. Regards, Gary.

▲

⟩⟩

HappyHaggis

Graham93

stevedownunder

Colin H

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 176 Views · 5 Likes

Flag

Thanks Steve,

I have a name in mind. All will be revealed on the maiden voyage 😉 Graham93 ▲

⟩⟩

pressonreguardless

cormorant

Colin H

MouldBuilder

stevedownunder

|

|

💬 Re: Finishing the hatch

1 year ago by 🇬🇧 cormorant (

Lieutenant Commander) Lieutenant Commander)✧ 166 Views · 5 Likes

Flag

Hi Graham

What a superb build. Very well done indeed! I must admit to not following the build very closely. I was not set up for receiving updates, which I now am. Did you ever sort out a name for the paddler? I think we decided Eskimo Nell was a non-starter for gender reasons? Regards Steve ▲

⟩⟩

HappyHaggis

MouldBuilder

stevedownunder

Colin H

Graham93

|

📝 Buoyancy

1 year ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 184 Views · 14 Likes · 13 Comments

Flag

💬 Add Comment

I'm concerned about the risk of the kayak sinking. It will be very low on the water and being long and narrow, it likely won't have a lot of lateral stability. Also, because of the mechanical connections to the paddle, even with a spray deck in place, it won't be possible to fully seal the cockpit against water ingress.

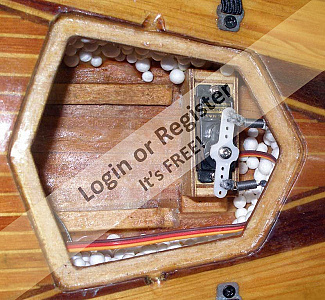

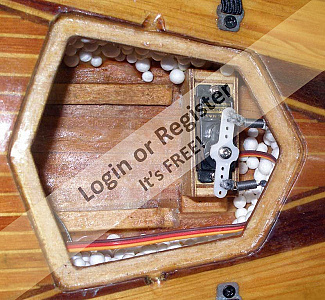

To reduce the risk, I decided to fill the empty space in the hull with polystyrene beads. The red lines on the first picture show the areas to be filled. I hope this will ensure that even with a capsize, the hull will remain afloat and not disappear to the bottom of the lake.

The hull was hung on a cord from the workshop roof and polystyrene beads were poured in to almost fill the spare space. To hold the beads in place, a handful of beads were coated with (waterproof) PVA and added to the top of the fill. Once dry, these formed a plug to hold the loose polystyrene in place. It will be a simple matter to dig out the plug and pour out the loose fill if it ever proves necessary.

The process was repeated to fill the other end of the hull.

Once everything was dry, it was time for a first float test in the domestic test tank. The mechanism, the RC gear, battery and the paddler were installed. It was a great relief to find that the kayak floated level, is reasonably stable and is self righting when tipped from side to side.

All up weight is just 1kg.

To reduce the risk, I decided to fill the empty space in the hull with polystyrene beads. The red lines on the first picture show the areas to be filled. I hope this will ensure that even with a capsize, the hull will remain afloat and not disappear to the bottom of the lake.

The hull was hung on a cord from the workshop roof and polystyrene beads were poured in to almost fill the spare space. To hold the beads in place, a handful of beads were coated with (waterproof) PVA and added to the top of the fill. Once dry, these formed a plug to hold the loose polystyrene in place. It will be a simple matter to dig out the plug and pour out the loose fill if it ever proves necessary.

The process was repeated to fill the other end of the hull.

Once everything was dry, it was time for a first float test in the domestic test tank. The mechanism, the RC gear, battery and the paddler were installed. It was a great relief to find that the kayak floated level, is reasonably stable and is self righting when tipped from side to side.

All up weight is just 1kg.

▲

⟩⟩

hermank

HappyHaggis

MouldBuilder

Ronald

dave976

AndyB

jbkiwi

DWBrinkman

stevedownunder

GaryLC

pressonreguardless

Colin H

River Rat

Newby7

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 177 Views · 5 Likes

Flag

Hi Dave,

If ever the aerial is below the waterline I think I’ll have a lot more to worry about than loss of signal. ☹️ With the kayak upright, both aerials are above the waterline. I admit they are not a long way above the water, but I don’t expect to be paddling at any significant distance from the shore so I expect the signal will be OK. Graham93 ▲

⟩⟩

HappyHaggis

dave976

MouldBuilder

stevedownunder

Colin H

|

|

Login To

Remove Ads 💬 Re: Buoyancy

1 year ago by 🇬🇧 dave976 (

Captain) Captain)✧ 178 Views · 2 Likes

Flag

Hi Graham

I see you are using 2.4Ghz. My experience is that if the aerial is below the waterline thye signal drops and you lose the binding so I am interested to hear how your model performs dave ▲

⟩⟩

stevedownunder

Colin H

|

|

💬 Re: Buoyancy

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 173 Views · 2 Likes

Flag

Your Talent knows no bounds, Graham👍👍👍👍

It is a treat to watch your creations come to life! Trev ▲

⟩⟩

stevedownunder

Colin H

|

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 178 Views · 5 Likes

Flag

Thanks Dave,

When I was first mulling over the idea of building the kayak, I had the idea that it would be great if I could make it do an ‘Eskimo roll’! I thought about how to do it for several weeks before finally giving up on the idea. Kayakers use the paddle as a ‘lever’ pushing against the water to right the kayak when inverted. The required changes in paddle position and movement are just too complex for me to engineer - I think! The other concern was the need to seal all the electronics/servos to cope with being inverted. From the trial in the domestic test tank, very little of the kayak is submerged. With it’s light weight and a length of almost 1m it doesn’t have much displacement. There are photos of the radio/servo/battery installation in an earlier post (before I fitted the deck) Graham93 ▲

⟩⟩

stevedownunder

Colin H

MouldBuilder

dave976

pressonreguardless

|

|

💬 Re: Buoyancy

1 year ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 176 Views · 5 Likes

Flag

Superb Graham. I think there are very few people who could have done this. The build is amazing but the mechanism is just a masterpiece. Were you a clock maker in a previous life?

Peter.😊 ▲

⟩⟩

HappyHaggis

stevedownunder

Graham93

Colin H

pressonreguardless

|

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 dave976 (

Captain) Captain)✧ 182 Views · 3 Likes

Flag

Hi Graham

Don't the full size kayakers have a procedure for righting a boat. Should be fairly simple for you to program a Pic to take over control and complete the procedure in the event of a capsize. As your model will be largely submerged I am interested to see what radio you will install. Very impressive so far dave976 ▲

⟩⟩

stevedownunder

Graham93

Colin H

|

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 183 Views · 5 Likes

Flag

Hi Michael,

I’m very concerned to hear that you “have no doubt at all about it sinking” . But I do understand what you mean 😂🤣 Graham93 ▲

⟩⟩

stevedownunder

mturpin013

pressonreguardless

MouldBuilder

Colin H

|

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 183 Views · 3 Likes

Flag

That's great to hear Graham, you may have had doubts about your creation floating. However I had no doubts at all about it sinking

" Oh ye of little faith" above comment (delete-sinking) (replace with floating) read and read again🤔 ▲

⟩⟩

stevedownunder

Graham93

Colin H

|

|

💬 Re: Buoyancy

1 year ago by 🇬🇧 philcaretaker (

Commodore) Commodore)✧ 182 Views · 4 Likes

Flag

Lookin ` good Graham !!

⛵ ▲

⟩⟩

Colin H

pressonreguardless

stevedownunder

Graham93

|

|

💬 Re: Buoyancy

1 year ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 178 Views · 4 Likes

Flag

Good Insurance, Graham!!

Well Done👍👍 Trev ▲

⟩⟩

Colin H

Graham93

philcaretaker

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Buoyancy

1 year ago by 🇺🇸 River Rat (

Captain) Captain)✧ 184 Views · 4 Likes

Flag

Very clever Graham! It's always good to have insurance that it can't sink into the abyss. I have one at the bottom of Taylorsville Lake near my home. I still think of it now and then. Great job, Thank You for sharing your build. Dave RR

▲

⟩⟩

Colin H

Graham93

stevedownunder

pressonreguardless

|

|

💬 Re: Buoyancy

1 year ago by 🇨🇦 Newby7 (

Fleet Admiral) Fleet Admiral)✧ 189 Views · 4 Likes

Flag

Level and reasonable is a good thing. Well done.

Rick ▲

⟩⟩

Colin H

Graham93

stevedownunder

pressonreguardless

|

United Kingdom

United Kingdom